Atlas Copco Blasthole Drills - Matco

Atlas Copco Blasthole Drills - Matco

Atlas Copco Blasthole Drills - Matco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

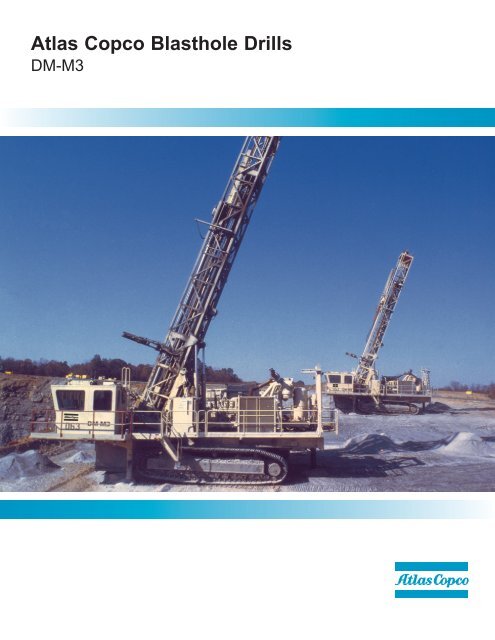

<strong>Atlas</strong> <strong>Copco</strong> <strong>Blasthole</strong> <strong>Drills</strong><br />

DM-M3

It all starts with the blasthole . . .<br />

and the blasthole starts with the<br />

DM-M3 power and performance.<br />

A unique patented feed system:<br />

• Longer head travel with smaller cylinder<br />

rod.<br />

• Heavy-duty cables that provide 1:4<br />

weight reduction over chain.<br />

• Interchangable cable pieces.<br />

• Less tower weight with better<br />

distribution for tramming.<br />

• Cable that detects wear earlier and is less<br />

expensive than chain.<br />

An unparalleled rotation system:<br />

• Largest continuous torque/RPM envelope<br />

available.<br />

• Instant compensation to changes in<br />

ground conditions without special gear<br />

set removal or addition.<br />

• 2-stage reduction with large spur gears<br />

maintains inertia and is more durable<br />

than external planetary gears.<br />

• High pressure, low flow, pressure<br />

compensated closed loop hydraulic<br />

system is more efficient and longer lived.<br />

• Power head weight exceeds 5,000 lbs<br />

(2,313 kg) to add to bit loading.<br />

A strong and rigid drill tower:<br />

• Four main member, open front ASTM<br />

A500 Grade B rectangular steel tubing;<br />

cold sawed and welded.<br />

• Double cut lacing used to contain<br />

bending moments within the tower<br />

structure.<br />

• Two (2) hydraulic 8" bore (20.3cm) tower<br />

raising cylinders.<br />

• Tower can be raised and lowered in<br />

seconds with a full complement of drill<br />

pipe in the carousel and under the rotary<br />

head.<br />

• Remote pinning from the cab.<br />

• Patented angle drill system available as<br />

an option - keeps pivot point at drill deck<br />

and drill pipe always within the dust<br />

curtain even at 30 maximum.

Versatility and adaptability:<br />

• The DM-M3 is available with many options and<br />

choices of features to permit it to adapt to any<br />

mining situation anywhere in the world.<br />

• New processes are in place to expand the<br />

capabilities of the DM-M3 even more.<br />

Product support and parts:<br />

• <strong>Atlas</strong> <strong>Copco</strong> worldwide network will support the<br />

DM-M3 wherever there is drilling to be done.<br />

• Genuine <strong>Atlas</strong> <strong>Copco</strong> parts will keep your<br />

DM-M3 running at peak efficiency.<br />

A reliable and efficient power pack group:<br />

• Air compressor, prime mover and hydraulic<br />

pumps in-line, driven by double-ended shaft<br />

with flexible coupling to better maintain<br />

alignment.<br />

• Floating subframe minimizes transmission of<br />

shock loads to power pack.<br />

• Separate, 3-stage inlet dry-type air filters for<br />

compressor and engine.<br />

• Standard split cooling to 125 F (52 C) with<br />

separate cooler for hydraulic oil and compressor<br />

oil.<br />

• Ambient air used through the coolers rather<br />

than heated air over the engine.<br />

• Closed loop hydraulic system for greater<br />

efficiency.<br />

• Three (3) hydraulic pumps as opposed to 5-7, to<br />

reduce parasitic load.<br />

• Diverter value used rather than clumsy<br />

mechanical disconnects, prevents accidential<br />

tramming while in drill mode.<br />

• Excellent access to the hydraulic pumps for<br />

reduced service time.<br />

• Two (2) sets of 3 micron filters minimize<br />

hydraulic contamination.<br />

• Compressed air is not used to supercharge<br />

pumps in order to reduce fire hazard.<br />

• Ingersoll-Rand asymmetrical, oil-flooded rotary<br />

screw air compressor for single-source<br />

warranty and service responsibilty.<br />

• Compressor is rated at 110 psig (758 kPa) for<br />

better bit cleaning, cooling and lubrication.<br />

• A gear pump provides positive lubrication to<br />

the compressor bearings at all times.<br />

• A "zero-load" system to unload compressor<br />

when not needed to extend compressor life,<br />

reduce fuel use and promote easier cold<br />

weather starting.<br />

• Coolers are located on the sides of the drill<br />

deck, not under the tower rest where drill dust<br />

can be ingested when the tower is lowered.

