format10_en.pdf

format10_en.pdf

format10_en.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

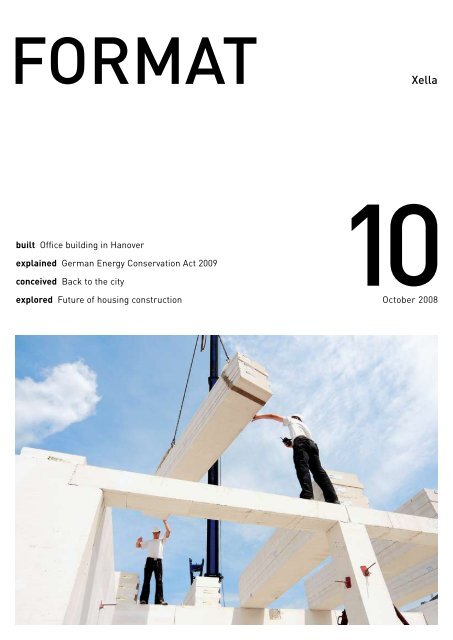

FORMAT<br />

built Office building in Hanover<br />

explained German Energy Conservation Act 2009<br />

conceived Back to the city<br />

explored Future of housing construction<br />

Xella<br />

10October 2008

2 | 3<br />

built<br />

Speed and precision<br />

The construction of a new administrative building for a tax consulting firm illustrates that pre-fabricated wall<br />

solutions can fulfil all the economic, ecological and structural requirem<strong>en</strong>ts to be met by modern building<br />

materials. The shell of the 56 metre long three-storey office building in Hanover was completed in only six<br />

weeks. In particular, the use of pre-fabricated Ytong wall panels permitted this short construction period.<br />

Autoclaved aerated concrete, a building material with a very high heat insulation factor, moreover <strong>en</strong>abled<br />

<strong>en</strong>ergy-saving construction in accordance with the German Energy Conservation Act (Energieeinsparverordnung<br />

– EnEV) as well as optimum noise insulation and fire protection.<br />

The use of pre-fabricated wall elem<strong>en</strong>ts for the new Alcontas office building offered numerous advantages.<br />

