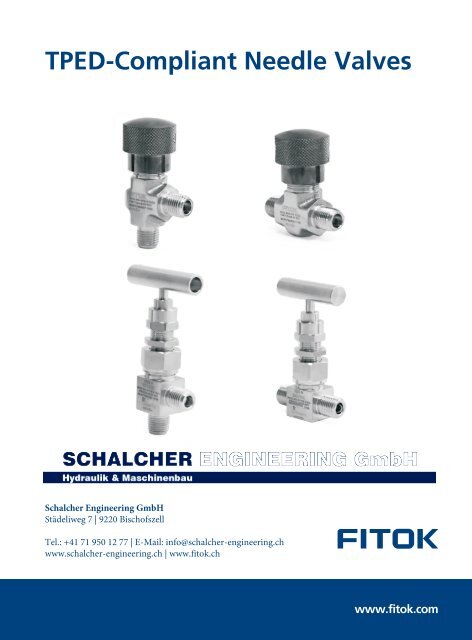

TPED-Compliant Needle Valves FITOK EN

TPED-Compliant Needle Valves FITOK EN Available @ https://fitok.ch and https://schalcher-engineering.ch FITOK Group has been an industry-leading developer and manufacturer of superior quality instrumentation valves and fittings. We have the capability to manufacture and supply 5 different product categories, including: ■ General Instrumentation Valves and Fittings ■ Medium & High Pressure Valves and Fittings ■ High Purity & Ultra High Purity Products ■ Sampling Systems ■ Tubing Our mission is to provide the best quality products and the most professional services to our customers. The performance of our products is guaranteed during the whole manufacturing cycle from our employment of customized materials which should be controlled more strictly than just according to ASTM requirements to our implementation of production and testing exceeding the industry standards. Since our inception, FITOK has been applying sound quality control standards in all activities. FITOK is an ISO 9001 :2015 certified company and our products have been certified by different industry authorities and third-party inspection institutions in different countries to have obtained a variety of certificates, among which there are the TA-Luft, ABS, ASTM F1387, ISO15848, TPED, E-Mark, CRN, DVGW, PED, API and DOT certificates. Benefiting from our global facilities, we are able to optimize the most cost-effective resources worldwide. Paired with flexible manufacturing systems, we deliver a wide range of the best quality products within a competitive lead time and the most professional services to our customers in an array of applications and industries.

TPED-Compliant Needle Valves FITOK EN

Available @ https://fitok.ch and https://schalcher-engineering.ch

FITOK Group has been an industry-leading developer and manufacturer of superior quality instrumentation valves and fittings. We have the capability to manufacture and supply 5 different product categories, including:

■ General Instrumentation Valves and Fittings

■ Medium & High Pressure Valves and Fittings

■ High Purity & Ultra High Purity Products

■ Sampling Systems

■ Tubing

Our mission is to provide the best quality products and the most professional services to our customers. The performance of our products is guaranteed during the whole manufacturing cycle from our employment of customized materials which should be controlled more strictly than just according to ASTM requirements to our implementation of production and testing exceeding the industry standards.

Since our inception, FITOK has been applying sound quality control standards in all activities. FITOK is an ISO 9001 :2015 certified company and our products have been certified by different industry authorities and third-party inspection institutions in different countries to have obtained a variety of certificates, among which there are the TA-Luft, ABS, ASTM F1387, ISO15848, TPED, E-Mark, CRN, DVGW, PED, API and DOT certificates.

Benefiting from our global facilities, we are able to optimize the most cost-effective resources worldwide. Paired with flexible manufacturing systems, we deliver a wide range of the best quality products within a competitive lead time and the most professional services to our customers in an array of applications and industries.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TPED</strong>-<strong>Compliant</strong> <strong>Needle</strong> <strong>Valves</strong><br />

Schalcher Engineering GmbH<br />

Städeliweg 7 | 9220 Bischofszell<br />

Tel.: +41 71 950 12 77 | E-Mail: info@schalcher-engineering.ch<br />

www.schalcher-engineering.ch | www.fitok.ch<br />

www.fitok.com

Contents<br />

<strong>TPED</strong>-<strong>Compliant</strong> <strong>Needle</strong> <strong>Valves</strong><br />

