1900-7 MERV 13 CUBE BROCHURE - Tri-Dim Filter Corporation

1900-7 MERV 13 CUBE BROCHURE - Tri-Dim Filter Corporation

1900-7 MERV 13 CUBE BROCHURE - Tri-Dim Filter Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

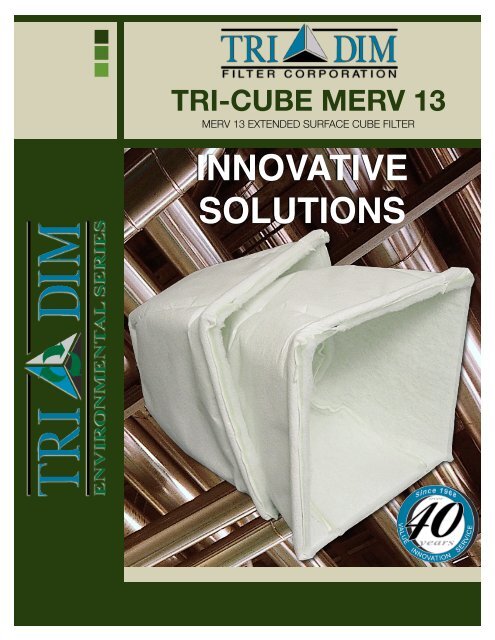

TRI-<strong>CUBE</strong> <strong>MERV</strong> <strong>13</strong><br />

<strong>MERV</strong> <strong>13</strong> EXTENDED SURFACE <strong>CUBE</strong> FILTER<br />

INNOVATIVE<br />

SOLUTIONS

<strong>MERV</strong> <strong>13</strong><br />

FEATURES<br />

LEED Points<br />

Depth Loading<br />

Media<br />

Extended Surface<br />

Area<br />

Trapezoid Shape<br />

Self Gasketing<br />

Reduced Waste<br />

to Landfill<br />

Extended <strong>Filter</strong><br />

Service Life<br />

Mold/Mildew<br />

Resistant<br />

Post Consumer<br />

Recycled Content<br />

TRI-<strong>CUBE</strong> <strong>MERV</strong> <strong>13</strong><br />

<strong>Tri</strong>-<strong>Dim</strong>’s innovative TRI-<strong>CUBE</strong> <strong>MERV</strong> <strong>13</strong> filter offers high efficiency and<br />

LEED points with all the features and benefits of the conventional TRI-<strong>CUBE</strong><br />

filters.<br />

DEPTH LOADING MEDIA - TRI-DEK® media utilizes<br />

different layers or deniers of media arranged from<br />

coarsest to finest to create a depth loading<br />

arrangement. The media is a unique needle-felted<br />

electrostatic blended synthetic. Larger particles are<br />

captured on the air entering side of the media and as<br />

the air works its way through the media finer particles<br />

are removed. This approach maximizes filter life<br />

especially when compared to pleated filters that utilize<br />

the ‘strainer‘ method of filtration. Media contains 11%<br />

Post-Consumer recycled content.<br />

AIRFLOW<br />

EXTENDED SURFACE AREA - The TRI-<strong>CUBE</strong> <strong>MERV</strong> <strong>13</strong> filter offers<br />

extended surface area in a unique trapezoid shape to maximize performance.<br />

The benefits of more surface area are a longer filter service life and a lower<br />

operating resistance (pressure drop). These will help you achieve lower<br />

energy cost, reduced filter related cost, higher efficiency, cleaner air handler<br />

surfaces, and reduced landfill waste - and these can help you achieve<br />

additional LEED credits.

SELF GASKETING - The TRI-<br />

<strong>CUBE</strong> filters use an integral wire<br />

support that is heat sealed into the<br />

media - this in turn creates the selfgasketing<br />

perimeter edge. The selfgasketing<br />

eliminates the bypass of<br />

contaminated unfiltered air around<br />

the filter. This perimeter edge<br />

allows for a ‘friction’ fit that<br />

eliminates the need for cumbersome<br />

holding clips in some applications.<br />

Self-Gasketing<br />

No Bypass<br />

MOLD/MOISTURE RESISTANT - TRI-DEK media is resistant to moisture and<br />

microbial growth – much more so than traditional cardboard framed filters.<br />

Cardboard framed filters inherently hold moisture regardless of what<br />

protective coatings are used. This means the frame will eventually deteriorate<br />

