Workflow for creating ICC Profiles

Workflow for creating ICC Profiles

Workflow for creating ICC Profiles

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

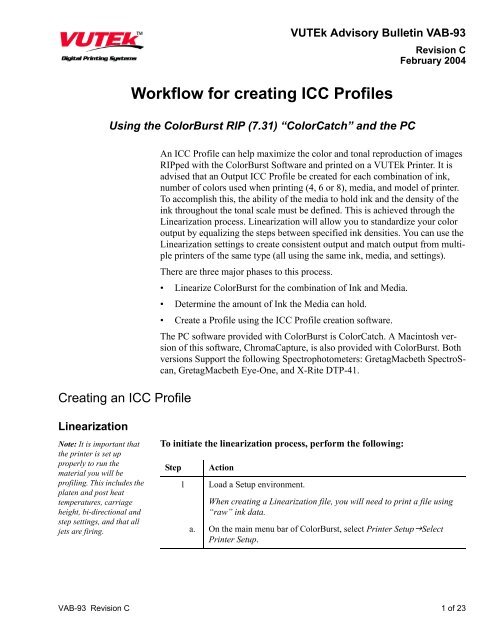

VUTEk Advisory Bulletin VAB-93<br />

<strong>Workflow</strong> <strong>for</strong> <strong>creating</strong> <strong>ICC</strong> <strong>Profiles</strong><br />

Using the ColorBurst RIP (7.31) “ColorCatch” and the PC<br />

Creating an <strong>ICC</strong> Profile<br />

Linearization<br />

Note: It is important that<br />

the printer is set up<br />

properly to run the<br />

material you will be<br />

profiling. This includes the<br />

platen and post heat<br />

temperatures, carriage<br />

height, bi-directional and<br />

step settings, and that all<br />

jets are firing.<br />

Revision C<br />

February 2004<br />

An <strong>ICC</strong> Profile can help maximize the color and tonal reproduction of images<br />

RIPped with the ColorBurst Software and printed on a VUTEk Printer. It is<br />

advised that an Output <strong>ICC</strong> Profile be created <strong>for</strong> each combination of ink,<br />

number of colors used when printing (4, 6 or 8), media, and model of printer.<br />

To accomplish this, the ability of the media to hold ink and the density of the<br />

ink throughout the tonal scale must be defined. This is achieved through the<br />

Linearization process. Linearization will allow you to standardize your color<br />

output by equalizing the steps between specified ink densities. You can use the<br />

Linearization settings to create consistent output and match output from multiple<br />

printers of the same type (all using the same ink, media, and settings).<br />

There are three major phases to this process.<br />

• Linearize ColorBurst <strong>for</strong> the combination of Ink and Media.<br />

• Determine the amount of Ink the Media can hold.<br />

• Create a Profile using the <strong>ICC</strong> Profile creation software.<br />

The PC software provided with ColorBurst is ColorCatch. A Macintosh version<br />

of this software, ChromaCapture, is also provided with ColorBurst. Both<br />

versions Support the following Spectrophotometers: GretagMacbeth SpectroScan,<br />

GretagMacbeth Eye-One, and X-Rite DTP-41.<br />

To initiate the linearization process, per<strong>for</strong>m the following:<br />

Step Action<br />

1 Load a Setup environment.<br />

When <strong>creating</strong> a Linearization file, you will need to print a file using<br />

“raw” ink data.<br />

a. On the main menu bar of ColorBurst, select Printer Setup�Select<br />

Printer Setup.<br />

VAB-93 Revision C 1 of 23

Figure 1.<br />

Setup (printer<br />

name).env<br />

Step Action<br />

b. In the c:\cbvutek_72\Profiling tools & Docs\Icc Profile Creations Setup<br />

Env folder, open the folder <strong>for</strong> your printer and select the setup file <strong>for</strong><br />

your printer and the numbers of colors (4, 6, 8) named “Setup (printer<br />

name).env” (Figure 1 on page 2).<br />

Step Action<br />

This will set all the options necessary <strong>for</strong> Linearization.<br />

