TIRA WPM Leipzig

TIRA WPM Leipzig

TIRA WPM Leipzig

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TIRA</strong> <strong>WPM</strong> LEIPZIG a name in the field of material testing

<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong><br />

List of content<br />

Foreword .............................................................3<br />

Applications for <strong>TIRA</strong> <strong>WPM</strong>-test technology ............4<br />

Assemblies, standard test machines ........................6<br />

Control/software for standard test machines ...........8<br />

Accessories .......................................................10<br />

Servo-hydraulic test machines ..............................12<br />

Impact pendulum tester .......................................17<br />

Modernization/service .......................................19<br />

2

<strong>TIRA</strong> <strong>WPM</strong> LEIPZIG – A NAME IN THE FIELD OF MATERIAL TESTING<br />

The traditionally company <strong>WPM</strong> <strong>Leipzig</strong> and the product area <strong>TIRA</strong> material testing merged in January 2004.<br />

The new company <strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong> GmbH is under the roof of <strong>TIRA</strong>-Group and is in the position of offering a<br />

wider range of machines and equipment for testing material and assemblies.<br />

Both locations of the company can look back at a long tradition. The extensive know-how of our company and the<br />

sound knowlegde and ability of our engineers and technician are confirmed by thousands of equipments and systems<br />

which were supplied around the world.<br />

<strong>TIRA</strong>-parent company in Schalkau<br />

<strong>TIRA</strong>-location in <strong>Leipzig</strong>-Wachau<br />

The traditionally location in <strong>Leipzig</strong> produces<br />

material testing machines since almost 125<br />

years. The company Thüringer Industriewerk<br />

Rauenstein (TIW) has taken the production of<br />

electromechanical testing machines 50 years<br />

ago while Werkstoffmaschinen <strong>Leipzig</strong> (<strong>WPM</strong>)<br />

has specialized in hydraulic testing machines<br />

and equipments. Both companies are joined<br />

together to a competent producer of testing<br />

machines and equipments under the roof of<br />

<strong>TIRA</strong>-Group!<br />

The headquarter of the <strong>TIRA</strong>-Group is located<br />

in Schalkau in Thuringia. The construction of a<br />

new manufacturing plant in Schalkau was the<br />

reponse to the permanent innovations and expansions<br />

of the different departments<br />

� <strong>TIRA</strong> vibration<br />

� <strong>TIRA</strong> balancing<br />

� <strong>TIRA</strong> climatic systems<br />

� <strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong><br />

The team in <strong>Leipzig</strong> moved to a new manufacturing<br />

in January 2004 - at the same time as the<br />

company <strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong> GmbH was founded.<br />

The new company makes synergies possible<br />

which increase the developments of innovative<br />

products. Two qualified and high motivated<br />

teams guarantee the renowned high quality of<br />

the products from the advice up to the aftersales-service<br />

for industry and science.<br />

As a accredited DKD-laboratory, <strong>TIRA</strong> <strong>WPM</strong><br />

<strong>Leipzig</strong> GmbH is authorised to check and calibrate<br />

testing machines and equipments.<br />

3

<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong><br />

test unit for air craft body white body<br />

<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong> is able to develop special solutions according<br />

to the individual customer standards and requests for<br />

making static and dynamic tests. An extensive<br />

advice to the customers, the permanent<br />

care of the operator and a professional service<br />

are a part of the tradition of company<br />

„<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong>“.<br />

universal testing machine<br />

<strong>TIRA</strong>test 2820 (20 kN)<br />

4<br />

Examples of applications<br />

The requirements of the producer and user on<br />

quality and reliability of products increase permanent.<br />

In order to fulfil these requirements,<br />

new test standards are necessary and the demand<br />

for customized solutions regarding test<br />

technologies, clamping devices, load cells, software<br />

and automation levels of test equipments<br />

increase. Testing machines of <strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong><br />

fulfil these requirements.

