Proportional Relief Valves FITOK EN

Proportional Relief Valves FITOK EN Available @ https://fitok.ch and https://schalcher-engineering.ch FITOK Group has been an industry-leading developer and manufacturer of superior quality instrumentation valves and fittings. We have the capability to manufacture and supply 5 different product categories, including: ■ General Instrumentation Valves and Fittings ■ Medium & High Pressure Valves and Fittings ■ High Purity & Ultra High Purity Products ■ Sampling Systems ■ Tubing Our mission is to provide the best quality products and the most professional services to our customers. The performance of our products is guaranteed during the whole manufacturing cycle from our employment of customized materials which should be controlled more strictly than just according to ASTM requirements to our implementation of production and testing exceeding the industry standards. Since our inception, FITOK has been applying sound quality control standards in all activities. FITOK is an ISO 9001 :2015 certified company and our products have been certified by different industry authorities and third-party inspection institutions in different countries to have obtained a variety of certificates, among which there are the TA-Luft, ABS, ASTM F1387, ISO15848, TPED, E-Mark, CRN, DVGW, PED, API and DOT certificates. Benefiting from our global facilities, we are able to optimize the most cost-effective resources worldwide. Paired with flexible manufacturing systems, we deliver a wide range of the best quality products within a competitive lead time and the most professional services to our customers in an array of applications and industries.

Proportional Relief Valves FITOK EN

Available @ https://fitok.ch and https://schalcher-engineering.ch

FITOK Group has been an industry-leading developer and manufacturer of superior quality instrumentation valves and fittings. We have the capability to manufacture and supply 5 different product categories, including:

■ General Instrumentation Valves and Fittings

■ Medium & High Pressure Valves and Fittings

■ High Purity & Ultra High Purity Products

■ Sampling Systems

■ Tubing

Our mission is to provide the best quality products and the most professional services to our customers. The performance of our products is guaranteed during the whole manufacturing cycle from our employment of customized materials which should be controlled more strictly than just according to ASTM requirements to our implementation of production and testing exceeding the industry standards.

Since our inception, FITOK has been applying sound quality control standards in all activities. FITOK is an ISO 9001 :2015 certified company and our products have been certified by different industry authorities and third-party inspection institutions in different countries to have obtained a variety of certificates, among which there are the TA-Luft, ABS, ASTM F1387, ISO15848, TPED, E-Mark, CRN, DVGW, PED, API and DOT certificates.

Benefiting from our global facilities, we are able to optimize the most cost-effective resources worldwide. Paired with flexible manufacturing systems, we deliver a wide range of the best quality products within a competitive lead time and the most professional services to our customers in an array of applications and industries.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

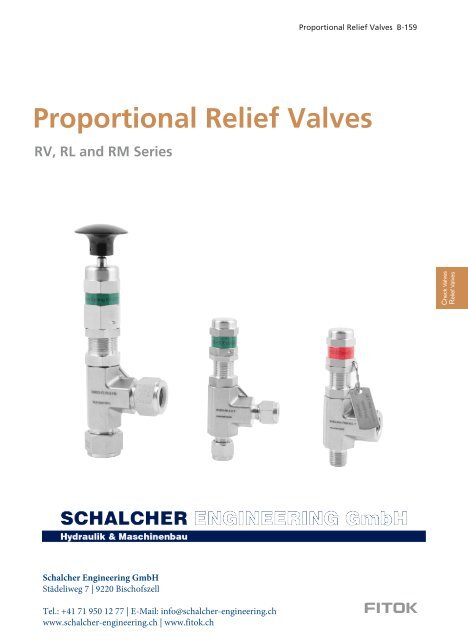

<strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong> B-159<br />

<strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong><br />

RV, RL and RM Series<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

Schalcher Engineering GmbH<br />

Städeliweg 7 | 9220 Bischofszell<br />

Tel.: +41 71 950 12 77 | E-Mail: info@schalcher-engineering.ch<br />

www.schalcher-engineering.ch | www.fitok.ch

B-160 <strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong><br />

<strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong><br />

RV, RL and RM Series<br />

Introduction<br />

<strong>FITOK</strong> proportional relief valves release the pressure in pipelines by diverting the flow of media as a way to protect the<br />

pipeline components. The valves open in proportion as the upstream pressure increases above the set pressure and close<br />

gradually as the upstream pressure decreases.<br />

Features<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

◎ Set pressure:<br />

RV series: 7 color-coded springs available for a wide range of set pressures, 50 to 6000 psig @ 70°F (3.4 to 414 bar @ 20°C)<br />