A sturdy and stable drill platform:<br />

• Mainframe designed and weld fabricated<br />

of ASTM A-441-50 I-beam; 24 x 146.<br />

• Radius gussets used for reinforcement<br />

at major stress points for reduced<br />

deflection and better stress distribution.<br />

• Three hydraulic leveling jacks for<br />

maximum "tripod stability".<br />

• An "Excavator-type" undercarriage is<br />

used for better traction and slewing<br />

ability.<br />

• Triple-bar grouser pads are replaceable<br />

for reduced maintenance and down time.<br />

• Oscillation yoke mounting with 5 each<br />

direction or total 10 up and down to<br />

minimize stress on frame and<br />

components.<br />

• Two (2) hydraulic motor drive powered<br />

by hydro static closed loop system,<br />

through planetary gear speed reducers<br />

for maximum efficiency.<br />

• Spring applied, hydraulic release brake<br />

system for safety.<br />

• Drive system can be disengaged for<br />

towing.<br />

A comfortable and efficient operator<br />

environment:<br />

• Sealed, pressurized and heated cab with<br />

large tinted windows; sound abatement;<br />

ample work area and headroom.<br />

• Air conditioner available as an option.<br />

• Controls are electric over hydraulic for<br />

ease of operation, and concise and rapid<br />

response.<br />

• Excellent visibility of the drill deck for<br />

safe and efficient operation.<br />

• Standard 6 light package for safe nigh<br />

time operation with option for 12.<br />

• Machine access lighting of ladder and<br />

cab when engine not operating, for<br />

added safety.<br />

Quality assurance:<br />

• ISO 9001/Q9001 registry.<br />

• In-place Quality Assurance Programs<br />

and Objectives at the manufacturing<br />

plant headed by full-time staff.<br />

• Employee involvement quality program<br />

at all levels.<br />

• Preferred supplier program to assure the<br />

high level of proficiency and performance<br />

levels that <strong>Atlas</strong> <strong>Copco</strong> demands.

Specifications<br />

NORMAL HOLE DIAMETER<br />

WEIGHT ON BIT<br />

FEED SPEED<br />

RETRACT SPEED<br />

CAROUSEL CAPACITY<br />

ROTARY HEAD TORQUE (STANDARD)<br />

AIR COMPRESSOR<br />

DIESEL FUEL CAPACITY<br />

DIESEL ENGINE 2<br />

COOLING SYSTEM<br />

UNDERCARRIAGE<br />

ESTIMATED OPERATING WEIGHT<br />

OVERALL WIDTH<br />

OVERALL LENGTH (TOWER DOWN)<br />

OVERALL LENGTH (TOWER UP)<br />

AVAILABLE OPTIONS INCLUDE<br />

1 Performance figures are based on maximum computed values at 100% efficiency.<br />

2 Electric drive available, but may extend delivery.<br />

9-7/8 in. to 12-1/4 in. / 251 to 311 mm<br />

0 to 90,000 lbf. / 0 to 400 kN<br />

Up to 144 feet/minute / 43.9 m/minute<br />

Up to 138 feet/minute / 42.1 m/minute<br />

4 pieces 10-3/4 in. x 40 ft. / 273 mm x 12.2 m<br />

5 pieces 8-5/8 in. x 40 ft. / 219 mm x 12.2 m<br />

10,607 ft-lbs / 14,383 Nm<br />

Ingersoll-Rand asymmetrical rotary screw<br />

2600 cfm @ 110 psig / 74.6 m 3 /min. @7.6 bar<br />

650 US gallons / 2,460 liters<br />

Caterpillar C32 950 HP/709 kW or Cummins QST30 1000 HP/745 kW<br />

125 F/ 52 C separate cooler for hydraulic oil and compressor oil<br />

Intertrac B8 or Caterpillar 350 Custom<br />

230,000 lb. / 104,327 kg<br />

18 ft. 10-3/8 in. / 5.75 m<br />

66 ft. 6 in. / 20.27 m<br />

45 ft. 5 in. / 12.32 m<br />

0 to 30 angle drill package (patented); water injection;<br />

dry dust control; cab air conditioner; fire suppression; central lubrication;<br />

central service of fluids; automatic leveling; accessories, etc.

Committed to your superior productivity<br />

Nothing contained in this brochure is intended to extend any warranty or representation,<br />

expressed or implied, regarding the products described herein. Any such warranties or other<br />

terms and conditions of sale shall be in accordance with <strong>Atlas</strong> <strong>Copco</strong>’s standard terms and<br />

conditions of sale for such products which are available upon request. Commitment to inno-<br />

Worldwide Dealer Network<br />

With the largest distribution network in the<br />

industry, <strong>Atlas</strong> <strong>Copco</strong> has a sales center near you<br />

providing products, accessories, and financing<br />

options to fit all your drilling needs.<br />

Worldwide Product Support<br />

Our team of experienced drill specialists are<br />

strategically located near you to offer troubleshooting<br />

expertise and to help solve difficult problems.<br />

Worldwide Availability<br />

Our worldwide distribution network is committed<br />

to providing the parts and service you need to keep<br />

your drills running efficiently and cost<br />

effectively.<br />

<strong>Atlas</strong> <strong>Copco</strong> Drilling Solutions Inc<br />

A company within the <strong>Atlas</strong> <strong>Copco</strong> Group<br />

www.atlascopco.com/drillingsolutions<br />

Part No. 57826737 2.5M0706EP Printed in USA