Brazilian Journal of Analytical Chemistry - BRJAC - Brazilian Journal ...

Brazilian Journal of Analytical Chemistry - BRJAC - Brazilian Journal ...

Brazilian Journal of Analytical Chemistry - BRJAC - Brazilian Journal ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

edua r d o sidinei ch av e s, Ju l i a n o ca rva l h o ra m o s , Kl a i a n i bez Fo n ta n a, sa m u e l mo d o l o n, a n d ad i l s o n Jo s é cu rt i u s<br />

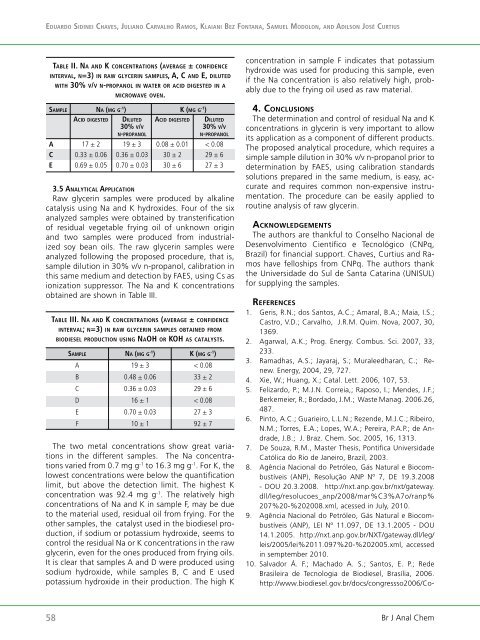

Ta b l e ii. na an d k C o n C e n T r a T i o n s (a v e r a g e ± C o n f i d e n C e<br />

i n T e r v a l, n=3) in r a w gl y C e r i n samples, a, C a n d e, d i l u T e d<br />

w iT h 30% v/v n-pr o p a n o l in wa T e r or aC i d digesTed in a<br />

m iC r o w a v e ov e n.<br />

sa m p l e na (m g g -1 ) k (m g g -1 )<br />

aCid digesTed di l u T e d aCid digesTed di l u T e d<br />

30% v/v 30% v/v<br />

n-p r o p a n o l n-p r o p a n o l<br />

A 17 ± 2 19 ± 3 0.08 ± 0.01 < 0.08<br />

C 0.33 ± 0.06 0.36 ± 0.03 30 ± 2 29 ± 6<br />

E 0.69 ± 0.05 0.70 ± 0.03 30 ± 6 27 ± 3<br />

3.5 an a l y T i C a l ap pl iC a T i on<br />

Raw glycerin samples were produced by alkaline<br />

catalysis using Na and K hydroxides. Four <strong>of</strong> the six<br />

analyzed samples were obtained by transterification<br />

<strong>of</strong> residual vegetable frying oil <strong>of</strong> unknown origin<br />

and two samples were produced from industrialized<br />

soy bean oils. The raw glycerin samples were<br />

analyzed following the proposed procedure, that is,<br />

sample dilution in 30% v/v n-propanol, calibration in<br />

this same medium and detection by FAES, using Cs as<br />

ionization suppressor. The Na and K concentrations<br />

obtained are shown in Table III.<br />

Ta b l e iii. na an d k C o n C e n T r a T i o n s (a v e r a g e ± C o n f i d e n C e<br />

i n T e r v a l; n=3) in r a w gl y C e r i n samples ob T a i n e d fr o m<br />

