Water & Wastewater Asia March/April 2022

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FOCUS<br />

34-35 tons/day of distillate as pure water and<br />

about 3-4 tons/day of concentrate recovered<br />

as compost after composting.<br />

The distillate produced by the evaporator is<br />

reused internally in the plant that requires<br />

the highest quality. The concentrate is sent<br />

to the composting plant to be mixed with the<br />

solid fraction separated after the anaerobic<br />

stage and transformed into compost which<br />

is then sold as fertiliser to farmers, realising a<br />

completely closed and highly valuable circular<br />

approach.<br />

The vacuum system extracts the condensed<br />

distillate together with any non-condensable<br />

gases and sends them to a storage tank. The<br />

distillate and the concentrate are discharged<br />

through a pump. All operations are controlled<br />

by a PLC.<br />

The heat exchange is effectively assured<br />

by the forced circulation principle, meaning<br />

that the liquid is transferred by a centrifugal<br />

pump which imposes a certain velocity so<br />

that scaling and fouling are prevented to<br />

happen on the surface of the tubes of the heat<br />

exchanger, thus assuring the possibility to get<br />

the highest recovery combined with the lowest<br />

maintenance possible. It is the preferred<br />

choice, especially in wastewater treatment and<br />

especially when the streams to treat are highly<br />

polluted, with high concentrations of organics<br />

and other compounds close to solubility which<br />

is reached later as long as concentration and<br />

recovery increase to assure smooth operation.<br />

steels which ensure high tolerance to anions<br />

such as chlorides, sulfates and more in high<br />

concentrations.<br />

The hot water comes from the co-generation<br />

plant that transforms the biogas produced by<br />

the anaerobic co-digestion process upfront<br />

into electrical energy which is sold. The<br />

engine of the co-generation plant requires<br />

to be cooled down and this generates a hot<br />

water stream which is normally not recovered<br />

but that in this plant is considered a precious<br />

resource and sustains the evaporation<br />

process in the Evaled unit.<br />

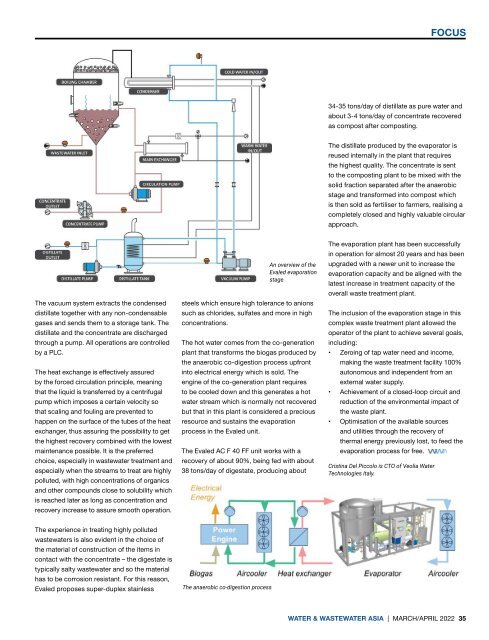

An overview of the<br />

Evaled evaporation<br />

stage<br />

The Evaled AC F 40 FF unit works with a<br />

recovery of about 90%, being fed with about<br />

38 tons/day of digestate, producing about<br />

The evaporation plant has been successfully<br />

in operation for almost 20 years and has been<br />

upgraded with a newer unit to increase the<br />

evaporation capacity and be aligned with the<br />

latest increase in treatment capacity of the<br />

overall waste treatment plant.<br />

The inclusion of the evaporation stage in this<br />

complex waste treatment plant allowed the<br />

operator of the plant to achieve several goals,<br />

including:<br />

• Zeroing of tap water need and income,<br />

making the waste treatment facility 100%<br />

autonomous and independent from an<br />

external water supply.<br />

• Achievement of a closed-loop circuit and<br />

reduction of the environmental impact of<br />

the waste plant.<br />

• Optimisation of the available sources<br />

and utilities through the recovery of<br />

thermal energy previously lost, to feed the<br />

evaporation process for free.<br />

Cristina Del Piccolo is CTO of Veolia <strong>Water</strong><br />

Technologies Italy.<br />

The experience in treating highly polluted<br />

wastewaters is also evident in the choice of<br />

the material of construction of the items in<br />

contact with the concentrate – the digestate is<br />

typically salty wastewater and so the material<br />

has to be corrosion resistant. For this reason,<br />

Evaled proposes super-duplex stainless<br />

The anaerobic co-digestion process<br />

WATER & WASTEWATER ASIA | MARCH/APRIL <strong>2022</strong> 35