Gravis english

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1<br />

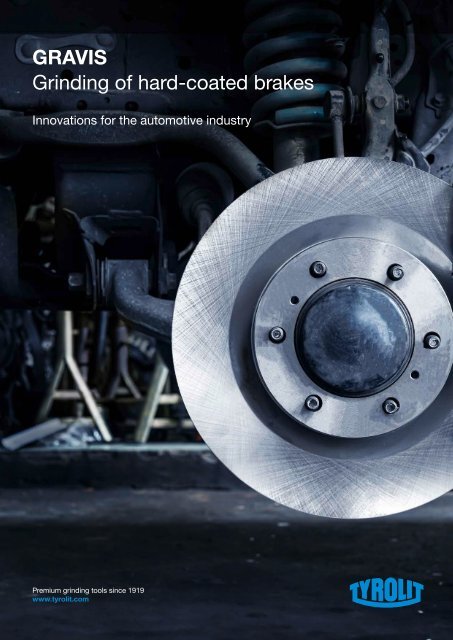

GRAVIS<br />

Grinding of hard-coated brakes<br />

Innovations for the automotive industry<br />

Premium grinding tools since 1919<br />

www.tyrolit.com

INNOVATIONS 2<br />

FOR THE AUTOMOTIVE INDUSTRY<br />

Economical grinding<br />

of hard-coated brakes<br />

The automotive industry is currently<br />

undergoing rapid change. With the<br />

Euro 7 emissions standard by the EU,<br />

which should apply from 2025 on,<br />

a significant reduction of fine dust<br />

pollution is driven forward.<br />

At the same time, regulations for the permissible<br />

brake abrasion and for tyres will come into effect,<br />

which will drastically change the requirements for<br />

vehicle manufacturers. For the first time, electric<br />

cars are also directly affected. This leads inevitably<br />

to a further development of the brake concepts<br />

currently in use.<br />

Thanks to the introduction of hard-coated brakes,<br />

manufacturers will be able to reach an optimal<br />

combination of first-class braking properties and<br />

minimal abrasion, which will lead to a reduction in<br />

fine dust pollution according to the new standards.<br />

Due to these innovations, advanced production<br />

technologies are needed to grind brake discs<br />

economically and efficiently. With the GRAVIS<br />

portfolio we support you in this change. In addition,<br />

we offer unrivalled application technology support<br />

in order to develop new grinding processes<br />

and continuously optimise production together<br />

with our partners.<br />

Your benefits with Tyrolit at a glance:<br />

Know-how<br />

of the world's best development team<br />

in the grinding industry<br />

First-class quality<br />

from the leading manufacturer<br />

of precision abrasives<br />

Cost savings<br />

thanks to the most economical<br />

grinding solutions on the market<br />

Customised grinding tools<br />

which are perfectly tailored<br />

to your needs

INNOVATIONS 3<br />

FOR THE AUTOMOTIVE INDUSTRY<br />

Grinding concepts<br />

with cup wheels<br />

with segments<br />

The stock removal on coatings made from hard<br />

materials is extremely difficult. Therefore, excellent<br />

abrasives and high spindle capacities are essential<br />

for the machining of brake discs.<br />

The new Tyrolit GRAVIS product line offers tools for double side face<br />

grinding of hard-coated brake discs with first-rate segments and cup<br />

wheels. These specially developed products achieve an even stock<br />

removal rate on both sides of the brake disc and offer you maximum<br />

cutting ability, resulting in low grinding forces. With Tyrolit products,<br />

you can achieve the best surface results in the shortest possible time<br />

combined with incomparable durability.<br />

no grinding<br />

Your benefits with GRAVIS:<br />

+ Low grinding forces thanks to high cutting ability<br />

+ Uniform surface results<br />

+ Highest lifetime<br />

+ Short cycle times and high economic efficiency<br />

+ Solutions for all grinding processes and coatings<br />

cross-grinding

INNOVATIONS 4<br />

FOR THE AUTOMOTIVE INDUSTRY<br />

Products<br />

Hard coatings on brake discs pose a number<br />

of challenges for the grinding process and<br />

tools. Thanks to decades of experience in<br />

the production of CBN and diamond grinding<br />

wheels, our experts can ideally assess the<br />

characteristics of a wide range of coating<br />

processes and align the abrasives perfectly.<br />

With GRAVIS, you are able to fully meet requirements<br />

concerning the ground brake disc and the grinding<br />

process, regardless of the machine concept. Our focus<br />

lies on the continuous optimisation of our production<br />

in order to manufacture excellent products, using<br />

the latest manufacturing methods, and to equip our<br />

customers with them. Additionally, our experts support<br />

you in designing the right grinding procedure and<br />

selecting the fitting grinding tool. In series production,<br />

you can rely on a global partner who works with you to<br />

continuously improve processes and results. Tyrolit is<br />

your reliable and competent partner for grinding hardcoated<br />

brake discs.<br />

cup wheel<br />

Coating processes<br />

At the moment, the hard materials used, the coating<br />

processes and the process parameters are constantly<br />

changing, which has a major impact on the grindability<br />

of brake discs. Tyrolit is in intensive dialogue<br />

with machine manufacturers in order to incorporate<br />

the rapid development of coating variants into our<br />

grinding concepts. We offer our customers solutions<br />

for all coating processes and hard materials in order<br />

to offer the best products for future requirements.<br />

grinding segment<br />

Your contact<br />

Daniel Herzog<br />

Industry Group Manager<br />

daniel.herzog@tyrolit.com

In 3 steps to your product:<br />

1. Initial consultancy by our technical sales<br />

department incl. assessment of the requirements<br />

2. Specification of the appropriate<br />

grinding wheel<br />

3. You receive the perfect grinding wheel<br />

and application engineering support for<br />

the ideal grinding process

Tyrolit - Schleifmittelwerke Swarovski AG & Co. K.G.<br />

Swarovskistraße 33 | 6130 Schwaz | Austria<br />

Tel. +43 5242 606-0 | Fax +43 5242 63398<br />

Our worldwide subsidiary companies can be found<br />

on our website at www.tyrolit.com