Behr 100 Magazine [3128 KB, PDF]

Behr 100 Magazine [3128 KB, PDF]

Behr 100 Magazine [3128 KB, PDF]

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

[Contents]<br />

Contents .................................. Page 3<br />

Forewords ................................ Page 4<br />

Chronicle .................................. Page 6<br />

Cover Story ............................ Page 14<br />

Technology ............................ Page 26<br />

<strong>Behr</strong> Thermot-tronik .............. Page 34<br />

Performance Partnership ........ Page 36<br />

<strong>Behr</strong> Service .......................... Page 40<br />

<strong>Behr</strong> Industry ........................ Page 42<br />

Production .............................. Page 44<br />

Globality ................................ Page 50<br />

Cooperations .......................... Page 54<br />

Corporate Culture .................... Page 58<br />

Human Resources .................... Page 64<br />

Corporate Citizenship .............. Page 72<br />

Prospects ................................ Page 76<br />

Imprint .................................. Page 78<br />

3

4<br />

Dear Readers,<br />

<strong>100</strong> years <strong>Behr</strong>. This is the success story of<br />

a company that started in Stuttgart as a small<br />

family business and is now one of the world’s<br />

leading automobile suppliers.<br />

<strong>Behr</strong> was always geared to sustained growth.<br />

The strategic and technical milestones reported<br />

on in our centennial magazine substantiate<br />

this. Despite this growth, we have maintained<br />

qualities characteristic of a medium-sized<br />

company, e.g. flexibility and independence.<br />

These are more important than ever as a<br />

competitive edge. You can also read more<br />

about that in this magazine.<br />

<strong>100</strong> years after being established, <strong>Behr</strong>’s<br />

strategic target is to be a performance leader<br />

offering the best price-performance ratio in<br />

all major market sectors. We have established<br />

ourselves as a technological leader worldwide.<br />

Now it is a matter of consistently strengthening<br />

and expanding this position.<br />

However, we are not willing to just settle for<br />

that. In terms of customer support, we are also<br />

aiming to take over the lead globally. We must<br />

continue to produce top quality at competitive<br />

costs wherever our customers need us.<br />

This self-commitment goes hand in hand<br />

with our explicit commitment to Germany and<br />

Baden-Württemberg as our industrial base.<br />

Considerable resources will also be invested<br />

here in the future to extend the plants and<br />

development facilities.<br />

What makes us confident – particularly in a<br />

sector seldom outstripped when it comes to<br />

harsh competition – that we can actually attain<br />

these ambitious targets? The answer is to be<br />

found in our deep-rooted corporate culture<br />

that is lived day in, day out: we benefit from<br />

an immense inner strength throughout our<br />

global network. It gives us the necessary bond<br />

to ensure that <strong>Behr</strong> remains an independent<br />

company and can continue to develop<br />

consistently.<br />

Our corporate culture and the <strong>Behr</strong> values –<br />

innovative, cost-focused, reliable and peopleoriented<br />

– are the broad basis for sustained,<br />

successful development. This is how we are<br />

succeeding to form a successful performance<br />

team out of the 17,000 employees we meanwhile<br />

employ throughout the world.<br />

This way, <strong>Behr</strong> is well equipped to continue<br />

the success story of its first <strong>100</strong> years of<br />

company history. We are supported by our<br />

committed workforce, both old and new,<br />

satisfied customers, reliable business partners<br />

and a stable circle of shareholders that gives<br />

us through its long-term commitment the<br />

necessary room for maneuver – an important<br />

competitive advantage.<br />

Yours sincerely,<br />

Dr. Markus Flik<br />

Spokesman of the Board of Management

Ladies and Gentlemen,<br />

As high-tech products, cars depend on<br />

innovations. In 2004 alone, the German<br />

automobile industry invested some 15 billion<br />

euros in research and development. That is<br />

one third of all R&D expenses of the German<br />

economy and, consequently, the highest figure<br />

of all the branches of industry. It is the<br />

suppliers within our sector who are taking on<br />

more and more responsibility for the complete<br />

automobile as a product. They are increasingly<br />

becoming systems partners of the manufacturers<br />

and investing substantial capital to help make<br />

the end product “automobile” even better –<br />

whether in terms of fuel consumption, lower<br />

emissions, safety, comfort, quality or costs, in<br />

order to keep vehicles competitive.<br />

Facing up to global challenges also has an<br />

influence on the long-term success of our sector.<br />

The suppliers are similarly well positioned<br />

here: they successfully pressed ahead with the<br />

internationalization of their business at an<br />

early stage. They are involved throughout the<br />

world – incidentally, also quite understandably<br />

to the benefit of Germany as an industrial base.<br />

Last year, the German suppliers were able to<br />

increase their turnover by nine percent to a<br />

new record level of almost 66 billion euros.<br />

And they created some 2,000 new jobs here –<br />

against the general economic trend in Germany.<br />

Great flexibility, consistent technological<br />

orientation, pronounced innovative strength<br />

and a service concept assiduously aligned to<br />

customer wishes are characteristics that<br />

distinguish companies of the supplier industry.<br />

This possibly applies even more specifically<br />

to companies that are family-owned. The fact<br />

that these attributes set the standard for<br />

enterprising action makes the industrial middle<br />

market even more competitive in the harshly<br />

contested automobile business.<br />

<strong>Behr</strong> is a particularly good example of this.<br />

The customer-oriented company has brought<br />

innovative products onto the market, opened<br />

up news fields of activity and successfully<br />

managed the step to becoming a global player<br />

without neglecting the roots of its Swabian<br />

origins and its corporate culture. Driven by<br />

the quest for technological progress, <strong>Behr</strong> has<br />

played a part in shaping the automotive success<br />

story for <strong>100</strong> years and has set numerous<br />

innovative trends in cooling and air conditioning<br />

technology.<br />

I sincerely congratulate <strong>Behr</strong> GmbH & Co. KG,<br />

its owners, its management and its successful<br />

team on its centennial anniversary and wish<br />

good fortune, margins and growth for the next<br />

<strong>100</strong> years as well.<br />

With best wishes,<br />

Prof. Dr. Bernd Gottschalk<br />

President of the German Association of the<br />

Automotive Industry VDA<br />

[Forewords]<br />

5

<strong>Behr</strong> Chronicle:<br />

Innovative by Tradition<br />

The first 30 years …<br />

1905<br />

• Julius Friedrich <strong>Behr</strong> takes over from<br />

Andreas Veigel the interest in Veigel and<br />

Zoller, a workshop for the construction of<br />

car radiators, tachometers and cake tins for<br />

pastry shops. The new company is named<br />

<strong>Behr</strong> & Zoller and specializes in constructing<br />

radiators.<br />

• After leaving Gustav Zoller, Andreas Veigel<br />

concentrates on the construction of<br />

instruments and later merges with Deuta<br />

and Ota forming VDO.<br />

1907<br />

• Gustav Zoller leaves the joint company.<br />

Julius Fr. <strong>Behr</strong> thus becomes sole owner. The<br />

company operates under the new name Süddeutsche<br />

Kühlerfabrik Julius Fr. <strong>Behr</strong> and is<br />

located in the Neue Weinsteige 8 in Stuttgart.<br />

6<br />

1910<br />

• In addition to air tube cooling systems,<br />

<strong>Behr</strong> also tests different fin systems.<br />

• Customers of the Süddeutsche Kühlerfabrik<br />

(S.K.F.) include Benz, Opel, NSU and Saurer.<br />

In addition, the company supplies the still<br />

new sector of engine flying.<br />

1911<br />

• Move to the newly constructed Plant 1<br />

in Feuerbach.<br />

1913<br />

• The company employs a workforce of 85 on<br />

average. The average hourly wage is<br />

55 pfennigs, a working week has 54 hours.<br />

There is no entitlement to vacation.<br />

1914<br />

• Start of<br />

hose clamp<br />

production<br />

as a second<br />

foothold. The<br />

hose clamps<br />

are supplied<br />

to automobile<br />

and aircraft manufacturers, breweries,<br />

engineering works and companies in the<br />

telegraph industry.