RL series: 10 to 225 psig @ 70°F (0.68 to 15.5 bar @ 20°C)<br />

RM series: 3 color-coded springs available for a wide range of set pressures, 50 to 1500 psig @ 70°F (3.4 to 103 bar @ 20°C)<br />

◎ Maximum outlet pressure:<br />

RV series: 1500 psig (103 bar)<br />

RL series: 225 psig (15.5 bar)<br />

RM series: 1500 psig (103 bar)<br />

◎ Orifice size:<br />

RV series: 0.14 " (3.6 mm)<br />

RL series: 0.19 " (4.8 mm) and 0.25 " (6.4 mm)<br />

RM series: 0.25 " (6.4 mm)<br />

◎ Back pressure<br />

Back pressure is the pressure of the outlet of valves. It increases the set pressure of proportional relief valves.<br />

RV and RM series: Balanced stem design to eliminate the effect of system back pressure<br />

RL series: Pre-set pressure = Desired pressure - 0.8 × Back pressure<br />

◎ Working temperature: -40°F to 300°F (-40°C to 148°C)<br />

◎ Variety of end connections<br />

◎ Liquid or gas service<br />

◎ Adjustable bonnet cap and adjustable set pressure<br />

◎ Lead seal lock wire through lock wire holes to lock proportional relief valve so as to secure a set pressure effectively<br />

◎ Variety of seal materials<br />

◎ Label identifies the set pressure range<br />

Applications<br />

<strong>Relief</strong> valves are proportional relief valves that open gradually as the pressure increases. Consequently, they do not have a<br />

capacity rating at a given pressure rise (accumulation), and they are not certified to ASME or any other codes.<br />

!<br />

!<br />

!<br />

Some system applications require relief valves to meet specific safety codes. The system designer and user<br />

must determine when such codes apply and whether these relief valves conform to them.<br />

<strong>FITOK</strong> proportional relief valves should never be used as ASME Boiler and Pressure Vessel Code safety relief<br />

devices.<br />

<strong>FITOK</strong> proportional relief valves are not “Safety Accessories” as defined in the Pressure Equipment Directive<br />

2014/68/EU.

<strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong> B-161<br />

Pressure-Temperature Rated Value<br />

Series<br />

RV<br />

RM<br />

RL<br />

1<br />

Max. Inlet Pressure<br />

1<br />

Max. Allowable<br />

Outlet Pressure<br />

Set Pressure<br />

6000 psig (413 bar),up to<br />

8000 psig (551 bar) during relief process<br />

1500 psig (103 bar)<br />

50 to 6000 psig<br />

(3.4 to 413 bar)<br />

6000 psig (413 bar)<br />

1500 psig (103 bar)<br />

50 to 1500 psig<br />

(3.4 to 105 bar)<br />

300 psig (20.6 bar)<br />

225 psig (15.5 bar)<br />

10 to 225 psig<br />

(0.7 to 15.5 bar)<br />

Sealing Material<br />

Temperature, ° C ( ° F)<br />

FKM<br />

Buna-N Neoprene<br />

EPDM<br />

FFKM<br />

FKM<br />

Buna Neoprene<br />

EPDM FKM Buna-N Neoprene<br />

-N<br />

Max. Set Pressure, psig (bar)<br />

EPDM<br />

FFKM<br />

-40 (-40)<br />

_<br />

_<br />

_<br />

-34 (-30)<br />

-23 (-10)<br />

_<br />

_<br />

_<br />

_<br />

_<br />

- 17 ( 0)<br />

- 12 ( 10)<br />

-4 (25)<br />

-1 (30)<br />

4 (40)<br />

10 (50)<br />

20 (70)<br />

65 (150)<br />

93 (200)<br />

121 (250)<br />

135 (275)<br />

148 ( 300)<br />

6000<br />

(413)<br />

6000<br />

(413)<br />

6000<br />

(413)<br />

6000<br />

(413)<br />

6000<br />

(413)<br />

1500<br />

(103)<br />

1500<br />

(103)<br />

1500<br />

(103)<br />

5580<br />

(384)<br />

5160<br />

(355)<br />

4910<br />

5580<br />

(384)<br />

5160<br />

(355)<br />

4910<br />

3000<br />

(207)<br />

1500<br />

(103)<br />

5580<br />

(384)<br />

5160<br />

(355)<br />

4910<br />

5580<br />

(384)<br />

5160<br />

(355)<br />

4910<br />

700<br />

(48)<br />

(338) (338) (338) (338) 700<br />

_ (48)<br />

_<br />

_ _ _ 2500<br />

(172)<br />

_<br />

1500<br />

(103)<br />

_<br />

225<br />

(15.5)<br />

225<br />

(15.5)<br />

225<br />

(15.5)<br />

225<br />

(15.5)<br />

225<br />

(15.5)<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

1 Outlet pressure shall not exceed inlet pressure.

B-162 <strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong><br />

Set Pressure and Resealing Pressure<br />

Set pressure: the upstream pressure at which the valve opens and the indication of flow occurs.<br />

Set pressure of each valve after initial relief fluctuates within:<br />

± 3.0 psig (0.20 bar) or ±5% (whichever is greater) of the initial set pressure at 60 to 80°F (15 to 26°C),<br />

±6.0 psig (0.40 bar) or ±20% (whichever is greater) of the initial set pressure below 60°F (15°C) or above 80°F (26°C).<br />

Note: For valves not opened for a period of time, the set pressure may be higher.<br />

Resealing pressure: the upstream pressure at which the valve is fully closed as a result of a drop of upstream pressure<br />

after the valve opens. Resealing pressure is always lower than set pressure.<br />

