High Strength Steel Stamping Design Manual - Auto/Steel Partnership

High Strength Steel Stamping Design Manual - Auto/Steel Partnership

High Strength Steel Stamping Design Manual - Auto/Steel Partnership

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

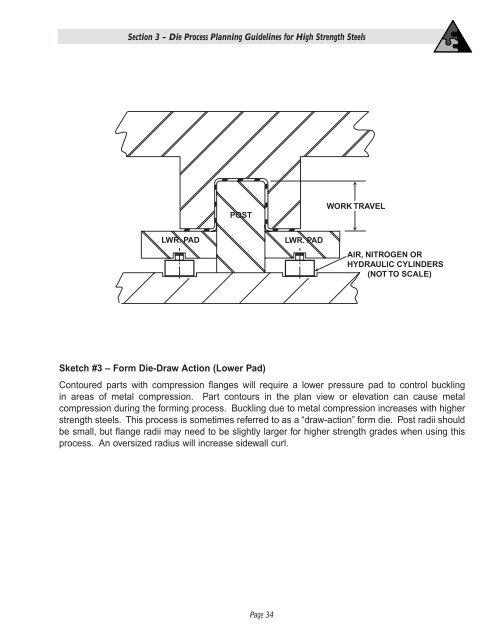

Section 3 – Die Process Planning Guidelines for <strong>High</strong> <strong>Strength</strong> <strong>Steel</strong>s<br />

LWR. PAD<br />

POST<br />

Sketch #3 – Form Die-Draw Action (Lower Pad)<br />

Page 34<br />

LWR. PAD<br />

WORK TRAVEL<br />

AIR, NITROGEN OR<br />

HYDRAULIC CYLINDERS<br />

(NOT TO SCALE)<br />

Contoured parts with compression flanges will require a lower pressure pad to control buckling<br />

in areas of metal compression. Part contours in the plan view or elevation can cause metal<br />

compression during the forming process. Buckling due to metal compression increases with higher<br />

strength steels. This process is sometimes referred to as a “draw-action” form die. Post radii should<br />

be small, but flange radii may need to be slightly larger for higher strength grades when using this<br />

process. An oversized radius will increase sidewall curl.