The Advantages of Ceramic Heaters - Kyocera Americas

The Advantages of Ceramic Heaters - Kyocera Americas

The Advantages of Ceramic Heaters - Kyocera Americas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

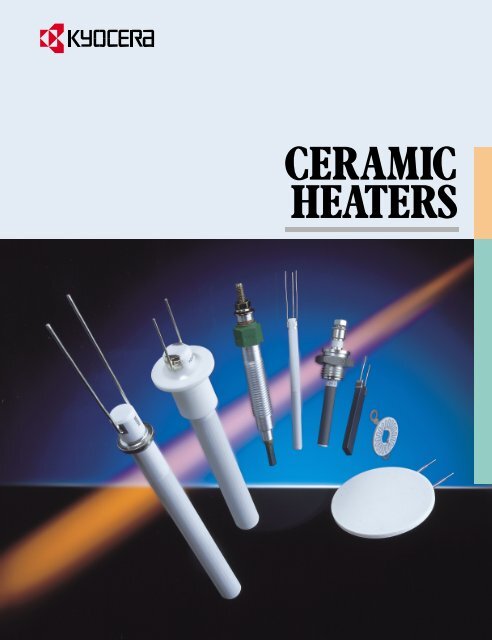

<strong>Kyocera</strong>'s <strong>Ceramic</strong> <strong>Heaters</strong> are characterized by<br />

their compact design, ability to generate heat<br />

rapidly, and high reliability under harsh<br />

environments.<br />

Alumina <strong>Heaters</strong><br />

<strong>The</strong> Alumina Heater is produced by implementing unique metallizing and<br />

ceramic laminating processes. Due to the advanced manufacturing<br />

techniques in the electric element, the Alumina Heater can provide higher<br />

reliability than ever before. It is being used, as an innovative type <strong>of</strong> heater,<br />

in such industries as Automotive, Medical, and Semiconductor.<br />

Silicon Nitride <strong>Heaters</strong> (SN <strong>Heaters</strong>)<br />

Silicon Nitride material has high temperature strength, and outstanding<br />

thermal shock resistance. <strong>Kyocera</strong> was the first company in the world to<br />

commercialize and mass produce the ceramic glow plug, made <strong>of</strong> Silicon<br />

Nitride, for the diesel engine. Due to its outstanding performance, the<br />

Silicon Nitride heater is effectively used in a wide range <strong>of</strong> industrial fields.

Alumina <strong>Heaters</strong><br />

Silicon Nitride <strong>Heaters</strong> (SN <strong>Heaters</strong>)

<strong>The</strong> <strong>Advantages</strong> <strong>of</strong> <strong>Ceramic</strong> <strong>Heaters</strong><br />

<strong>Kyocera</strong>’s ceramic heaters have unparalleled advantages over conventional heaters.<br />

Compact and Light Weight<br />

● High watt density<br />

● Multiple heating elements per unit available<br />

Superior <strong>The</strong>rmal Properties<br />

● Rapid Heat Increase<br />

● Custom designed temperature distribution<br />

available<br />

● High levels <strong>of</strong> insulation allow direct contact<br />

with metal and water<br />

● SN Heater: Heat increase to 1000˚C in one<br />

second with controller<br />

High Reliability<br />

● Superior dielectric strength and volume<br />

resistivity<br />

● Longer life due to oxidation-pro<strong>of</strong> design on<br />

resistive material<br />

● Superior chemical resistance<br />

Environmental Qualities<br />

● No electric noise<br />

● Energy-saving due to the superior thermal<br />

efficiency<br />

<strong>The</strong>rmal distribution <strong>of</strong> Alumina Heater<br />

<strong>The</strong>rmal distribution <strong>of</strong> SN Heater

Design Structure<br />

<strong>Ceramic</strong> heaters are manufactured by printing resistors on alumina sheets or silicon nitride plates, being<br />

laminated and sintered into one piece.<br />

●Plate Type<br />

●Rod Type<br />

●Tube Type<br />

Lead wire<br />

Lead wire<br />

Lead wire<br />

Configuration and Dimensions<br />

Alumina Heater<br />

SN Heater<br />

Configuration<br />

Tube/Rod<br />

Plate<br />

or<br />

Square/Round<br />

Plate<br />

Configuration<br />

Plate Type<br />

Rod Type<br />

Tube Type<br />

Dimension (mm) Tolerance (mm) Camber (mm)<br />

Length<br />

r120max<br />

r200max<br />

Diameter<br />

ø2min~ø50max<br />

ø3min~ø20max<br />

Length r50min.±1%<br />

r50max.±0.5<br />

Diameter ø10min.±2%<br />

ø10max.±0.2<br />

Side or Diameter Thickness<br />

Side or Diameter 20min.±1%<br />

160 × 160<br />

0.3min<br />

20max.±0.2<br />

or<br />

Thickness 1min.±10%<br />

ø160<br />

5.4max<br />

1max.0.1<br />

~<br />

Length ( r) Width (w) Thickness (t)<br />

30~100 4~50 1~20<br />

t<br />

w<br />

r<br />

ød<br />

Length ± 3%<br />

Width ± 3%<br />

Thickness ±10%<br />

r<br />

0.4/100<br />

0.4/100<br />

0.4/100<br />

Note: Will comply to other requirements besides the above described, whenever required.