Note: The Printer Setup files, Setup.env, will turn OFF the following options:<br />

<strong>ICC</strong> Profile and Linearization functions, and set the Color Adjustment and Ink<br />

Balance menus to the defaults.<br />

2 Print the linearization target.<br />

a. Go to File/Open and choose the folder (C:\cbvutek_72\Profiling Tools<br />

& Docs\Linearization and Profiling Targets). Inside this folder, there<br />

are several different targets.<br />

b. Choose the Lin target file that corresponds to the type of<br />

spectrophotometer you will be using (Figure 2 on page 3 and Figure 3<br />

on page 3).<br />

Note: The scaling and rotation <strong>for</strong> the Target files must remain at 100%.<br />

These files are <strong>for</strong>matted <strong>for</strong> specific spectrophotometers.<br />

2 of 23 VAB-93 Revision C

Figure 2.<br />

Lin Chroma Cap<br />

CMYK XY.tif<br />

Figure 3.<br />

Lin Chroma Cap<br />

CMYK Strip.tif<br />

Step Action<br />

c. Click the START button in the file in<strong>for</strong>mation box to print the target to<br />

a RTL file.<br />

The file will be printed with 100% of your CMYK primaries. By<br />

printing out at 100% ink, ColorBurst will be able to determine a<br />

printer's maximum ink density. The Linearization function is only<br />

concerned with the four solid inks, and not the light inks.<br />

Note: Be sure the printer temperature settings are correct <strong>for</strong> the material.<br />

3 Launch the data capture applications (VUTEk ColorCatch).<br />

a. Launch the VUTEk ColorCatch applications <strong>for</strong>m the shortcut icon on<br />

the desktop.<br />

VAB-93 Revision C 3 of 23

Figure 4.<br />

Path Selection<br />

Step Action<br />

b. Verify the default path where the data files will be saved and change it<br />

if necessary.<br />

Step Action<br />

To change the default path, select the Browse button next to the path<br />

location, in the Edit�Preferences menu (Figure 4).<br />

Note: The data file should be saved to the Output Profile folder <strong>for</strong> the printer<br />

type you are using in the ColorBurst installed folder. For example:<br />

C:\CBVutek_72\Profile\output\3360.<br />

c. Select New Job from the file menu or use the shortcut keys, CTRL-N.<br />

d. In the Create Job window, enter a name into the Job Name field<br />

(Figure 5 on page 5).<br />

This file will be saved into the default folder.<br />

e. Select the Device�Interface, and set the Mode to Reflective.<br />

Note: Always leave Illuminant at D50. Print Conditions fields are not used.<br />

f. Click OK.<br />

Note: After clicking OK, the job name becomes a sub-folder in the default<br />

folder.<br />

Note: Refer to “Trouble Shooting ColorCatch <strong>for</strong> PC Users” on page 20 <strong>for</strong><br />

in<strong>for</strong>mation on changing the default folder path or a Failed to Create Job<br />

error message.<br />

Note: X-Rite DTP-41 users go to step 4. GretagMacbeth SpectroScan users go<br />

to step 5.<br />

4 of 23 VAB-93 Revision C

Figure 5.<br />

Create Job Window<br />

Step Action<br />

Figure 6. ColorCatch Operating Menu<br />

4 For the X-Rite DTP-41, load and measure the target.<br />

a. Select the Choose a Target pull down menu and in the “Target name”<br />

field, select ColorBurst Strip Lin <strong>for</strong> the DTP-41 (Figure 6).<br />

b. Click Connect, the software will auto-sense the Baud Rate and then<br />

initialize and calibrate the Spectrophotometer. In the lower left corner<br />

the text line will show the progress.<br />

Note: Refer to (“Trouble Shooting ColorCatch <strong>for</strong> PC Users” on page 20) if<br />