01<br />

Application<br />

01<br />

Test<br />

01<br />

Pi (<br />

) Making<br />

01<br />

ND Series <strong>Needle</strong> <strong>Valves</strong><br />

02<br />

NU Series <strong>Needle</strong> <strong>Valves</strong><br />

05

<strong>TPED</strong>-<strong>Compliant</strong> <strong>Needle</strong> <strong>Valves</strong><br />

1<br />

<strong>FITOK</strong> <strong>TPED</strong>-<strong>Compliant</strong> needle valves have been designed, manufactured, documented and tested in accordance with the<br />

requirements of the Transportable Pressure Equipment Directive 2010/35/EU. This directive sets out detailed rules concerning<br />

transportable pressure equipment to enhance safety and ensure free movement of such equipment within the European Union.<br />

<strong>FITOK</strong> <strong>TPED</strong>-<strong>Compliant</strong> needle valves comply with the Transportable Pressure Equipment Directive 2010/35/EU (<strong>TPED</strong>), and<br />

have been approved by a notified body, and acquired EC Type Approval Certificate.<br />

Application<br />

<strong>FITOK</strong> <strong>TPED</strong>-<strong>Compliant</strong> needle valves apply to compressed, liquefied or dissolved gases except acetylene, oxygen or oxidizing<br />

gas. In addition, they are not suitable for cryogenic equipment, portable fire extinguishers, liquefied and petroleum gas (LPG),<br />

and cannot be used as quick-release valves (e.g. for fire-extinguishing, explosion protection and rescue application).<br />

Test<br />

Every <strong>FITOK</strong> <strong>TPED</strong>-<strong>Compliant</strong> needle valve has been subjected to both internal leak tightness and external leak tightness test<br />

with nitrogen or compressed air at 1.2 times of rated working pressure prior to dispatch. The <strong>TPED</strong>-<strong>Compliant</strong> needle valves<br />

3<br />

have a maximum allowable internal and external leakage rate of 6 std cm /h.<br />

Pi (<br />

) Making<br />

Every <strong>FITOK</strong> <strong>TPED</strong>-<strong>Compliant</strong> needle valve has been Pi-marked and the identification number of the notified body involved in<br />

the initial inspections and tests.

2<br />

ND Series <strong>Needle</strong> <strong>Valves</strong><br />

Features<br />

◎ One-piece forged body<br />

◎ Compact design<br />

◎ Non-rotating stem<br />

◎ Soft tip design to seal easily<br />

◎ Special designed handle to stop contamination from entering into the valve<br />

Technical Data<br />

Rated working temperature<br />

Rated working pressure<br />

Flow coefficient Cv<br />

-4~150 °F (-20~65°C)<br />

2500 psig ( 172 bar) 0.53<br />

Standard Materials Of Construction<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

Item<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

Component<br />

Handle<br />

Stop Pin<br />

Set Screw<br />

Spool<br />

Packing Bolt<br />

O-Ring<br />

Backup Ring<br />

Washer<br />

Stem<br />

Stem Tip<br />

Body<br />

Lubricant<br />

Valve Material 316 SS<br />

Material Grade/ASTM Specification<br />

C36000/B16<br />

Stainless Steel<br />

Steel<br />

Aluminum<br />

316SS/A479<br />

Buna-N(NBR) or Ethylene<br />

Propylene Diene Monomer (EPDM)<br />

PTFE/D1710<br />

316SS/A479<br />

316SS/A479<br />

PEEK<br />

316SS/A182<br />

Magnesium silicate-based<br />

Note: Wetted components listed in italics.

