Water & Wastewater Asia March/April 2023

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IN THE FIELD<br />

must be handled at a hazardous waste<br />

management facility.<br />

For Wallac, this posed two challenges: Firstly,<br />

wastewaters containing phenolic ethoxylates<br />

had to be transported over long distances;<br />

and secondly, handling the wastewater at a<br />

hazardous waste management facility was<br />

costly.<br />

For those reasons Wallac was keen to try<br />

out an alternative after they found out about<br />

Roxia’s non-thermal plasma technology.<br />

The solution presented by Roxia provided a<br />

possible alternative to the earlier-mentioned<br />

conventional water treatment methods.<br />

FROM LAB TESTING TO FULL SCALE<br />

Shortly after reaching out to Roxia, a lab test<br />

was run with a water sample from Wallac.<br />

The RPO’s purification process worked<br />

as follows: firstly, treated water would run<br />

through a non-thermal plasma field. This<br />

would create strong oxidants from the treated<br />

water and surrounding air, which in turn would<br />

destroy pollutants and disinfect the water with<br />

lasting effects. The product’s design would<br />

create a large plasma-water contact area,<br />

which would make the removal of pollutants<br />

from the water more efficient. The water from<br />

the process could then be reused on-site.<br />

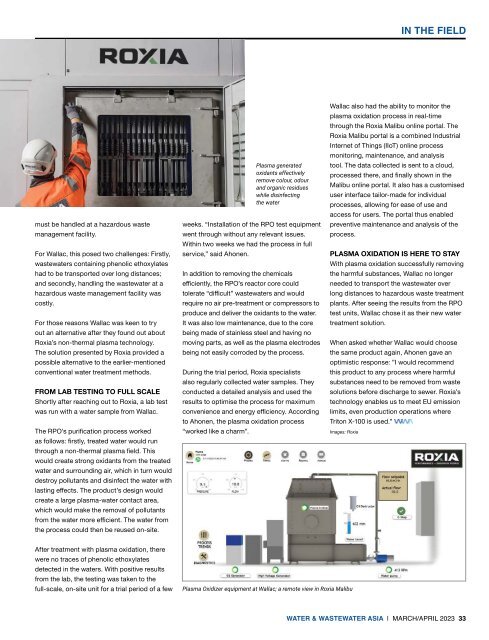

Plasma generated<br />

oxidants effectively<br />

remove colour, odour<br />

and organic residues<br />

while disinfecting<br />

the water<br />

weeks. “Installation of the RPO test equipment<br />

went through without any relevant issues.<br />

Within two weeks we had the process in full<br />

service,” said Ahonen.<br />

In addition to removing the chemicals<br />

efficiently, the RPO’s reactor core could<br />

tolerate “difficult” wastewaters and would<br />

require no air pre-treatment or compressors to<br />

produce and deliver the oxidants to the water.<br />

It was also low maintenance, due to the core<br />

being made of stainless steel and having no<br />

moving parts, as well as the plasma electrodes<br />

being not easily corroded by the process.<br />

During the trial period, Roxia specialists<br />

also regularly collected water samples. They<br />

conducted a detailed analysis and used the<br />

results to optimise the process for maximum<br />

convenience and energy efficiency. According<br />

to Ahonen, the plasma oxidation process<br />

“worked like a charm”.<br />

Wallac also had the ability to monitor the<br />

plasma oxidation process in real-time<br />

through the Roxia Malibu online portal. The<br />

Roxia Malibu portal is a combined Industrial<br />

Internet of Things (IIoT) online process<br />

monitoring, maintenance, and analysis<br />

tool. The data collected is sent to a cloud,<br />

processed there, and finally shown in the<br />

Malibu online portal. It also has a customised<br />

user interface tailor-made for individual<br />

processes, allowing for ease of use and<br />

access for users. The portal thus enabled<br />

preventive maintenance and analysis of the<br />

process.<br />

PLASMA OXIDATION IS HERE TO STAY<br />

With plasma oxidation successfully removing<br />

the harmful substances, Wallac no longer<br />

needed to transport the wastewater over<br />

long distances to hazardous waste treatment<br />

plants. After seeing the results from the RPO<br />

test units, Wallac chose it as their new water<br />

treatment solution.<br />

When asked whether Wallac would choose<br />

the same product again, Ahonen gave an<br />

optimistic response: ”I would recommend<br />

this product to any process where harmful<br />

substances need to be removed from waste<br />

solutions before discharge to sewer. Roxia’s<br />

technology enables us to meet EU emission<br />

limits, even production operations where<br />

Triton X-100 is used.”<br />

Images: Roxia<br />

After treatment with plasma oxidation, there<br />

were no traces of phenolic ethoxylates<br />

detected in the waters. With positive results<br />

from the lab, the testing was taken to the<br />

full-scale, on-site unit for a trial period of a few<br />

Plasma Oxidizer equipment at Wallac; a remote view in Roxia Malibu<br />

WATER & WASTEWATER ASIA | MARCH/APRIL <strong>2023</strong> 33