The Ferritic Solution - Euro Inox

The Ferritic Solution - Euro Inox

The Ferritic Solution - Euro Inox

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

group 1 ferritics are best suited to non-severe conditions,<br />

such as inside the home (where the material is either not<br />

exposed to water contact or gets regularly wiped dry) or<br />

outdoors in contexts where some superficial corrosion is<br />

acceptable. in such contexts, this group of ferritics has a<br />

longer life than carbon steel,.<br />

group 2 grades are effective in contexts involving<br />

intermittent contact with water, in non-severe conditions.<br />

group 3 grades are suitable for similar contexts to those<br />

appropriate for group 2 grades, but are easier to weld.<br />

group 4 ferritics are more corrosion resistant than type<br />

304 and are suitable for a wide variety of uses.<br />

group 5 includes, for example, grades with a very high<br />

chromium content of around 29% cr, plus 4% Mo, which<br />

makes them as corrosion resistant in seawater as titanium<br />

metal.<br />

“Nickel plays no role in resistance<br />

to pitting corrosion.”<br />

Storage tank, in grade 444, Brazil.<br />

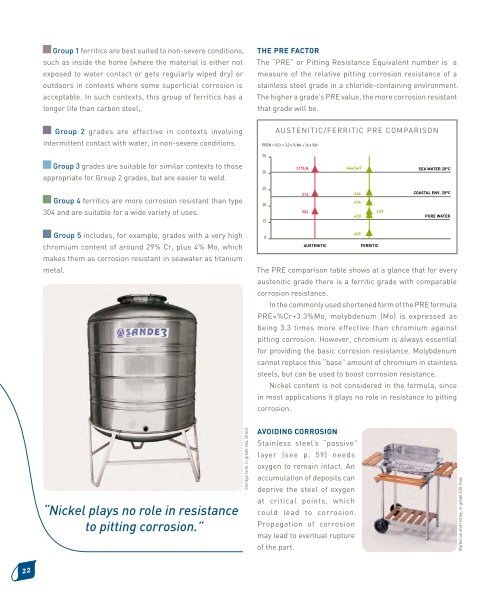

<strong>The</strong> pre FacTor<br />

the “pre” or pitting resistance equivalent number is a<br />

measure of the relative pitting corrosion resistance of a<br />

stainless steel grade in a chloride-containing environment.<br />

the higher a grade’s pre value, the more corrosion resistant<br />

that grade will be.<br />

35<br />

30<br />

25<br />

20<br />

15<br />

0<br />

the pre comparison table shows at a glance that for every<br />

austenitic grade there is a ferritic grade with comparable<br />

corrosion resistance.<br />

in the commonly used shortened form of the pre formula<br />

pre=%cr+3.3%Mo, molybdenum (Mo) is expressed as<br />

being 3.3 times more effective than chromium against<br />

pitting corrosion. however, chromium is always essential<br />

for providing the basic corrosion resistance. Molybdenum<br />

cannot replace this “base” amount of chromium in stainless<br />

steels, but can be used to boost corrosion resistance.<br />

nickel content is not considered in the formula, since<br />

in most applications it plays no role in resistance to pitting<br />

corrosion.<br />

AustENitiC/fERRitiC PRE CoMPARisoN<br />

PREN = %Cr = 3,3 x % Mo + 16 x %N<br />

avoIdIng corroSIon<br />

Stainless steel’s “passive”<br />

layer (see p. 59) needs<br />

oxygen to remain intact. an<br />

accumulation of deposits can<br />

deprive the steel of oxygen<br />

at critical points, which<br />

could lead to corrosion.<br />

propagation of corrosion<br />

may lead to eventual rupture<br />

of the part.<br />

317lN 446/447<br />

316<br />

304<br />

444<br />

436<br />

430<br />

409<br />

AUSTENITIC FERRITIC<br />

439<br />

SEA wATER 20°C<br />

CoASTAl ENv. 20°C<br />

PURE wATER<br />

Barbecue and trolley, in grade 430, Italy.