Disc Mowers Disc Mower Conditioners - New Idea - AGCO

Disc Mowers Disc Mower Conditioners - New Idea - AGCO

Disc Mowers Disc Mower Conditioners - New Idea - AGCO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

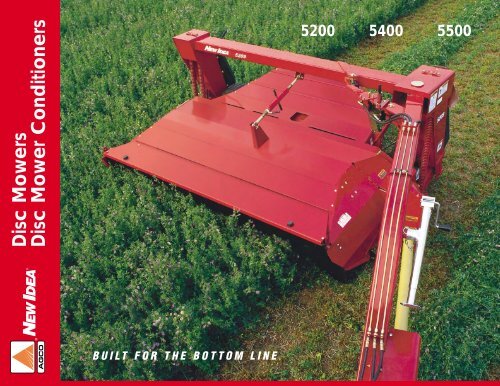

<strong>Disc</strong> <strong><strong>Mower</strong>s</strong><br />

<strong>Disc</strong> <strong>Mower</strong> <strong>Conditioners</strong><br />

5200 5400 5500

5400, 5200, 5500<br />

Innovative Design Cuts Crops —<br />

And Maintenance — Down To Size<br />

Whether you cut hundreds of<br />

hay acres or clip a handful of pasture<br />

or conservation acres, there’s a<br />

<strong>New</strong> <strong>Idea</strong> disc mower conditioner or<br />

disc mower with the rugged dependability<br />

and easy upkeep you need.<br />

Every model features low-profile,<br />

high-speed disc cutterbars that glide<br />

through fields of lush alfalfa, tangled<br />

vegetation or towering prairie grass<br />

quickly and easily, while standing up<br />

to unusual field conditions, such as<br />

gopher mounds and fireant hills, that<br />

choke and stall other mowers.<br />

<strong>New</strong> <strong>Idea</strong> developed the technology<br />

for segmented hex driveshafts and<br />

true modular cutterbars, to significantly<br />

reduce downtime and maintenance<br />

costs. Two short hex driveshafts<br />

replace six different driveshaft lengths,<br />

on the 5400 Series mowers and 5200<br />

Series mower conditioners. The new<br />

5512 mower conditioner features a<br />

low-profile cutterbar design with gear-<br />

to-gear drive for smooth operation<br />

and cutting heights down to 1.3”<br />

(33mm).<br />

On all <strong>New</strong> <strong>Idea</strong> models, the discs<br />

are oval shaped to increase the overlap<br />

for cleaner cutting. Two doubleedged<br />

knives on each disc can easily<br />

be reversed or replaced. Their modular<br />

design allows individual removal and<br />

quick servicing of any unit.<br />

Other innovative features include:<br />

A slip clutch to extend the life of the<br />

gearcase, cutterbar and PTO driveline.<br />

An overrunning clutch to protect<br />

the tractor’s PTO and driveline when<br />

the PTO is disengaged. A floating,<br />

three-point header suspension system<br />

on mower conditioners to cut close<br />

without scalping.<br />

The 5512 features a new<br />

spur-gear cutterbar for rugged<br />

durable, easy servicing, and<br />

lower power requirements.<br />

Driven by durable, segmented<br />

hex driveshafts, the alternaterotating<br />

units on the 5200 and<br />

5400 series bolt together to<br />

form the patented modular<br />

cutterbar.