you are having problems connection to the device.<br />

VAB-93 Revision C 5 of 23

Figure 7.<br />

Setting the<br />

Linearization Target<br />

Step Action<br />

c. Insert the Cyan strip on the printed target, into the DTP-41 up to the<br />

black line near the Number 1. Press the “Black” Button on the DTP-41<br />

to read the strip (Figure 7 on page 6).<br />

The strip should automatically be pulled in through the reader. You may<br />

need to give the strip a small push to start. The strip should travel<br />

straight through the device. If it is not moving straight, gently move the<br />

target strip in a straight line.<br />

d. Repeat step C <strong>for</strong> the Magenta, Yellow, and Black strips.<br />

e. When complete, a message box will appear indicating “Target Saved”.<br />

Click OK.<br />

The data file is saved to the Default Folder.<br />

Note: The “Position” or “Calibrate” button on the DTP-41 should not be<br />

needed.<br />

f. Skip to step 6.<br />

Step Action<br />

5 For the GretagMacbeth SpectroScan, load and measure the target.<br />

a. Select the Choose a Target pull down menu and in the “Target name”<br />

field, select ColorBurst Strip XY Lin (Figure 8 on page 7).<br />

6 of 23 VAB-93 Revision C

Figure 8. ColorBurst XY Lin Selection<br />

Figure 9.<br />

Robot Configuration<br />

Menu<br />

Step Action<br />

b. Click Connect, the software will initialize a connection with the XY<br />

table, check the Baud Rate, and per<strong>for</strong>m a Calibration. When finished it<br />

will display a message that Calibration Succeeded. Click Ok.<br />

c. Position the XY tables read head.<br />

• Place the printed Profile Target onto the SpectroScan XY Table.<br />

• Press the Pad Hold button on the table.<br />

• Select Position on the ColorCatch software.<br />

• The Robot Configuration Menu will appear(Figure 9 on page 7).<br />

Note: Do not change any settings in the Robot Configuration menu.<br />

VAB-93 Revision C 7 of 23

Figure 10. XY Table<br />

Step Action<br />

Step Action<br />

• Using the “arrow” buttons on the XY table, position the<br />

cross hairs on the read head over the black cross hairs in<br />

the upper left corner of the target.<br />

• When the cross hair is in the position, press Enter on the<br />

XY table (Figure 10).<br />

• Repeat <strong>for</strong> the top right and bottom right corners.<br />

d. Select OK on the Robot Configuration Menu (Figure 9 on page 7).<br />

e. Select the Start button in the ColorCatch menu (Figure 6 on page 5).<br />

The SpectroScan will now start to read the target patch automatically.<br />

f. When complete, a message box appears stating Target Saved. Click<br />

OK. The data filed is saved to the Default Folder (i.e. CBVutek_72\lin<br />

folder.<br />

6 Load and Read the Lin file - Density Based Linearization.<br />

a. In the ColorBurst Software, select the Options�Linearization menu<br />

(Figure 11 on page 9).<br />

b. Select Allow Linearization.<br />

c. Select Find and locate the .lin file that was created in step 4 or 5.<br />

d. This will load in the Original DMax (densities) from the .lin file.<br />

8 of 23 VAB-93 Revision C

Figure 11.<br />

Linearization Menu<br />

Figure 12.<br />

Linearization Options<br />

Dialog box<br />

Step Action<br />

e. Click Set Baseline Values and it will update your desired densities<br />

(Figure 12 on page 9).<br />

Step Action<br />

The Set Baseline Values button will reduce the original densities by<br />

5% and will display new values under the original values in the desired<br />

row. Lower density values allow the color controls to compensate <strong>for</strong><br />

small changes that may occur in the actual day-to-day printed densities.<br />

f. Optional, to move the .lin file to the default ColorBurst Lin folder<br />

select Copy.<br />

g. Select OK.<br />

Note For in<strong>for</strong>mation on Chroma Based Linearization see Addendum.<br />

