compact brazed heat exchanger b12 - Lyngson

compact brazed heat exchanger b12 - Lyngson

compact brazed heat exchanger b12 - Lyngson

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

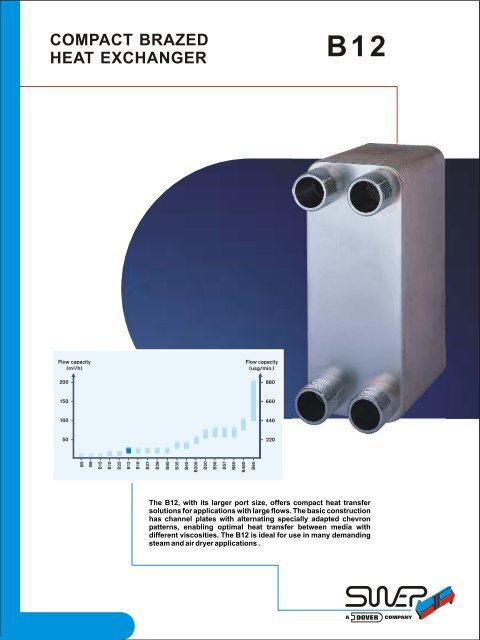

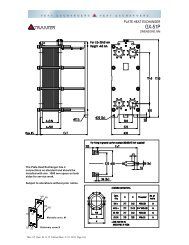

COMPACT BRAZED<br />

HEAT EXCHANGER<br />

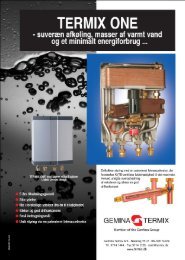

Flow capacity<br />

(m³/h)<br />

200<br />

150<br />

100<br />

50<br />

B5<br />

B8<br />

B15<br />

B10<br />

B25<br />

B12<br />

B16<br />

B27<br />

B28<br />

B80<br />

B35<br />

B45<br />

B200<br />

B50<br />

B56<br />

B57<br />

B60<br />

B400<br />

Flow capacity<br />

(usg/min.)<br />

B65<br />

B12<br />

The B12, with its larger port size, offers <strong>compact</strong> <strong>heat</strong> transfer<br />

solutions for applications with large flows. The basic construction<br />

has channel plates with alternating specially adapted chevron<br />

patterns, enabling optimal <strong>heat</strong> transfer between media with<br />

different viscosities. The B12 is ideal for use in many demanding<br />

steam and air dryer applications .<br />

880<br />

660<br />

440<br />

220

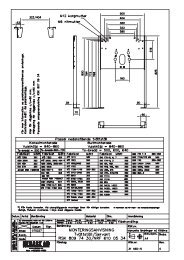

287 mm (11.30 inch)<br />

234 mm (9.21 inch)<br />

B12<br />

STANDARD CONNECTIONS<br />

For specific dimensions, or information about other types of connections, please<br />

contact your SWEP sales representative.<br />

Externally<br />

threaded<br />

TECHNICAL DATA<br />

Max flow rate 22 m³/h (97 usg/min.)<br />

Max working pressure at 155°C (311°F) 31 bar (450 psi)<br />

Max working pressure at 225°C (437°F) 27 bar (392 psi)<br />

Min working temperature -196°C (-321°F)<br />

Test pressure 50 bar (725 psi)<br />

Max. Number of plates 140<br />

CBE weight dry (approx.) 1.7+0.116×NP* kg (3.75+0.256×NP* lb)<br />

Hold-up volume: inner circuit (H&L plates) 0.061×(NP*/2-1) liter (0.016x(NP*/2-1) gal.)<br />

Hold-up volume: inner circuit (MT plates) 0.063×(NP*/2-1) liter (0.017x(NP*/2-1) gal.)<br />

Hold-up volume: outer circuit (H&L plates) 0.061×NP*/2 liter (0.016x(NP*/2) gal.)<br />

Hold-up volume: outer circuit (MT plates) 0.063×NP*/2 liter (0.017x(NP*/2) gal.)<br />

Standard connection size 1 1/4”<br />

Connection height 27.1 mm (1.06 inch) or 45.1 mm (1.78 inch)<br />

*NP = Number of plates<br />

MATERIAL<br />

117 mm (4.61 inch)<br />

63 mm<br />

(2.48 inch)<br />

F1 F2<br />

F3 F4<br />

Internally<br />

threaded<br />

6 mm<br />

( 0.24 inch)<br />

4.4+2.34xNP* mm<br />

(0.17+0.09xNP* inch)<br />

Soldering<br />

Plate material: EN 10028/7-1.4401 (AlSI 316)<br />

Brazing material: Pure copper<br />

Connection material: EN 10272-1.4401 (AlSI 316)<br />

THIRD-PARTY APPROVALS (selection)<br />

Europe, Pressure Equipment Directive (PED 97/23/EC)<br />

USA, Underwriters Laboratories (UL)<br />

Canada, Canadian Standard Association (CSA)<br />

Japan, The High Pressure Gas Safety Institute of Japan (KHK)<br />

For additional information please contact your local SWEP representative.<br />

SWEP reserves the right to make changes without prior notice<br />

27.1 mm<br />

(1.06 inch)<br />

F1<br />

F2<br />

F3<br />

F4<br />

Int. Threaded<br />

with Hex. Ext.<br />

P1<br />

P2<br />

P3<br />

P4<br />

Copyright SWEP<br />

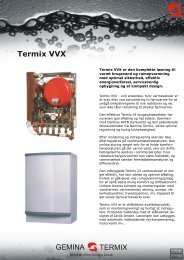

THE B LINE<br />

– OUR BASIC RANGE<br />

The majority of SWEP's CBEs<br />

are classified as B-types. The Btypes<br />

are suitable for most<br />

applications. Although the Btype<br />

CBEs are "standard", there<br />

is a huge variety of plate sizes,<br />

port sizes, plate pattern combinations,<br />

connections etc. And<br />

SWEP's unique plate design<br />

enables a virtually unlimited<br />

number of combinations in any<br />

given plate package execution to<br />

precisely match the thermal<br />

transfer requirements of your<br />

application.<br />

Easy to choose the right<br />

product solution<br />

With SWEP's unique SSP CBE,<br />

the SWEP Software Package,<br />

you can do advanced <strong>heat</strong><br />

transfer calculations yourself,<br />

and choose the product solution<br />

that suits your application best.<br />

It's also easy to choose connections<br />

and generate drawings of<br />

the complete product. If you<br />

would like advice, or you would<br />

like to discuss different product<br />

solutions, SWEP offers all the<br />

service and support you need.<br />

If you would like more information<br />

about B12 or our other<br />

products, please contact your<br />

local SWEP representative.<br />

SWEP INTERNATIONAL AB<br />

Box 105, SE-261 22 Landskrona, Sweden<br />

Phone +46 418 40 04 00<br />

Fax +46 418 292 95<br />

Internet: www.swep.net<br />

E-mail: info@swep.net