5400, 5200, 5500<br />

5200 and 5500 Series <strong>Disc</strong><br />

<strong>Mower</strong> <strong>Conditioners</strong><br />

<strong>New</strong> <strong>Idea</strong> disc mower conditioners<br />

are designed to help you improve relative<br />

feed value and maximize crude<br />

protein in your hay. Thanks to innovative<br />

<strong>New</strong> <strong>Idea</strong> cutterbar technology,<br />

you’ll glide through fields of lush alfalfa<br />

and other crops quickly and easily.<br />

Yet, your crops will be treated gently,<br />

so nutrient-rich leaves and stems keep<br />

their feed value longer, maximizing<br />

your return per acre.<br />

<strong>New</strong> <strong>Idea</strong> uses brand name TiCor ®<br />

rolls that feature a unique, shallowlugged<br />

intermeshing spiral design that<br />

provides gentle handling and positive<br />

feeding. TiCor ® rolls are formed by<br />

compressing stacks of tough tire<br />

cores, which are then machined for<br />

precise roll gap adjustment. Crops are<br />

conditioned uniformly, and stems are<br />

lightly crimped to speed drydown,<br />

without damaging leaves.<br />

TiCor ® rolls also offer other distinct<br />

advantages over rubber-on-steel<br />

conditioner rolls. TiCor ® rolls absorb<br />

shocks from rocks or other foreign<br />

objects with less damage. And,<br />

because TiCor ® rolls are made out of<br />

rubber through and through, rubber<br />

can’t peel away from steel rolls.<br />

<strong>New</strong> optional drawbarmounted<br />

swivel hitch permits<br />

sharper than 90º turns<br />

without driveline stress, chatter<br />

or damage on the 5512.<br />

Thanks to hydraulic powerout<br />

plug removal on the<br />

5200 series, you can<br />

separate the conditioning<br />

rolls, quickly dislodging tree<br />

limbs and other debris,<br />

without leaving your seat.<br />

An adjustable windrow<br />

deflector shapes uniform<br />

swaths and lets you match<br />

width to crop and weather<br />

conditions, for fast, even<br />

drydown.

5400 Series <strong>Disc</strong> <strong><strong>Mower</strong>s</strong><br />

Available in five sizes, from the compact 5’6” (1.68m)<br />

Model 5406 to the big 10’4” (3.12m) Model 5410, <strong>New</strong><br />

<strong>Idea</strong> disc mowers are reliable workhorses, year after year.<br />

These strong, all-purpose mowers take on tall, tangled,<br />

thick stands at speeds other mowers can’t match.<br />

What’s more, thanks to the most reliable cutterbar<br />

technology in the industry, you’ll do more than save time<br />

in the field. You’ll also save time on upkeep, reduce<br />

downtime and cut maintenance costs. The modular<br />

cutterbar bevel gear design even lets you operate with<br />

less horsepower, further reducing operating costs.<br />

The team effort of the<br />

full-length broach and<br />

segmented hex driveshafts<br />

significantly reduces wear<br />

and tear on the mower’s<br />

drive components.<br />

When the cutterbar contacts<br />

large objects, like<br />

rocks or limbs, it automatically<br />

pivots rearward to<br />

clear the obstruction<br />

and protect the mower<br />

from damage.<br />

Outer flotation springs<br />

(optional on Models 5406<br />

and 5407) and inner flotation<br />

springs provide support for<br />

both ends of the cutterbar,<br />

reducing drag and increasing<br />

cutting efficiency.

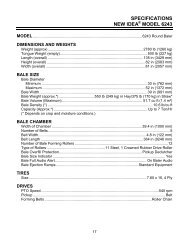

S P E C I F I C A T I O N S<br />

Model 5209 5212 5512 (Center Pivot)<br />

MOWING WIDTH 9’3” (2.82 m) 11’9” (3.58 m) 12’ (3.65 m)<br />

TRANSPORT WIDTH 11’ (3.35 m) 13’8” (4.16 m) 12’6” (3.81 m)<br />

GROUND CLEARANCE 14” (356 mm) 14” (356 mm) 14” (356 mm)<br />

(Below cutterbar with header raised)<br />

DRIVE SYSTEM Constant Velocity Driveline Constant Velocity Driveline U-joints and swivel gearboxes -or-<br />

Constant Velocity Driveline (Standard Tongue)<br />

CUTTERBAR<br />

Type Modular <strong>Disc</strong> Modular <strong>Disc</strong> Modular <strong>Disc</strong><br />

Drive Segmented Shaft & Beveled Gears Segmented Shaft & Beveled Gears Spur Gear<br />

DISCS<br />

Number 7 9 8<br />

Knives Per <strong>Disc</strong> 2 2 2<br />

<strong>Disc</strong> Speed 3000 rpm 3000 rpm 2600 rpm<br />

Knife Tip Speed 175.8 mph (282.9 kph) 175.8 mph (282.9 kph) 184 mph 296 kph)<br />

CONDITIONING ROLLS<br />

Inches 84” (2.13 m) 114” (2.90 m) 110” (2.79 m)<br />

Type Spiral Intermeshing Machined Ti-Cor ® Rolls Spiral Intermeshing Machined Ti-Cor ® Rolls Spiral Intermeshing Machined Ti-Cor ® Rolls<br />