The valve is tested for set and resealing performance before shipment.<br />

Series<br />

Test Set Pressure<br />

psig (bar)<br />

Minimum Resealing<br />

Pressure as a Percentage<br />

of Set Pressure, %<br />

RL<br />

10 to 20 (0.7 to 1.3)<br />

50<br />

175 to 225 (12.0 to 15.5)<br />

91<br />

RV/RM<br />

100 to 200 (6.8 to 13.7)<br />

850 to 1000 (58.5 to 68.9)<br />

50<br />

85<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong>

<strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong> B-163<br />

Flow Data at 70°F (20°C)<br />

Air<br />

RV and RM Series<br />

Inlet Pressure (psig)<br />

0 100<br />

6000<br />

Set pressure<br />

5500 psig (378 bar)<br />

5600<br />

5200<br />

Air Flow (std L/min)<br />

200<br />

300 400<br />

500<br />

RV Series<br />

400<br />

360<br />

4800<br />

320<br />

4400<br />

4000 psig (275 bar)<br />

4000<br />

280<br />

0 2 4 6 8 10 12 14 16 18 20<br />

3<br />

Air Flow ( std ft / min)<br />

Inlet Pressure (bar)<br />

Water<br />

Inlet Pressure (psig)<br />

6000<br />

5500<br />

5000<br />

4500<br />

4000<br />

3500<br />

0<br />

0 0.2 0.4 0.6 0.8<br />

Set pressure<br />

5500 psig (378 bar)<br />

4000 psig (275 bar)<br />

Water Flow (L/min)<br />

1.0<br />

0.04 0.08 0.12 0.16 0.20 0.24 0.28<br />

Water Flow ( U.S. gal/min)<br />

400<br />

350<br />

300<br />

250<br />

RV Series<br />

Inlet Pressure (bar)<br />

Inlet Pressure (psig)<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

0<br />

500<br />

Set pressure<br />

3000 psig (206 bar)<br />

2000 psig (137 bar)<br />

Air Flow (std L/min)<br />

1000 1500 2000<br />

3<br />

Air Flow ( std ft /min)<br />

2500<br />

RV Series<br />

RM Series<br />

250<br />

200<br />

150<br />

1500<br />

100<br />

1000 psig (68.9 bar)<br />

1000<br />

0 10 20 30 40 50 60 70 80 90 100<br />

Inlet Pressure (bar)<br />

Inlet Pressure (psig)<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

Water Flow (L/min)<br />

0 0.2 0.4 0.6 0.8<br />

Set pressure<br />

3000 psig (206 bar)<br />

2000 psig (137 bar)<br />

1500<br />

1000 psig (68.9 bar)<br />

1000<br />

0<br />

1.0<br />

0.04 0.08 0.12 0.16 0.20 0.24 0.28<br />

Water Flow (U.S. gal/min)<br />

250<br />

200<br />

150<br />

100<br />

RV Series<br />

RM Series<br />

Inlet Pressure (bar)<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

Inlet Pressure (psig)<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

0<br />

0<br />

500<br />

Set pressure<br />

550 psig (37.8 bar)<br />

350 psig (24.1 bar)<br />

200 psig (13.7 bar)<br />

Air Flow (std L/min)<br />

1000 1500 2000<br />

2500<br />

10 20 30 40 50 60 70 80 90 100<br />

3<br />

Air Flow ( std ft /min)<br />

RV Series<br />

RM Series<br />

50<br />

40<br />

30<br />

20<br />

Inlet Pressure (bar)<br />

Inlet Pressure (psig)<br />

RM Series<br />

Water Flow (L/min)<br />

0 1 2 3 4 5 6 7<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

Set pressure<br />

550 psig (37.8 bar)<br />

0<br />

350 psig (24.1 bar)<br />

200 psig (13.7 bar)<br />

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0<br />

Water Flow (U.S. gal/min)<br />

RV Series<br />

50<br />

40<br />

30<br />

20<br />

Inlet Pressure (bar)<br />

RL Series<br />

Inlet Pressure (psig)<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

0<br />

0<br />

100<br />

Set pressure<br />

225 psig (15.5 bar)<br />

150 psig (10.3 bar)<br />

100 psig (6.8 bar)<br />

50 psig (3.4 bar)<br />

Air Flow (std L/min)<br />

200<br />

300 400<br />

RL Series 7 Orifice<br />

RL Series 8 Orifice<br />

500<br />

0<br />

2 4 6 8 10 12 14 16 18 20<br />

3<br />

Air Flow ( std ft / min)<br />

20<br />

16<br />

12<br />

8<br />

4<br />

Inlet Pressure (bar)<br />

Inlet Pressure (psig)<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Water Flow (L/min)<br />

0 1 2 3 4 5 6 7<br />

Set pressure<br />

225 psig (15.5 bar)<br />

150 psig (10.3 bar)<br />

0<br />

100 psig (6.8 bar)<br />

50 psig (3.4 bar)<br />

RL Series 7 Orifice<br />

RL Series 8 Orifice<br />

0<br />

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0<br />

Water Flow (U.S. gal/min)<br />

20<br />

16<br />

12<br />

8<br />

4<br />

Inlet Pressure (bar)

B-164 <strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong><br />

Standard Materials of Construction<br />

RV Series<br />

Component<br />

Material Grade/ASTM Specification<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

