Agoria ETC Business Guide Hydrogen 2023

An overview of the finest Belgian based companies active in the broad hydrogen value chain. From H2 production over storage & transportation to H2 utilization.

An overview of the finest Belgian based companies active in the broad hydrogen value chain. From H2 production over storage & transportation to H2 utilization.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

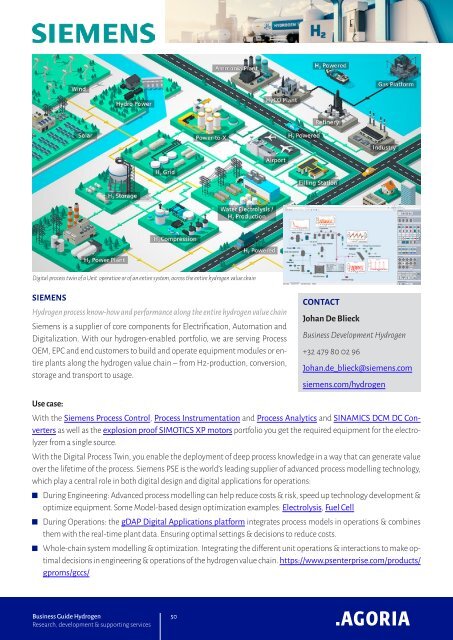

Digital process twin of a Unit operation or of an entire system, across the entire hydrogen value chain<br />

SIEMENS<br />

<strong>Hydrogen</strong> process know-how and performance along the entire hydrogen value chain<br />

Siemens is a supplier of core components for Electrification, Automation and<br />

Digitalization. With our hydrogen-enabled portfolio, we are serving Process<br />

OEM, EPC and end customers to build and operate equipment modules or entire<br />

plants along the hydrogen value chain – from H2-production, conversion,<br />

storage and transport to usage.<br />

CONTACT<br />

Johan De Blieck<br />

<strong>Business</strong> Development <strong>Hydrogen</strong><br />

+32 479 80 02 96<br />

Johan.de_blieck@siemens.com<br />

siemens.com/hydrogen<br />

Use case:<br />

With the Siemens Process Control, Process Instrumentation and Process Analytics and SINAMICS DCM DC Converters<br />

as well as the explosion proof SIMOTICS XP motors portfolio you get the required equipment for the electrolyzer<br />

from a single source.<br />

With the Digital Process Twin, you enable the deployment of deep process knowledge in a way that can generate value<br />

over the lifetime of the process. Siemens PSE is the world’s leading supplier of advanced process modelling technology,<br />

which play a central role in both digital design and digital applications for operations:<br />

During Engineering: Advanced process modelling can help reduce costs & risk, speed up technology development &<br />

optimize equipment. Some Model-based design optimization examples: Electrolysis, Fuel Cell<br />

During Operations: the gDAP Digital Applications platform integrates process models in operations & combines<br />

them with the real-time plant data. Ensuring optimal settings & decisions to reduce costs.<br />

Whole-chain system modelling & optimization. Integrating the different unit operations & interactions to make optimal<br />

decisions in engineering & operations of the hydrogen value chain. https://www.psenterprise.com/products/<br />

gproms/gccs/<br />

<strong>Business</strong> <strong>Guide</strong> <strong>Hydrogen</strong><br />

Research, development & supporting services<br />

50