Diameter 9 1/2” (240 mm) 9 1/2” (240 mm) 8” (203 mm)<br />

Speed 735 rpm 735 rpm 1100 rpm<br />

Windrow/Swath Width 30” to 72” (760-1830 mm) 32” to 98” (810-2490 mm) 36” to 106” (910-2690 mm)<br />

Drive Type Enclosed Lubricant Gears Enclosed Lubricant Gears Enclosed Lubricant Gears<br />

with U-joints with U-joints with U-joints<br />

TRACTOR REQUIREMENTS<br />

Horsepower* 60 hp (44.7 kW) 75 hp (55.9 kW) 85 hp (63 kW)<br />

Hydraulics One double or single-acting & Two double-acting Two double-acting remote valves<br />

One double-acting<br />

PTO 540 rpm 540 rpm (1000 rpm optional) 1000 rpm<br />

Weight (Shipping) 3240 lbs (1458 kg) 4300 lbs (2189 kg) 5970 lbs (2708 kg)<br />

TIRES 9.5L x 14SL 6-ply 11L x 14SL 6-ply 11L x 15<br />

TRANSPORT LIGHTS Standard Standard Standard<br />

TOPPING SKIDS Optional Optional Optional<br />

* NOTE: These are minimum horsepower requirements based on machine size and power requirements.<br />

Some crops and conditions will require more power for the machine to properly operate.

<strong>Disc</strong> Models 5406 5407 5408 5409 5410<br />

MOWING WIDTH. 5’6” (1.68 m) 6’8” (2.03 m) 7’10” (2.38 m) 9’2” (2.79 m) 10’4” (3.12 m)<br />

DISCS 4 5 6 7 8<br />

KNIVES PER DISC 2 2 2 2 2<br />

DISC SPEED 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpm<br />

PTO REQUIREMENTS 30 hp 35 hp 40 hp 45 hp 50 hp<br />

WEIGHT (Approx.) 1,100 lbs (499 kg) 1,165 lbs (528 kg) 1,340 lbs (608 kg) 1,425 lbs (646 kg) 1,510 (685 kg)<br />

POWER BELT (B-Section) 3V “HB” 3V “HB” 4V “HB” 4V Banded “HB” 4V Banded “HB”<br />

OVERRUNNING CLUTCH Standard Standard Standard Standard Standard<br />

PARKING STAND Standard Standard Standard Standard Standard<br />

OUTER FLOTATION SPRING Option Option Standard Standard Standard<br />

Options include: Offset hitch (5406 and 5407), topping skids, swathboard and tall crop divider. High lift knives and inner crop divider available through service parts.

Every piece of <strong>New</strong> <strong>Idea</strong> equipment comes with one benefit nobody else can match –<br />

the support of your <strong>New</strong> <strong>Idea</strong> dealer. Only your <strong>New</strong> <strong>Idea</strong> dealer can deliver the complete line of<br />

rugged, dependable <strong>New</strong> <strong>Idea</strong> hay tools you want, along with the genuine parts and service you need.<br />

Talk to your dealer about <strong>New</strong> <strong>Idea</strong> disc mowers, disc mower conditioners and other <strong>New</strong> <strong>Idea</strong><br />

equipment, as well. And ask about special financing programs available through <strong>AGCO</strong> Finance, to<br />

help you with flexible purchase options, flexible down payments, competitive variable and fixed rates,<br />

and flexible payment terms.<br />

© 2001<strong>AGCO</strong> Corporation. Printed in the U.S.A. <strong>AGCO</strong>®<strong>New</strong> <strong>Idea</strong> may at any time, and from time to time, for technical or other necessary reasons, modify<br />

any of the data or specifications of the products described herein. The information contained in this brochure is intended to be of a general nature only,<br />

specific operations may vary from the average, and both crop and machine management, as well as the weather, are important factors in the end result.<br />

Attention! Photographs in this publication may show protective shields or guards opened or removed for the purposes of illustration. Be certain all shields and<br />

guards are in place during operation. <strong>AGCO</strong> Corporation • 4205 River Green Parkway• Duluth, Georgia 30096 • 1-800-767-3221 • Fax: 770-813-6030<br />

www.newidea.agcocorp.com • (07)20<br />

NI01393