VAB-93 Revision C 9 of 23

Determine the Ink Limit<br />

Figure 13.<br />

Vutek Media Ink Limit<br />

Test Files 1-3.eps<br />

Step Action<br />

7 Save the Printer Setup File.<br />

a. On the main menu bar of ColorBurst, select Printer Setup�Save<br />

Printer Setup; locate the proper folder and name the file. Do Not pick<br />

the Select Printer Setup menu.<br />

You should name the Printer Setup file according to the machine type,<br />

material and number of colors being printed.<br />

(i.e. XYZ Material_3360_4C.env).<br />

b. Click Save.<br />

To determine the amount of ink the media can hold:<br />

Step Action<br />

1 Determine the proper ink load <strong>for</strong> the material.<br />

a. Open the “Vutek Media Ink Limit Test Files 1-3.eps” file located in the<br />

C:\cbvutek_72\testfiles folder (Figure 13).<br />

Step Action<br />

Note: Check the Temperature, Step Size and Bi-directional settings are correct<br />

<strong>for</strong> the material.<br />

b. Select Start to RIP the target into a single RTL file.<br />

c. Print them on the material to be profiled.<br />

10 of 23 VAB-93 Revision C

Step Action<br />

Figure 14. Vutek Media Ink Limit Test File 1.eps<br />

Note: Check the Temperature, Step Size, and Bi-directional settings are correct<br />

<strong>for</strong> the material.<br />

2 On the Test File 1.eps image (Figure 14), look <strong>for</strong> the darkest patch that<br />

is uni<strong>for</strong>mly dry, does not bleed out into the white, does not show any<br />

dry banding or ink puddles, and has a solid fill with no material<br />

showing through (pinholes).<br />

Step Action<br />

On some materials you can see a difference in the shine or Gloss of the<br />

ink between the dry and wet areas.<br />

Note: Look <strong>for</strong> the highest level of ink that does not show any bleeding of the<br />

black into the red or yellow areas.<br />

3 Select the Color Adjustments from the Options menu (Figure 15 on<br />

page 12).<br />

VAB-93 Revision C 11 of 23

Figure 15.<br />

Color Adjustment<br />

Dialog Box<br />

Step Action<br />

To create a profile:<br />

Step Action<br />

The Color Adjustments Dialog box will open up to the “Adjustments<br />

tab”.<br />

a. In the Color Adjustments Dialog box, click on the Ink Limits tab.<br />

b. Click on the Enable Ink Limiting check box and enter the total ink<br />

limit established in Step 2, in the “Total ink limit %” field.<br />

All other features in this menu should be left at the defaults.<br />

c. Click OK.<br />

4 Re-save the Printer Setup File.<br />

a. On the main menu bar of ColorBurst, select Printer Setup�Save<br />

Printer Setup, and select the printer setup file that you named in step 7<br />

of the linearization procedure. Click Save.<br />

b. Click OK to overwrite the existing file.<br />

12 of 23 VAB-93 Revision C

Building the <strong>ICC</strong> Profile<br />

Figure 16.<br />

Strip CMYK Profile<br />

To build the <strong>ICC</strong> profile, per<strong>for</strong>m the following:<br />

Step Action<br />

1 Print the <strong>ICC</strong> Profile patch targets.<br />

a. Open, RIP, and Print the <strong>ICC</strong> Profile patch targets.<br />

• The Eye-One and the DTP 41 use the “Strip CMYK Profile Strip<br />

1.tif” file. There are 4 targets that must be printed and read (Page 1-<br />

4) (Figure 16).<br />

• The GretagMacbeth Spectroscan uses the “XY CMYK Profile Page<br />

1.tif” file. There are 2 targets that must be printed and read (Page 1<br />

and 2) (Figure 17 on page 14).<br />

Note: Do not scale the patches. They are <strong>for</strong>matted to be used with specific<br />

spectrophotometers. There will be several files to print since the ColorBurst<br />