and can blow out of the air handler. The presence of moisture is also one of<br />

the key components for the growth of microbials.<br />

Microbial growth in an HVAC system can have a detrimental affect on the<br />

health of the building occupants. Microbial growth can increase allergy and<br />

asthma attacks and depending upon the specific microbial can cause<br />

illnesses - including those that are severe. TRI-<strong>CUBE</strong> filters use no cardboard<br />

or other materials that hold moisture – in-fact synthetic media and a<br />

galvanized internal wire support frame are the only materials utilized.<br />

LEED CREDITS<br />

1 Point<br />

Indoor Environmental<br />

Quality - IEQ Credit 1.4:<br />

IAQ Best Management<br />

Practices: Reduce<br />

Particulates in Air<br />

Distribution<br />

Requirement - Have in<br />

place filtration media with<br />

a minimum efficiency<br />

reporting value (<strong>MERV</strong>)<br />

greater than or equal to<br />

<strong>13</strong> for all outside air<br />

intakes and inside air<br />

recirculation returns<br />

during the performance<br />

period. Establish and<br />

follow a regular schedule<br />

for maintenance and<br />

replacement of these<br />

filters according to the<br />

manufacturer’s<br />

recommended interval.<br />

Additional LEED Credits<br />

may exist.

TRI-<strong>CUBE</strong> <strong>MERV</strong> <strong>13</strong><br />

<strong>Filter</strong> Specifications<br />

Media<br />

! ! ! ! ! ! Needle-Felted Electrostatic<br />

! ! ! ! ! ! Blended Synthetic<br />

! ! ! ! ! ! 11% Post Consumer Recycled Content<br />

Frame - Internal<br />

! ! ! ! ! ! Galvanized Steel<br />

Seal<br />

! ! ! ! ! ! Thermally Generated and Sewn<br />

Efficiency - <strong>MERV</strong><br />

! ! ! ! ! ! <strong>13</strong><br />

Initial Resistance<br />

10” Deep<br />

! 375 FPM (1.90 m/sec) ! ! 0.69” WG (172 PA)<br />

15” Deep<br />

! 375 FPM (1.90 m/sec) ! ! 0.56” WG (<strong>13</strong>9 PA)<br />

! 500 FPM (2.54 m/sec) ! ! 0.78” WG (194 PA)<br />

20” Deep<br />

! 375 FPM (1.90 m/sec) ! ! 0.35” WG (97 PA)<br />

! 500 FPM (2.54 m/sec) ! ! 0.57” WG (142 PA)<br />

Final Resistance<br />

! ! ! ! ! ! 1.5” WG (373 PA)<br />

<strong>Tri</strong>-<strong>Dim</strong> <strong>Filter</strong> <strong>Corporation</strong> is committed to continual product development – all descriptions, specifications and performance data are subject to change without notice.<br />

<strong>Tri</strong>-<strong>Dim</strong> products are manufactured to exacting criteria - there can be a ±10% variance in filter performance.<br />

<strong>Tri</strong>-<strong>Dim</strong>® and <strong>Tri</strong>-Dek® are Registered Trademarks of <strong>Tri</strong>-<strong>Dim</strong> <strong>Filter</strong> <strong>Corporation</strong>. <strong>Tri</strong>-Cube is a Trademark of <strong>Tri</strong>-<strong>Dim</strong> <strong>Filter</strong> <strong>Corporation</strong>.<br />

TRI-DIM FILTER CORPORATION<br />

P.O. BOX 466 • 93 INDUSTRIAL DRIVE<br />

LOUISA, VA 23093<br />

(540) 967-2600 • FAX: (540) 967-2835<br />

EMAIL: info@tridim.com • Website: www.tridim.com<br />

TOLL FREE 1-800-458-9835<br />

Local Representation:<br />

PLEASE RECYCLE - This paper may not be recyclable in your<br />

area if facilities do not exist. This brochure is printed on paper<br />

that is certified by the Sustainable Forestry Initiative (SFI) - for<br />

more information go to www.sfiprogram.org.<br />

Fractional Removal Efficiency<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

.35 .62 1.15 1.9 3.5 6.25<br />

Micron Size<br />

Initial Resistance<br />

20” Deep Cube<br />

0<br />

123 246 369 492 615<br />

<strong>BROCHURE</strong> #<strong>1900</strong>-7<br />

Revision: 11/2012