vehicle for testing stress of bridges BELFA<br />

SOME EXAMPLES FOR INDIVIDUAL SOLUTIONS:<br />

• special test machines for aircraft parts for static and dynamictests<br />

• special test machine for part for the car industry like shock sorber,<br />

doors, seats, brake cables, clutch discs (plates), plastic<br />

parts<br />

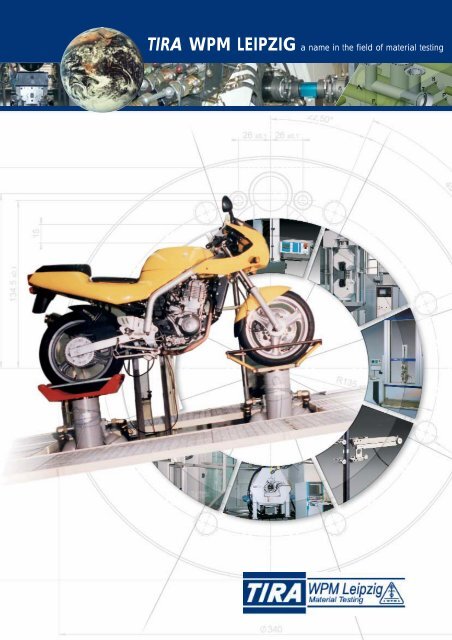

• testing machines for motorbikes for testing the assemblies and<br />

the whole bikes<br />

• vibrating test machines with dyn. vibratory excitation by mass<br />

• fracture mechanical tests<br />

• test of torsion<br />

• tests with extreme temperatures and climatic conditions<br />

• tensile tests of electric energy cables, cables and chains in a<br />

horizontal load frame<br />

• fatique and bending tests of cables<br />

• load of cartons, containers and pallets of all kinds in a compression<br />

press with appropriate dimensions of the test area<br />

• dynamic test of bridges, ground and road composition as<br />

well as of building material<br />

• testing and measurement of insulators<br />

• deadweight standardinzing machine<br />

• testing machine for springs<br />

• compression and bending tests of wooden beams<br />

• customer-specified automatic solutions<br />

modernized deadweight machine (2 MN)<br />

Physikalisch-Technische Bundesanstalt (PTB)<br />

test unit for roads<br />

5

<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong><br />

Standard testing machines (500 N up to 600 kN)<br />

A wide spectrum of standard testing machines in form of table-top<br />

machines and free-standing machines are covered by a test<br />

range from 500 N up to 600 kN. These electromechanical machines<br />

can be universally used in reseach, gauging and quality<br />

control for production of metals, plastic, textiles, construction<br />

materials, wood, ceramics and many others. <strong>TIRA</strong> <strong>WPM</strong> testing<br />

machines can be armed according to the wishes of the customers<br />

by the modular structure of the system at any time. The machines<br />

are effective and work reliable and well-established.<br />

A user-friendly and clear operation by the graphic operating<br />

interface "WINDOWS" are a feature of our machines.<br />

LOAD FRAMES<br />

You can see the required load frame configurations in the chart<br />

opposite. Precision construction with guide pillars and recirculating<br />

ball spindles free from play guarantee a high degree of<br />

rigidity and tensile, compression and alternating load testing in a<br />

lower test space. As an option, all models can be supplied with<br />

a second upper test space. The large test area width and height<br />

can be expanded on your request.<br />

This makes it able to test highly ductile specimen as well as complete<br />

sub-assemblies including the fitting of a large variety of<br />

accessories such as force, path and elongation sensors as well as<br />

temperature chambers and tube furnace. For special tests of particular<br />

sub-assemblies, we can supply a number of special designs<br />

of horizontal, extended and extra wide load frames eg. for<br />

pallets and packaging materials. All load frames can be fitted<br />

with corresponding operator protection, depending on individual<br />

test requirements.<br />

6<br />

�mechanical test machine (20 kN)<br />

hydraulic testing machine (2000 kN)<br />

t <strong>TIRA</strong>test 28005 (500 N)