Profiler uses readings from over 1248 patches to get the best reading of a<br />

printer, ink, and media combinations total gamut.<br />

VAB-93 Revision C 13 of 23

Figure 17.<br />

XY CMYK Profile<br />

Step Action<br />

2 Read the printer targets.<br />

a. If the VUTEk ColorCatch application is still open, select the Target<br />

name <strong>for</strong> your device (i.e. <strong>for</strong> the DTP-41, “Strip CMYK Profile” or <strong>for</strong><br />

the SpectroScan, “XY CMYK Profile”) (Figure 6 on page 5).<br />

b. If the ColorCatch is not open, launch ColorCatch and select File�Open<br />

Job.<br />

c. From the Select Job Dialog box, highlight the proper job and click OK.<br />

3 Select the type of target to be measured (Figure 6 on page 5).<br />

a. Click on the Target Name pull down menu and select (i.e. <strong>for</strong> the DTP-<br />

41, “Strip CMYK Profile” or <strong>for</strong> the SpectroScan, “XY CMYK<br />

Profile”) (Figure 6 on page 5).<br />

Note: For the X-Rite DTP-41 go to step 4. For the GretagMacbeth<br />

SpectroScan to step 5.<br />

4 For the X-Rite DTP-41, read in the Profile Target Patches.<br />

a. Insert strip (A) on target page 1 into the DTP-41 and press the button.<br />

b. Once the column is pulled through the device move on to the next<br />

column (B). Repeat steps a and b <strong>for</strong> all columns.<br />

c. Once a page is completed, the software will automatically move to the<br />

next target page.<br />

Note: Verify that the target is straight. You can adjust the target slightly as it<br />

moves through the DTP-41. If the target is not straight and/or you receive a<br />

bad reading(Figure 18 on page 15), re-read the column by selecting the<br />

column on the screen with the mouse and re-insert the column into the device.<br />

14 of 23 VAB-93 Revision C

Figure 18.<br />

Device Error Dialog<br />

Box<br />

Step Action<br />

d. After completing all four pages, a message will appear “Target Saved”.<br />

Click OK.<br />

Note: PC ColorCatch will add the .cie extension to the job name (i.e. XYZ<br />

Material 4C.cie). Two files will be saved into the default path. The .cie file is<br />

used in the next step not the .cie.spectraldata file.<br />

e. Skip to Step 8.<br />

5 For the GretagMacbeth SpectroScan, read in the profile target patches:<br />

a. Place the printed copy of the XY CMYK Profile - Page 1.tif onto the<br />

SpectroScan XY table.<br />

b. Press the “Pad Hold” button on the XY Table.<br />

c. Press the “Position” button in the ColorCatch software.<br />

d. The Robot Configuration menu will appear. Do not change any settings<br />

in this menu.<br />

e. Using the “arrow” buttons on the XY table, position the cross hairs on<br />

the read head over the black cross hairs in the upper left corner of the<br />

target.<br />

f. When the cross hair is in position press the “Enter” button on the XY<br />

table.<br />

g. Repeat <strong>for</strong> the top right and bottom right corners.<br />

h. Once the cross hair has been positioned on three corners, select the OK<br />

button on the Robot Configuration menu.<br />

i. Select Start on the main ColorCatch menu. The GretagMacbeth<br />

Spectroscan XY table will now start to read the target. When finished<br />

with Page 1, you will be prompted to attach Page 2 (Figure 19 on<br />

page 16). Click OK and attach page 2 of the GretagMacbeth<br />

Spectroscan XY Table.<br />

VAB-93 Revision C 15 of 23

Figure 19.<br />

Page Prompt Dialog<br />

Box<br />

Step Action<br />

j. When the second page is finished, a message will appear “Target<br />

Saved”. Click OK.<br />

Note: PC ColorCatch will add the .cie extension to the job name (i.e. XYZ<br />

Material 4C.cie). Two files will be saved into the default path. The .cie file is<br />

