CU Nov-Dec 2023

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CASE study<br />

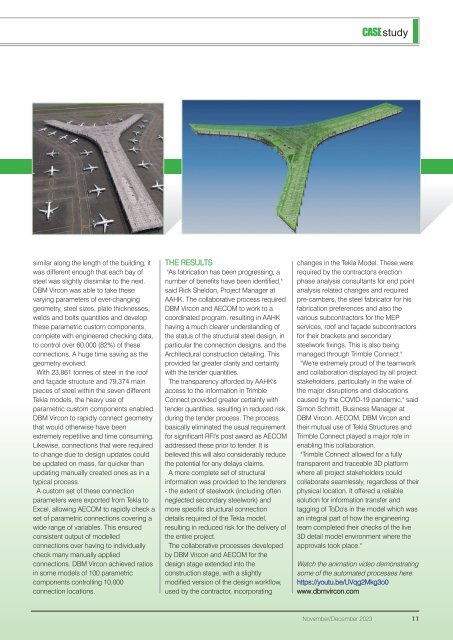

similar along the length of the building, it<br />

was different enough that each bay of<br />

steel was slightly dissimilar to the next.<br />

DBM Vircon was able to take these<br />

varying parameters of ever-changing<br />

geometry, steel sizes, plate thicknesses,<br />

welds and bolts quantities and develop<br />

these parametric custom components,<br />

complete with engineered checking data,<br />

to control over 60,000 (82%) of these<br />

connections. A huge time saving as the<br />

geometry evolved.<br />

With 23,861 tonnes of steel in the roof<br />

and façade structure and 79,374 main<br />

pieces of steel within the seven different<br />

Tekla models, the heavy use of<br />

parametric custom components enabled<br />

DBM Vircon to rapidly connect geometry<br />

that would otherwise have been<br />

extremely repetitive and time consuming.<br />

Likewise, connections that were required<br />

to change due to design updates could<br />

be updated on mass, far quicker than<br />

updating manually created ones as in a<br />

typical process.<br />

A custom set of these connection<br />

parameters were exported from Tekla to<br />

Excel, allowing AECOM to rapidly check a<br />

set of parametric connections covering a<br />

wide range of variables. This ensured<br />

consistent output of modelled<br />

connections over having to individually<br />

check many manually applied<br />

connections. DBM Vircon achieved ratios<br />

in some models of 100 parametric<br />

components controlling 10,000<br />

connection locations.<br />

THE RESULTS<br />

"As fabrication has been progressing, a<br />

number of benefits have been identified,"<br />

said Rick Sheldon, Project Manager at<br />

AAHK. The collaborative process required<br />

DBM Vircon and AECOM to work to a<br />

coordinated program, resulting in AAHK<br />

having a much clearer understanding of<br />

the status of the structural steel design, in<br />

particular the connection designs, and the<br />

Architectural construction detailing. This<br />

provided far greater clarity and certainty<br />

with the tender quantities.<br />

The transparency afforded by AAHK's<br />

access to the information in Trimble<br />

Connect provided greater certainty with<br />

tender quantities, resulting in reduced risk<br />

during the tender process. The process<br />

basically eliminated the usual requirement<br />

for significant RFI's post award as AECOM<br />

addressed these prior to tender. It is<br />

believed this will also considerably reduce<br />

the potential for any delays claims.<br />

A more complete set of structural<br />

information was provided to the tenderers<br />

- the extent of steelwork (including often<br />

neglected secondary steelwork) and<br />

more specific structural connection<br />

details required of the Tekla model,<br />

resulting in reduced risk for the delivery of<br />

the entire project.<br />

The collaborative processes developed<br />

by DBM Vircon and AECOM for the<br />

design stage extended into the<br />

construction stage, with a slightly<br />

modified version of the design workflow,<br />

used by the contractor, incorporating<br />

changes in the Tekla Model. These were<br />

required by the contractor's erection<br />

phase analysis consultants for end point<br />

analysis related changes and required<br />

pre-cambers, the steel fabricator for his<br />

fabrication preferences and also the<br />

various subcontractors for the MEP<br />

services, roof and façade subcontractors<br />

for their brackets and secondary<br />

steelwork fixings. This is also being<br />

managed through Trimble Connect."<br />

"We're extremely proud of the teamwork<br />

and collaboration displayed by all project<br />

stakeholders, particularly in the wake of<br />

the major disruptions and dislocations<br />

caused by the COVID-19 pandemic," said<br />

Simon Schmitt, Business Manager at<br />

DBM Vircon. AECOM, DBM Vircon and<br />

their mutual use of Tekla Structures and<br />

Trimble Connect played a major role in<br />

enabling this collaboration.<br />

"Trimble Connect allowed for a fully<br />

transparent and traceable 3D platform<br />

where all project stakeholders could<br />

collaborate seamlessly, regardless of their<br />

physical location. It offered a reliable<br />

solution for information transfer and<br />

tagging of ToDo's in the model which was<br />

an integral part of how the engineering<br />

team completed their checks of the live<br />

3D detail model environment where the<br />

approvals took place."<br />

Watch the animation video demonstrating<br />

some of the automated processes here:<br />

https://youtu.be/UVqg2Mkg3o0<br />

www.dbmvircon.com<br />

<strong>Nov</strong>ember/<strong>Dec</strong>ember <strong>2023</strong> 11