3<br />

Dimensions<br />

Straight Pattern<br />

Angle Pattern<br />

D<br />

D<br />

C<br />

L1<br />

H ( Open )<br />

H ( Open )<br />

L1<br />

L2<br />

C<br />

L2<br />

Buna N O-Ring<br />

NDSS-FNS4-8PB-<strong>TPED</strong><br />

NDSS-FNS4-8PB-<strong>TPED</strong>-F2<br />

NDSS-FNS4-8PB-A-<strong>TPED</strong><br />

NDSS-FNS4-8PB-A-<strong>TPED</strong>-F2<br />

NDSS-NS4-8PB-<strong>TPED</strong><br />

NDSS-NS4-8PB-<strong>TPED</strong>-F2<br />

NDSS-NS4-8PB-A-<strong>TPED</strong><br />

NDSS-NS4-8PB-A-<strong>TPED</strong>-F2<br />

NDSS-NS6-8PB-<strong>TPED</strong><br />

NDSS-NS6-8PB-A-<strong>TPED</strong><br />

NDSS-NS4-FNS4-8PB-<strong>TPED</strong><br />

NDSS-NS4-FNS4-8PB-<strong>TPED</strong>-F2<br />

NDSS-NS8-FNS4-8PB-<strong>TPED</strong><br />

NDSS-NS8-FNS4-8PB-A-<strong>TPED</strong><br />

Basic Ordering Number<br />

NDSS-NS4-FNS4-8PB-A-<strong>TPED</strong><br />

NDSS-NS4-FNS4-8PB-A-<strong>TPED</strong>-F2<br />

NDSS-NS4-FL6-8PB-<strong>TPED</strong><br />

NDSS-NS4-FL6-8PB-A-<strong>TPED</strong><br />

NDSS-FL6-8PB-<strong>TPED</strong><br />

NDSS-FL6-8PB-A-<strong>TPED</strong><br />

Ethylene Propylene O-Ring<br />

NDSS-FNS4-8PE-<strong>TPED</strong><br />

NDSS-FNS4-8PE-<strong>TPED</strong>-F2<br />

NDSS-FNS4-8PE-A-<strong>TPED</strong><br />

NDSS-FNS4-8PE-A-<strong>TPED</strong>-F2<br />

NDSS-NS4-8PE-<strong>TPED</strong><br />

NDSS-NS4-8PE-<strong>TPED</strong>-F2<br />

NDSS-NS4-8PE-A-<strong>TPED</strong><br />

NDSS-NS4-8PE-A-<strong>TPED</strong>-F2<br />

NDSS-NS6-8PE-<strong>TPED</strong><br />

NDSS-NS6-8PE-A-<strong>TPED</strong><br />

NDSS-NS4-FNS4-8PE-<strong>TPED</strong><br />

NDSS-NS4-FNS4-8PE-<strong>TPED</strong>-F2<br />

NDSS-NS4-FNS4-8PE-A-<strong>TPED</strong><br />

NDSS-NS4-FNS4-8PE-A-<strong>TPED</strong>-F2<br />

NDSS-NS8-FNS4-8PE-<strong>TPED</strong><br />

NDSS-NS8-FNS4-8PE-A-<strong>TPED</strong><br />

NDSS-NS4-FL6-8PE-<strong>TPED</strong><br />

NDSS-NS4-FL6-8PE-A-<strong>TPED</strong><br />

NDSS-FL6-8PE-<strong>TPED</strong><br />

NDSS-FL6-8PE-A-<strong>TPED</strong><br />

Connection<br />

Orifice<br />

Dimensions, in.(mm)<br />

Type and Size<br />

in.(mm)<br />

Inlet Outlet L1 L2 C D H<br />

1/4<br />

Female<br />

NPT<br />

1/4<br />

Male<br />

NPT<br />

3/8<br />

Male<br />

NPT<br />

1/4<br />

Male<br />

NPT<br />

1/4<br />

Male<br />

NPT<br />

1/<br />

2<br />

Male<br />

NPT<br />

1/4<br />

Male<br />

NPT<br />

3/8 in.<br />

<strong>FITOK</strong><br />

1/4<br />

Female<br />

NPT<br />

1. Connection type of “<strong>FITOK</strong>” means <strong>FITOK</strong> double ferrule tube fittings. When the connection type of valves is <strong>FITOK</strong> double ferrule<br />

tube fitting, the working pressures of the valves are related to the wall thickness of the tubing applied. For specific working pressure<br />

of the valves, please refer to the allowable working pressure in <strong>FITOK</strong> Catalog Tubing.<br />

