Modification of Davisson's method

Modification of Davisson's method

Modification of Davisson's method

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

S ult = (0.08 *D+3.8) + (Q ultL/AE) (1)<br />

Where: S ult: settlement (mm) <strong>of</strong> pile at ultimate load, D:<br />

diameter <strong>of</strong> the pile at the pile tip (cm), Qult: ultimate load (ton),<br />

A: base area <strong>of</strong> the pile (mm 2 ), E: modulus <strong>of</strong> elasticity <strong>of</strong> the<br />

pile material (2 ton/mm 2 ) and L: length <strong>of</strong> the pile shaft (mm).<br />

Settlement, S<br />

0 50 100 150 200 250<br />

Qult<br />

300 350<br />

0<br />

O<br />

2<br />

4<br />

6<br />

8 C<br />

10<br />

12<br />

14<br />

16<br />

18<br />

20<br />

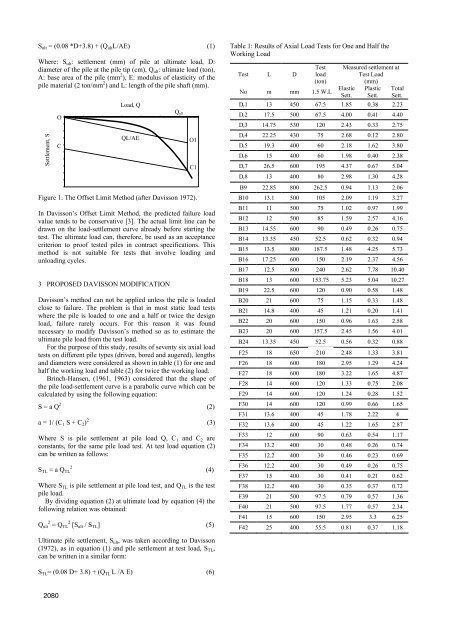

Figure 1. The Offset Limit Method (after Davisson 1972).<br />

In Davisson’s Offset Limit Method, the predicted failure load<br />

value tends to be conservative [3]. The actual limit line can be<br />

drawn on the load-settlement curve already before starting the<br />

test. The ultimate load can, therefore, be used as an acceptance<br />

criterion to pro<strong>of</strong> tested piles in contract specifications. This<br />

<strong>method</strong> is not suitable for tests that involve loading and<br />

unloading cycles.<br />

3 PROPOSED DAVISSON MODIFICATION<br />

Davisson’s <strong>method</strong> can not be applied unless the pile is loaded<br />

close to failure. The problem is that in most static load tests<br />

where the pile is loaded to one and a half or twice the design<br />

load, failure rarely occurs. For this reason it was found<br />

necessary to modify Davisson’s <strong>method</strong> so as to estimate the<br />

ultimate pile load from the test load.<br />

For the purpose <strong>of</strong> this study, results <strong>of</strong> seventy six axial load<br />

tests on different pile types (driven, bored and augered), lengths<br />

and diameters were considered as shown in table (1) for one and<br />

half the working load and table (2) for twice the working load.<br />

Brinch-Hansen, (1961, 1963) considered that the shape <strong>of</strong><br />

the pile load-settlement curve is a parabolic curve which can be<br />

calculated by using the following equation:<br />

S = a Q 2<br />

(2)<br />

a = 1/ (C 1 S + C 2) 2<br />

Where S is pile settlement at pile load Q, C 1 and C 2 are<br />

constants, for the same pile load test. At test load equation (2)<br />

can be written as follows:<br />

STL = a Q TL 2<br />

Where S TL is pile settlement at pile load test, and Q TL is the test<br />

pile load.<br />

By dividing equation (2) at ultimate load by equation (4) the<br />

following relation was obtained:<br />

Qult 2 = Q TL 2 [Sult / S TL] (5)<br />

Ultimate pile settlement, Sult, was taken according to Davisson<br />

(1972), as in equation (1) and pile settlement at test load, STL,<br />

can be written in a similar form:<br />

S TL= (0.08 D+ 3.8) + (Q TL L /A E) (6)<br />

2080<br />

Load, Q<br />

QL/AE O1<br />

C1<br />

(3)<br />

(4)<br />

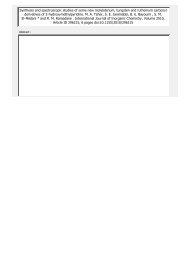

Table 1: Results <strong>of</strong> Axial Load Tests for One and Half the<br />

Working Load<br />

Test L D<br />

Test<br />

load<br />

(ton)<br />

No m mm 1.5 W.L Elastic<br />

Sett.<br />

Measured settlement at<br />

Test Load<br />

(mm)<br />

Plastic<br />

Sett.<br />

Total<br />

Sett..<br />

Dr1 13 450 67.5 1.85 0.38 2.23<br />

Dr2 17.5 500 67.5 4.00 0.41 4.40<br />

Dr3 14.75 530 120 2.43 0.33 2.75<br />

Dr4 22.25 430 75 2.68 0.12 2.80<br />

Dr5 19.3 400 60 2.18 1.62 3.80<br />

Dr6 15 400 60 1.98 0.40 2.38<br />

Dr7 26.5 600 195 4.37 0.67 5.04<br />

Dr8 13 400 80 2.98 1.30 4.28<br />

B9 22.85 800 262.5 0.94 1.13 2.06<br />

B10 13.1 500 105 2.09 1.19 3.27<br />

B11 11 500 75 1.02 0.97 1.99<br />

B12 12 500 85 1.59 2.57 4.16<br />

B13 14.55 600 90 0.49 0.26 0.75<br />

B14 13.35 450 52.5 0.62 0.32 0.94<br />

B15 13.5 800 187.5 1.48 4.25 5.73<br />

B16 17.25 600 150 2.19 2.37 4.56<br />

B17 12.5 800 240 2.62 7.78 10.40<br />

B18 13 600 153.75 5.23 5.04 10.27<br />

B19 22.5 600 120 0.90 0.58 1.48<br />

B20 21 600 75 1.15 0.33 1.48<br />

B21 14.8 400 45 1.21 0.20 1.41<br />

B22 20 600 150 0.96 1.63 2.58<br />

B23 20 600 157.5 2.45 1.56 4.01<br />

B24 13.35 450 52.5 0.56 0.32 0.88<br />

F25 18 650 210 2.48 1.33 3.81<br />

F26 18 600 180 2.95 1.29 4.24<br />

F27 18 600 180 3.22 1.65 4.87<br />

F28 14 600 120 1.33 0.75 2.08<br />

F29 14 600 120 1.24 0.28 1.52<br />

F30 14 600 120 0.99 0.66 1.65<br />

F31 13.6 400 45 1.78 2.22 4<br />

F32 13.6 400 45 1.22 1.65 2.87<br />

F33 12 600 90 0.63 0.54 1.17<br />

F34 13.2 400 30 0.48 0.26 0.74<br />

F35 12.2 400 30 0.46 0.23 0.69<br />

F36 12.2 400 30 0.49 0.26 0.75<br />

F37 15 400 30 0.41 0.21 0.62<br />

F38 12.2 400 30 0.35 0.37 0.72<br />

F39 21 500 97.5 0.79 0.57 1.36<br />

F40 21 500 97.5 1.77 0.57 2.34<br />

F41 15 600 150 2.95 3.3 6.25<br />

F42 25 400 55.5 0.81 0.37 1.18