Body<br />

Seat<br />

O-ring<br />

Gasket<br />

Seat Retainer<br />

O-ring<br />

Stem<br />

O-ring<br />

Bonnet<br />

Spring Support<br />

Spring<br />

316 SS/A182<br />

316 SS/A479<br />

Fluorocarbon FKM<br />

PEEK<br />

316 SS/A479<br />

Fluorocarbon FKM<br />

316 SS/A479<br />

Fluorocarbon FKM<br />

316 SS/A479<br />

316 SS/A479<br />

S17700 SS/AMS 5678<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

12<br />

Lock Nut<br />

17-4PH powdered metal<br />

13<br />

Label<br />

Polyester<br />

14<br />

Bonnet Cap<br />

316 SS/A479<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

Note: Wetted components are listed in italics.<br />

1. Lubricant: Silicone-based<br />

2. Contact <strong>FITOK</strong> Group or our authorized distributors for other materials<br />

RL Series<br />

Component<br />

Material Grade/ASTM<br />

Specification<br />

1<br />

Body<br />

316 SS/A182<br />

2<br />

Gasket<br />

316 SS/A479<br />

3<br />

4<br />

5<br />

6<br />

6a<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

Seat<br />

Bonded disc<br />

Stem<br />

Retainer<br />

Ring<br />

Quad Seal<br />

O-ring<br />

Bonnet<br />

Spring Support<br />

Spring<br />

Lock Nut<br />

Sleeve<br />

316 SS/A479<br />

316 SS/A479+Fluorocarbon FKM<br />

316 SS/A479<br />

316 SS/A479<br />

316 SS/A479<br />

Fluorocarbon FKM<br />

Fluorocarbon FKM<br />

316 SS/A479<br />

316 SS/A479<br />

S17700 SS/AMS 5678<br />

17-4PH powdered metal<br />

304SS/A240<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6a<br />

5<br />

4<br />

1<br />

14<br />

15<br />

Label<br />

Bonnet Cap<br />

Polyester<br />

316 SS/A479<br />

Orifice 7<br />

0.19 in. (4.8 mm)<br />

Orifice 8<br />

0.25 in. (6.4 mm)<br />

Note: Wetted components are listed in italics.<br />

1. Lubricant: Silicone-based<br />

2. Contact <strong>FITOK</strong> Group or our authorized distributors for other materials

<strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong> B-165<br />

RM Series<br />

Component<br />

Material Grade/ASTM Specification<br />

1<br />

2<br />

3<br />

Body<br />

Stem<br />

Retainer<br />

316 SS/A182<br />

316 SS/A479+Fluorocarbon FKM<br />

316 SS/A479<br />

11<br />

10<br />

4<br />

5<br />

Square sealing piece<br />

Bonnet<br />

Fluorocarbon FKM<br />

316 SS/A479<br />

9<br />

8<br />

6<br />

O-ring<br />

Fluorocarbon FKM<br />

7<br />

7<br />

Spring Support<br />

316 SS/A479<br />

6<br />

8<br />

9<br />

Spring<br />

Lock Nut<br />

S17700 SS/AMS 5678<br />

17-4PH powdered metal<br />

5<br />

4<br />

3<br />

10<br />

11<br />

Label<br />

Bonnet Cap<br />

Polyester<br />

316 SS/A479<br />

2<br />

1<br />

Note: Wetted components are listed in italics.<br />

1. Lubricant: Silicone-based<br />

2. Contact <strong>FITOK</strong> Group or our authorized distributors for other materials<br />

Manual Override Handles<br />

Lift the aluminum handle with hand<br />

to open the proportional relief valve<br />

without changing the set pressure.<br />

For use on the following valves :<br />

Aluminum Handle<br />

Pull Rod<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

RV Series<br />

RL Series<br />

RM Series<br />

set pressure range 50~1500 psig<br />

set pressure range 10~225 psig<br />

set pressure range 50~300 psig<br />

Spring Support<br />

Dimensions<br />

0.06 " (1.5 mm)<br />

Lock Wire Hole<br />

0.09 " (2.2 mm)<br />

Lock Wire Hole<br />

0.06 " (1.5 mm)<br />

Lock Wire Hole<br />

0.09 " (2.2 mm)<br />

Lock Wire Hole<br />

F max<br />

C<br />

D max<br />

E max<br />

A<br />

B

B-166 <strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong><br />

RV Series<br />

Basic<br />

Ordering<br />

Number<br />

Connection Type and Size<br />

Inlet<br />

Outlet<br />

Orifice<br />

in. (mm)<br />

A<br />

B<br />

Dimensions, in. (mm)<br />

C<br />

D<br />

E<br />

F<br />

RV□□-FL4-6-□<br />

RV□□-FL6-6-□<br />

1/4" <strong>FITOK</strong><br />

3/8" <strong>FITOK</strong><br />

1/4" <strong>FITOK</strong><br />

3/8" <strong>FITOK</strong><br />

0.46<br />

(11.9)<br />