2. Sizes and types listed are standard.<br />

3. Dimensions are shown with <strong>FITOK</strong> tube fitting nuts finger-tight. All dimensions are for reference only and are subject to change.<br />

For dimensions not shown above, please contact <strong>FITOK</strong> Group or our authorized distributors.<br />

1/4<br />

Male<br />

NPT<br />

3/8<br />

Male<br />

NPT<br />

1/4<br />

Female<br />

NPT<br />

1/4<br />

Female<br />

NPT<br />

1/4<br />

Female<br />

NPT<br />

3/8 in.<br />

<strong>FITOK</strong><br />

3/8 in.<br />

<strong>FITOK</strong><br />

0.22<br />

(5.6)<br />

1.13<br />

(28.6)<br />

1.13<br />

(28.6)<br />

1.<br />

06<br />

( 26. 9)<br />

1.13<br />

(28.6)<br />

1.32<br />

(33.5)<br />

1.29<br />

(32.8)<br />

1.<br />

06<br />

( 26.9)<br />

1.29<br />

(32.8)<br />

0.49<br />

(12.5)<br />

0.62<br />

(15.8)<br />

0.49<br />

(12.5)<br />

1.22<br />

(31.0)<br />

2.04<br />

(51.8)

Ordering Number Description<br />

4<br />

NDSS - NS4 - FNS4 - 8PB - A - <strong>TPED</strong> - F2<br />

Serie<br />

Body<br />

Materials<br />

Inlet Type<br />

Inlet Size<br />

Outlet<br />

Type<br />

Outlet<br />

Size<br />

Orifice<br />

Size<br />

Tip<br />

Material<br />

O-Ring<br />

Material<br />

Flow<br />

Pattern<br />

Valve Type<br />

Cleaning and<br />

packaging<br />

ND<br />

SS<br />

316 SS<br />

FNS Female NPT<br />

NS<br />

FL<br />

Male NPT<br />

Fractional<br />

Tube Fitting<br />

4 1/4"<br />

6 3/8"<br />

8 1/2 "<br />

Same as<br />

inlet<br />

Specify in<br />

the same way<br />

as inlet type<br />

and inlet size<br />

0.22"<br />

8<br />

(5.6 mm)<br />

P<br />

PEEK<br />

B Buna-N<br />

(NBR)<br />

Ethylene<br />

Propylene<br />

E Diene<br />

Monomer<br />

(EPDM)<br />

Straight<br />

A Angle<br />

<strong>TPED</strong> -<br />

<strong>Compliant</strong><br />

<strong>TPED</strong><br />

<strong>Needle</strong><br />

Valve<br />

F2<br />

FC-01<br />

FC-02<br />

Note: “Ordering Number Description” is a reference to understand the combination<br />

rules of <strong>FITOK</strong> product part number. Not all combination is available. If any questions,<br />

please contact <strong>FITOK</strong> Group or our authorized distributors.<br />

1.Cleaning and Packing:<br />

FC-01: Standard cleaning and packaging for general industrial procedures.<br />

FC-02: Special cleaning and packaging for wetted system components to<br />

ensure compliance with product cleanliness requirement of ASTM G93 Level C.

5<br />

NU Series <strong>Needle</strong> <strong>Valves</strong><br />

Features<br />

◎ One-piece forged body<br />

◎ Simple stem to operate stably<br />

◎ Soft tip design to seal easily<br />

◎ Safety back seating seal in the fully open position<br />

◎ Union bonnet construction to avoid accidental valve disassembly<br />

◎ Stem thread lubricant isolated from system media<br />

◎ Panel mounting available<br />

Technical Data<br />

Rated working temperature Rated working pressure Flow coefficient Cv<br />

-4~150 °F (-20~65°C)<br />

5000 psig ( 345 bar) 0.35<br />

Standard Materials of Construction<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Item<br />