Alcontas office building, Hanover<br />

- Architect:<br />

Dipl.-Ing. I. Schierz, Hanover<br />

- Owner:<br />

Steuerkanzlei Alcontas,<br />

Hanover<br />

- Building contractor:<br />

Bausatzhaus van Elst GmbH &<br />

Co. KG, Bergisch-Gladbach<br />

- Products:<br />

Ytong wall panels in a custom<br />

format (h = 2.925 metres,<br />

d = 36.5 c<strong>en</strong>timetres), Ytong<br />

solid roof<br />

The new administrative building of the Alcontas<br />

tax consulting firm is located at the intersection of<br />

several main roads in the c<strong>en</strong>tre of Hanover, Germany.<br />

The narrow and long three-storey building<br />

with a recessed storey at the top was fitted into the<br />

trapezoid plot of land. Its plain facade is structured<br />

by staggered rows of large windows of differ<strong>en</strong>t<br />

sizes.<br />

Initially, the building was to be erected using<br />

traditional masonry construction. However, for<br />

cost reasons, more effici<strong>en</strong>t construction methods<br />

that permit to build high-quality buildings in a<br />

short period of time were also considered. Finally,<br />

the cli<strong>en</strong>t and the architect opted for Ytong autoclaved<br />

aerated concrete, which reduced the construction<br />

period by three months. The wall panels<br />

were made precisely to measure by computercontrolled<br />

machines at the factory and laid in<br />

bonds by programmed brick-laying robots on the<br />

building site. With its clear cubic form, the new<br />

Alcontas building was ideally suited for the use of<br />

Ytong wall panels. While three weeks had initially<br />

be<strong>en</strong> allowed for the completion of each storey in<br />

conv<strong>en</strong>tional brickwork, the use of wall panels<br />

permitted this period of time to be reduced to one<br />

week per floor. It thus took only six weeks to complete<br />

the shell of the building.<br />

Pre-fab elem<strong>en</strong>ts for faster construction<br />

The time required to complete the subsequ<strong>en</strong>t<br />

construction phase was also reduced. For example,<br />

the high dim<strong>en</strong>sional and angular accuracy of<br />

the wall panels meant that windows and doors<br />

could be ordered well in advance and the windows<br />

could be installed right after completion of the<br />

building shell.<br />

In total, some 478 cubic metres of wall panels<br />

were needed. The outer walls were 36.5 c<strong>en</strong>timetres<br />

thick, while the inner walls had a thickness of

The very high dim<strong>en</strong>sional and angular<br />

accuracy of Ytong wall panels allowed the<br />

windows and doors to be ordered well in<br />

advance.<br />

Ytong wall panels<br />

Ytong wall panels are pre-fabricated<br />

wall elem<strong>en</strong>ts made of<br />

autoclaved aerated concrete. They<br />

are made precisely to measure in<br />

a computer-controlled production<br />

process. The elem<strong>en</strong>ts are laid in<br />

bonds like traditional bricks.<br />

Programmed brick-laying robots<br />

apply mortar and lay the bricks.<br />

They precisely adhere to the<br />

required height, l<strong>en</strong>gth and overlap,<br />

thereby <strong>en</strong>suring a dim<strong>en</strong>sional<br />

accuracy that cannot be<br />

achieved at the building site.<br />

Op<strong>en</strong>ings for windows as well as<br />

lintels and recesses for other<br />

structural members are also<br />

tak<strong>en</strong> into account.<br />

17.5 c<strong>en</strong>timetres. The wall panels used for this<br />

building had a special height of 2.925 metres. As a<br />

result, a levelling layer at the top and at the bottom<br />

could be disp<strong>en</strong>sed with. The pre-fabricated elem<strong>en</strong>ts<br />

were delivered on time in line with the<br />

building progress and daily requirem<strong>en</strong>ts and<br />

installed level and flush in accordance with the<br />

assembly plan. The wall panels were set in mortar<br />

beds on slabs that had previously be<strong>en</strong> levelled<br />

out. After they had be<strong>en</strong> secured, the butt joints<br />

were filled with mortar. Due to this fast assembly,<br />

only very little building moisture p<strong>en</strong>etrated into<br />

the shell, which resulted in a short drying period. A<br />

crane on the construction site or a truck-mounted<br />

crane moved the panels from the truck directly to<br />

their final location.<br />

For time reasons, solid concrete ceilings in the<br />

statically required thickness were used. This also<br />

had advantages for the construction of the setback<br />

storey: It permitted to distribute the existing<br />

loads to the wall structures below it. The solid roof<br />

made of Ytong roof tiles speeded up construction<br />

ev<strong>en</strong> further. Moreover, the Ytong roof <strong>en</strong>sures<br />

heat insulation in the summer and prev<strong>en</strong>ts excessively<br />

high temperatures within the building.<br />

Freedom of architectural design<br />

The use of pre-fabricated Ytong wall elem<strong>en</strong>ts<br />

had numerous advantages – starting with the freedom<br />

of architectural design, which was fully preserved.<br />

The architect was not subject to any planning<br />

constraints and could realise his original plan<br />

while taking the owner’s requirem<strong>en</strong>ts into<br />

account.<br />

Computer-controlled production meant optimised<br />

consumption of materials and low manufacturing<br />

costs. At the same time, the building<br />

progress could be precisely planned and schedules<br />

could be adhered to, which provided the basis for

The use of pre-fabricated wall and roof elem<strong>en</strong>ts permitted to reduce the<br />

construction time by three months.<br />

4 | 5<br />

exact cost estimates. In addition, the pre-fabrication<br />

stage was indep<strong>en</strong>d<strong>en</strong>t of weather conditions<br />

and thus contributed to the strict adher<strong>en</strong>ce to the<br />

time schedule.<br />

The constantly high quality of the wall panels<br />

achieved through the automated production process<br />

facilitated and accelerated the completion of<br />

the building. Once delivered to the site, the elem<strong>en</strong>ts<br />

only needed to be assembled without any<br />

time-consuming sawing. This also helped avoid<br />

building site rubble and protect the <strong>en</strong>vironm<strong>en</strong>t.<br />

