format10_en.pdf

format10_en.pdf

format10_en.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

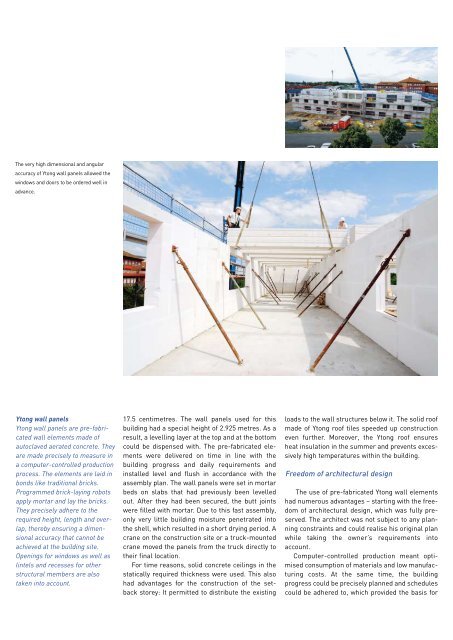

The very high dim<strong>en</strong>sional and angular<br />

accuracy of Ytong wall panels allowed the<br />

windows and doors to be ordered well in<br />

advance.<br />

Ytong wall panels<br />

Ytong wall panels are pre-fabricated<br />

wall elem<strong>en</strong>ts made of<br />

autoclaved aerated concrete. They<br />

are made precisely to measure in<br />

a computer-controlled production<br />

process. The elem<strong>en</strong>ts are laid in<br />

bonds like traditional bricks.<br />

Programmed brick-laying robots<br />

apply mortar and lay the bricks.<br />

They precisely adhere to the<br />

required height, l<strong>en</strong>gth and overlap,<br />

thereby <strong>en</strong>suring a dim<strong>en</strong>sional<br />

accuracy that cannot be<br />

achieved at the building site.<br />

Op<strong>en</strong>ings for windows as well as<br />

lintels and recesses for other<br />

structural members are also<br />

tak<strong>en</strong> into account.<br />

17.5 c<strong>en</strong>timetres. The wall panels used for this<br />

building had a special height of 2.925 metres. As a<br />

result, a levelling layer at the top and at the bottom<br />

could be disp<strong>en</strong>sed with. The pre-fabricated elem<strong>en</strong>ts<br />

were delivered on time in line with the<br />

building progress and daily requirem<strong>en</strong>ts and<br />

installed level and flush in accordance with the<br />

assembly plan. The wall panels were set in mortar<br />

beds on slabs that had previously be<strong>en</strong> levelled<br />

out. After they had be<strong>en</strong> secured, the butt joints<br />

were filled with mortar. Due to this fast assembly,<br />

only very little building moisture p<strong>en</strong>etrated into<br />

the shell, which resulted in a short drying period. A<br />

crane on the construction site or a truck-mounted<br />

crane moved the panels from the truck directly to<br />

their final location.<br />

For time reasons, solid concrete ceilings in the<br />

statically required thickness were used. This also<br />

had advantages for the construction of the setback<br />

storey: It permitted to distribute the existing<br />

loads to the wall structures below it. The solid roof<br />

made of Ytong roof tiles speeded up construction<br />

ev<strong>en</strong> further. Moreover, the Ytong roof <strong>en</strong>sures<br />

heat insulation in the summer and prev<strong>en</strong>ts excessively<br />

high temperatures within the building.<br />

Freedom of architectural design<br />

The use of pre-fabricated Ytong wall elem<strong>en</strong>ts<br />

had numerous advantages – starting with the freedom<br />

of architectural design, which was fully preserved.<br />

The architect was not subject to any planning<br />

constraints and could realise his original plan<br />

while taking the owner’s requirem<strong>en</strong>ts into<br />

account.<br />

Computer-controlled production meant optimised<br />

consumption of materials and low manufacturing<br />

costs. At the same time, the building<br />

progress could be precisely planned and schedules<br />

could be adhered to, which provided the basis for