1915<br />

• <strong>Behr</strong> is granted the patent for standard<br />

element radiators.<br />

1916<br />

• <strong>Behr</strong> employs a staff of 170.<br />

1917<br />

• The association “Jugendlust” is set up to<br />

take care of employees’ children.<br />

• A welfare service is established in order to<br />

counteract the relatively high number of<br />

employees absent from work owing to sickness.<br />

• Start of cooler construction for special vehicles.<br />

1919<br />

• The first test stand to measure cooling<br />

performance is installed.<br />

1920<br />

• There are <strong>100</strong> automobile manufacturers in<br />

Germany; radiators become a design feature<br />

of each and every car.<br />

1921<br />

• Three years after the end of the war, business<br />

starts looking up again, although production<br />

at <strong>Behr</strong> is not at full capacity.<br />

• <strong>Behr</strong> is represented at the Berlin Automobile<br />

Exhibition for the first time.<br />

1923<br />

• Building of the first administration building<br />

next to Plant 1 in Feuerbach commences.<br />

• Automobiles in Germany number 98,000.<br />

1924<br />

• The first heavy-duty cooling aggregate for<br />

diesel rail engines is developed.<br />

1926<br />

• The production of steel doors is taken up as<br />

a further foothold (until 1935).<br />

• Julius Fr. <strong>Behr</strong> (second from right) undertakes<br />

a study trip to the USA and meets technology<br />

pioneers Thomas Alva Edison (fourth from<br />

left) and Henry Ford (crouching).<br />

1930<br />

[Chronicle]<br />

• Julius Fr. <strong>Behr</strong> dies on December 7 at the<br />

age of 58 after a short illness. Coheirs take<br />

over management of the company shortly<br />

afterwards.<br />

• The new Plant 2 (today’s main plant) goes<br />

into operation in Feuerbach.<br />

1932<br />

• <strong>Behr</strong> sets up its first trial and testing facilities<br />

in Plant 2.<br />

1934<br />

• Installation of facilities and production of the<br />

first large-volume radiator series in Plant 2.<br />

1935<br />

• The <strong>Behr</strong> training workshop is established<br />

and starts with the training of twelve<br />

apprentices.<br />

• The works’ choir<br />

is founded.<br />

• Manfred <strong>Behr</strong>, son<br />

of the company<br />

founder, officially<br />

joins the company<br />

as technical<br />

manager with<br />

power of attorney.<br />

7

… 1936 – 1962 …<br />

1936<br />

• <strong>Behr</strong> initiates company vacations and staff<br />

outings.<br />

• <strong>Behr</strong> has a workforce of 615. Turnover<br />

amounts to 4.2 million Reichsmarks.<br />

1937<br />

• <strong>Behr</strong> builds its first wind tunnel. A year later,<br />

the legendary Mercedes “Silver Arrows”<br />

undergo cooler performance tests there.<br />

1938<br />

• <strong>Behr</strong> employs 939 staff. Sales reach<br />

7.8 million Reichsmarks.<br />

8<br />

1939<br />

• Outbreak of the war also brings about<br />

alterations to <strong>Behr</strong>’s production range.<br />

Aircraft coolers, coolers for half-track<br />

vehicles and tanks as well as charge-air<br />

coolers and heat exchangers for high-speed<br />

launches are supplied in increasing numbers.<br />

• The first aluminum aircraft coolers are<br />

developed.<br />

1941<br />

• <strong>Behr</strong> supplies the one thousandth aluminum<br />

aircraft cooler.<br />

1942<br />

• The company is restructured as a limited<br />

partnership (KG) and is now called Süddeutsche<br />

Kühlerfabrik Julius Fr. <strong>Behr</strong> KG.<br />

• Manfred <strong>Behr</strong> is appointed managing partner.<br />

1944<br />

• <strong>Behr</strong> introduces the award of premiums for<br />

improvement suggestions.<br />

• During the Second World War, <strong>Behr</strong> also<br />

employs foreign workers. For this reason,<br />

in the year 2000 a compensation payment<br />

is made to the Federal Foundation “Remembrance,<br />

Responsibility and Future” which<br />

indemnifies former forced laborers.<br />

1945<br />

• <strong>Behr</strong> repairs radiators and produces<br />

household articles out of aluminum.<br />

1946<br />

• Just one year after the end of the war some<br />

radiators are being produced again.<br />

1948<br />

• The serial production of car radiators starts<br />

anew.<br />

• The “<strong>Behr</strong> Provident Fund” for staff in need<br />

is set up.<br />

1949<br />

• <strong>Behr</strong> starts producing heaters for cars and<br />

commercial vehicles.

1950<br />

• The production of fresh-air heaters for cars,<br />

commercial vehicles and buses commences –<br />

a <strong>Behr</strong> innovation.<br />

1951<br />

• A license agreement is entered into with<br />

India Radiators Ltd. to manufacture radiators.<br />

• The “<strong>Behr</strong> Assistance, Julius Fr. <strong>Behr</strong>,<br />

Support Association Stuttgart-Feuerbach”<br />

is established.<br />

1953<br />

• The first engine cooling units with a<br />

hydrostatic fan drive are constructed for<br />

trucks and buses.<br />

1954<br />

• Juan Manuel Fangio wins the European<br />

Grand Prix and the Formula One world<br />

championship in a Mercedes-Benz W 196<br />

fitted with a <strong>Behr</strong> cooler.<br />

• <strong>Behr</strong> cooling aggregates with a hydraulic<br />

fan drive for diesel rail engines are used<br />

throughout the world.<br />

1955<br />

• <strong>Behr</strong>-Thomson Dehnstoffregler GmbH<br />

is founded.<br />

• <strong>Behr</strong>’s staff of 1,318 includes 1,113 industrial<br />

workers. A working week has 46 hours. The<br />

minimum hourly wage for a skilled worker<br />

is DM 1.62 and standard vacation amounts<br />

to up to 18 days.<br />

1956<br />

• <strong>Behr</strong>’s first testing and development facilities<br />

go into operation.<br />

1957<br />

• <strong>Behr</strong> builds the first temperature-controlled<br />

wind tunnel in Europe.<br />

• The company takes up the production of<br />

aircraft coolers again.<br />

• The first mechanical data processing system<br />

goes into operation.<br />

[Chronicle]<br />

• <strong>Behr</strong> constructs the first HVAC system for<br />

a car (Mercedes-Benz 300) to go into serial<br />

production in Europe.<br />

1958<br />

• Plastic is used in the production of vehicle<br />

heaters for the first time.<br />

1959<br />

• The standard hourly wage is DM 2.44.<br />

1960<br />

• The workforce of 2,000 receives vacation<br />

money for the first time instead of the<br />

former “fall allowance”.<br />

1961<br />

• Ford in Cologne produces its millionth<br />

vehicle with <strong>Behr</strong> cooling and heating.<br />

• <strong>Behr</strong> acquires the licenses to produce Visco®<br />

clutches and fans.<br />

• Dr. Heinz Breuer becomes Managing Director,<br />

Finance and Administration.<br />

1962<br />

• The first salt-bath brazed oil cooler is<br />

developed.<br />

9

… 1963 – 1992 …<br />

1963<br />

• The new Visco® fans for trucks go into serial<br />

production.<br />

• Production begins in the first section of the<br />

new Mühlacker plant.<br />

1964<br />

• The first aluminum charge-air cooler is<br />

produced for heavy-duty engines.<br />

1965<br />

• Start of serial production of Visco® clutches<br />

for cars.<br />

• The first “air conditioner” for cars, a<br />

recirculated air system with temperature<br />

control, goes into serial production.<br />

1966<br />

• <strong>Behr</strong> establishes the technical division Air<br />

Conditioners and Fuel Heaters.<br />

10<br />

1967<br />

• The company is converted into a limited<br />

partnership with a limited liability company<br />

(GmbH & Co. KG).<br />

1969<br />

<strong>Behr</strong> of America<br />

• <strong>Behr</strong> of America (Little Ferry) and <strong>Behr</strong> France<br />

(Rouffach) are founded.<br />

• <strong>Behr</strong> acquires shares in Frape S.A., Barcelona.<br />

<strong>Behr</strong> France<br />

1970<br />

• <strong>Behr</strong> is recognized as a manufacturing firm<br />

for aviation equipment by the German Federal<br />

Civil Aviation Authority.<br />

• Production begins at the new Pforzheim plant.<br />

1973<br />

• Inauguration of the new administration<br />

building in Feuerbach.<br />

• Helene <strong>Behr</strong>,<br />

widow of the<br />

company<br />

founder, dies at<br />

the age of 89.<br />

1974<br />

• <strong>Behr</strong> introduces flexible working hours.<br />

1975<br />

• The company develops a flux-free and thus<br />

environment-friendly method of brazing<br />

(vacuum brazing) for aluminum car radiators.<br />

• Aluminum radiators and heater cores with<br />

plastic water tanks go into serial production.<br />

• Production of mechanically joined fin and<br />

tube heater cores begins.<br />

1976<br />

• The export of large-volume series begins.<br />

• By increasing its capital stock, <strong>Behr</strong> acquires<br />

majority interest in Frape S.A., Barcelona.<br />

• <strong>Behr</strong> is the first manufacturer in Europe to<br />

produce an integrated HVAC system for<br />

trucks.

1977<br />

• Acquisition and building up of Plant 8 in<br />

Feuerbach for the serial production of coolers.<br />

1979<br />

• <strong>Behr</strong> takes an interest in India Radiators Ltd.<br />

in Pune, India.<br />

• Production commences at the new plant for<br />

Visco® products in Vaihingen/Enz.<br />

1980<br />

• Dr. Heinz Breuer is the first external manager<br />

to take over as Chairman of the Board of<br />

Management.<br />

• Frape S.A., based in Barcelona/Spain,<br />

becomes Frape <strong>Behr</strong> S.A.<br />

• <strong>Behr</strong> has a workforce of 4,900.<br />

1981<br />

• Horst Geidel joins the <strong>Behr</strong> Board of<br />

Management.<br />

• <strong>Behr</strong> brings a new generation of aluminum<br />

radiators onto the market with the<br />

mechanically joined fin and tube system.<br />

1985<br />

• On account of urban development measures,<br />

the site of the main plant (Plant 1) is sold<br />

to the Stuttgart municipal authorities.<br />

• The first Advisory Board is appointed, with<br />

which Manfred <strong>Behr</strong> discusses important<br />

strategic issues.<br />

1986<br />

• The technical center (“Building 29”) opens<br />

in Feuerbach.<br />

1987<br />

• The new plant constructed in Neustadt/<br />

Danube in Bavaria starts producing air<br />

conditioning components.<br />

• The first <strong>Behr</strong> Quality Assurance Handbook<br />

is approved by the Board of Management.<br />

1988<br />

• Horst Geidel succeeds Dr. Heinz Breuer and<br />

becomes Spokesman – later Chairman – of<br />

the Board of Management. He opens up the<br />

company internally and externally: “New<br />

Horizons and Change”. A systematic strategy<br />

is developed. The first structure and process<br />

analysis is completed.<br />

• The first Supervisory Board emerges from<br />

the Advisory Board and Dr. Heinz Breuer is<br />

appointed Chairman. Dr. Manfred <strong>Behr</strong> is<br />

Honorary Chairman.<br />

1989<br />

• The first written strategy concept is<br />

developed.<br />

• <strong>Behr</strong> is one of the first automobile suppliers<br />

to introduce project management throughout<br />

the company.<br />

• <strong>Behr</strong> and Bosch establish a joint venture to<br />

manufacture electronic operating controls.<br />

The joint venture exists for some 10 years.<br />

1990<br />

[Chronicle]<br />

• Manfred <strong>Behr</strong> dies on November 19 at the<br />

age of 81.<br />

• In the context of restructuring, the company<br />

name is changed from Süddeutsche<br />

Kühlerfabrik Julius Fr. <strong>Behr</strong> GmbH & Co. KG<br />

to <strong>Behr</strong> GmbH & Co.<br />

• <strong>Behr</strong> Industrietechnik is founded as a<br />

wholly-owned subsidiary based in Stuttgart.<br />

All <strong>Behr</strong> activities beyond the scope of the<br />

automobile industry are transferred to the<br />

new company.<br />

1991<br />

• <strong>Behr</strong> Industrietechnik starts producing<br />

fuel tanks for motorcycles at its new plant<br />

in Mylau.<br />

• The first <strong>Behr</strong> wind tunnel in the USA goes<br />

into operation.<br />

1992<br />

• <strong>Behr</strong> acquires the company Fahrzeugheizungen<br />

Kirchberg GmbH in Kirchberg/Saxony.<br />

• A technical project is managed on the basis<br />

of simultaneous engineering for the first<br />

time.<br />

• The first company Works Council is established.<br />

• Dr. Dr. h.c. Walther Zügel takes over as<br />

Chairman of the Supervisory Board.<br />

• Horst Geidel is elected member of the VDA<br />

General Committee, which opens up new<br />

contacts to top representatives of the sector.<br />

11

… 1993 to date …<br />

1993<br />

• <strong>Behr</strong> starts serial production of flat-tube<br />

condensers.<br />

• The first extensive cost-cutting offensive<br />

begins.<br />

• <strong>Behr</strong> of America merges with the leading<br />

American truck cooler manufacturer McCord,<br />

a subsidiary of Cummins Engine Corporation.<br />

<strong>Behr</strong> America – as the company is renamed –<br />

expands considerably as a result and<br />

becomes market leader in the American<br />

truck business.<br />

1994<br />

• The first construction stage of <strong>Behr</strong> Lorraine<br />

in Hambach/France commences operation.<br />

The Nocolok method of brazing is used there<br />

in serial production for the first time.<br />

• <strong>Behr</strong> takes over majority interest in RCN<br />

Radiadores S.A. in São Paulo/Brazil, now<br />

<strong>Behr</strong> Brasil.<br />

• Customer centers come into being. They<br />

manage and coordinate all activities for<br />

<strong>Behr</strong> customers at home and abroad.<br />

• <strong>Behr</strong> develops plate-and-fin evaporators<br />

to serial production stage.<br />

12<br />

• Vaihingen is the first <strong>Behr</strong> plant to introduce<br />

team work in all production areas.<br />

• Radiators, oil coolers, charge-air coolers,<br />

refrigerant condensers and electric fans in<br />

standard sizes are assembled on a modular<br />

basis. This results in reasonably priced,<br />

large-volume serial production of customized<br />

modules using standardized products.<br />

1995<br />

• Implementation of “<strong>Behr</strong> 95”, the most<br />

far-reaching restructuring process to date<br />

in the company’s history.<br />

• The “Total Quality and People Orientation”<br />

project (referred to as TQM from the German)<br />

commences and becomes a part of corporate<br />

philosophy.<br />

• The production of copper/brass radiators,<br />

commenced in 1905, ceases in Germany and<br />

is transferred to Frape <strong>Behr</strong>.<br />

1996<br />

• <strong>Behr</strong>-Thomson Dehnstoffregler GmbH becomes<br />

<strong>Behr</strong> Thermot-tronik GmbH & Co.<br />

• <strong>Behr</strong> is market leader for vehicle air<br />

conditioning in Europe.<br />

• The great-grandsons of the company founder<br />

– Alexander Rauschenbusch and Ariane Piëch –<br />

cease to be partners. The corporate holding<br />

company (Baden-Württembergische Kapitalanlagegesellschaft<br />

BWK) becomes a new<br />

partner with minority interest.<br />

• First serial production of aluminum stackedplate<br />

oil coolers.<br />

1997<br />

• <strong>Behr</strong> Industrietechnik is the leading<br />

European systems supplier in the field<br />

of cooling systems for rail vehicles.<br />

1998<br />

• <strong>Behr</strong> Japan, based in Tokyo, is established.<br />

• <strong>Behr</strong> Brasil goes into air conditioning.<br />

• <strong>Behr</strong> America records initial success in the<br />

passenger car sector.<br />

• The quality management system is certified<br />

in accordance with VDA 6.1 and QS 9000<br />

so it complies with globally valid system<br />

standards of the automobile industry.<br />

• <strong>Behr</strong> generates sales of DM three billion.<br />

1999<br />

• The two joint ventures <strong>Behr</strong>-Hella Thermocontrol<br />

and Hella-<strong>Behr</strong> Fahrzeugsysteme<br />

are founded together with Hella. This is<br />

<strong>Behr</strong>’s first step toward becoming a virtual<br />

supplier company: cooperations open up<br />

new fields of competence and new<br />

international markets.<br />

• The twenty-millionth aluminum cooler for<br />

cars is produced in Mühlacker.<br />

• Serial production of exhaust gas coolers<br />

commences.<br />

• Foundation of <strong>Behr</strong> Czech and <strong>Behr</strong> South<br />

Africa in Mnichovo Hradiste/Czech Republic<br />

and Durban/South Africa.<br />

• <strong>Behr</strong> Service is established at the end<br />

of 1999 and commences operations in<br />

Schwäbisch Hall in 2000.

2000<br />

• The production of wheel rims and wheels<br />

for motorcycles commences at the new <strong>Behr</strong><br />

Industrietechnik plant in Reichenbach/<br />

Saxony.<br />

• The shareholders demonstrate long-term<br />

commitment by increasing the share capital,<br />

thereby securing future development of the<br />

company.<br />

• <strong>Behr</strong> establishes joint ventures with Toyo<br />

(third-largest radiator manufacturer in Japan)<br />

and the Sanden Corporation (leading<br />

Japanese manufacturer of A/C compressors<br />

for motor vehicles).<br />

• <strong>Behr</strong> takes over Cummins’ interests in <strong>Behr</strong><br />

America.<br />

• The first all-aluminum radiator for road<br />

vehicles goes into serial production.<br />

• Every fourth vehicle manufactured in Europe<br />

is equipped with a cooling system from <strong>Behr</strong>.<br />

• <strong>Behr</strong> sales top DM four billion.<br />

• Visco® fans go into production at the new<br />

plant in Webberville/USA.<br />

• <strong>Behr</strong>-Hella Thermocontrol commences<br />

production in a new plant in Lippstadt.<br />

2001<br />

• <strong>Behr</strong> opens an office in Shanghai.<br />

• The new climatic wind tunnel in Stuttgart is<br />

inaugurated, the most modern of its kind in<br />

Europe.<br />

2002<br />

• Acquisition of Dayton Thermal Products brings<br />

about a breakthrough in the key passenger<br />

vehicle market in the USA.<br />

• The new Technical Center in Troy near<br />

Detroit/USA is inaugurated.<br />

• The cost-cutting offensive “Ratio 350” is<br />

launched.<br />

• <strong>Behr</strong> starts with just-in-sequence deliveries.<br />

• Production of the four-zone HVAC system<br />

denotes a further innovative <strong>Behr</strong><br />

development worldwide.<br />

2003<br />

• Generational change: Dr. Markus Flik becomes<br />

Spokesman of the Board of Management.<br />

Horst Geidel takes over as Chairman of the<br />

Supervisory Board.<br />

• Lilo <strong>Behr</strong>, widow of Manfred <strong>Behr</strong>, dies in<br />

Stuttgart at the age of 88.<br />

• <strong>Behr</strong> establishes its first joint venture in China<br />

with Shanghai Automotive (subsidiary of the<br />

largest Chinese automobile manufacturer and<br />

supplier group SAIC).<br />

• The plant in Canton/USA is sold in the<br />

context of a management buyout.<br />

2004<br />

[Chronicle]<br />

• The new wind tunnel in Troy/USA is<br />

inaugurated.<br />

• <strong>Behr</strong> launches “Performance Partnership”,<br />

a comprehensive program to further develop<br />

customer relations.<br />

• The first <strong>Behr</strong> products are manufactured in<br />

China.<br />

• <strong>Behr</strong> establishes its second joint venture in<br />

China with Shanghai Automotive and Sanden<br />

Corporation.<br />

• A third joint venture in the world’s fastestgrowing<br />

auto market is signed with<br />

Dongfeng.<br />

• Hella and <strong>Behr</strong> combine Hella-<strong>Behr</strong><br />

Fahrzeugsysteme with the French company<br />

Plastic Omnium, a leading specialist in<br />

plastic bumpers, to form a new joint venture.<br />

2005<br />

• <strong>Behr</strong> celebrates its centennial anniversary.<br />

• <strong>Behr</strong> has a workforce of 17,000 worldwide<br />

and generates sales of over three billion<br />

euros in fiscal year 2004.<br />

• Various other <strong>Behr</strong> anniversaries are<br />

celebrated: <strong>Behr</strong> Thermot-tronik is 50, the<br />

Pforzheim plant 35, <strong>Behr</strong> Industry 15 and<br />

<strong>Behr</strong> Services five years old. Abroad, <strong>Behr</strong><br />

Paris celebrates its 20th anniversary, while<br />

<strong>Behr</strong> Industry America and <strong>Behr</strong>-Toyo Engine<br />

Cooling Systems are five years old.<br />

13

[Cover Story]<br />

Success of a Special Kind<br />

By founding his workshop for car radiators<br />

in 1905, Julius Fr. <strong>Behr</strong> lays the foundation<br />

for a remarkable company history.<br />

As early as 1910, not long after foundation of the Süddeutsche<br />

Kühlerfabrik Julius Fr. <strong>Behr</strong>, Carl Benz fits his racing car with<br />

a radiator from our company.<br />

15

In 1915 <strong>Behr</strong> sets a milestone in the<br />

development of radiators with its<br />

standard element radiator.<br />

Workshop for the construction of jigs and fixtures<br />

and for maintenance of works equipment, 1920<br />

16<br />

<strong>Behr</strong> company logo from the early years<br />

Drawing of radiator cowls for automobiles<br />

in Plant 1, 1930<br />

Advertising attracts particular attention.<br />

A small workshop for motor vehicle radiators<br />

in a rear building of the Neue Weinsteige 8 in<br />

Stuttgart develops into a global company that<br />

today ranks among the significant names of<br />

the sector. That almost sounds like the script<br />

of a successful TV film. However, the remarkable<br />

success story was not written by a novelist –<br />

it is reality and describes the development of<br />

<strong>Behr</strong> over the last <strong>100</strong> years.<br />

Production of steel doors as further foothold<br />

in Plant 2, 1934

Today, our company is one of the leading<br />

original equipment manufacturers in the field<br />

of vehicle air conditioning and engine cooling<br />

for cars and commercial vehicles. We are an<br />

important partner of the international automobile<br />

industry with some 17,000 staff as well<br />

as 30 production plants and 10 development<br />

bases in Europe, North and South America,<br />

South Africa and Asia. We aim to be represented<br />

wherever our customers base their production.<br />

Despite increasing activities abroad, we<br />

explicitly profess our commitment to Germany<br />

as our industrial base and to our headquarters<br />

in Stuttgart. <strong>Behr</strong> will continue to uphold its<br />

strong Swabian character in the future – just<br />

as over the past <strong>100</strong> years.<br />

Major Investments in German Plants<br />

and Research Facilities<br />

Germany is and remains more than just an<br />

important production base for <strong>Behr</strong>. We are<br />

continuing to concentrate our research and<br />

development activities in Stuttgart and are<br />

expanding these consistently. Extension of<br />

the Technical Center in the centennial year,<br />

for example, is one aspect. However, that is<br />

certainly not all: <strong>Behr</strong> annually invests over<br />

six percent of its turnover in the development<br />

Soldering of headers for aircraft coolers<br />

in Plant 1, 1938<br />

[Cover Story]<br />

The management from NSU (Neckarsulmer Fahrzeugwerke AG) visits the new <strong>Behr</strong> plant in Feuerbach<br />

in 1912.<br />

of new products and methods – more than<br />

most of our competitors. In the next three<br />

years, a further 150 million euros will be<br />

spent in Germany alone in order to strengthen<br />

and improve our position as global<br />

technology leader in vehicle air conditioning<br />

and engine cooling for cars and commercial<br />

vehicles.<br />

Pressing of radiator components<br />

in Plant 2, 1943<br />

View of drawing office<br />

in Plant 2, 1950<br />

17

It is not only the<br />

technological achievements<br />

of Julius Fr. <strong>Behr</strong> that are<br />

convincing. He also has an<br />

exceptionally good intuition<br />

for market niches.<br />

Assembly of fresh-air heaters<br />

in Plant 3, 1956<br />

18<br />

<strong>Behr</strong> cooling in the air: the four-engined Junkers G 38, the largest land plane of its time, first went into<br />