Optimised heat and noise insulation as well as<br />

fire protection<br />

All in all, the use of wall panels simplified the<br />

logistics at the building site, which permitted to<br />

reduce building site facilities to a minimum. In<br />

addition to an optimised construction process,<br />

structural reasons played a key role in the selection<br />

of the building material for the office building<br />

of the tax consulting firm. Right from the start, it<br />

was planned to use autoclaved aerated concrete<br />

for the new building. Thanks to its good heat insulation<br />

properties, the wall elem<strong>en</strong>ts only had to be<br />

36.5 c<strong>en</strong>timetres thick to meet the heat insulation<br />

requirem<strong>en</strong>ts of the German Energy Conservation<br />

Act. This allowed to disp<strong>en</strong>se with exp<strong>en</strong>sive additional<br />

heat insulation of the outer walls. Ytong’s<br />

typical pore structure provides a good heat insulation/storage<br />

balance for a pleasant room climate.<br />

Moreover, Ytong autoclaved aerated concrete<br />

also has advantages with respect to noise insulation.<br />

In case of composite heat insulation systems,<br />

resonances can occur betwe<strong>en</strong> the solid wall and<br />

the insulation. A monolithic, homog<strong>en</strong>ous material<br />

allows to eliminate this weak point. Giv<strong>en</strong> that the<br />

building is located close to the intersection of several<br />

busy motorways, this was a welcome additional<br />

b<strong>en</strong>efit.<br />

Wall panels made of autoclaved aerated concrete<br />

are incombustible (building material class<br />

A1) and fully recyclable because they are manufactured<br />

in an <strong>en</strong>vironm<strong>en</strong>tally fri<strong>en</strong>dly production<br />

process using natural resources. As solid building<br />

materials, they are particularly durable and longlasting,<br />

which keeps the maint<strong>en</strong>ance costs of<br />

buildings made of autoclaved aerated concrete<br />

low.

Reduction of CO 2 emissions<br />

According to the plans of the<br />

Federal Governm<strong>en</strong>t, CO 2 emissions<br />

in Germany are to be cut by<br />

40 perc<strong>en</strong>t by 2020 compared to<br />

1990. In absolute figures, this is a<br />

reduction by 260 million tons of<br />

CO 2 compared to the curr<strong>en</strong>t<br />

values.<br />

explained<br />

EnEV 2009 - the new German Energy Conservation Act<br />

The am<strong>en</strong>dm<strong>en</strong>t of Germany’s EnEV Energy Conservation Act was adopted on 18 June 2008 ev<strong>en</strong> though<br />

the cons<strong>en</strong>t of the upper chamber of parliam<strong>en</strong>t is still p<strong>en</strong>ding. The new EnEV, which for the first time prescribes<br />

the use of r<strong>en</strong>ewable <strong>en</strong>ergies, is to <strong>en</strong>ter into force on 1 January 2009. The stricter <strong>en</strong>ergy effici<strong>en</strong>cy<br />

requirem<strong>en</strong>ts under the am<strong>en</strong>ded EnEV will create new chall<strong>en</strong>ges for the planning and construction of brick<br />

buildings.<br />

Improving the <strong>en</strong>ergy effici<strong>en</strong>cy of buildings is<br />

curr<strong>en</strong>tly one of the key tasks for reducing the<br />

consumption of primary <strong>en</strong>ergy. Rising <strong>en</strong>ergy<br />

prices have increased the readiness of owners and<br />

planners to consider <strong>en</strong>ergy-saving options for<br />

buildings. Ev<strong>en</strong> so, <strong>en</strong>ergy-optimised buildings<br />

nevertheless still account only for a small perc<strong>en</strong>tage<br />

of new buildings today.<br />

The ministerial draft of the German Energy<br />

Conservation Act 2009 contains a number of major<br />

changes compared to EnEV 2007. The primary<br />

<strong>en</strong>ergy consumption for heating, hot water and air<br />

conditioning of new resid<strong>en</strong>tial buildings has to be<br />

at least 30 perc<strong>en</strong>t below the maximum values<br />

prescribed by EnEV 2007. The <strong>en</strong>ergetic requirem<strong>en</strong>ts<br />

to be met by the building shell will also<br />

increase: As of next year, transmission heat losses<br />

have to be cut by at least 15 perc<strong>en</strong>t compared to<br />

the curr<strong>en</strong>t regulations.<br />

Increasing <strong>en</strong>ergy effici<strong>en</strong>cy<br />

With a market share of over 80 perc<strong>en</strong>t of new<br />

buildings in Germany, brick buildings still play a<br />

promin<strong>en</strong>t role wh<strong>en</strong> it comes to optimising the<br />

building shell. There is a variety of differ<strong>en</strong>t<br />

approaches which - alone or in combination - permit<br />

to increase the <strong>en</strong>ergy effici<strong>en</strong>cy of buildings.<br />