1.60<br />

(40.6)<br />

1.44<br />

(36.6)<br />

2.70<br />

(68.6)<br />

4.14<br />

(105.2)<br />

RV□□-FL8-6-□<br />

1/2'' <strong>FITOK</strong><br />

1/2'' <strong>FITOK</strong><br />

0.54<br />

(13.7)<br />

1.79<br />

(45.4)<br />

1.66<br />

(42.2)<br />

2.72<br />

(69.0)<br />

4.38<br />

(111.2)<br />

RV□□-ML6-6-□ 6 mm <strong>FITOK</strong><br />

RV□□-ML8-6-□ 8 mm <strong>FITOK</strong><br />

RV□□-ML12-6-□ 12 mm <strong>FITOK</strong><br />

RV□□-FNS4-6-□<br />

RV□□-NS4-6-□<br />

1/4 Female NPT<br />

1/4 Male NPT<br />

RV□□-FRT4-6-□ 1/4 Female BSPT<br />

6 mm <strong>FITOK</strong><br />

8 mm <strong>FITOK</strong><br />

12 mm <strong>FITOK</strong><br />

1/4 Female NPT<br />

1/4 Male NPT<br />

1/4 Female BSPT<br />

0.14<br />

(3.6)<br />

0.46<br />

(11.9)<br />

0.54<br />

(13.7)<br />

0.46<br />

(11.9)<br />

1.60<br />

(40.6)<br />

1.83<br />

(46.5)<br />

1.17<br />

(29.7)<br />

1.17<br />

(29.7)<br />

1.17<br />

(29.7)<br />

1.44<br />

(36.6)<br />

1.83<br />

(46.5)<br />

1.38<br />

(34.9)<br />

1.27<br />

(32.2)<br />

1.38<br />

(34.9)<br />

2.70<br />

(68.6)<br />

4.09<br />

(103.9)<br />

2.70<br />

(68.6)<br />

2.70<br />

(68.6)<br />

2.70<br />

(68.6)<br />

4.14<br />

(105.2)<br />

5.92<br />

(150.4)<br />

4.08<br />

(103.5)<br />

3.96<br />

(100.7)<br />

4.08<br />

(103.5)<br />

3.68<br />

(98.0)<br />

RL Series<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

Basic Ordering<br />

Number<br />

RL□□-FL4-7<br />

RL□□-ML6-7<br />

Connection Type and Size<br />

Inlet Size Outlet Size<br />

1/4" <strong>FITOK</strong> 1/4" <strong>FITOK</strong><br />

6 mm <strong>FITOK</strong> 6 mm <strong>FITOK</strong><br />

Orifice<br />

in. (mm)<br />

A<br />

B<br />

1.60<br />

(40.6)<br />

Dimensions, in. (mm)<br />

C<br />

1.44<br />

( 36.6)<br />

D<br />

E<br />

4.14<br />

(105.0)<br />

F<br />

RL□□-NS4-7<br />

RL□□-RT4-7<br />

RL□□-FNS4-7<br />

1/4 Male NPT<br />

1/4 Male BSPT<br />

1/4 Female NPT<br />

1/4 Male NPT<br />

1/4 Male BSPT<br />

1/4 Female NPT<br />

0.19<br />

(4.8)<br />

0.46<br />

(11.9)<br />

1.17<br />

(29.7)<br />

1.38<br />

(34.9)<br />

4.08<br />

(103.5)<br />

3.74<br />

(95.0)<br />

RL□□-FRT4-7<br />

1/4 Female BSPT<br />

1/4 Female BSPT<br />

RL□□-FL8-8<br />

RL□□-ML12-8<br />

RL□□-NS8-8<br />

RL□□-RT8-8<br />

RL□□-FNS8-8<br />

RL□□-FRT8-8<br />

1/2'' <strong>FITOK</strong><br />

12 mm <strong>FITOK</strong><br />

1/2 Male BSPT<br />

1/2 Female NPT<br />

1/2 Female BSPT<br />

1/2'' <strong>FITOK</strong><br />

12 mm <strong>FITOK</strong><br />

1/2 Male NPT 1/2 Male NPT<br />

1/2 Male BSPT<br />

1/2 Female NPT<br />

1/2 Female BSPT<br />

0.25<br />

(6.4)<br />

0.54<br />

(13.7)<br />

0.58<br />

(14.7)<br />

1.83<br />

(46.5)<br />

1.44<br />

(36.6)<br />

1.83<br />

(46.5)<br />

1.44<br />

(36.6)<br />

3.87<br />

(98.4)<br />

5.92<br />

(150.0)<br />

5.31<br />

(135.0)<br />

4.89<br />

(124.3)

<strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong> B-167<br />

RM Series<br />

Basic<br />

Ordering<br />

Number<br />

Connection Type and Size<br />

Inlet Size<br />

Outlet Size<br />

Orifice<br />

in. (mm)<br />

A<br />

B<br />

Dimensions, in. (mm)<br />

C<br />

D<br />

E<br />

F<br />

RM□□-FL8-8-□<br />

RM□□-ML12-8-□<br />

RM□□-NS8-8-□<br />

RM□□-RT8-8-□<br />

RM□□-FNS8-8-□<br />

RM□□-FRT8-8-□<br />

1/2'' <strong>FITOK</strong><br />

12 mm <strong>FITOK</strong><br />

1/2 Male NPT<br />

1/2 Male BSPT<br />

1/2 Female NPT<br />

1/2 Female BSPT<br />

1/2'' <strong>FITOK</strong><br />

12 mm <strong>FITOK</strong><br />

1/2 Male NPT<br />

1/2 Male BSPT<br />

1/2 Female NPT<br />

1/2 Female BSPT<br />

0.25<br />

(6.4)<br />

0.54<br />

(13.7)<br />

0.58<br />

(14.7)<br />

1.83<br />

(46.5)<br />

1.44<br />

(36.6)<br />

1.83<br />

(46.5)<br />

1.44<br />

(36.6)<br />

3.87<br />

(98.4)<br />

5.73<br />

(145.0)<br />

5.31<br />

(135.0)<br />

4.89<br />

(124.3)<br />

1. <strong>FITOK</strong> means <strong>FITOK</strong> double ferrule tube fittings.<br />

