Effects of heat release in laminar diffusion flames - Mechanical ...

Effects of heat release in laminar diffusion flames - Mechanical ...

Effects of heat release in laminar diffusion flames - Mechanical ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

for the Landau-Squire jet discussed above. This procedure<br />

saves a great deal <strong>of</strong> computational time and<br />

allows for compar<strong>in</strong>g the cold-flow theory <strong>of</strong> lifted<br />

<strong>flames</strong> with simulations under the same framework.<br />

But on the other hand, the predictive capabilities <strong>of</strong><br />

the simulations are restricted. Only the correction to<br />

the lift-<strong>of</strong>f height, h, due to the impact <strong>of</strong> <strong>heat</strong> <strong>release</strong><br />

effects can be computed. In addition, the computations<br />

would not be reliable <strong>in</strong> describ<strong>in</strong>g <strong>flames</strong> lifted<br />

very close to the burner, because, the self-similar<br />

solution is not valid <strong>in</strong> the close field <strong>of</strong> the round jet.<br />

The full simulation would require a careful description<br />

<strong>of</strong> both the lam<strong>in</strong>ar round jet boundary layers<br />

and the far field, a task that is difficult to achieve<br />

together with the accurate fully compressible Direct<br />

Numerical Simulation (DNS) <strong>of</strong> the flame base.<br />

Numerical simulations <strong>of</strong> lam<strong>in</strong>ar lifted <strong>flames</strong> are<br />

performed us<strong>in</strong>g a DNS tool previously developed<br />

for study<strong>in</strong>g turbulent combustion [35–38]. The DNS<br />

procedure follows well established methods [39].<br />

The fully compressible Navier Stokes equations are<br />

solved us<strong>in</strong>g a sixth order PADE scheme [40] comb<strong>in</strong>ed<br />

with third order Runge-Kutta time stepp<strong>in</strong>g and<br />

Navier Stokes characteristic boundary conditions<br />

(NSCBC) [41]. The possibility <strong>of</strong> deal<strong>in</strong>g with axi-<br />

J. Boulanger et al. / Combustion and Flame 134 (355–368)<br />

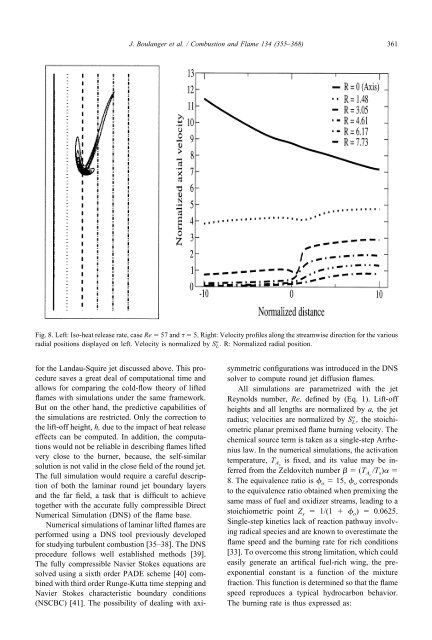

Fig. 8. Left: Iso-<strong>heat</strong> <strong>release</strong> rate, case Re � 57 and � � 5. Right: Velocity pr<strong>of</strong>iles along the streamwise direction for the various<br />

radial positions displayed on left. Velocity is normalized by S L o . R: Normalized radial position.<br />

361<br />

symmetric configurations was <strong>in</strong>troduced <strong>in</strong> the DNS<br />

solver to compute round jet <strong>diffusion</strong> <strong>flames</strong>.<br />

All simulations are parametrized with the jet<br />

Reynolds number, Re, def<strong>in</strong>ed by (Eq. 1). Lift-<strong>of</strong>f<br />

heights and all lengths are normalized by a, the jet<br />

o<br />

radius; velocities are normalized by SL, the stoichiometric<br />

planar premixed flame burn<strong>in</strong>g velocity. The<br />

chemical source term is taken as a s<strong>in</strong>gle-step Arrhenius<br />

law. In the numerical simulations, the activation<br />

temperature, TAc is fixed, and its value may be <strong>in</strong>ferred<br />

from the Zeldovitch number � � (TAc /Ts)� �<br />

8. The equivalence ratio is �o � 15, �o corresponds<br />

to the equivalence ratio obta<strong>in</strong>ed when premix<strong>in</strong>g the<br />

same mass <strong>of</strong> fuel and oxidizer streams, lead<strong>in</strong>g to a<br />

stoichiometric po<strong>in</strong>t Zs � 1/(1 � �o) � 0.0625.<br />

S<strong>in</strong>gle-step k<strong>in</strong>etics lack <strong>of</strong> reaction pathway <strong>in</strong>volv<strong>in</strong>g<br />

radical species and are known to overestimate the<br />

flame speed and the burn<strong>in</strong>g rate for rich conditions<br />

[33]. To overcome this strong limitation, which could<br />

easily generate an artifical fuel-rich w<strong>in</strong>g, the preexponential<br />

constant is a function <strong>of</strong> the mixture<br />

fraction. This function is determ<strong>in</strong>ed so that the flame<br />

speed reproduces a typical hydrocarbon behavior.<br />

The burn<strong>in</strong>g rate is thus expressed as: