You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

��������� ������ ����������������������������� ������������<br />

�<br />

���������������<br />

�����������������<br />

���������������

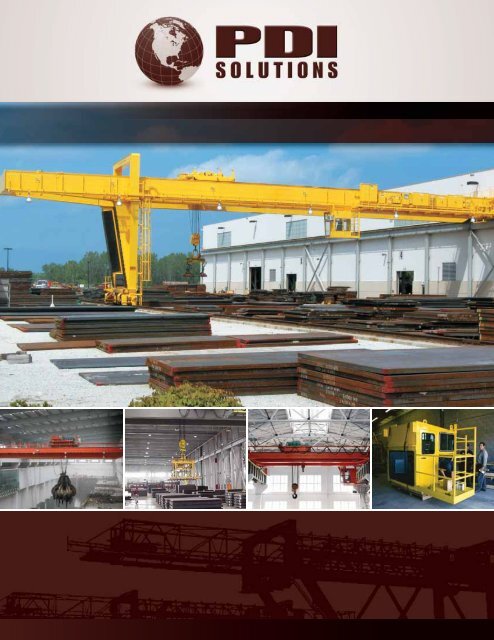

Initially founded in 1989, Pro-Direct Industriel Inc.<br />

(<strong>PDI</strong>) implemented sound engineering equipment<br />

solutions within the material handling industry.<br />

As an exclusive representative for many High-<br />

Tech Industrial Products, <strong>PDI</strong> soon became a<br />

systems integrator offering Turnkey Installations<br />

specializing in mechanical and electrical modernizations<br />

on all types of Custom Cranes.<br />

<strong>PDI</strong>’s solid reputation achieved by successfully<br />

completing major crane projects for the<br />

most demanding applications had ultimately<br />

forced <strong>PDI</strong> to expand operations in order to<br />

meet increased customers’ demands.<br />

In 1990, <strong>PDI</strong> introduced the engineering<br />

and fabrication of fully enclosed and<br />

ventilated Custom Built Operator’s Crane<br />

Cabins and Electrical Control Rooms, which<br />

soon became a standard of excellence<br />

within the complete range of <strong>PDI</strong> products<br />

& services.<br />

In 1998, <strong>PDI</strong> purchased Station 2000,<br />

custom built Operator Stations, in order<br />

�������������<br />

�����������<br />

Through innovation and cutting-edge technology, provide sound engineering solutions while<br />

improving equipment efficiency, reliability, and safety.<br />

Achieve the highest level of customer satisfaction throughout all stages of the project including,<br />

project management, engineering, fabrication, installation, and final commissioning.<br />

�������<br />

to provide ergonomics and flexibility while<br />

complementing the Operator’s Crane Cabins.<br />

In 2005, <strong>PDI</strong> pursued its efforts in offering Sound<br />

Engineering <strong>Solutions</strong> by joining the world of<br />

Custom Cranes manufacturing and incorporated<br />

an extensive line of standard overhead & gantry<br />

cranes, jib cranes, monorail systems, trolleys,<br />

hoists, and specialized below the hook devices.<br />

In 2010, <strong>PDI</strong> <strong>Solutions</strong> was launched; a division<br />

fully dedicated in providing Custom Overhead &<br />

Gantry Cranes while using <strong>PDI</strong>’s basic principles<br />

employed since day one... that is source the<br />

best Industrial Equipments & Fabricators while<br />

building the equipment in accordance to customer<br />

specifications.<br />

<strong>PDI</strong> <strong>Solutions</strong> continues a long standing tradition<br />

of delivering the highest quality product supported<br />

by a dedicated team of highly qualified technical<br />

personnel.<br />

<strong>PDI</strong> <strong>Solutions</strong>, your Standard & Custom Crane care<br />

center, looks forward in serving you soon.<br />

������������ ����� �������������������<br />

����������������<br />

�

����<br />

�������������<br />

Heavy duty hot metal, scrap handling & coil handling<br />

steel mills cranes, general purpose potroom &<br />

casthouse aluminum smelter cranes, overhead &<br />

gantry cranes for power generation facilities,<br />

gate hoists, automated stacker cranes, battery &<br />

electrically powered transfer cars, and various other<br />

heavy-duty production process cranes, are all part<br />

of <strong>PDI</strong> <strong>Solutions</strong> comprehensive range of custom<br />

engineered solutions.<br />

Design standards used :<br />

CMAA, CSA, AIST, AISE, OSHA, FEM, HMI, CWB,<br />

AWS, ANSI, ASME, ASTM, AGMA, NEC, NEMA,<br />

IEEE, UL, ISO

�������������<br />

2 x 35-ton scrap handling cranes<br />

2 x 35-ton CMAA F scrap handling, cab controlled<br />

overhead cranes for steel mill application; 95’-0” span.<br />

Cranes complete with dual magnet system, inverter<br />

duty drive controls for high speed operation.<br />

30-ton steel handling crane<br />

30-ton CMAA E steel handling, cab controlled overhead<br />

crane for steel mill application; 85’-0” span. Crane<br />

complete with rotating trolley and magnet systems.<br />

50/10-ton hangar crane<br />

50/10-ton heavy-duty, cab controlled hangar overhead<br />

crane; 65’-0” span. Crane complete with main &<br />

auxiliary hoists.<br />

��������

����<br />

Gantry cranes<br />

31-ton plate handling semi-gantry crane<br />

31-ton CMAA D plate handling, cab-controlled<br />

semi-gantry crane for mine equipment manufacturer;<br />

101’-0” span. Crane designed with 25’-0” cantilever for<br />

extended trolley travel operation.<br />

Single & double girder gantry cranes with hoisting<br />

capabilities up to 300 metric tons.

Gantry cranes<br />

Top right: 40/5-ton single girder gantry crane.<br />

Right: 63/10-ton double girder gantry crane.<br />

Bottom: 50/10-ton double girder container handling<br />

gantry crane.<br />

Bottom right: 40-ton double girder semi-gantry plate<br />

handling crane.<br />

�������������<br />

�������

�<br />

45-ton coil handling crane<br />

45-ton CMAA E coil handling overhead<br />

crane for steel service center; 100’-0” span.<br />

Crane complete with motorized coil grab &<br />

operator’s cabin mounted on the main trolley.<br />

100-ton hot metal handling trolley & hoist<br />

100-ton CMAA F hot-metal handling replacement<br />

trolley & hoist for steel mill crane.

�������������<br />

50-ton transfer car<br />

50-ton locomotive transfer car operating<br />

on a four-rail travel runway system.<br />

100-ton transfer car<br />

100-ton locomotive transfer car<br />

complete with outdoor environmental<br />

shield protection.<br />

70-ton transfer car<br />

70-ton dual coil transfer car for steel<br />

mill application.<br />

�

��<br />

Specialized below-the-hook devices<br />

Full range of specialized below-the-hook devices<br />

including C-hooks, coil grabs, grapples, buckets,<br />

motorized hook blocks, spreader and load beams.<br />

150-ton custom<br />

ladle hook block

150-ton gearbox<br />

150-ton custom built, heavy-duty gearbox for<br />

steel mill crane.<br />

300-ton ladle beam<br />

300-ton heavy-duty ladle beam custom built for<br />

steel mill application.<br />

�������������<br />

Bridge drive assembly<br />

Typical CMAA A1 bridge drive assembly custom<br />

built with floating shafts.<br />

Gantry drive assembly<br />

Drive assembly custom designed for a 30-ton<br />

outdoor plate handling gantry crane.<br />

��

��<br />

• Dock Yard Cranes<br />

• Port Cranes<br />

• Ship to Shore Barge / Bucket Cranes<br />

• Container Cranes<br />

• Luffing Cranes<br />

• Multi-Purpose Revolving Boom Cranes<br />

• Iron Ore Unloader Cranes<br />

• Mine Yard Cranes

�������������<br />

��

�� ����������������<br />

���������������<br />

In conjunction with renowned industrial equipment manufacturers,<br />

<strong>PDI</strong> <strong>Solutions</strong> can provide an extensive range of specifically<br />

selected material handling equipments and components. Safety,<br />

reliability, flexibility, and high performance form the backbone of<br />

<strong>PDI</strong> <strong>Solutions</strong> standard cranes.

Stahl compact wire rope hoist<br />

Stahl compact wire rope hoist with lifting<br />

capabilities up to 25,000 kg. A low maintenance,<br />

versatile, and high performance hoist available<br />

as a base mounted version or mounted on a top<br />

running / under running trolley.<br />

���������������<br />

Stahl compact chain hoist<br />

Stahl compact chain hoist with lifting<br />

capabilities over 6,300 kg. A very durable and<br />

reliable hoist capable of providing two-speeds<br />

hoisting and traveling.<br />

Stahl open-winch wire rope hoist<br />

Stahl open-winch wire rope hoist designed<br />

for loads up to 160,000 kg. A very powerful<br />

hoist, yet very flexible and versatile for the most<br />

demanding application.<br />

�� �����������

�� ���<br />

38,000 kg waste reloading crane<br />

38,000 kg double girder overhead crane<br />

complete with spreader beam for waste<br />

reloading station.<br />

Stahl modernization<br />

3 x 10,000 kg under running<br />

double girder cranes

���������������<br />

250 kg Stahl chain hoist<br />

250 kg off-standard single-fall chain hoist with an<br />

available height of lift of 110 meters and a hoist<br />

speed of 25 m/min. Stahl chain hoists are ideal<br />

for the maintenance of wind power stations.<br />

�� ��������������������

�� ��<br />

30,000 kg paper coil crane<br />

30,000 kg double girder overhead crane complete with<br />

three (3) wire rope hoists for paper coil handling.