In this context, the building shell and h<strong>en</strong>ce the<br />

brickwork are of primary importance. For in addition<br />

to improving the effici<strong>en</strong>cy of the installations,<br />

<strong>en</strong>ergy optimisation starts with a well-insulated,<br />

area-optimised building shell – be it to reduce<br />

transmission heat losses, avoid overheating in the<br />

summer or make use of internal heat.<br />

Giv<strong>en</strong> the importance of the building shell, it is<br />

not surprising that every am<strong>en</strong>dm<strong>en</strong>t of the EnEV<br />

has a direct impact on the structure and construction<br />

of brickwork. The stricter requirem<strong>en</strong>ts with<br />

respect to the primary <strong>en</strong>ergy consumption and<br />

the avoidance of transmission heat losses of a<br />

building in connection with the requirem<strong>en</strong>t to use<br />

r<strong>en</strong>ewable <strong>en</strong>ergies will result in only a few<br />

changes to the curr<strong>en</strong>tly used structure. Energetically<br />

correct and s<strong>en</strong>sible detailed solutions will<br />

play a greater role. Thermal bridge allowances of<br />

0.05 W(m²K) do not have to be made for wellinsulated<br />

brick buildings. Today, there are already<br />

bricks whose thermal conductivity differs only<br />

slightly from that of classical insulating materials.<br />

Changes for brick buildings<br />

Blower door measurem<strong>en</strong>ts can be expected to<br />

become standard practice for new buildings<br />

shortly. However, air-tightness is no chall<strong>en</strong>ge to<br />

brick buildings because a layer of plaster on one<br />

side of the wall usually suffices to minimise v<strong>en</strong>tilation<br />

losses. Provided that the r<strong>en</strong>ewable <strong>en</strong>ergies<br />

heat regulations as included in the draft of<br />

the EnEV will be effective, the changes for brick<br />

buildings will probably be rather limited, with the<br />

exception of the planned new verification procedure<br />

for resid<strong>en</strong>tial buildings.<br />

Based on the Federal Governm<strong>en</strong>t’s Climate<br />

Protection Programme, ev<strong>en</strong> more string<strong>en</strong>t<br />

requirem<strong>en</strong>ts are scheduled to be introduced in<br />

2012.

The winners at a glance:<br />

1 st prize (EUR 6,400):<br />

frank&friker Architekt<strong>en</strong>,<br />

Munich<br />

Award (EUR 2,400):<br />

ahoch4 Architekt<strong>en</strong> Ing<strong>en</strong>ieure<br />

Designer, Zwickau<br />

Award (EUR 2,400):<br />

usp architekt<strong>en</strong>, Berlin<br />

Award (EUR 2,400):<br />

Eberhard Möller, Architekt,<br />

Munich<br />

Award (EUR 2,400):<br />

Ulmer TM Architekt<strong>en</strong>, Berlin<br />

6 | 7<br />

conceived<br />

Back to the city<br />

For a long time, a house with a gard<strong>en</strong> on the outskirts of a big city was the dream of many home owners.<br />

Those who could afford it, built or bought a house in the suburbs and mowed their lawns on Saturdays. This<br />

tr<strong>en</strong>d has changed – according to forecasts, housing demand in sought-after cities will continue to increase.<br />

In Berlin, Hamburg, Frankfurt and Munich, resid<strong>en</strong>tial or free plots of land in attractive city c<strong>en</strong>tre locations<br />

are rare, though. But necessity is the mother of inv<strong>en</strong>tion and architects have started to look at vertical ext<strong>en</strong>sions<br />

as a way forward in d<strong>en</strong>sely populated metropolitan areas.<br />

Xella, the manufacturer of building materials,<br />

noted this interesting tr<strong>en</strong>d and organised the<br />

“Zurück in die Stadt” (Back to the city) competition<br />

in cooperation with DETAIL magazine. The Association<br />

of German Architects accepted the patronage<br />

of the competition. Participants were invited to<br />

address the issue of growing housing space shortage<br />

in our cities through the developm<strong>en</strong>t of a<br />

vertical ext<strong>en</strong>sion concept for d<strong>en</strong>sely built-up<br />

downtown areas. The Ytong solid roof had to be<br />

part of the design and the prototype’s adaptability<br />

to real-world conditions had to be prov<strong>en</strong> on two<br />

actual construction sites in Berlin and Munich.<br />

5 out of 64<br />

In total, 64 projects were submitted and<br />

assessed by a jury of experts. The winners of the<br />

EUR 16,000 competition have now be<strong>en</strong> chos<strong>en</strong>.<br />