operation in 1931.<br />

The ambition and self-commitment to<br />

repeatedly surprise customers throughout the<br />

world with innovative ideas and to seek trendsetting<br />

solutions together with them is a<br />

tradition at <strong>Behr</strong>. The company founder himself<br />

maintains close business and personal contacts<br />

with many pioneers of the automobile industry.<br />

Julius Fr. <strong>Behr</strong> already applies for numerous<br />

patents in the first years after founding his<br />

company and recognizes that the radiator is<br />

Durability testing of water coolers<br />

in Plant 3, 1960<br />

not only a necessary means of dissipating<br />

heat. His good intuition for market niches<br />

prompts him, for example, to develop pointed<br />

radiators which quickly become top sellers.<br />

The Swiss and Dutch adorn their motor vehicles<br />

with the decorative <strong>Behr</strong> products and this<br />

brings in plenty of foreign currency in an<br />

inflationary period. When times are difficult<br />

for the Süddeutsche Kühlerfabrik, the money<br />

helps to finance the company’s first own office<br />

building – something that attracts considerable<br />

Tool shop in<br />

Plant 2, 1961

interest at the time and is proof of the great<br />

faith <strong>Behr</strong> has in the development of the<br />

automobile industry.<br />

Contacts Abroad at an<br />

Early Stage<br />

Julius Fr. <strong>Behr</strong> realizes at an early stage that<br />

it does not suffice merely to gather inspiration<br />

in his home country to optimize products and<br />

methods. Consequently, he sets off in 1926 on a<br />

study trip to the USA. He meets the engineering<br />

pioneers Thomas Alva Edison and Henry Ford<br />

there.<br />

His son Manfred, who takes over technical<br />

management of his father’s company in 1935,<br />

is of the same conviction. He also turns his<br />

attention abroad, primarily toward America. The<br />

engineer returns from a visit there with ideas<br />

which, in addition to numerous products he<br />

develops himself, become milestones in the<br />

company’s history. These include, for example,<br />

the “<strong>Behr</strong> fresh-air heater”, which heats the<br />

interior of the vehicle using warm water from the<br />

radiator and is first used in the “Buckel-Taunus”.<br />

Visco® clutch production initially commences<br />

under license. Subsequently, in the sixties, first<br />

activities in vehicle air conditioning follow,<br />

something which is already popular in the USA.<br />

Assembly of a truck water cooler<br />

in Plant 2, 1978<br />

Today, approximately half of the group sales are<br />

attributed to this field. At the same time, the<br />

son of the company founder presses ahead with<br />

developments for the aircraft and shipping<br />

industry as well as for rail vehicles.<br />

Consistent Promotion of<br />

Internationalization<br />

Manfred <strong>Behr</strong> renders our company a great<br />

service not only as an indefatigable innovator,<br />

who is continually on the look-out for new<br />

product solutions. He recognizes at an early<br />

stage what great significance expansion<br />

beyond the borders of Germany has on the<br />

profitable growth of his company. The offensive<br />

approach to gain access to foreign markets<br />

commences in 1969 with the foundation of<br />

<strong>Behr</strong> France and <strong>Behr</strong> of America. Horst Geidel,<br />

who takes over management in 1988, develops<br />

<strong>Behr</strong> into a globally operating company and<br />

later, in 2002, seizes a good opportunity to<br />

establish <strong>Behr</strong> in the top league of global<br />

suppliers by acquiring the Dayton Thermal<br />

Products plant in Ohio/USA. By venturing<br />

into the strongly growing Chinese market, his<br />

successor Dr. Markus Flik successfully continues<br />

to pursue the expansion strategy. The first year<br />

of activities in China realizes a return for the<br />

<strong>Behr</strong> Group.<br />

Rolling of cooling fins at the<br />

Mühlacker plant, 1980<br />

[Cover Story]<br />

As the poster illustrates, almost all important<br />

forms of transport are fitted with <strong>Behr</strong> products<br />

even in the thirties.<br />

Production of cooling aggregates for diesel<br />

train engines in Plant 3, 1985<br />

19

Test stand for HVAC units<br />

at the Feuerbach plant, 2003<br />

Assembly of cooling modules<br />

at the Mühlacker plant, 2000<br />

20<br />

Continual Focus on Customer Needs<br />

The sustained success of <strong>Behr</strong> is not only<br />

based on the fact that we support our customers<br />

at their production locations throughout the<br />

world and are strengthening and further<br />

expanding our position as technological leader.<br />

In the nineties, we achieved the step from<br />

the premium segment into large-volume serial<br />

production. In the case of commercial vehicles,<br />

Production of air conditioners<br />

at the Neustadt plant, 2002<br />

<strong>Behr</strong> is meanwhile market leader. However,<br />

we are not prepared to just settle for these<br />

results.<br />

Today, it is a matter of becoming the leader<br />

as far as customer support is concerned. We<br />

are on the right course in that direction. By<br />

introducing product lines and customer centers<br />

worldwide in 2000, <strong>Behr</strong> creates the necessary<br />

basis to be able to respond more specifically<br />

Plate-and-fin evaporator production<br />

at the Mühlacker plant, 2003

Staff as Success Factor<br />

Continuous optimization of the quality of<br />

our products and services is essential to <strong>Behr</strong>’s<br />

sustained positive development. In this respect,<br />

we do not differ from many other companies<br />

that promote Total Quality Management (TQM).<br />

However, <strong>Behr</strong> does not leave it at just<br />

managing quality. We understand considerably<br />

more under the term TQM. For us it stands<br />

for the German motto “Totale Qualität und<br />

Menschlichkeit” (Total Quality and People<br />

Orientation). Experience repeatedly shows<br />

that motivated staff are the best qualification<br />

to consistently offer our customers convincing,<br />

innovative support. For this reason, <strong>Behr</strong><br />

offers a high degree of individual responsibility<br />

as well as plenty of scope for development.<br />

This way, we create the necessary environment<br />

for innovative ideas, which are essential to<br />

the continuous improvement process.<br />

TQM Becomes a Part of Corporate<br />

Philosophy<br />

Launching of the TQM project takes place<br />

in 1995 and it is initially applied in the parent<br />

company. One year later, the starting signal<br />

is given for implementation throughout the<br />

Group. Dr. Andreas-Claus Windecker, TQM<br />

Project Manager at the time and now head of<br />

Group Human Resources Development, defines<br />

his understanding of “Total Quality and People<br />

Orientation”: “To me, TQM means finding a<br />

positive way to mutually solve our day-to-day<br />

tasks. Managerial staff and employees agree<br />

on clear targets to solve problems and those<br />

concerned are integrated into the solution<br />

process so they are able to identify themselves<br />

with it.” Today, TQM is firmly anchored in all<br />

structures and procedures and ensures uniform<br />

standards and processes throughout our<br />

global network.<br />

The concept comprises two elements, which<br />

complement each other. First, it is a matter of<br />

making clear where we currently stand and<br />

Family events uphold the TQM tradition.<br />

implementing a target management system in<br />

order to remain competitive. Second, TQM is<br />

aimed at convincing employees that they are<br />

our focal asset, irrespective whether they work<br />

in production or administration, are trainees<br />

or managerial staff.<br />

Diverse Measures as Basis for<br />

Success of TQM<br />

Dialog on a partnership basis between<br />

superiors and employees, an open information<br />

policy, the delegation of responsibility, a wide<br />

range of further training opportunities for all<br />

hierarchical levels and many other features are<br />

all standard at <strong>Behr</strong> these days – at the parent<br />

company in Stuttgart-Feuerbach just as at all<br />

other locations in the world.<br />

Horst Geidel, Chairman of <strong>Behr</strong>’s Supervisory<br />

Board, sees this as precisely the right way to<br />

achieve long-term top quality and continuous<br />

improvement. He is convinced: “It cannot work<br />

without consistently integrating employees in<br />

[Cover Story]<br />

what is happening.” The sustained success of<br />

TQM at <strong>Behr</strong> proves him right.<br />

Above-average commitment, the high rate of<br />

attendance at in-house events as well as the<br />

excellent working atmosphere (see page 71)<br />

prove that the majority of employees enjoy<br />

working for <strong>Behr</strong>. This attitude generates an<br />

inner strength which is the envy of many other<br />

companies. The mutual target of all <strong>Behr</strong> staff<br />

continues to read: “We are not settling for what<br />

we have achieved, but are consistently working<br />

on further optimization of our product quality.”<br />

Managerial Staff Assume Responsibility<br />

for the TQM Process<br />

Responsibility for the consistent implementation<br />

of TQM has been with our managerial<br />

staff since 1999. No mean task as the concept<br />

demands a completely new style of management:<br />

the superior at <strong>Behr</strong> is a coach. He encourages,<br />

challenges and spurs on his team to attain top<br />

performance together.<br />

21

In its centennial year,<br />

<strong>Behr</strong> has all the necessary<br />

qualifications to continue<br />

to grow profitably and be<br />

an innovative and reliable<br />

partner of its customers.<br />

Automatic cooler core production line,<br />

2000<br />

22<br />

Eurostar with oil-cooled transformers from <strong>Behr</strong> Industry, Waterloo Station, London<br />

