His Highness Sheikh Khalifa Bin Zayed Al Nahyan ... - Mabey Bridge

His Highness Sheikh Khalifa Bin Zayed Al Nahyan ... - Mabey Bridge

His Highness Sheikh Khalifa Bin Zayed Al Nahyan ... - Mabey Bridge

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

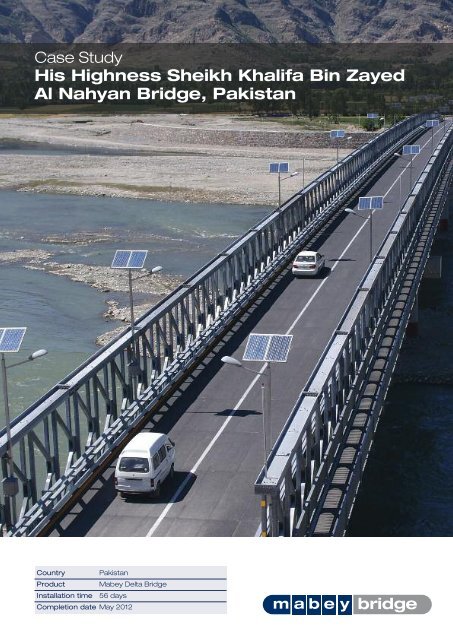

Case Study<br />

<strong>His</strong> <strong>Highness</strong> <strong>Sheikh</strong> <strong>Khalifa</strong> <strong>Bin</strong> <strong>Zayed</strong><br />

<strong>Al</strong> <strong>Nahyan</strong> <strong>Bridge</strong>, Pakistan<br />

Country Pakistan<br />

Product <strong>Mabey</strong> Delta <strong>Bridge</strong><br />

Installation time 56 days<br />

Completion date May 2012

Case Study<br />

<strong>His</strong> <strong>Highness</strong> <strong>Sheikh</strong> <strong>Khalifa</strong> <strong>Bin</strong> <strong>Zayed</strong> <strong>Al</strong> <strong>Nahyan</strong> <strong>Bridge</strong>, Pakistan<br />

The Challenges<br />

In 2010 the annual rainy season in Pakistan caused<br />

great devastation and damage to vital infrastructure.<br />

The Swat Valley in the Khyber-Pakhtunkhwa province<br />

was badly affected, and a multi span concrete slab<br />

deck bridge over the River Swat near the town of<br />

Barikot was severely damaged, leaving only one short<br />

span in place. Due to the importance of the bridge as a<br />

key supply route, a rapid replacement was essential.<br />

The United Arab Emirates, which funds many charitable<br />

causes, was approached with a view to funding a<br />

bridge replacement project managed by the<br />

engineering and construction branch of the Pakistan<br />

Army. Manpower was to be provided by the Pakistan<br />

Army Corps of Engineers and the finished structure was<br />

to be named ‘<strong>His</strong> <strong>Highness</strong> <strong>Sheikh</strong> <strong>Khalifa</strong> <strong>Bin</strong> <strong>Zayed</strong> <strong>Al</strong><br />

<strong>Nahyan</strong> <strong>Bridge</strong>’, also known locally as ‘Gammon <strong>Bridge</strong>’.<br />

Top: Launching the bridge with nose attached.<br />

Above Left: Separating the bridge into individual spans and<br />

jacking down.<br />

Above Right: A view of the underside of the bridge showing<br />

plan bracing. Swaybracing is connected diagonally between<br />

the transoms to provide a lateral bracing system to resist<br />

transverse loads such as wind loading. Vertical Bracing is<br />

connected longitudinally between the top of one transom and<br />

the bottom of the next transom to form a longitudinal bracing<br />

system which resists braking/traction forces.<br />

For more case studies and information on our products and services...<br />

visit www.mabeybridge.co.uk email mail@mabeybridge.co.uk or scan here<br />

@<strong>Mabey</strong>bridge<br />

<strong>Mabey</strong> <strong>Bridge</strong> Limited<br />

The Solution<br />

The <strong>Mabey</strong> Delta <strong>Bridge</strong> was selected for speed of<br />

installation and for its full highway load capability.<br />

The structure is fully galvanised to ensure a long design<br />

life with minimal maintenance. Once intermediate piers<br />

and abutments had been reconstructed, work began<br />

on building the bridge, starting with the launching nose.<br />

With only limited mechanical equipment available on<br />

site, the 24-strong workforce, assisted by a <strong>Mabey</strong><br />

<strong>Bridge</strong> Site Advisor, began constructing the bridge one<br />

bay at a time on top of launching rollers.<br />

Upon completion, the bridge was launched over the piers<br />

as a continuous structure using hauling rams supplied by<br />

<strong>Mabey</strong> <strong>Bridge</strong> as part of the launching and erection<br />

equipment. As the bridge reached the landing abutment,<br />

the launching nose was removed and the team began<br />

the operation of separating the bridge at each pier into<br />

individual spans and jacking them down onto bearings at<br />

each abutment and pier location.<br />

Once the bridge was in place, the deck units, parapets<br />

and the external footwalk were fitted and the approach<br />

roads at each end completed. Solar powered street<br />

lights were installed and the bridge was ready to be<br />

officially opened on 25 May 2012. Total installation time<br />

was just 56 days, with the entire project completed only<br />

eleven months from the start of pier construction.<br />

The Result<br />

The finished bridge is a permanent, two-lane structure<br />

with an external pedestrian footwalk. The overall length<br />

of the bridge is 328.5m, divided into five spans of<br />

around 65m each.<br />

About The <strong>Mabey</strong> Delta <strong>Bridge</strong><br />

The <strong>Mabey</strong> Delta <strong>Bridge</strong> is a positive cambered heavy-duty<br />

modular bridge system specifically designed for high traffic<br />

volumes and heavy loadings. This system is particularly<br />

excellent for solving long spans or multi-lane traffic<br />

requirements. The delta can carry up to 4 lanes of traffic and<br />

can span up to 90m between supports.<br />

<strong>Mabey</strong><strong>Bridge</strong>Ltd<br />

Limited