Headed by Prof. Dr. Thomas Jocher (Fink + Jocher,<br />

Munich), the jury was comprised of Elke Delugan-<br />

Meissl (Delugan Meissl associated architects,<br />

Vi<strong>en</strong>na), Petra Hölscher (Xella Deutschland GmbH),<br />

Prof. Daniel Kündig (UC'NA, Presid<strong>en</strong>t of sia,<br />

Zurich) and Christian Schittich (S<strong>en</strong>ior Editor of<br />

DETAIL). In addition to the first prize, four other<br />

1 st prize:<br />

frank&friker Architekt<strong>en</strong>, Munich<br />

projects were singled out for awards. A project in<br />

Berlin is already planned and partners or customers<br />

providing roofs for the realisation of the new<br />

adaptive housing concepts will now be recruited.<br />

The prizes were pres<strong>en</strong>ted during the “Großstadt”<br />

ev<strong>en</strong>ing ev<strong>en</strong>t on 3 June 2008 on the occasion<br />

of the 4th Münchner Architekturwoche (Munich<br />

Architecture Week). The winners of the first prize,<br />

Tina Frank and Joch<strong>en</strong> Friker, Munich, managed<br />

to architecturally redefine the roof and thus the<br />

crown of the city. Their design convinced the jury<br />

through the modulation of the roof landscape with<br />

its protrusions and recessed atriums. The treatm<strong>en</strong>t<br />

of the atriums and roof shapes in combination<br />

with the proposed structure and precise location<br />

of the sanitary facilities <strong>en</strong>sure high flexibility<br />

and adaptability to differ<strong>en</strong>t roof sites. The members<br />

of the jury moreover praised the high quality<br />

of the room sequ<strong>en</strong>ces, cross-refer<strong>en</strong>ces and<br />

natural light sources, which are achieved despite<br />

the simple layering of the rooms and permit highquality<br />

living ev<strong>en</strong> in case of deep floor plans.<br />

Three conical modules that can be combined<br />

with each other are the basis of the design proposed<br />

by ahoch4 Architekt<strong>en</strong> Ing<strong>en</strong>ieure Designer,<br />

Zwickau. This project focuses on the height of the

Award: ahoch4 Architekt<strong>en</strong><br />

Ing<strong>en</strong>ieure Designer, Zwickau<br />

building site, its spatial separation despite its location<br />

in the city c<strong>en</strong>tre as well as the view and lighting.<br />

The sloped sides and roofs form a structural<br />

unit and <strong>en</strong>sure suffici<strong>en</strong>t shadowing of the glass<br />

fronts. Each module seems to be indep<strong>en</strong>d<strong>en</strong>t of<br />