to customer requirements and strengthen<br />

global expansion.<br />

The Company as Performance<br />

Partner of its Customers<br />

2004 sees launching of the Performance<br />

Partnership Program. The objective of this<br />

initiative is to further develop <strong>Behr</strong> as a<br />

performance partner and offer more than a<br />

classical customer/supplier relationship.<br />

A particular strength of <strong>Behr</strong> is virtual development:<br />

CAD workplace, 1998<br />

Experience gained from the first pilot projects<br />

and recent awards from our customers makes<br />

us optimistic that we are on the right course<br />

with the Performance Partnership Program.<br />

Cooperations Pave the Way<br />

for Additional Fields of Business<br />

and New Markets<br />

The course is set at <strong>Behr</strong> for sustained<br />

growth. Our cooperations are helping in this<br />

connection. <strong>Behr</strong>-Hella Thermocontrol was<br />

already established with Hella in 1999. This<br />

joint venture enables us to benefit from the<br />

increasing trend toward automatic air<br />

conditioning. In the same year, Hella-<strong>Behr</strong><br />

Fahrzeugsysteme (HBF), a company that<br />

develops and manufactures front-ends, is<br />

established. Five years later, the two partners<br />

combine the joint venture with Plastic Omnium<br />

to establish the new joint company HBPO –<br />

the world’s first company to specialize in frontends.<br />

The recent development cooperation<br />

with Eberspächer, a specialist in stationary<br />

and auxiliary heaters, also promises successful<br />

activities.<br />

These are just some of the reasons for our<br />

sustained, profitable growth and the high<br />

quality of our products. You will learn more<br />

on the following pages.

Keeping the <strong>Behr</strong> History Alive<br />

A life without <strong>Behr</strong> is barely conceivable<br />

for Heinz Leyrer (*1925), Manfred Illg (*1938)<br />

and Siegfried Jenz (*1936). The three are<br />

apprentices at <strong>Behr</strong> and embark on remarkable<br />

careers. Each of the men can look back on<br />

more than 45 years’ employment with the<br />

company. And even in well-deserved retirement,<br />

the trio enthusiastically spends a considerable<br />

amount of spare time at <strong>Behr</strong>: as chroniclers<br />

of the meanwhile hundred-year-old company<br />

history, who are responsible for our museum.<br />

Veritable treasures are to be seen there.<br />

These include, for example, the first fresh-air<br />

heater that was developed by <strong>Behr</strong>, or Europe’s<br />

first serial air conditioner with automatic<br />

temperature control for the Mercedes-Benz 600.<br />

The original of the first radiator is on show,<br />

just as the first aluminum cooler for aircraft<br />

dating back to 1939. The three gentlemen<br />

present well over 700 engine cooling and air<br />

conditioning components and modules in the<br />

<strong>Behr</strong> museum.<br />

However, the three dedicated pensioners do<br />

not restrict themselves to engineering by any<br />

means. In their museum, visitors also find an<br />

extensive photo archive as well as posters and<br />

advertising material covering <strong>Behr</strong>’s history.<br />

There is barely a question concerning our<br />

company that the three are unable to answer.<br />

And this should continue to be the case.<br />

Neither Heinz Leyrer nor Manfred Illg or<br />

Siegfried Jenz are thinking of giving up.<br />

A small selection from their collection is<br />

meanwhile to be seen in the new product<br />

exhibition set up in the <strong>Behr</strong> Forum in Stuttgart<br />

to celebrate our centennial anniversary.<br />

[Cover Story]<br />

A view of the <strong>Behr</strong> museum with its wealth<br />

of exhibits<br />

In charge of the <strong>Behr</strong> museum: Siegfried Jenz,<br />

Heinz Leyrer and Manfred Illg (from left to right)<br />

23

Founder Julius Fr. <strong>Behr</strong> manages the company<br />

from 1905 until his early death in 1930.<br />

Dr.-Ing. E.h. Manfred <strong>Behr</strong> joins the<br />

Board of Management in 1931<br />

and takes over as Chairman in 1942.<br />

24<br />

Guarantors of Success<br />

Five managers have guided our company through its hundred-<br />

year-old history, upheld traditions and promoted innovations.<br />

A stable circle of shareholders guarantees our independence.<br />

Excellent qualifications for further success.<br />

Enthusiasm for the company’s products,<br />

great identification with the company, understanding<br />

for customer requirements, strong<br />

determination to succeed, as well as the talent<br />

to motivate are essential prerequisites for the<br />

success of a company manager. From the<br />

beginning, <strong>Behr</strong> is managed by persons with<br />

these characteristics.<br />

First and foremost is company founder Julius<br />

Fr. <strong>Behr</strong>. At the beginning of the twentieth<br />

century, he belongs to a circle of people who<br />

foresee that motor vehicles will significantly<br />

change everyday life. In 1905, the then<br />

33-year-old joins the Stuttgart company Veigel<br />

und Zoller as a partner. Shortly afterwards, the<br />

Dr. Heinz Breuer initiates the transition<br />

to external management. He is head of <strong>Behr</strong><br />

until 1988.<br />

company trades under the name <strong>Behr</strong> & Zoller<br />

and produces car radiators. Two years after<br />

becoming self-employed, Julius Fr. <strong>Behr</strong><br />

becomes sole owner of the company.<br />

Courage to Venture and Enterprising<br />

Vision<br />

Nothing can prevent him from promoting<br />

the success story of the motor vehicle with<br />

successive new developments. In times during<br />

which the number of competitors increases<br />

rapidly and many suppliers fail, <strong>Behr</strong>’s<br />

enthusiasm helps him to consistently<br />

strengthen the position of his company.<br />

Horst Geidel shapes <strong>Behr</strong> into a successful<br />

globally operating company group between<br />

1988 and 2003.

26<br />

One of the first wind tunnels in the world goes into operation at <strong>Behr</strong> in 1937 to measure the<br />

performance of engine cooling. In 1957, Europe’s first adjustable climatic wind tunnel for<br />

the development of vehicle heating and cooling systems follows. Today, we offer our customers<br />

throughout the world key testing facilities for air conditioning and engine cooling in wind tunnels<br />

of the fourth generation in Stuttgart (inaugurated 2001) and Troy/USA (inaugurated 2004).