1<br />

2<br />

3<br />

Component<br />

Handle<br />

Set Screw<br />

Packing Bolt<br />

Valve Material 316 SS<br />

Material Grade/ASTM Specification<br />

Stainless Steel<br />

Steel<br />

304SS/A479<br />

6<br />

4<br />

Lock Nut<br />

304SS/A479<br />

7<br />

5<br />

Panel Nut<br />

316SS/A479<br />

8<br />

9<br />

10<br />

6<br />

7<br />

8<br />

9<br />

Gland<br />

Packing<br />

Packing Washer<br />

Bonnet<br />

316SS/A479<br />

PEEK<br />

PEEK<br />

316SS/A479<br />

11<br />

10<br />

Union Nut<br />

316SS/A479<br />

12<br />

11<br />

Stem<br />

Stem Tip<br />

316SS/A479<br />

PEEK<br />

12<br />

Body<br />

316/A182<br />

Lubricant<br />

Magnesium silicate-based<br />

Note: Wetted components listed in italics.

6<br />

Dimensions<br />

Straight Pattern<br />

Angle Pattern<br />

C<br />

C<br />

Panel Mount<br />

Thickness 1/16 " to 3/8 "<br />

(1.6 mm to 9.5 mm)<br />

F-Panel<br />

Hole Drill<br />

H (Open)<br />

Panel Mount<br />

Thickness 1/16 " to 3/8 "<br />

(1.6 mm to 9.5 mm)<br />

F-Panel<br />

Hole Drill<br />

D<br />

E<br />

H (Open)<br />

L4<br />

E<br />

L1<br />

L2<br />

D<br />

L3<br />

Basic Ordering Number<br />

NUSS-FNS2-7P-PM-<strong>TPED</strong><br />

NUSS-FNS2-7P-PM-A-<strong>TPED</strong><br />

NUSS-FNS4-7P-PM-<strong>TPED</strong><br />

NUSS-FNS4-7P-PM-<strong>TPED</strong>-F2<br />

NUSS-FNS4-7P-PM-A-<strong>TPED</strong><br />

NUSS-FNS4-7P-PM-A-<strong>TPED</strong>-F2<br />

NUSS-NS4-7P-PM-<strong>TPED</strong><br />

NUSS-NS4-7P-PM-<strong>TPED</strong>-F2<br />

NUSS-NS4-7P-PM-A-<strong>TPED</strong><br />

NUSS-NS4-7P-PM-A-<strong>TPED</strong>-F2<br />

NUSS-RT4-FRT4-7P-PM-<strong>TPED</strong><br />

NUSS-RT4-FRT4-7P-PM-A-<strong>TPED</strong><br />

Connection<br />

Type and Size Orifice<br />

Dimensions, in.(mm)<br />

in.(mm)<br />

Inlet Outlet L1 L2 L3 L4 C D E<br />

1/8<br />

Female<br />

NPT<br />

1/4<br />

Female<br />

NPT<br />

1/4<br />

Male<br />

NPT<br />

NUSS-NS4-FNS4-7P-PM-<strong>TPED</strong><br />

1/4<br />

NUSS-NS4-FNS4-7P-PM-<strong>TPED</strong>-F2<br />

Male<br />

NUSS-NS4-FNS4-7P-PM-A-<strong>TPED</strong><br />

NPT<br />

NUSS-NS4-FNS4-7P-PM-A-<strong>TPED</strong>-F2<br />

R 1/4<br />

Male<br />

BSPT<br />

1/8<br />

Female<br />

NPT<br />

1/4<br />

Female<br />

NPT<br />

1/4<br />

Male<br />

NPT<br />

1/4<br />

Female<br />

NPT<br />

RC 1/4<br />

Female<br />

BSPT<br />

0.16<br />

(4.0)<br />

1.00<br />

(25.4)<br />

1.00<br />

(25.4)<br />

1.03<br />

(26.2)<br />

1.00<br />

(25.4)<br />

1.03<br />

(26.2)<br />

0.<br />

85<br />

(21.6)<br />

1.00<br />

(25.4)<br />

0.85<br />

(21.6)<br />

1.00<br />

(25.4)<br />

2.17<br />

(55)<br />

0.39<br />

(9.<br />

9)<br />

1.1<br />

(27.9)<br />

F<br />

0.59<br />

(15)<br />

H<br />

3.08<br />

(78.2)<br />

NUSS-FL4-7P-PM-<strong>TPED</strong><br />

NUSS-FL4-7P-PM-A-<strong>TPED</strong><br />

1/4 in.<br />

<strong>FITOK</strong><br />

1/4 in.<br />

