in this issue - Electricity Today Magazine

in this issue - Electricity Today Magazine

in this issue - Electricity Today Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Transformer Study<br />

Cont<strong>in</strong>ued from Page 48<br />

The rupture disks manufactured for the TRANSFORMER<br />

PROTECTOR are made of sta<strong>in</strong>less steel and dimensioned for<br />

different tarred pressures. For <strong>this</strong> study, a 0.8 bar set po<strong>in</strong>t<br />

depressurization pressure has been settled.<br />

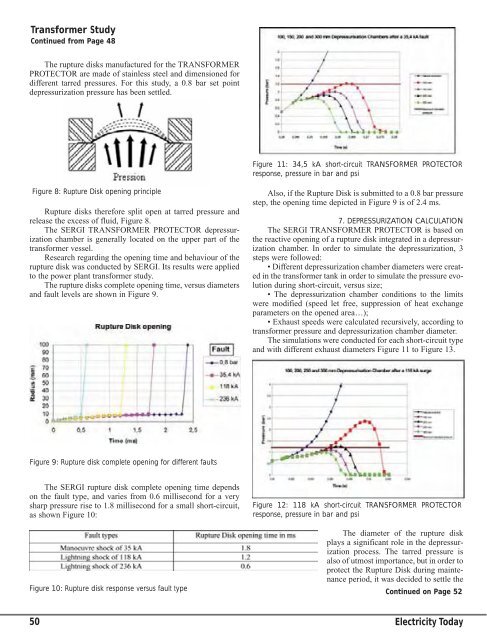

Figure 8: Rupture Disk open<strong>in</strong>g pr<strong>in</strong>ciple<br />

Rupture disks therefore split open at tarred pressure and<br />

release the excess of fluid, Figure 8.<br />

The SERGI TRANSFORMER PROTECTOR depressurization<br />

chamber is generally located on the upper part of the<br />

transformer vessel.<br />

Research regard<strong>in</strong>g the open<strong>in</strong>g time and behaviour of the<br />

rupture disk was conducted by SERGI. Its results were applied<br />

to the power plant transformer study.<br />

The rupture disks complete open<strong>in</strong>g time, versus diameters<br />

and fault levels are shown <strong>in</strong> Figure 9.<br />

Figure 9: Rupture disk complete open<strong>in</strong>g for different faults<br />

The SERGI rupture disk complete open<strong>in</strong>g time depends<br />

on the fault type, and varies from 0.6 millisecond for a very<br />

sharp pressure rise to 1.8 millisecond for a small short-circuit,<br />

as shown Figure 10:<br />

Figure 10: Rupture disk response versus fault type<br />

50<br />

Figure 11: 34,5 kA short-circuit TRANSFORMER PROTECTOR<br />

response, pressure <strong>in</strong> bar and psi<br />

Also, if the Rupture Disk is submitted to a 0.8 bar pressure<br />

step, the open<strong>in</strong>g time depicted <strong>in</strong> Figure 9 is of 2.4 ms.<br />

7. DEPRESSURIZATION CALCULATION<br />

The SERGI TRANSFORMER PROTECTOR is based on<br />

the reactive open<strong>in</strong>g of a rupture disk <strong>in</strong>tegrated <strong>in</strong> a depressurization<br />

chamber. In order to simulate the depressurization, 3<br />

steps were followed:<br />

• Different depressurization chamber diameters were created<br />

<strong>in</strong> the transformer tank <strong>in</strong> order to simulate the pressure evolution<br />

dur<strong>in</strong>g short-circuit, versus size;<br />

• The depressurization chamber conditions to the limits<br />

were modified (speed let free, suppression of heat exchange<br />

parameters on the opened area…);<br />

• Exhaust speeds were calculated recursively, accord<strong>in</strong>g to<br />

transformer pressure and depressurization chamber diameter.<br />

The simulations were conducted for each short-circuit type<br />

and with different exhaust diameters Figure 11 to Figure 13.<br />

Figure 12: 118 kA short-circuit TRANSFORMER PROTECTOR<br />

response, pressure <strong>in</strong> bar and psi<br />

The diameter of the rupture disk<br />

plays a significant role <strong>in</strong> the depressurization<br />

process. The tarred pressure is<br />

also of utmost importance, but <strong>in</strong> order to<br />

protect the Rupture Disk dur<strong>in</strong>g ma<strong>in</strong>tenance<br />

period, it was decided to settle the<br />

Cont<strong>in</strong>ued on Page 52<br />

<strong>Electricity</strong> <strong>Today</strong>