2. Dimensions are shown with <strong>FITOK</strong> nuts finger-tightened. All dimensions are for reference only and are subject to change.<br />

3. Sizes and types listed are standard. For other connection types and sizes, please contact <strong>FITOK</strong> Group or our authorized distributors.<br />

Sealing Kit<br />

Series<br />

RV<br />

RL<br />

RM<br />

Orifice<br />

Designator<br />

6<br />

7<br />

8<br />

8<br />

Sealing Kit Basic Ordering Number<br />

FKM Buna-N Neoprene EPDM FFKM<br />

VI-RV-6<br />

RLSS-7-VI<br />

RLSS-8-VI<br />

BN-RV-6<br />

RLSS-7-B<br />

RLSS-8-B<br />

N-RV-6<br />

RLSS-7-N<br />

RLSS-8-N<br />

E-RV-6<br />

RLSS-7-E<br />

RLSS-8-E<br />

Z-RV-6<br />

RLSS-7-Z<br />

RLSS-8-Z<br />

RMSS-8-VI RMSS-8-B RMSS-8-N RMSS-8-E -<br />

Sealing Kit Content<br />

O-ring (3)<br />

O-ring, square sealing piece, adhesive disc, retainer<br />

O-ring, square sealing piece, adhesive disc<br />

O-ring, square sealing piece, stem<br />

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

The basic ordering number of the listed RL and RM series sealing kits specifies 316 stainless steel.<br />

For other materials, such as alloy 400, replace SS with M in the basic ordering number, for example: RLM-7-VI<br />

Spring Kit<br />

Series<br />

Orifice<br />

Designator<br />

Spring Kit Basic<br />

Ordering Number<br />

Set Pressure Range<br />

psig (bar)<br />

Spring<br />

Color<br />

7PRV-SP6 -F-B<br />

50 to 300 (3.4 to 20.7)<br />

Green<br />

7PRV-SP6 -O-B<br />

300 to 700 (20.7 to 48.3)<br />

Orange<br />

7PRV-SP6 -Y-B<br />

700 to 1500 (48.3 to 103)<br />

Yellow<br />

RV<br />

6<br />

7PRV-SP6 -P-B<br />

1500 to 2500 (103 to 172)<br />

Purple<br />

7PRV-SP6 -W-B<br />

2500 to 3500 (172 to 241)<br />

White<br />

7PRV-SP6 -J-B<br />

3500 to 4500 (241 to 310)<br />

Blue<br />

7PRV-SP6 -C-B<br />

4500 to 6000 (310 to 414)<br />

Red<br />

RL<br />

RM<br />

7<br />

8<br />

8<br />

7PRL-SP7 -Y-B<br />

7PRL-SP8 -Y-B<br />

7PRM-SP8 -F-B<br />

7PRM-SP8-O-B<br />

10 to 255 (0.7 to 15)<br />

50 to 300 (3.4 to 20.7)<br />

300 to 700 (20.7 to 48.3)<br />

Yellow<br />

Green<br />

Orange<br />

7PRM-SP8-Y-B<br />

700 to 1500 (48.3 to 103)<br />

Yellow<br />

The content of the spring kit includes: spring and label.<br />

To order spring kit with springs, labels, and lead seal lock wire, add "-L" to the spring kit basic ordering number.<br />

For example: 7PRV-SP6-F-B-L.