used in the next step not the .cie.spectraldata file.<br />

6 Create an <strong>ICC</strong> Profile using ColorBurst's Built-in <strong>ICC</strong> Profile software.<br />

a. In ColorBurst, go to Options�<strong>ICC</strong> Profile Options �Build Profile Tab<br />

menu.<br />

b. Click Find then go to the folder where PC ColorCatch saved the<br />

measurements.<br />

c. Select your measurement file (it will end in .cie).<br />

Note: ColorBurst will only recognize .cie files.<br />

Note: Most profiles can be built with the Default settings. It is recommended<br />

that the Ink Limit and Black Controls be set to the following:<br />

Total Ink - 300% (between 200% - 320% depending on the material)<br />

Total Black Ink - 100%<br />

Black Starting Point - 20%<br />

Black Intensity - 65%,<br />

Color GCR - 0%<br />

Neutral GCR - 0%<br />

Note: For later reference the “Profile Descriptor” data entry line can be filled<br />

in with the in<strong>for</strong>mation entered in the ink limit values;<br />

i.e. 300 100 20 60 0 0.<br />

This in<strong>for</strong>mation will appear under the profile name in the Output Profile<br />

menu and when the profile is used in some other application such as<br />

PhotoShop.<br />

16 of 23 VAB-93 Revision C

Figure 20.<br />

<strong>ICC</strong> Profile Options<br />

Step Action<br />

Table 1. <strong>ICC</strong> Profile Options - Build Profile Settings Description<br />

Control Description<br />

d. Select Build Profile and your profile will be generated and saved into<br />

the Output Profile folder.<br />

You could also select the Prompt <strong>for</strong> Output File Name box and give it a<br />

different name or location.<br />

Note: For a complete description of what each setting does, please refer to<br />

Table 1.<br />

Total Ink Limit This setting will limit the total ink even further. It is probably the most<br />

frequently used feature in building profiles. If your patches come out a little<br />

wet choose a total ink limit of 300% <strong>for</strong> your first test. If it is still wet go to<br />

250%, if it is still wet after that go to 200%. Remember, this is ink limiting<br />

on top of all the other ink limiting you have done. It tends to be much less<br />

dramatic than other ink limiting methods. This is the most often used<br />

feature.<br />

VAB-93 Revision C 17 of 23

Control Description<br />

Total Black Ink This setting will further limit your total black ink. If your prints are dark,<br />

you could use this feature to lighten them up a bit. It should be used<br />

sparingly.<br />

Black Starting Point This defines the starting point <strong>for</strong> where black ink should be used. Prior to<br />

the Black starting point, all Blacks are CMY builds. After the starting point,<br />

Black color Builds will be a combination of CMY and Black.<br />

Black Intensity This determines the rate at which black ink is added once the black starting<br />

point has been reached. For example: a black intensity of 30 is a very slow<br />

build <strong>for</strong> the black channel and a black of 70 is a much faster build. The<br />

default is set at 60 so if a deeper black is desired a setting of 90 or 100 is<br />

recommended.<br />

Neutral GCR Takes control of the NEUTRAL AXIS/GRAYS only. Over-rides the black<br />

starting point. The Higher the neutral GCR, the more quickly Black will be<br />

added and CMY will be removed. This should be used very sparingly as<br />

prints tend to speckle when you use it.<br />

Color GCR Has the same function as Neutral GCR, but will add Black and remove<br />

CMY in colors other than neutral. This should be used very sparingly as<br />

prints tend to speckle when you use it.<br />

Step Action<br />

7 Load the <strong>ICC</strong> Profile.<br />

a. Load the <strong>ICC</strong> Profile into ColorBurst by going to the Options\<strong>ICC</strong><br />

<strong>Profiles</strong> menu and select the General tab.<br />

b. Select Enable <strong>ICC</strong> profile color management.<br />

c. Select the Output <strong>Profiles</strong> tab and turn on the CMYK color Type by<br />

selecting the On/Off button. (Figure 21 on page 19).<br />

d. Select Find and locate the <strong>ICC</strong> Profile that was just created. Select OK.<br />