biodiesel pr o d u C T i o n us i n g naoh o r koh a s Ca T a l y s T s.<br />

sa m p l e na (m g g -1 ) k (m g g -1 )<br />

A 19 ± 3 < 0.08<br />

B 0.48 ± 0.06 33 ± 2<br />

C 0.36 ± 0.03 29 ± 6<br />

D 16 ± 1 < 0.08<br />

E 0.70 ± 0.03 27 ± 3<br />

F 10 ± 1 92 ± 7<br />

The two metal concentrations show great variations<br />

in the different samples. The Na concentrations<br />

varied from 0.7 mg g -1 to 16.3 mg g -1 . For K, the<br />

lowest concentrations were below the quantification<br />

limit, but above the detection limit. The highest K<br />

concentration was 92.4 mg g -1 . The relatively high<br />

concentrations <strong>of</strong> Na and K in sample F, may be due<br />

to the material used, residual oil from frying. For the<br />

other samples, the catalyst used in the biodiesel production,<br />

if sodium or potassium hydroxide, seems to<br />

control the residual Na or K concentrations in the raw<br />

glycerin, even for the ones produced from frying oils.<br />

It is clear that samples A and D were produced using<br />

sodium hydroxide, while samples B, C and E used<br />

potassium hydroxide in their production. The high K<br />

concentration in sample F indicates that potassium<br />

hydroxide was used for producing this sample, even<br />

if the Na concentration is also relatively high, probably<br />

due to the frying oil used as raw material.<br />

4. co n c l u s I o n s<br />

The determination and control <strong>of</strong> residual Na and K<br />

concentrations in glycerin is very important to allow<br />

its application as a component <strong>of</strong> different products.<br />

The proposed analytical procedure, which requires a<br />

simple sample dilution in 30% v/v n-propanol prior to<br />

determination by FAES, using calibration standards<br />

solutions prepared in the same medium, is easy, accurate<br />

and requires common non-expensive instrumentation.<br />

The procedure can be easily applied to<br />

routine analysis <strong>of</strong> raw glycerin.<br />

AcK n o w l e d g e m e n t s<br />

The authors are thankful to Conselho Nacional de<br />

Desenvolvimento Científico e Tecnológico (CNPq,<br />

Brazil) for financial support. Chaves, Curtius and Ramos<br />

have felloships from CNPq. The authors thank<br />

the Universidade do Sul de Santa Catarina (UNISUL)<br />

for supplying the samples.<br />

ref e re n c e s<br />

1. Geris, R.N.; dos Santos, A.C.; Amaral, B.A.; Maia, I.S.;<br />

Castro, V.D.; Carvalho, J.R.M. Quim. Nova, 2007, 30,<br />

1369.<br />

2. Agarwal, A.K.; Prog. Energy. Combus. Sci. 2007, 33,<br />

233.<br />

3. Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C.; Renew.<br />

Energy, 2004, 29, 727.<br />

4. Xie, W.; Huang, X.; Catal. Lett. 2006, 107, 53.<br />

5. Felizardo, P.; M.J.N. Correia,; Raposo, I.; Mendes, J.F.;<br />

Berkemeier, R.; Bordado, J.M.; Waste Manag. 2006.26,<br />

487.<br />

6. Pinto, A.C.; Guarieiro, L.L.N.; Rezende, M.J.C.; Ribeiro,<br />

N.M.; Torres, E.A.; Lopes, W.A.; Pereira, P.A.P.; de Andrade,<br />

J.B.; J. Braz. Chem. Soc. 2005, 16, 1313.<br />

7. De Souza, R.M., Master Thesis, Pontifica Universidade<br />

Católica do Rio de Janeiro, Brazil, 2003.<br />

8. Agência Nacional do Petróleo, Gás Natural e Biocombustíveis<br />

(ANP), Resolução ANP Nº 7, DE 19.3.2008<br />

- DOU 20.3.2008. http://nxt.anp.gov.br/nxt/gateway.<br />

dll/leg/resolucoes_anp/2008/mar%C3%A7o/ranp%<br />

207%20-%202008.xml, acessed in July, 2010.<br />

9. Agência Nacional do Petróleo, Gás Natural e Biocombustíveis<br />

(ANP), LEI Nº 11.097, DE 13.1.2005 - DOU<br />

14.1.2005. http://nxt.anp.gov.br/NXT/gateway.dll/leg/<br />

leis/2005/lei%2011.097%20-%202005.xml, accessed<br />

in semptember 2010.<br />

10. Salvador Á. F.; Machado A. S.; Santos, E. P.; Rede<br />

Brasileira de Tecnologia de Biodiesel, Brasília, 2006.<br />

http://www.biodiesel.gov.br/docs/congressso2006/Co-<br />

58 Br J Anal Chem