Ideas, Inspiration,<br />

Innovations<br />

Target-oriented research and development activities are essential to the success of<br />

our company. Company founder Julius Fr. <strong>Behr</strong> focuses on attaining a technological<br />

edge from the start. Manfred <strong>Behr</strong> expands the successful strategy of his father and<br />

firmly anchors inventiveness and customer-orientation in <strong>Behr</strong>’s corporate culture.<br />

Further expansion of technological leadership is one of <strong>Behr</strong>’s important strategic<br />

objectives today and in future.<br />

[Technology]<br />

27

2002: start of serial production of the<br />

first four-zone HVAC system combined<br />

in one unit – for individual comfort<br />

for the driver, front-seat passenger<br />

and passengers in the back.<br />

<strong>Behr</strong> starts producing the standard<br />

element radiator in 1915. If an element<br />

was damaged, it could easily be replaced<br />

by a new one.<br />

28<br />

At the beginning of the 20th century in the<br />

then German Reich there are numerous companies<br />

working on the construction of radiators.<br />

In 1913, the <strong>Behr</strong> chronicle lists 30 “reputable<br />

rival companies” and ten “automobile factories<br />

with their own radiator production”.<br />

In order to stand out from the competition,<br />

Julius Fr. <strong>Behr</strong> focuses on efficient, technologi-<br />

Manfred <strong>Behr</strong> solves the problem of installing the radiator<br />

in the rear of a vehicle in 1934 with his dissertation<br />

“The automatically ventilated cooler installed in<br />

the vehicle interior”. The innovation is installed in the<br />

Mercedes-Benz rear-engine vehicle 130/170 H.<br />

cally sophisticated products. Development work<br />

becomes a substantial part of the company’s<br />

activities. Even around 1907 the perfectionist<br />

Julius Fr. <strong>Behr</strong> works on aero- and thermodynamic<br />

tests. He soon recognizes that the<br />

design of the air-side of the radiator is of<br />

particular significance to heat dissipation into<br />

the atmosphere. In 1915, the Aerodynamics<br />

Institute for Aircraft Craftsmanship at the<br />

Technical University in Dresden carries out<br />

scientific measurements on radiators for <strong>Behr</strong>.<br />

He systematically evaluates the results and<br />

attains a major competitive edge in the sector.<br />

Differentiating ourselves from the competition<br />

through technological leadership is one of the<br />

most important strategic objectives of our<br />

company today. We purposefully invest in<br />

research and development to this end.<br />

Close Cooperation with Customers<br />

is Tradition at <strong>Behr</strong><br />

Technological know-how and innovational<br />

strength are essential to the development of<br />

forward-looking products. However, solutions<br />

offering genuine added value can only emerge<br />

by intensively analyzing the requirements of<br />

the automobile manufacturers. That is why we<br />

attach great importance to close, reliable<br />

cooperation with our customers. This approach<br />

The first “air conditioner”, a recirculated air system<br />

with temperature control, goes into serial production<br />

in 1965.

Successful with <strong>Behr</strong> coolers on board: the racing<br />

cars of Auto Union founded in 1932<br />

is a tradition at <strong>Behr</strong>, as two examples from<br />

the thirties illustrate: Manfred <strong>Behr</strong>, son of<br />

the company founder, is involved at an early<br />

stage in preparatory work for the subsequent<br />

Volkswagen. The same applies to development<br />

of the Auto Union Grand Prix racing car, which<br />

is celebrated as a sensation in 1934.<br />

Trustful cooperation – to <strong>Behr</strong> that means<br />

not just simply fulfilling customer demands but<br />

questioning existing solutions and, if possible,<br />

offering better alternatives. In this connection,<br />

developers are also attending more to the<br />

opinions of end users. After all, the extent of<br />

drivers’ satisfaction with their vehicles also<br />

depends on <strong>Behr</strong> products.<br />

Better performance, less weight, lower costs:<br />

after intensive development work, <strong>Behr</strong> brings<br />

the first flux-free brazed aluminum radiator<br />

onto the market in 1975.<br />

From “Radiator <strong>Behr</strong>” to a Leading<br />

Specialist in Air Conditioning<br />

and Engine Cooling<br />

In 1949, <strong>Behr</strong> starts producing heaters –<br />

a logical extension of the existing product<br />

portfolio. In the case of the “Gulf Stream<br />

heater”, fin and tube panels that are connected<br />

to the cooling system and through which water<br />

flows, warm the passengers’ feet. Eight years<br />

later, <strong>Behr</strong> constructs the first complete car<br />

HVAC system to go into serial production in<br />

Europe. The portfolio is extended again in<br />

1961: <strong>Behr</strong> acquires the license to produce<br />

Visco® clutches and Visco® fans and duly<br />

develops the product further.<br />

For several years auto makers have been<br />

transferring more and more development and<br />

integration work to suppliers. This acts as an<br />

incentive and challenge to <strong>Behr</strong> to tread new<br />

paths and consistently expand its system<br />

expertise. At the same time, project-related<br />

cooperation with other companies gains<br />

significance – <strong>Behr</strong>’s partner network strengthens.<br />

This makes project work more demanding,<br />

but we are able to offer our customers genuine<br />

added value: they benefit from perfectly<br />

coordinated systems, e.g. front-end modules,<br />

and a noticeable reduction in coordination,<br />

development and logistics.<br />

Greater system competence: together with competent partners such as Hella and Plastic Omnium,<br />

<strong>Behr</strong> now takes on additional development and integration work and supplies complete<br />

coordinated modules such as control and operating units for vehicle HVAC systems (left)<br />

and front-end modules (right).<br />

[Technology]<br />

Solutions offering genuine<br />

added value emerge from<br />

intensive analysis of customer<br />

requirements. And that has<br />

been the case for <strong>100</strong> years.<br />

29

<strong>Behr</strong> engineers think<br />

in terms of complete vehicle<br />

air conditioning and<br />

engine cooling systems.<br />

In 1919 the first test stand to<br />

measure cooling performance<br />

is installed.<br />

30<br />

Always on the Ball: Test Facilities<br />

at <strong>Behr</strong><br />

An important pillar in <strong>Behr</strong>’s development<br />

work are its test facilities, which customers<br />

also like to fall back on. At the beginning<br />

of the thirties, for example, Daimler-Benz<br />

engineers test the oil and cooling water<br />

circulation in their vehicles at <strong>Behr</strong>. Around<br />

the same time, development of the German<br />

freeway network means new challenges for<br />

the automobile industry. Vehicles capable of<br />

higher average speeds but with the same<br />

fuel consumption and comfort need to be<br />

manufactured. In order to obtain more<br />

accurate and comparable test results, Manfred<br />

<strong>Behr</strong> decides to supplement road tests with<br />

measurements carried out in the company’s<br />

own wind tunnel in Stuttgart. Even the<br />

legendary Mercedes “Silver Arrows” are tested<br />

in the <strong>Behr</strong> wind tunnel inaugurated in Stuttgart<br />

in 1937. In 1957, <strong>Behr</strong> builds Europe’s first<br />

adjustable climatic wind tunnel for the<br />

development of vehicle heating and cooling<br />

systems. The testing facilities are enlarged in<br />

1972 to create a development center unmatched<br />

anywhere in Europe. The centennial year 2005<br />

sees completion of further development of<br />

the research and development facilities in<br />

Stuttgart, the largest development base of the<br />

<strong>Behr</strong> Group. Modern performance, durability<br />

The measurement of cooling efficiency today:<br />

car and truck cooling systems can be tested<br />

to their limits in the wind tunnel.<br />

and acoustic test stands enable the efficient<br />

development of high-quality, reliable products,<br />

that take into account ever increasing<br />

demands in terms of comfort, ecology and<br />

integration.<br />

Klemens Schmiederer, Managing Director,<br />

Air Conditioning Product Division: “Drivers’<br />

expectations, e.g. regarding acoustic comfort<br />

inside the vehicle, are becoming increasingly<br />

demanding. By applying our acoustic analysis<br />

methods in the new acoustics laboratories,<br />

we are able to establish local sources of sound<br />

and the spreading mechanisms. Our products<br />

undergo continual detailed refinement on the<br />

basis of these results.”<br />

Virtual Product Development:<br />

A particular strength of <strong>Behr</strong>’s<br />

A particular strength of <strong>Behr</strong>’s is virtual<br />

development. What started in 1988 with the<br />

first durability analyses is now an integral part<br />

of all development projects. State-of-the-art<br />

simulation tools provide informative data on<br />

performance, reliability and required installation<br />

space of separate components at an early stage.<br />

All along, <strong>Behr</strong> engineers think in terms of<br />

complete vehicle air conditioning and engine<br />

cooling systems.<br />

Continuous improvement of the acoustic comfort is<br />

an integral part of the development process at <strong>Behr</strong>.<br />

Components, modules and systems are optimized in<br />

state-of-the-art acoustic laboratories.