18 of 23 VAB-93 Revision C

Figure 21.<br />

<strong>ICC</strong> Profile Options -<br />

Output <strong>Profiles</strong><br />

Step Action<br />

8 Re-save the Printer Setup file.<br />

a. On the main menu bar of ColorBurst, select Printer Setup�Save Printer<br />

Setup and select the printer setup file that you named in step 7 of the<br />

linearization procedure. Click Save.<br />

b. Click OK to overwrite the existing Printer Setup File.<br />

The Profile is now complete and you should now be ready to print<br />

images on this material.<br />

VAB-93 Revision C 19 of 23

Trouble Shooting ColorCatch <strong>for</strong> PC Users<br />

Changing the Default Path where Jobs are Saved<br />

Figure 22.<br />

Saving to a Local<br />

Drive<br />

Saving the Data to a Local Drive:<br />

Step Action<br />

1 From the Edit\Preferences menu, select Browse (Figure 22 on<br />

page 20).<br />

2 Select drive and folder location to save the data.<br />

3 Click OK.<br />

Saving Data to a Network Drive:<br />

Step Action<br />

1 Prior to setting the default path in ColorCatch the network drive must<br />

be mapped to a local drive letter on the PC where ColorCatch is<br />

installed (Figure 23 on page 21).<br />

2 Form the Desktop left click My Network Places.<br />

3 Click Map Network Drive.<br />

4 Select the drive and folder you want to use.<br />

5 Click Finish.<br />

6 Open ColorCatch, select the Browse button from the Edit�Preferences<br />

menu.<br />

7 Select the drive and folder you want to use.<br />

8 Click OK.<br />

20 of 23 VAB-93 Revision C

Figure 23. Saving to a Network Drive<br />

Naming a Job<br />

A unique name must be entered each time you start a new job.<br />

To re-enter the job name:<br />

Communications Problems with the DTP-41 or Spectroscan<br />

No Device Found<br />

Step Action<br />

1 If you enter a name in the Name Job field that already exists in the<br />

default folder, ColorCatch will prompt that it “Failed to create Job”.<br />

2. Click OK and enter a new name.<br />

To Select the Device:<br />

Step Action<br />

1. Launch ColorCatch.<br />

2. From the menu bar, select Edit�Preferences�Device (Figure 24 on<br />

page 22).<br />

3. From the Interface pull down menu select the correct COM port.<br />

VAB-93 Revision C 21 of 23

Figure 24.<br />

Device Menu<br />

22 of 23 VAB-93 Revision C

Addendum: Using the Chroma based Linearization<br />

The Chroma Based Linearization can help to open the shadow detail and allow<br />

<strong>for</strong> a greater amount of ink to be used.<br />

The “Use chroma based linearization” checkbox is available when a LIN file<br />

that contains both ink density and L*a*b data is loaded. The PC ColorCatch<br />

software creates LIN files with both ink density and L*a*b data.<br />

When this box is checked, the L*a*b data in the LIN file is used to per<strong>for</strong>m<br />

chroma based linearization; the ink density data in the LIN file will be ignored.<br />

When this box is not selected, the ink density data will be used <strong>for</strong> linearization<br />

and any L*a*b data is ignored. If the a LIN file containing L*a*b data has not<br />

been loaded, this checkbox will be greyed out and linearization will be based<br />

on ink density.<br />

The Chroma Based Linearization can help to open the shadow detail and allow<br />

<strong>for</strong> a greater amount of ink to be used.<br />

(Chroma values will typically be in the range of 60-80 <strong>for</strong> CMK and 85-110 <strong>for</strong><br />

Y, and will vary based on the ink set).<br />

Note: PressVu UV Customers<br />

Chroma Based Linearization should not use the PressVu UV.<br />

VAB-93 Revision C 23 of 23