<strong>FITOK</strong><br />

1.14<br />

(29.0)<br />

NUSS-ML6-7P-PM-<strong>TPED</strong><br />

NUSS-ML6-7P-PM-A-<strong>TPED</strong><br />

6 mm<br />

<strong>FITOK</strong><br />

6 mm<br />

<strong>FITOK</strong><br />

1.22<br />

(30.9)<br />

1.16<br />

(29.5)<br />

1.22<br />

(30.9)<br />

NUSS-ML8-7P-PM-<strong>TPED</strong><br />

NUSS-ML8-7P-PM-A-<strong>TPED</strong><br />

8 mm<br />

<strong>FITOK</strong><br />

8 mm<br />

<strong>FITOK</strong><br />

1.17<br />

(29.7)<br />

1. Connection type of “<strong>FITOK</strong>” means <strong>FITOK</strong> double ferrule tube fittings. When the connection type of valves is <strong>FITOK</strong> double ferrule<br />

tube fitting, the working pressures of the valves are related to the wall thickness of the tubing applied. For specific working pressure<br />

of the valves, please refer to the allowable working pressure in <strong>FITOK</strong> Catalog Tubing.<br />

2. Sizes and types listed are standard.<br />

3. Dimensions are shown with <strong>FITOK</strong> tube fitting nuts finger-tight. All dimensions are for reference only and are subject to change.<br />

For dimensions not shown above, please contact <strong>FITOK</strong> Group or our authorized distributors.

Ordering Number Description<br />

NUSS - NS4 - FNS4 - 7P - PM - A - <strong>TPED</strong> - F2<br />

Serie<br />

Body<br />

Materials<br />

Inlet Type<br />

Inlet Size<br />

Outlet<br />

Type<br />

Outlet<br />

Size<br />

Orifice<br />

Size<br />

Stem Tip<br />

Type<br />

Packing<br />

Material<br />

Handle<br />

Flow<br />

Pattern<br />

Valve Type<br />

Cleaning and<br />

packaging<br />

NU<br />

SS<br />

316 SS<br />

FNS<br />

NS<br />

FRT<br />

RT<br />

FL<br />

ML<br />

Female NPT<br />

Male NPT<br />

Female BSPT<br />

Male BSPT<br />

Fractional<br />

Tube Fitting<br />

Metric Tube<br />

Fitting<br />

2 1/8"<br />

4 1/4"<br />

6 6 mm<br />

8 8 mm<br />

Same as<br />

inlet<br />

Specify in the<br />

same way as<br />

inlet type and<br />

inlet size<br />

0.16"<br />

7<br />

Stainless<br />

(4.0 mm) P<br />

Soft Tip P PEEK M<br />

-PEEK<br />

steel bar<br />

Straight<br />

A Angle<br />

<strong>TPED</strong> -<br />

<strong>Compliant</strong><br />

<strong>TPED</strong><br />

<strong>Needle</strong><br />

Valve<br />

F2<br />

FC-01<br />

FC-02<br />

Note: “Ordering Number Description” is a reference to understand the combination<br />

rules of <strong>FITOK</strong> product part number. Not all combination is available. If any questions,<br />

please contact <strong>FITOK</strong> Group or our authorized distributors.<br />

1.Cleaning and Packing:<br />

FC-01: Standard cleaning and packaging for general industrial procedures.<br />

FC-02: Special cleaning and packaging for wetted system components to<br />

ensure compliance with product cleanliness requirement of ASTM G93 Level C.<br />

7

info@fitok.com<br />

www.fitok.com<br />

FK-IC-GV-15-<strong>EN</strong>-230804