LAMOUS™ inherent advantages - GIGABASE

LAMOUS™ inherent advantages - GIGABASE

LAMOUS™ inherent advantages - GIGABASE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

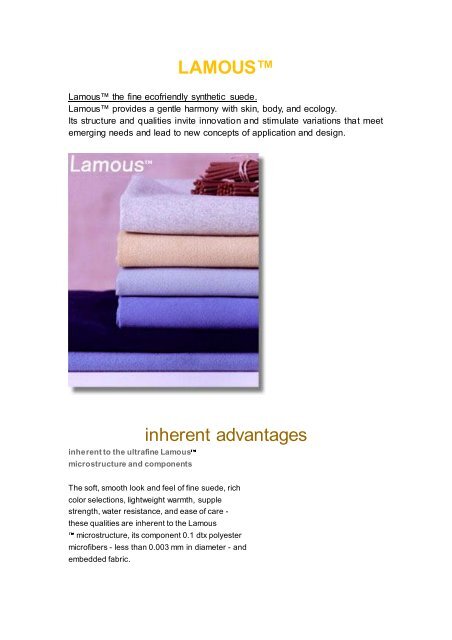

LAMOUS<br />

Lamous the fine ecofriendly synthetic suede.<br />

Lamous provides a gentle harmony with skin, body, and ecology.<br />

Its structure and qualities invite innovation and stimulate variations that meet<br />

emerging needs and lead to new concepts of application and design.<br />

<strong>inherent</strong> to the ultrafine Lamous<br />

microstructure and components<br />

<strong>inherent</strong> <strong>advantages</strong><br />

The soft, smooth look and feel of fine suede, rich<br />

color selections, lightweight warmth, supple<br />

strength, water resistance, and ease of care -<br />

these qualities are <strong>inherent</strong> to the Lamous<br />

microstructure, its component 0.1 dtx polyester<br />

microfibers - less than 0.003 mm in diameter - and<br />

embedded fabric.

Soft,<br />

gentle touch<br />

Deep,<br />

true colors<br />

Lightweight warmth<br />

Supple<br />

strength<br />

Water resistance<br />

Ease of care<br />

Wealth of variations<br />

Ecoefficiency<br />

The look and feel of fine<br />

suede, through advanced<br />

microfiber spinning and<br />

processing technology.<br />

Elegant hues and shades, in<br />

single-color and melange,<br />

enabled by superior color<br />

take-up and development<br />

Optimum warmth, comfort,<br />

and breathability, <strong>inherent</strong> to<br />

the three-dimensional<br />

nonwoven microstructure.<br />

Supple grace and lithe<br />

comfort together with lasting<br />

strength imparted by the<br />

embedded fabric core.<br />

Resistance to hardening,<br />

shrinking, and color loss<br />

after water exposure or<br />

immersion<br />

Light, simple brushing for<br />

day-to-day care, and<br />

occasional washing or dry<br />

cleaning. See details<br />

inCare.<br />

Rich variety of types,<br />

grades, and applications, by<br />

optimization of the trilayer<br />

microstructure.<br />

Produced without organic<br />

solvents, using high-purity<br />

recycled polyester. See<br />

details in Ecoefficiency.

microstructure<br />

where the quality and <strong>advantages</strong> begin<br />

The trilayer Lamous microstructure consists of a core layer composed of a fine, thin "scrim" fabric,<br />

and front and back layers composed of three-dimensionally intermeshed ultrafine polyester microfibers,<br />

with polyurethane in the microfiber interstices.<br />

The core layer imparts high strength and dimensioal stability. The microfiber layers impart the soft,<br />

supple touch and resilience of the Lamous fabric. The three-dimensional microstructure enables a wide<br />

variety of types, grades, and fields of application<br />

Micrograph of Lamous cross-section<br />

Overview of Lamous ecoefficiency<br />

clean and easy on the environment

Lamous is distinguished by reduced resources consumption and freedom from<br />

environmentally burdening substances, in its production materials, production process,<br />

and composition,<br />

Production from high-purity recycled polyester<br />

The Lamous microfibers are produced primarily from high-purity recycled polyester.<br />

