High Strength Steel Stamping Design Manual - Auto/Steel Partnership

High Strength Steel Stamping Design Manual - Auto/Steel Partnership

High Strength Steel Stamping Design Manual - Auto/Steel Partnership

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

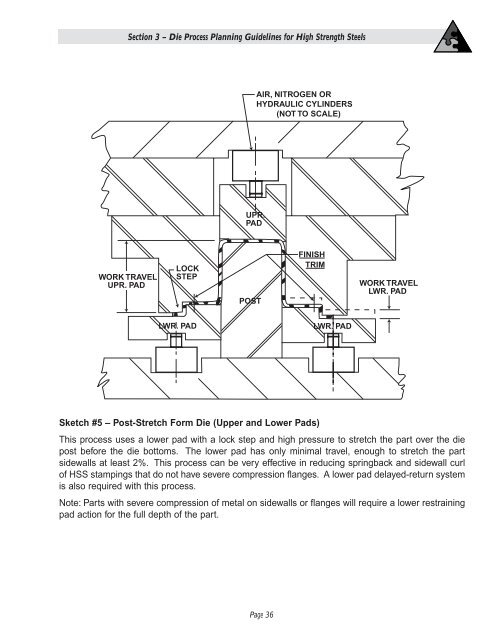

Section 3 – Die Process Planning Guidelines for <strong>High</strong> <strong>Strength</strong> <strong>Steel</strong>s<br />

WORK TRAVEL<br />

UPR. PAD<br />

LOCK<br />

STEP<br />

LWR. PAD<br />

POST<br />

AIR, NITROGEN OR<br />

HYDRAULIC CYLINDERS<br />

(NOT TO SCALE)<br />

UPR.<br />

PAD<br />

Page 36<br />

FINISH<br />

TRIM<br />

LWR. PAD<br />

WORK TRAVEL<br />

LWR. PAD<br />

Sketch #5 – Post-Stretch Form Die (Upper and Lower Pads)<br />

This process uses a lower pad with a lock step and high pressure to stretch the part over the die<br />

post before the die bottoms. The lower pad has only minimal travel, enough to stretch the part<br />

sidewalls at least 2%. This process can be very effective in reducing springback and sidewall curl<br />

of HSS stampings that do not have severe compression flanges. A lower pad delayed-return system<br />

is also required with this process.<br />

Note: Parts with severe compression of metal on sidewalls or flanges will require a lower restraining<br />

pad action for the full depth of the part.