one-column table<br />

unit 28005 28025<br />

Max: test force (N) 500 2500<br />

working area height (G) mm 640 980<br />

width (E) mm – –<br />

depth mm 38 90<br />

Max. stroke (mm) 550 900<br />

tot. height (A) (mm) 840 1200<br />

tot. width (B) (mm) 450 450<br />

tot. depth (mm) 400 500<br />

weight (kg) 35 55<br />

resolut. crosshead better than 0,1 m m 0,1 m m<br />

Max. test speed 500 mm/min 800 mm/min<br />

Max. return speed 500 mm/min 1200 mm/min<br />

electr. connection (VA) 200 200<br />

two-column table<br />

unit 2803 2805 2810 2820<br />

Max. test force (kN) 3 5 10 20<br />

working area height (G) mm 1000 1080 1080 1060<br />

width (E) mm 390 450 450 450<br />

depth mm – – – –<br />

Max. stroke (mm) 880 960 960 940<br />

tot. height (A) (mm) 1250 1410 1410 1430<br />

with machine table (mm) – 2000 2000 2020<br />

tot. width (B) (mm) 900 1000 1000 960<br />

tot. depth (mm) 340 500 500 560<br />

weight (kg) 85 185 200 225<br />

resolut. crosshead better than 0,1um 0,1m m 0,1m m 0,1m m<br />

Max. test speed 500mm/min 500mm/min 500mm/min 500mm/min<br />

Max. return speed 800mm/min 600mm/min 600mm/min 600mm/min<br />

electr. connection (VA) 200 200 400 700<br />

two-column<br />

Standing units 2850 28100 28300<br />

Max. test force (kN) 50 100 300<br />

working area height (G) mm 1080 1100 1320<br />

width (E) mm 450 580 650<br />

depth mm – – –<br />

Max. stroke (mm) 990 1080 1240<br />

tot. height (A) (mm) 2080 2120 2300<br />

tot. width (B) (mm) 1000 1260 1550<br />

tot. depth (mm) 510 700 950<br />

weight (kg) 330 870 1600<br />

resolut. crosshead better than 0,1m m 0,1m m 0,1m m<br />

Max. test speed 500mm/min 500mm/min 200mm/min<br />

Max. return speed 500mm/min 500mm/min 200mm/min<br />

electr. connection (VA) 1500 3000 3000<br />

1~230 3~400 3~400<br />

Standing units<br />

2 spindles, 4 column 28500 28600<br />

Max. test force (kN) 500 600<br />

working area height (G) mm 1500 1700<br />

width (E) mm 650 750<br />

depth mm – –<br />

Max. stroke (mm) 1300 1300<br />

tot. height (A) (mm) 2600 2600<br />

tot. width (B) (mm) 1550 1800<br />

tot. depth (mm) 1100 1000<br />

weight (kg) 2500 3000<br />

resolut. crosshead better than 0,1m m 0,1m m<br />

Max. test speed 200mm/min 200mm/min<br />

Max. return speed 200mm/min 200mm/min<br />

electr. connection (VA) 6000 6000<br />

3~400 3~400<br />

DRIVE<br />

The electromechanical drive of <strong>TIRA</strong> <strong>WPM</strong><br />

machines allows precise loading of the specimen<br />

in conjunction with the corresponding<br />

load frames. The test piece can be loaded adjusted<br />

for the path, force and expansion with<br />

aid of digital regulation. In this case the target<br />

value and control parameter can be adapted<br />

over a wide spectrum both manually and software-aided<br />

to the particular test requirements.<br />

It is also possible to change the type of control<br />

during the tests without problems. The crosshead<br />

speed range quoted for the individual basic<br />

models is only a standard case; any other<br />

range can also be supplied. Practically, any<br />

speed from vT = 0 up to vT = max. can be<br />

used.<br />

LOAD CELLS<br />

We use exclusively precision wire strain gauge<br />

DMS-sensors for all measurements in tensile,<br />

compression and bending tests. Sensors particularly<br />

stable against lateral force are employed<br />

for loads with increased side force. In<br />

addition, we can adapt individual customer<br />

load cells to our measurement systems.<br />

Standard testing machines<br />

(600 up to 5000 kN)<br />

Standard testing machines more than 600 kN<br />

are supplied with a hydraulic drive. The test<br />

area and the piston stroke are formed according<br />

to your requirements. A force, path and<br />

elongation regulation are made possible by the<br />

supply of appropriate transducers and an electronic<br />

drived hydraulic valve. The use of these<br />

machines allows the tensile, compression and<br />

bending tests of specimen as well as tests of<br />

components in the static and low-frequency<br />

range up to 50 Hz.<br />

7

<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong><br />

Measurement and control technology<br />

Our machines are equipped with a powerful and intelligent<br />

