E-IJPM: Vol. 44/4 - MPIF

E-IJPM: Vol. 44/4 - MPIF

E-IJPM: Vol. 44/4 - MPIF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

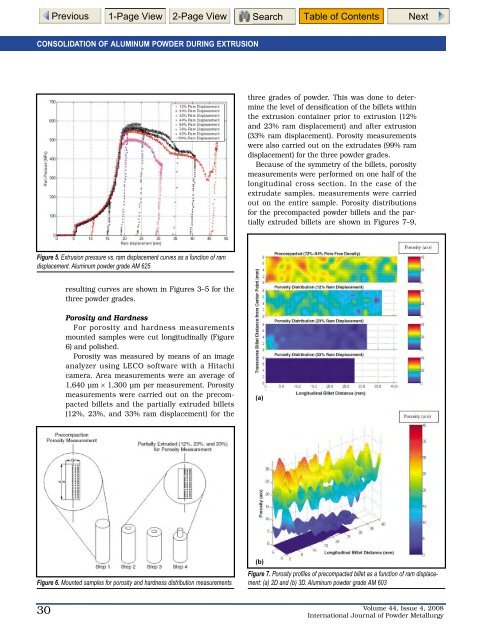

CONSOLIDATION OF ALUMINUM POWDER DURING EXTRUSION<br />

Figure 5. Extrusion pressure vs. ram displacement curves as a function of ram<br />

displacement. Aluminum powder grade AM 625<br />

30<br />

resulting curves are shown in Figures 3–5 for the<br />

three powder grades.<br />

Porosity and Hardness<br />

For porosity and hardness measurements<br />

mounted samples were cut longitudinally (Figure<br />

6) and polished.<br />

Porosity was measured by means of an image<br />

analyzer using LECO software with a Hitachi<br />

camera. Area measurements were an average of<br />

1,640 µm × 1,300 µm per measurement. Porosity<br />

measurements were carried out on the precompacted<br />

billets and the partially extruded billets<br />

(12%, 23%, and 33% ram displacement) for the<br />

Figure 6. Mounted samples for porosity and hardness distribution measurements<br />

three grades of powder. This was done to determine<br />

the level of densification of the billets within<br />

the extrusion container prior to extrusion (12%<br />

and 23% ram displacement) and after extrusion<br />

(33% ram displacement). Porosity measurements<br />

were also carried out on the extrudates (99% ram<br />

displacement) for the three powder grades.<br />

Because of the symmetry of the billets, porosity<br />

measurements were performed on one half of the<br />

longitudinal cross section. In the case of the<br />

extrudate samples, measurements were carried<br />

out on the entire sample. Porosity distributions<br />

for the precompacted powder billets and the partially<br />

extruded billets are shown in Figures 7–9,<br />

(a)<br />

(b)<br />

Figure 7. Porosity profiles of precompacted billet as a function of ram displacement:<br />

(a) 2D and (b) 3D. Aluminum powder grade AM 603<br />

<strong>Vol</strong>ume <strong>44</strong>, Issue 4, 2008<br />

International Journal of Powder Metallurgy