<strong>The</strong>rmal Properties<br />

Item<br />

Maximum Use Temperature ˚Cmax 1,000 1,400<br />

Operating Temperature ˚Cmax 800 1,300<br />

<strong>The</strong>rmal Conductivity20˚C w/(m k) 18 25.0<br />

Specific Heat J/(kg ⋅ k) 0.75 × 10 3 0.64 × 103 Coef. <strong>of</strong> Linear <strong>The</strong>rmal Expansion /˚C (40~800˚C ) 7.8 × 10-6 3.4 × 10-6 Alumina Heater<br />

SN Heater<br />

(A-473)<br />

(SN-361)<br />

Mechanical Properties<br />

■Properties<br />

Alumina Heater<br />

SN Heater<br />

SN Heater<br />

Item<br />

(A-473)<br />

(SN-220)<br />

(SN-361)<br />

Vickers Hardness (Load 500g) GPa 13.7 14.7 17.1<br />

Flexural Strength MPa 310 590 740<br />

■High Temperature Strength ■<strong>The</strong>rmal Shock Durability<br />

Flexural Strength (MPa)<br />

Chemical Durability<br />

Weight Loss (mg/cm 2<br />

)<br />

6 Sulfuric Acid 95% H2SO4<br />

5<br />

3<br />

2<br />

1<br />

0<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Silicon Nitride (SN-361)<br />

Silicon Nitride (SN-220)<br />

Alumina (A-473)<br />

200 400 600 800 1000 1200 1400<br />

Alumina<br />

Silicon Nitride<br />

Ni-Mo Alloy<br />

Stainless Steel<br />

Cr Steel<br />

6 Nitric Acid 60% HNO3<br />

5<br />

3<br />

1<br />

0<br />

Alumina<br />

Silicon Nitride<br />

Ni-Mo Alloy<br />

Flexural Strength<br />

After Quick Cooling (MPa)<br />

Stainless Steel<br />

800<br />

600<br />

400<br />

200<br />

Cr Steel<br />

Silicon Nitride (SN-361)<br />

Silicon Nitride (SN-220)<br />

Alumina (A-473)<br />

(˚C)<br />

0 200 400 600 800 (˚C)<br />

6 Sodium Hydroxide 30% NaOH<br />

5<br />

3<br />

2<br />

1<br />

0<br />

Alumina<br />

Silicon Nitride<br />

Ni-Mo Alloy<br />

Stainless Steel<br />

Cr Steel

Electrical Properties<br />

1.<strong>The</strong>rmal Coefficient <strong>of</strong> Resistivity<br />

●Alumina Heater<br />

Resistance Ratio vs.<br />

Temperature<br />

●SN Heater<br />

Resistance Ratio vs.<br />

Temperature<br />

2.Dielectric Strength<br />

Resistance Ratio (Rt/R23)<br />

Resistance Ratio (Rt/R25)<br />

Volume Resistivity (MΩ)<br />

6<br />

4<br />

2<br />

Alumina Heater: Paste A 4.44 × 10 -3<br />

T.C.R.<br />

(23~800˚C)<br />

Paste B 2.96 × 10 -3 (23~800˚ C)<br />

Ni-Cr Heater 110 × 10 -6 T.C.R.<br />

(20˚C)<br />

0<br />

23 200 400 600 800 1000 (˚C)<br />

5<br />

4<br />

3<br />

2<br />

1<br />

1000<br />

0<br />

25<br />

100<br />

10<br />

0<br />

0<br />

200<br />

200<br />

400<br />

Temperature (˚C)<br />

Paste AL : T.C.R. 3.5 × 10 -3<br />

600<br />

400<br />

800<br />

Temperature (˚C)<br />

Mica Heater<br />

Alumina Heater<br />

Paste AH : T.C.R. 1.4 × 10 -3<br />

600<br />

1000<br />

Surface Temperature (˚C)<br />

1200<br />

800<br />

1400<br />

Configuration 13ø–8ø × 53r<br />

Heating Area 2,123mm2 Metal Heater<br />

(˚C)

Automotive Related Heater Applications<br />

Applications<br />

Glow Plug<br />

Intake (Burner) Heater<br />

Others<br />

Water-Heating Applications<br />

Hot Water Heater<br />

Liquid Heater for Small Appliances<br />

Heater for Toilet Water

Other Industrial Heater Applications<br />

Applications<br />

Soldering Iron<br />

Curling Iron<br />

Steam Boiler Heater<br />

Air Heater<br />

IR Source & Igniter<br />

Vaporizer