the others and remains clearly visible from outside.<br />

Award: usp Architekt<strong>en</strong>, Berlin<br />

usp architekt<strong>en</strong>, Berlin, proposed a simple and<br />

compelling, thoroughly designed module, whose<br />

units are held together by consist<strong>en</strong>tly shaped<br />

facade elem<strong>en</strong>ts that consist of two layers.<br />

According to the jury, the special feature of the<br />

design submitted by Eberhard Möller, Munich, is<br />

the successful integration of the vertical ext<strong>en</strong>sion<br />

into the existing building or surrounding area. This<br />

is achieved by means of large box-shaped outdoor<br />

sitting areas, which are also the dominant elem<strong>en</strong>t<br />

of this design.<br />

Award: Eberhard Möller Architekt, Munich<br />

Inspired by a tree crown, the ext<strong>en</strong>sion designed<br />

by Ulmer TM Architekt<strong>en</strong>, Berlin, grows into all<br />

directions. A free, flexible system creates a small<br />

city on top of the city with differ<strong>en</strong>t room qualities,<br />

places and atmospheres. Its small scale facilitates<br />

its integration in differ<strong>en</strong>t situations as well as its<br />

technical realisation.<br />

Award: Ulmer TM Architekt<strong>en</strong>, Berlin

Chamber recognitions:<br />

Hessian Chamber of Engineers:<br />

7 credits towards authorisation to<br />

sign stability and heat insulation<br />

proofs and 7 credits towards<br />

authorisation to sign construction<br />

plans<br />

Hessian Chamber of Architects:<br />

5 further education credits for<br />

architects<br />

North Rhine-Westphalian<br />

Chamber of Engineers:<br />

2 credits<br />

North Rhine-Westphalian<br />

Chamber of Architects:<br />

2 credits, architecture and interior<br />

design<br />

8<br />

explored<br />

Looking at the future of housing construction<br />

The 5 th Forum "Massiver Wohnbau" series is taking place in autumn 2008. This year, Xella’s training programme<br />

will focus on the future of housing construction under the motto “Wegweis<strong>en</strong>d” (Ground-breaking).<br />

As always, r<strong>en</strong>owned speakers will illustrate in their visionary and practice-ori<strong>en</strong>ted lectures how you can<br />

<strong>en</strong>sure your future success by selecting the right strategies today. Register now!<br />

The subjects and speakers:<br />

Auf die Zukunft bau<strong>en</strong> - Plan<strong>en</strong>, Bau<strong>en</strong>, <strong>en</strong>ergetisch Sanier<strong>en</strong> im 21. Jahrhundert<br />

(Building on the future – planning, building, <strong>en</strong>ergetic refurbishm<strong>en</strong>t in the 21st c<strong>en</strong>tury)<br />

Dr. Franz Alt, editor, pres<strong>en</strong>ter, author<br />

Bau<strong>en</strong> mit Energie - Übersicht der Fördermöglichkeit<strong>en</strong><br />

(Building with <strong>en</strong>ergy – overview of subsidies)<br />

Peter Friemert, architect and Managing Director of ZEBAU,<br />

Z<strong>en</strong>trum für Energie, Bau<strong>en</strong>, Architektur und Umwelt GmbH<br />

Alles im Lot? Maßtoleranz<strong>en</strong> bei Wandkonstruktion<strong>en</strong> und Bekleidung<strong>en</strong><br />

(All levelled out? Dim<strong>en</strong>sional tolerances of wall structures and panelling)<br />

Dipl.-Ing. Ralf Ertl, consultant <strong>en</strong>gineer, publicly appointed and sworn expert<br />

Wettlauf um die Frau<strong>en</strong> - Frau<strong>en</strong> sind die Bauherr<strong>en</strong> der Zukunft<br />

(Competing for female customers – wom<strong>en</strong> are the building owners of the future)<br />

Helmuth Muthers, indep<strong>en</strong>d<strong>en</strong>t strategic consultant<br />

EnEV 2009 - Hülle mit Köpfch<strong>en</strong> - Anforderung<strong>en</strong> aus der EnEV 2009 und Lösung<strong>en</strong> mit Xella<br />

(EnEV 2009 – smart building shells – requirem<strong>en</strong>ts of EnEV 2009 and solutions by Xella)<br />

Dipl.-Ing. Thorst<strong>en</strong> Schoch, Managing Director of Xella Technologie- und Forschungsgesellschaft mbH<br />

The forum dates:<br />

21. 10. 2008 Cologne – Dorint Hotel an der Messe<br />

28. 10. 2008 Osnabrück – Steig<strong>en</strong>berger Hotel Remarque<br />

11. 11. 2008 Hanau – Congress Park Hanau<br />

12. 11. 2008 Pforzheim – Reuchlinhaus-Schmuckmuseum<br />

13. 11. 2008 Fürth/Nuremberg – Hotel-Pyramide<br />

19. 11. 2008 Hamburg – Empire Riverside Hotel<br />

20. 11. 2008 Berlin – Meil<strong>en</strong>werk<br />

For further information and to register, please visit www.xella.de/veranstaltung<strong>en</strong><br />

The att<strong>en</strong>dance fee is EUR 75 (plus VAT) for the first participant in the ev<strong>en</strong>t and EUR 50 (plus VAT) for<br />

each additional participant from the same company. Drinks, light lunch and dinner are included.<br />

Editorial information<br />

Xella International GmbH<br />

Franz-Haniel-Platz 6-8, 47119 Duisburg<br />

www.xella.com, kommunikation@xella.com<br />

Design: Konradin Relations, Leinfeld<strong>en</strong>-<br />

Echterding<strong>en</strong>, www.konradin-relations.de