This purity is made possible by advanced chemical-process recycling,<br />

which eliminates the problems of polymer contamination associated with<br />

the conventional mechanical-process recycling.<br />

Freedom from organic solvents<br />

Lamous , in almost all types and grades*, is produced with aqueous-dispersion polyurethane,<br />

rather than conventional organic-solution polyurethane, to impart the resilience, abrasion<br />

resistance, and soft look and feel essential for fine synthetic suede. This eliminates the need<br />

for DMF** or other organic solvents.<br />

The Lamous microfibers themselves are produced by an advanced direct-spinning process.<br />

This also eliminates the need for organic solvents, which are generally necessary in the<br />

conventional compound-spinning processes to remove other process materials from the spun<br />

fibers.<br />

*Several special grades are made with organic-solution polyurethane, using DMF.<br />

**Dimethylformamide, an organic solvent that is widely used in industry but generally requires<br />

careful control to prevent its release into the environment.<br />

ISO 14001 certification for environmental management system<br />

Lamous production is certified under the ISO 14001 standard for environmental

management system.<br />

Oeko-Tex Standerd 100 certification for product safetyLamous is certified<br />

under the Oeko-Tex standard 100 for textile products<br />

advanced<br />

chemical-process recycling<br />

saving resources and heightening purity by depolymerization<br />

Lamous microfibers made with high-purity recycled polyester enable outstanding product<br />

quality while contributing to resources conservation.<br />

Unlike conventional material-recycling processes, which generally involve problems in polymer<br />

purity and degradation and thus limit the performance and applications of the resulting polyester,<br />

the chemical-recycling process enables depolymerization of polyester from PET bottles and<br />

polyester yarns, fabrics, and apparel, resulting in a pure polyester that is virtually indistinguishable<br />

from the virgin polyesters produced directly from petroleum components.<br />

The end result is a synthetic suede of high quality, purity, and ecoefficiency.

certified environmental management<br />

system<br />

under the ISO 14001 standard<br />

Lamous production has been certified since 2001 under the ISO 14001 standard for<br />

environmental management system, as part of the continuing commitment to environmental<br />

protection and preservation.<br />

ISO 14001 Certificate<br />

certified freedom from harmful substances<br />

under the Oeko-Tex standard 100<br />

Lamous has been certified for product safety under the<br />

internationally recognized Oeko-Tex Standard 100 for freedom<br />

of fiber and textile products from substances and properties<br />

which may be harmful to people or their environment.<br />

Substances and properties prohibited or controlled under Oeko-Tex Standard 100<br />

Banned MAK amines found in specific azo dyestuffs

Carcinogenic and allergy-inducing dyestuffs<br />

Formaldehyde<br />

Pesticides<br />

Phenols<br />

Chlorinated aromatic compounds<br />

Extractable heavy metals : Ni, Cd, Cr, CrVI etc.<br />

Color fastness<br />

pH-value<br />

Phthalates(in baby articles)<br />

Organic tin compounds(TBT and DBT)<br />

Emission of volatile components<br />

Odor<br />

Biocides and flame retardant finishes are regulated separately

Lamous production process<br />

the six production stages, from microfiber to synthetic suede

Lamous care and handling

easy care, lasting quality apparel<br />

Regular<br />

care<br />

Dust, moisture, and wrinkling can be removed quickly and easily.<br />

Dust and other particles........... Light brushing with ordinary clothes brush.<br />

Rain and water......................... Light patting with towel or cloth to absorb<br />

excess water,<br />

followed by hang-drying in shade.<br />

Light wrinkles........................... Hanging several hours on clothes hanger.<br />

Heavy wrinkles......................... Ironing at 120 or lower, under ironing cloth.<br />

Mold and insects...................... Unaffected; no care necessary.<br />

Washing or dry cleaning<br />

Lamous itself* can be either hand-washed or dry cleaned.<br />

Washing<br />

Washwater temperature 30 or lower, followed by gentle wringing to<br />

remove excess water and hang-drying in shade.<br />

Dry cleaning<br />

Normal dry-cleaning procedure, with stipulation that the cleaning agent<br />

be petroleum-based.<br />

*For any garment, the appropriate cleaning method will<br />

also depend on the other materials present in the garment