Panels & Furniture Asia March/April 2023

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PANEL MANUFACTURING<br />

quickly became popular, especially in China. After two<br />

years of optimising the concept, Chinese authorities<br />

established a standard Fine OSB for the entire country.<br />

Subsequently, Dieffenbacher received further orders<br />

for Fine OSB plants. To date, Chinese manufacturers<br />

have already placed 10 orders for Fine OSB plants with<br />

Dieffenbacher.<br />

Container OSB: The floor of an ocean freight container<br />

is subject to major stresses. It has to transport heavy<br />

loads through all kinds of climate zones over periods of<br />

weeks or months. Previously, such demands could only<br />

be met by plywood panels made from tropical hardwood<br />

veneers, but these have steadily become scarcer and more<br />

expensive. Container OSB offers a low-cost alternative.<br />

By replacing the central veneers of plywood with an OSB<br />

core, the consumption of costly tropical timber can be<br />

reduced.<br />

1<br />

Because the strength requirements of OSB core board<br />

are greater than for commercially available OSB board,<br />

Dieffenbacher developed a new manufacturing process.<br />

Longer OSB strands are first sorted by new disc screens<br />

and then arranged crosswise in a precise, multilayer<br />

formation. Next, a specially designed press compresses<br />

the mat, enabling a much denser panel. Following<br />

compression, the OSB cores are brought together with<br />

glued veneers on a veneer lay-up station and processed in<br />

a hot press to produce Container OSB.<br />

In the future, it may be possible to manufacture OSB<br />

boards with unprecedented strength, without relying on<br />

additional veneers. This has already been achieved on a<br />

laboratory scale. Successful practical testing could pave<br />

the way for container floor manufacturers to dispense with<br />

the use of tropical veneers.<br />

2<br />

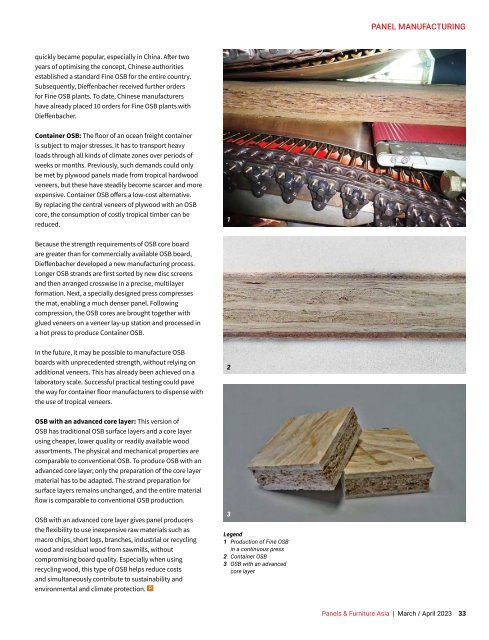

OSB with an advanced core layer: This version of<br />

OSB has traditional OSB surface layers and a core layer<br />

using cheaper, lower quality or readily available wood<br />

assortments. The physical and mechanical properties are<br />

comparable to conventional OSB. To produce OSB with an<br />

advanced core layer, only the preparation of the core layer<br />

material has to be adapted. The strand preparation for<br />

surface layers remains unchanged, and the entire material<br />

flow is comparable to conventional OSB production.<br />

OSB with an advanced core layer gives panel producers<br />

the flexibility to use inexpensive raw materials such as<br />

macro chips, short logs, branches, industrial or recycling<br />

wood and residual wood from sawmills, without<br />

compromising board quality. Especially when using<br />

recycling wood, this type of OSB helps reduce costs<br />

and simultaneously contribute to sustainability and<br />

environmental and climate protection. P<br />

3<br />

Legend<br />

1 Production of Fine OSB<br />

in a continuous press<br />

2 Container OSB<br />

3 OSB with an advanced<br />

core layer<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>March</strong> / <strong>April</strong> <strong>2023</strong> 33