COLM - DME

COLM - DME

COLM - DME

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

17/07/2012<br />

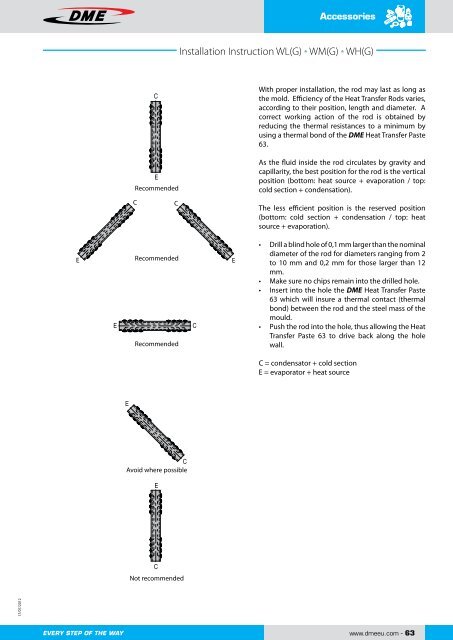

Recommended<br />

C C<br />

E Recommended<br />

E<br />

Recommended<br />

Avoid where possible<br />

Not recommended<br />

Accessories<br />

Installation Instruction WL(G) - WM(G) - WH(G)<br />

With proper installation, the rod may last as long as<br />

the mold. Efficiency of the Heat Transfer Rods varies,<br />

according to their position, length and diameter. A<br />

correct working action of the rod is obtained by<br />

reducing the thermal resistances to a minimum by<br />

using a thermal bond of the <strong>DME</strong> Heat Transfer Paste<br />

63.<br />

As the fluid inside the rod circulates by gravity and<br />

capillarity, the best position for the rod is the vertical<br />

position (bottom: heat source + evaporation / top:<br />

cold section + condensation).<br />

The less efficient position is the reserved position<br />

(bottom: cold section + condensation / top: heat<br />

source + evaporation).<br />

• Drill a blind hole of 0,1 mm larger than the nominal<br />

diameter of the rod for diameters ranging from 2<br />

to 10 mm and 0,2 mm for those larger than 12<br />

mm.<br />

• Make sure no chips remain into the drilled hole.<br />

• Insert into the hole the <strong>DME</strong> Heat Transfer Paste<br />

63 which will insure a thermal contact (thermal<br />

bond) between the rod and the steel mass of the<br />

mould.<br />

• Push the rod into the hole, thus allowing the Heat<br />

Transfer Paste 63 to drive back along the hole<br />

wall.<br />

C = condensator + cold section<br />

E = evaporator + heat source<br />

www.dmeeu.com - 63