Three questions put to Dr. Markus Flik<br />

Expanding technological leadership<br />

is one of <strong>Behr</strong>’s strategic objectives.<br />

What are the success factors to achieve<br />

this target?<br />

Dr. Markus Flik: Technological competence<br />

is an integral part of our corporate culture.<br />

Innovative enthusiasm and orientation to<br />

solve problems are <strong>Behr</strong> genes that have<br />

made the success of the past <strong>100</strong> years<br />

possible and will also form the basis<br />

for future success. <strong>Behr</strong>’s development<br />

engineers work with state-of-the-art tools<br />

and have the necessary freedom to transform<br />

ideas into innovative products. Selective<br />

market analyses and intensive dialog with<br />

customers and partners enable us to point<br />

By intelligently combining simulation and<br />

testing – validation – <strong>Behr</strong> streamlines development<br />

time and costs. Extensive reliability<br />

management gives our customers and ourselves<br />

additional assurance: this instrument enables<br />

weak points to be recognized and eliminated<br />

at a very early stage of the product engineering<br />

process. “We are very close to reality with our<br />

Success factor simulation: before investing<br />

in prototypes, we are able to depict the<br />

effect of various determining factors on<br />

the performance of separate components.<br />

the way for product development at an early<br />

stage and avoid wrong decisions. In future,<br />

we will continue to invest specifically in<br />

the knowledge of our workforce and in the<br />

modernization of our development tools.<br />

Key word costs: what influence does<br />

the enormous pressure on costs in the<br />

automobile industry have on development<br />

work at <strong>Behr</strong>?<br />

Dr. Markus Flik: These days an engineer<br />

is not just faced with the question as to<br />

how best solve a problem technically –<br />

he must also come up with the most costeffective<br />

solution. Or he must offer the<br />

customer an additional benefit which<br />

development methods, are able to make service<br />

life predictions and determine the failure<br />

probability of components”, explains Jochen<br />

Eitel, head of Advanced Engineering in the<br />

Engine Cooling Product Division. <strong>Behr</strong>’s<br />

validation processes are the key to the fast<br />

development of solutions geared to market<br />

requirements at optimum cost.<br />

[Technology]<br />

enables costs to be saved elsewhere. That<br />

demands additional know-how. This is<br />

one of the reasons why we launched an<br />

extensive competence offensive in 2002.<br />

What role do cooperations play in<br />

research and development?<br />

Dr. Markus Flik: The development<br />

departments of partners involved in a<br />

project have to cooperate very closely.<br />

It is a case of harmonizing priorities,<br />

working methods and mentalities. That<br />

demands intensive communication and<br />

a particularly attentive project manager.<br />

However, at the end of the day, everyone<br />

benefits: the development partners gain<br />

new know-how and our customers receive<br />

optimally coordinated systems that<br />

involve less development on their part.<br />

Development objective “maximum comfort”: since 2002 the thermal dummy has been helping to determine<br />

the subjective sense of well-being of drivers and passengers and provides valuable data to further improve<br />

automatic HVAC systems (photo left). Our system know-how enables us to optimize the airflow in the cabin<br />

and enhance passenger comfort (photo right).<br />

31

The <strong>Behr</strong> Development<br />

System facilitates efficient<br />

global development.<br />

32<br />

Global Knowledge Transfer<br />

Pradeep Palande has been with <strong>Behr</strong> India<br />

as a product design engineer since July<br />

1999. He travels to Stuttgart in July 2002<br />

in order to work on a customer project.<br />

Pradeep Palande takes on responsibility<br />

for development of the cooling module,<br />

liaises with customers and suppliers and<br />

coordinates tool design and construction.<br />

One of his ideas, which comes about during<br />

his work in Germany, is filed as a patent<br />

in 2004. Pradeep Palande will remain in<br />

Stuttgart until October 2005 to see through<br />

the serial production launching of the<br />

cooling module. The 28-year-old engineer<br />

is also currently involved in projects of<br />

Indian customers.<br />

Furthermore, while in Stuttgart, he is<br />

coordinating project activities of the Pune<br />

“Engineering Service”. Some 15 Indian<br />

development engineers at <strong>Behr</strong> India offer<br />

their services throughout the <strong>Behr</strong> Group.<br />

The Indian joint venture with the Anand<br />

Group has qualified engineers who provide<br />

expertise and work capacity to all <strong>Behr</strong><br />

research and development bases. A particular<br />

advantage is the fact that the region<br />

Global Research and Development<br />

<strong>100</strong> years after foundation of the company,<br />

<strong>Behr</strong> carries out development work at 10 international<br />

locations. The development engineers<br />

in Germany, Spain, France, the Czech Republic,<br />

the USA, Brazil, South Africa, India, Japan<br />

and China cooperate across national borders.<br />

Binding development standards are anchored<br />

in the <strong>Behr</strong> Development System (BDS), ensuring<br />

uniform quality of products throughout the<br />

company and facilitating efficient global<br />

development. All personnel involved in the<br />

development process have access to available<br />

company knowledge via BDS. Validation<br />

processes, testing procedures, design guidelines<br />

and methods of product cost optimization,<br />

of Pune has Thursdays, instead of Sundays,<br />

as its free day. Indian colleagues work six<br />

days a week from Friday to Wednesday. This<br />

means that work can be sent to India on<br />

a Friday and results are available by the<br />

following Monday.<br />

When he returns to India, Pradeep Palande<br />

will take over responsibility for all R&D<br />

activities in the engine cooling division.<br />

for example, are available at the touch of a<br />

button. Before a subject is filed in BDS, it is<br />

checked whether it represents best practice<br />

standards. This way, <strong>Behr</strong> ensures that only<br />

the best ideas and procedures are defined as<br />

binding standards.<br />

Test Laboratories on Four<br />

Continents<br />

Depending on the focus of their activities,<br />

the <strong>Behr</strong> development bases are equipped with<br />

appropriate testing facilities. Standardized<br />

testing methods as well as stipulations governing<br />

test laboratory equipment ensure that<br />

test results are comparable throughout <strong>Behr</strong>.<br />

He will pass on his newly acquired knowledge<br />

and elements of the <strong>Behr</strong> culture to<br />

his colleagues in India. “Here, in Stuttgart,<br />

I am working with the most advanced tools<br />

and methods and continually learning new<br />

things. I will be able to contribute this to<br />

the existing knowledge of my colleagues in<br />

Pune”, says Pradeep Palande. But it is not<br />

just a case of transferring knowledge. “Getting<br />

to know German colleagues personally<br />

is just as important. This helps to break<br />

down barriers and makes cooperation across<br />

national borders much easier.”<br />

Successful German-Indian cooperation: Pradeep Pralande (right)<br />

with his German colleague Boris Bangert

Focus on the Future<br />

Which products and forms of technology are<br />

relevant to markets of the future? Where can<br />

new sectors be opened up using <strong>Behr</strong> expertise?<br />

Which is the optimum simulation method that<br />

applies to all <strong>Behr</strong> development activities?<br />

Answers to these and similar questions are<br />

provided by the <strong>Behr</strong> Technology Center in<br />

Stuttgart that came into being in 1995. Today,<br />

a workforce of some 60 employees concentrates<br />

on technical issues of the future. They observe<br />

markets, identify trends, develop simulation<br />

methods and ensure that development expertise<br />

and state-of-the-art development methods<br />

are available throughout <strong>Behr</strong>. “To secure our<br />

success in the long term, we have to know the<br />

future demands of our customers as accurately<br />

as possible and derive strategies from these for<br />

the development of products and technologies”,<br />

explains Dr. Thomas Heckenberger, head of the<br />

Technology Center since 2001.<br />

The course is set for a successful future.<br />

Ideas and impetus from <strong>Behr</strong> will continue to<br />

characterize progress in vehicle air conditioning<br />

and engine cooling in the future as well.<br />

2004 – 67 years after opening the first <strong>Behr</strong> wind tunnel – <strong>Behr</strong> inaugurates the most modern<br />

climatic wind tunnel in the USA at its Technical Center in Troy. It is one of the few facilities in the<br />

world capable of testing air conditioning and engine cooling systems of all categories of vehicles –<br />

from small cars to the largest US truck.<br />

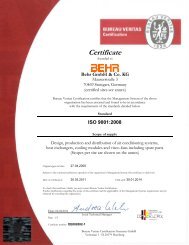

[Technology]<br />