���������������<br />

40,000 kg cranes<br />

40,000 kg cranes equipped with<br />

motorized hook blocks, frequency<br />

inverters, radio controls, condition<br />

monitoring system including load<br />

summation and load spectrum meter<br />

for simultaneous hoist operation.<br />

Cranes for automotive facility<br />

4 x 40,000 kg / 1 x 16,000 kg double girder<br />

overhead cranes for handling of casting<br />

moulds in automotive facility.<br />

35,000 kg / 20,000 kg cranes<br />

Double girder overhead crane complete with<br />

dual-open winch hoists; 35,000 kg / 20,000 kg.<br />

�� ����

�� ������������<br />

Custom-built magnet lift system<br />

Design & build a specialized magnet load beam complete with six heavy duty<br />

magnets and controller for a bar handling application in a Steel Mill.<br />

�������������<br />

<strong>PDI</strong> SOLUTIONS can provide turnkey engineered<br />

solutions on existing AC or DC operated cranes including<br />

the complete refurbishment of hoist, trolley & bridge drive<br />

systems, the integration of AC variable frequency drives,<br />

the integration of DC contactor panel & digital drives,<br />

the integration of heavy-duty air conditioning units &<br />

heaters, the design & fabrication of operator crane cabins<br />

& console stations (ergonomically designed), and the<br />

complete upgrade of crane electrification power systems.

Crane capacity upgrade<br />

<strong>PDI</strong> <strong>Solutions</strong> engineers can provide full<br />

detailed engineering studies for increased<br />

operational capacities. All crane components<br />

can be fully analyzed in accordance to current<br />

crane standards and local safety regulations.<br />

�������������<br />

Custom-built operator’s cabin<br />

Turnkey design, fabrication, and<br />

installation of a fully-enclosed and<br />

ventilated operator’s cabin complete with<br />

an ergonomic operator console station<br />

installed on an outdoor gantry crane at a<br />

power generation facility.<br />

�� ���������

�� ������<br />

Heavy-Duty Electrical Modernization<br />

Turnkey modernization project on two low profile,<br />

ship-to-shore, container handling gantry cranes<br />

including the supply of a 5kV power cable reel and a<br />

heavy-duty I-beam type festoon system.

�������������<br />

�� ����������

�� ���<br />

Power cable reel<br />

600 volt power cable reel installed on<br />

large hydro dam gantry crane.

Custom power reel<br />

Custom designed, level wind, power<br />

cable reel equipped with 1.5 kilometers<br />

of 4 C - 5 kV - 12 pass fibre optic<br />

cabling providing total power and<br />

control requirements for a stacker/<br />

reclaimer in an iron-ore facility.<br />

Custom power reel<br />

Turnkey installation of custom<br />

power reel.<br />

�������������<br />

�� ����������������

�� ��<br />

Rebuilding of existing crane components<br />

<strong>PDI</strong> <strong>Solutions</strong> can completely rebuild existing crane components including<br />

custom gearboxes, hoist drums, bridge and trolley drive systems.

Major DC digital control upgrade<br />

Refurbishment of a four-girder type traveling steel mill<br />

crane with a 640-metric tons hoist capacity. Integrate<br />

DC digital controls on the main hoist; 4 x 265 Hp.<br />

�������������<br />

Retrofit of DC digital controls<br />

Retrofit of DC digital controls installed on a steel<br />

mill crane. Main hoist 2 x 200 Hp, auxiliary hoist<br />

65 Hp, trolley 30 Hp, and bridge 2 x 75 Hp .<br />

AC frequency drives<br />

Four-motion traveling crane complete with AC flux<br />

vector & variable frequency drives.<br />

�� ��

��������������������������������������<br />

50 Sicard Street, Local 120<br />

Ste-Therese (Quebec) Canada J7E 5R1<br />

Office: +1 450.434.7660<br />

Fax: +1 450.434.7110<br />

www.pdis.ca<br />

8<br />

PRINTED IN CANADA Infinimage inc. - 03/2010