mesurement and control electronic which ensures a precise test<br />

control and high measurement accuracy.<br />

Two operating methods are provided to control the test machine:<br />

• Stand-alone-Mode for simple tests<br />

• PC-controlled for higher demands and universal applications<br />

The measurement and control electronics are installed in a separate<br />

housing on the front of which a screen digitally displays the<br />

force and path measurement variables as well as buttons to operate<br />

the test machine and enter the test parameters. We can provide<br />

an on-table unit and a control circuitry cabinet for the PCcontrolled<br />

mode.<br />

Two different configurations for the varying<br />

requirements are offered (see the chart<br />

above)<br />

We offer a digital measurement and control<br />

unit for servo-hydraulic test machines for<br />

the high-dynamic tests. (see page 14)<br />

8<br />

As an option, the control can be equipped with:<br />

TF-Module: carrier amplifier<br />

to connect an analog sensor<br />

INC-Module: two incremental sensor input<br />

man. keyboard: to control the testing machine<br />

(electromechanical machines)<br />

or the test cylinder<br />

(hydraulic machines)<br />

Measuring method EDC 60 EDC 120<br />

resolution load channel better than +/– 60.000 digit better than +/– 120.000 digit<br />

crosshead resolution inkremental inkremental<br />

for spindle machines better than ≤ 0,1 m m better than ≤ 0,1 m m<br />

distance resolution for<br />

hydraulic machines better than ≤ 1 m m bei 100 mm piston-stroke<br />

expansion 1 additional slot* 7 additional slots*<br />

*to connect extensometer, load cells and other measuring devices

Software<br />

In the PC-mode, we offer a modern and simple to use software<br />

package under MICROSOFT WINDOWS. Our continually updated<br />

software liabry contains a large selection of application<br />

programs (eg. acc. to DIN, EN, ASTM, ISO) and individual customer<br />

tests. The software can be supplied in many different languages<br />

like English, French, Spanish, Russian or Czech.<br />

The main menu window clearly shows the test data diagram,<br />

numerical test results and statistics in a tabular format. All software<br />

functions can be easily and quickly accessed via menus and<br />

a tool (set-up, test configuration, test protocol and so on).<br />

An online help menu explains all functions and gives detailed<br />

advice about individual test standards.<br />

The software package <strong>TIRA</strong>script makes it possible to define by<br />

the user himself how a test should be done and which results have<br />

to be determined. In this way, you can realise each test assignment<br />

by yourself with our testing machine.<br />

<strong>TIRA</strong>script consists of the following components:<br />

• controlling of the test according to any test procedure in permanent,<br />

swelling or changing load with determination of<br />

force, path, elongation or other measured quantities for the<br />

calculation of parameters which have to define.<br />

• calculation of parameters after the test with any arithmetical<br />

combination, fixing the output value and presentation of the<br />

test results in a current test graph.<br />

11. 05. 04<br />

online-help menu<br />

main menu window<br />

external digital controller (EDC 60/120)<br />

9

<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong><br />

Clamping devices<br />

A large range of clamping devices ensures secure clamping of<br />

specimen for testing different materials.<br />

manual clamping devices<br />

We offer a large range of clamping devices for almost all specimen<br />

and materials and ensure a secure clamping. Suitable jaw<br />

inserts (smooth, waved, serrated, coated) guarantee together<br />

with the work principles (parallel, wegde-shaped, wraped-arounding<br />

and so on) an optimized test performance.<br />

pneumatic clamping device<br />

Our large range of pneumatic grips distinguishes by an easy operation<br />

and high efficiency. Test material, which are problematic,<br />

can be optimal treated because of the variable clamping pressure.<br />

We are able to supply customer configuration with easy<br />

changeable jaws, manual shift and/or foot switch as well as computer-controlled<br />

