Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

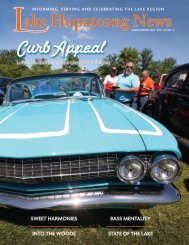

At Batten the Hatches, She Brings Boatloads of Experience<br />

Story by ELLEN WILKOWE<br />

Photos by Karen Fucito<br />

Maria Pappas of Mine Hill said she has<br />

boarded “thousands and thousands of<br />

boats,” but nearly all of them never actually left<br />

the docks—at least not with her at the helm.<br />

As the owner of Batten the Hatches in Lake<br />

Hopatcong, Pappas refurbishes boats in their<br />

resting states, specifically the interiors that are<br />

in various stages of disrepair.<br />

“I didn’t grow up thinking this is what I wanted<br />

to do with my life,” said the 56-year-old.<br />

Raised in Dover, Pappas was unfamiliar with<br />

nearby Lake Hopatcong until she took a job at<br />

Bill Smith’s Covers after graduating high school.<br />

“I thought that this is a cool thing, working<br />

on the lake,” she said. “It’s a different kind of<br />

job.”<br />

Not to mention, long-lasting. What started<br />

as a summer job turned into a full-fledged<br />

rewarding career, which has lasted 33 years.<br />

Smith’s shop was housed upstairs in what is<br />

now San Bar Marina on Howard Boulevard.<br />

Pappas praised Smith for showing her the<br />

ropes for all matters concerning boat covers,<br />

upholstery, cushions and materials. The seats<br />

and cushions of a boat are fitted with marinegrade<br />

vinyl, she said, while the covers are made<br />

from Sunbrella, an acrylic woven fabric. When<br />

she began, canvas, a natural cotton fiber, was<br />

the only material used to make boat covers. By<br />

the late 1980s, Sunbrella was introduced and<br />

has since become the industry standard for<br />

boat covers.<br />

“I worked for Bob for five years. Then in 1990,<br />

he wanted to move down south. I bought all his<br />

inventory, took over the business and changed<br />

the name,” she recalled.<br />

Being on her own was challenging, she said,<br />

but through trial and error and perseverance<br />

she learned more about the industry and was<br />

able to build her business.<br />

In the process, she also developed a<br />

tough skin, a byproduct of being a female<br />

entrepreneur in a lake environment dominated<br />

by male business owners—and male boat<br />

owners.<br />

“At the beginning it was intimidating,” she<br />

said. “Especially when I was younger—about<br />

30 plus years ago. I’ve held my own, though.”<br />

By 2013, Pappas said she was looking for<br />

a change and sold the business, thinking<br />

she would work instead as a sales rep in the<br />

industry. But circumstances set her on a<br />

different course, and she wound up buying<br />

back the business before the end of the year.<br />

“Within a year of selling it, the person who<br />

bought it realized it wasn’t something he<br />

wanted to do, so I took it back. He was the<br />

one who moved the shop here [at its current<br />

location on 70 Route 181 in Lake Hopatcong]<br />

and it has worked out very well in the end.”<br />

In working alongside Smith, Pappas<br />

awakened a latent passion for working with her<br />

hands, particularly the creative freedom and<br />

satisfaction that comes with witnessing the<br />

start-to-finish process.<br />

“Every day is different,” she said. “Every job is<br />

custom. Some things take longer than others<br />

and it’s challenging at times, but you figure it<br />

out as you go along.”<br />

She credits her team—three full-timers<br />

and one part-timer—for the success of her<br />

business. “I’ve got a good team here,” she said.<br />

“We bounce ideas off each other.”<br />

But a typical day is often atypical. The flow<br />

of work could be as simple as a single seat<br />

cushion or complex as a custom design.<br />

“Some customers drop off cushions and<br />

others leave their entire boat,” she said.<br />

Pappas pounces on the opportunity to<br />

fabricate a custom interior.<br />

A recent custom job included the<br />

upholstering of an American Offshore boat<br />

with black diamond stitching and checkered<br />

racing strips. The diamonds were individually<br />

cut boxes that were stitched together,<br />

Pappas said. The work was recently entered<br />

into a Chesapeake Marine Canvas Fabricators<br />

Association competition, which is held at the<br />

organization’s annual convention, but the<br />

project did not receive an award.<br />

Pappas said the convention is a great place<br />

to learn and meet other shop owners from<br />

around the country.<br />

“There are seminars for people like us who<br />

have been doing this forever. If there’s a<br />

problem, I can call one of those people and say,<br />

‘Hey, I’m in this situation. Have you dealt with<br />

this before?’ It’s a nice community because<br />

where else can you go and learn this stuff?” she<br />

said.<br />

Just recently, shop manager Travis Amico<br />

came away with top honors for his design on<br />

a 1991 HydroStream boat. The colorful striped<br />

pattern was created to mimic the boat’s<br />

geometric design and took first place in Miami<br />

Corporation’s Miami Madness contest. Miami<br />

Corporation is an industry supplier that hosts<br />

a nationwide competition each year.<br />

So, what exactly does it take to custom<br />

design the interior of a boat or reupholster a<br />

comfortable cushion for four?<br />

Well, physical strength, for one, and of course<br />

a boatload of equipment and the deftness<br />

to operate it. Think industrial-sized Consew<br />

sewing machines (circa 1970), staple guns, drills,<br />

pliers and saws, to name a few.<br />

The calorie burn just comes with the<br />

territory.<br />

“At the end of the day you’re exhausted,”<br />

Pappas said. “Between climbing up and down<br />

ladders, in and out of boats, removing and<br />

installing seats…the job is the workout.”<br />

Given the niche of her business, Pappas all<br />

but shrugged off the possibility of competition.<br />

Those who some might consider to be her<br />

competitors she sees as peers.<br />

“There’s not anything detrimental,” she said.<br />

“There’s enough to go around.”<br />

Physicality and competition aside, Pappas<br />

is most challenged by projects that may take<br />

longer than expected due to unanticipated<br />

snags that often come with renovations.<br />

“I may be doing a seat but then I find I have<br />

to drill out this bolt because it’s rusted,” she<br />

said. “All of a sudden you become a carpenter.<br />

You have to cut a piece of wood and a new<br />

piece of vinyl.”<br />

Left to right: Maria Pappas at one of the shop’s<br />

sewing machines. The seat design by Travis<br />

Amico on this 1991 HydroStream boat recently<br />

garnered a first place award. Amico and Pappas<br />

work side-by-side at one of the shop’s large<br />

work benches.<br />

18<br />

LAKE HOPATCONG NEWS <strong>Memorial</strong> <strong>Day</strong> <strong>2023</strong>