Check <strong>Valves</strong><br />

<strong>Relief</strong> <strong>Valves</strong><br />

Ordering Number Description<br />

<strong>Valves</strong><br />

Series<br />

Body<br />

Material<br />

Inlet Type<br />

Inlet Size<br />

RVSS - FL6 - ML8 - 6Z - WM - TSF2<br />

Outlet<br />

Type<br />

Outlet<br />

Size<br />

Orifice Size<br />

Seal Material<br />

Spring Kit<br />

Color<br />

Handle<br />

Set Pressure<br />

Special Cleaning and<br />

Application Packaging<br />

B-168 <strong>Proportional</strong> <strong>Relief</strong> <strong>Valves</strong><br />

RV SS 316 SS FNS Female NPT 2 1/8"<br />

RM<br />

RL<br />

S4<br />

S1<br />

6L<br />

4L<br />

304 SS<br />

321 SS<br />

316L SS<br />

304L SS<br />

904L 904L SS<br />

NS<br />

FRT<br />

RT<br />

FMS<br />

MS<br />

FRP<br />

BP<br />

FL<br />

ML<br />

Male NPT<br />

Female BSPT<br />

Male BSPT<br />

Female Metric<br />

Thread<br />

(for RG-M)<br />

Male Metric<br />

Thread<br />

(for RG-M)<br />

Female BSPP<br />

(for RP)<br />

Male BSPP<br />

(for RG)<br />

Fractional Tube<br />

Fitting<br />

Metric Tube<br />

Fitting<br />

4<br />

6<br />

Note: "Ordering Number Description" is a reference to understand the combination<br />

rules of <strong>FITOK</strong> product part number. Not all combinations are available.<br />

1. Standard thread pitch for metric threads are as follows:<br />

M10 and below: 1 mm<br />

M12 to M24: 1.5 mm<br />

M27 and above: 2 mm<br />

Standard thread pitch should be ignored in the ordering number, others should be specified.<br />

1/4"<br />

3/8" or 6 mm<br />

8 1/2" or 8 mm<br />

10 10 mm<br />

12<br />

3/4" or 12 mm<br />

Same as inlet<br />

Specified in the<br />

same way as<br />

the inlet type<br />

and size<br />

6<br />

7<br />

8<br />

0.14"<br />

(3.6 mm)<br />

RV Only<br />

0.19"<br />

(4.8 mm)<br />

RL Only<br />

0.25"<br />

(6.4 mm)<br />

RL and RM<br />

B<br />

E EPDM<br />

N Neoprene<br />

Z<br />

Fluorocarbon<br />

FKM<br />

Buna N<br />

FFKM (RV<br />

and RL Series)<br />

F<br />

O<br />

Y<br />

P<br />

W<br />

J<br />

C<br />

N<br />

Yellow 10~225 psig<br />

(RL Only)<br />

Green 50~300 psig<br />

(RV and RM)<br />

Orange 300~700 psig<br />

(RV and RM)<br />

Yellow 700~1500 psig<br />

(RV and RM)<br />

Purple 1500~2500 psig<br />

(RV Only)<br />

White 2500~3500 psig<br />

(RV Only)<br />

Blue 3500~4500 psig<br />

(RV Only)<br />

Red 4500~6000 psig<br />

(RV Only)<br />

No spring<br />

M<br />

MC<br />

None<br />

S<br />

Black<br />

Aluminum<br />

Handle<br />

Red<br />

Aluminum<br />

Handle<br />

No<br />

NACE<br />

MR0175<br />

L<br />

T<br />

FC-01<br />

F2 FC-02<br />

Set and test the<br />

valves with the<br />

minimum value<br />

of the spring<br />

pressure range<br />

Set and test the<br />

valves with the<br />

minimum value of<br />

the spring pressure<br />

range. Lead seal<br />

lock wire as<br />

accessories.<br />

Set, test and lock<br />

the valves with a<br />

specified set<br />

pressure. Hang a<br />

nameplate with<br />

the specified set<br />

pressure on it<br />

2. Cleaning and Packaging:<br />

FC-01: Standard cleaning and packaging for general industrial procedures.<br />

FC-02: Special cleaning and packaging for wetted system components to ensure compliance with product cleaning requirement of ASTM G93 Level C.<br />

3. For proportional relief valve with a specified set pressure and a nameplate, specify the desired set pressure when ordering.<br />

The set pressure value should be within the set pressure range of the selected spring, and the following requirements should be followed:<br />

10 psig≤ set pressure value≤500 psig , take the minimum interval 1 psig.<br />

500 psig ≤set pressure value≤1000 psig , take the minimum interval of 5 psig.<br />

1000 psig ≤set pressure value≤6000 psig , take the minimum interval of 10 psig.

info@fitok.com<br />

www.fitok.com<br />

FK-IC-GV-07-<strong>EN</strong>-240126