solutions.<br />

hydraulic clamping devices<br />

Hydraulic clamps offer a high safety standard (two-hand operation)<br />

in the force range from 20 up to 2000 KN. Variable clamping<br />

pressure can be adjusted for uniform specimen (clamping on<br />

one side) and variable-size specimen (clamping on two sides).<br />

Extensometer<br />

Extensometer are used for path measurement in compression and<br />

bending tests and also for thickness measurement. Depending on<br />

the particular application, we can offer inductive and wire straingauge<br />

sensors for individual measurement paths and temperature<br />

range. We can supply a wide range of electronic callipers to<br />

determine specific dimensions.<br />

10<br />

EXTENSOMETER FOR LONG WAYS<br />

LA 800 and MFN-A<br />

The automatic extensometer LA 800 meets the<br />

requirements of large extension up to 800 m of<br />

plastic and elastomers in tensile and alternating<br />

stress tests up to the break. The arms open and<br />

close automatically<br />

gauge length: 10 – 200 mm<br />

accuracy: < 0,01 mm<br />

carrying force: < 200 mN<br />

The half-automatic MFN-A is a two-range<br />

measurement extensometer for testing very<br />

small elongations to determine the E-Mode, the<br />

yield point and the elastic limit in the range up<br />

to 4 mm as well as to calculate the elongation<br />

without necking and rupture elongation values<br />

up to 300/500/800 mm (in each case depending<br />

on selected type) without interrupting the<br />

test process. Suitable for specimen up to 50<br />

mm thickness or diameter and 100 mm width<br />

up to rupture and automatic return.<br />

Special versions:<br />

with only one meaurement system; longer measurement<br />

arms for the use in temperature installation<br />

sets; r&n value detemination with MFQ.

MANUAL CLAMPED EXTENSOMETER<br />

MFA 25<br />

We offer a wide range of manual clamped sensors for measurement<br />

of fine extension up to max. 3 mm and for measurement of<br />

medium extension up to 25 mm. The inductive and wire strain<br />

gauge sensors are suitable for round and flat specimen up to 30<br />

mm thickness/diameter and for standards as well as special measurement<br />

lengths up to 100 mm on plastics, rubber and metallic<br />

specimen. They are also used at abnormal temperatures as width<br />

change sensors and in fracture mechanics for determination of<br />

the E-Mode, yield point and elastic limit.<br />

Fully automatic transducer<br />

The MFL 300 with computer-controlled servo motor is especially<br />

suitable in combination with hydraulic clamps for specimen up to<br />

30 mm thickness, 50 mm width and 80 mm diameter. The automatic<br />

start up of measurement path, opening and closing of feeler<br />

arms and the return are automatical.<br />

Details: positioning 200 mm, measurement path 300 mm, resolution<br />

1 µm or 0,1 µm.<br />

CONTACT-FREE ELONGATION SENSORS<br />

Contact-free elongation sensors (laser and video extensometer)<br />

are used to detect large length changes up to 800 mm for contactsensitive<br />

materials, highly rigid specimen up to rupture point<br />

or in temperature installation sets.<br />

Temperature chambers<br />

We offer temperature chambers of various temperature sizes for<br />

testing under extreme temperatures to reproduce cold and heat in<br />

a range of -150 °C up to +350 °C. We will be pleased to advice<br />

on the optimum specification for your particular use in the testmachine<br />

for example the most suitable cooling medium, the easy<br />

handling of clamping tools and if required extensometer, the possibility<br />

of efficient change between the tests at room temperature<br />

and in the temperature chamber, low operating costs and more.<br />

<strong>TIRA</strong> <strong>WPM</strong> <strong>Leipzig</strong> offers individual solutions for high complex<br />

test procedure.<br />

We recommend hinged furnaces for tests with middle and high<br />

temperatures like warm yield points, elastic limits and longterm/creep<br />

behaviour. Hinged furnace are heated in 3-zones<br />

and the pre-selected temperature is set with modern controllers.<br />

Special stands fit the tube furnace exactly in<br />

the test area. The scope of delivery includes<br />

heat-resistant brackets to hold the specimen,<br />

colling devices for the force transducer and a<br />

choice of high temperature extensometer. We<br />

offer various versions in the temperature range<br />

from + 500°C up to + 1500°C.<br />

Compression devices<br />

We offer compression devices of all types<br />

(round, rectangular) with upper adjustable<br />

compression plate and 3-point and 4-point<br />

bending devices according to standards and<br />

individual customer requirements.<br />

11