You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INSERT (3 JAW) TYPE<br />

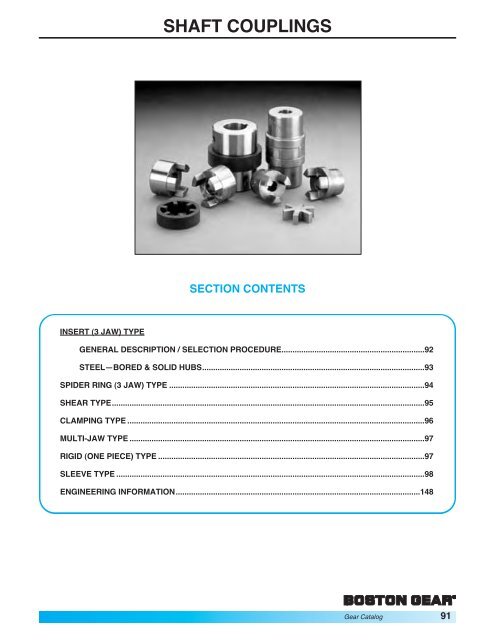

SHAFT COUPLINGS<br />

SECTION CONTENTS<br />

GENERAL DESCRIPTION / SELECTION PROCEDURE.................................................................92<br />

STEEL—BORED & SOLID HUBS.....................................................................................................93<br />

SPIDER RING (3 JAW) TYPE ....................................................................................................................94<br />

SHEAR TYPE..............................................................................................................................................95<br />

CLAMPING TYPE .......................................................................................................................................96<br />

MULTI-JAW TYPE ......................................................................................................................................97<br />

RIGID (ONE PIECE) TYPE .........................................................................................................................97<br />

SLEEVE TYPE ............................................................................................................................................98<br />

ENGINEERING INFORMATION...............................................................................................................148<br />

<strong>Gear</strong> Catalog 91<br />

®

92 <strong>Gear</strong> Catalog<br />

®<br />

SHAFT COUPLINGS<br />

INSERT (3-JAW) TYPE FC SERIES<br />

COUPLING INSERTS<br />

PRECISION MACHINED BORED OR SOLID HUBS<br />

THREE TYPES OF INSERTS for different service requirements.<br />

NO LUBRICATION NEEDED<br />

BORE SIZES FROM 3/8" TO 2-1/8"<br />

COMPLETE WITH KEYWAY AND SETSCREW<br />

OIL-IMPREGNATED BOST-BRONZ—Recommended for high torque loads, particularly at slower speeds.<br />

OIL-RESISTANT SYNTHETIC RUBBER—Recommended where quietness is desired, particularly at motor speeds.<br />

POLYURETHANE—Recommended where moderate to heavy shock loads are encountered.<br />

LOAD DATA<br />

Coup- Shaft<br />

HORSEPOWER AND TORQUE RATING AT<br />

RECOMMENDED SPEEDS FOR INSERTS INDICATED<br />

Maximum Horsepower Rating at RPM of * Max.<br />

ling Diameter Torque<br />

Size Range 50 100 300 690 870 1150 1750 3450 (Lb. Ins.)<br />

XFCBB BOST-BRONZ INSERTS<br />

FC12 3/8–5/8 .16 .32 .95 2.2 2.8 3.6 5.6 — 200<br />

FC15 1/2–7/8 .40 .79 2.4 5.5 6.9 9.1 13.9 — 500<br />

FC20 1/2–1-1/8 .79 1.6 4.8 10.9 13.8 18.2 — — 1000<br />

FC25 3/4–1-3/8 1.4 2.9 8.6 19.7 24.8 — — — 1800<br />

FC30 1–1-5/8 2.5 5.1 15.2 35.0 — — — — 3200<br />

FC38 1-1/4–1-7/8 5.6 11.1 33.3 — — — — — 7000<br />

FC45 1-3/4-–2-1/8 8.7 17.5 — — — — — — 11000<br />

XFCR RUBBER INSERTS<br />

FC12 3/8–5/8 — .10 .31 .71 .90 1.2 1.8 3.6 65<br />

FC15 1/2–7/8 — .20 .60 1.4 1.7 2.3 3.5 6.8 125<br />

FC20 1/2–1-1/8 — .40 1.2 2.7 3.5 4.6 6.9 13.7 250<br />

FC25 3/4–1-3/8 — .71 2.1 4.9 6.2 8.2 12.5 24.6 450<br />

FC30 1–1-5/8 — 1.3 3.8 8.8 11.0 14.6 22.2 43.8 800<br />

FC38 1-1/4–1-7/8 — 2.5 7.6 17.5 22.1 29.2 44.4 — 1600<br />

FC45 1-3/4–2-1/8 — 4.4 13.3 30.7 38.7 51.1 77.7 — 2800<br />

XFCA POLYURETHANE INSERTS<br />

FC12 3/8–5/8 .09 .19 .56 1.2 1.6 2.0 3.0 5.7 125<br />

FC15 1/2–7/8 .18 .37 1.1 2.5 3.1 4.0 6.0 11.3 250<br />

FC20 1/2–1-1/8 .35 .70 2.1 4.6 5.7 7.5 11.1 20.7 470<br />

FC25 3/4–1-3/8 .62 1.2 3.7 8.1 10.1 13.1 19.3 35.8 845<br />

FC30 1–1-5/8 1.1 2.2 6.5 14.4 17.9 23.3 34.3 63.6 1500<br />

FC38 1-1/4–1-7/8 2.2 4.3 12.9 28.4 35.3 45.8 67.3 — 3000<br />

FC45 1-3/4–2-1/8 3.7 7.5 22.4 49.2 61.0 79.0 115.9 — 5250<br />

*For Uniform Load.<br />

SELECTION PROCEDURE<br />

1. From Table select Service Factor.<br />

2. Determine Design Load<br />

Design HP = Application HP x S.F.<br />

or<br />

Design Torque = Application Torque x S.F.<br />

3. Select coupling size from Load Rating<br />

Table which has a rating equal to or<br />

greater than the design load.<br />

COUPLING SERVICE FACTORS<br />

Load Service<br />

Classification Factor<br />

Uniform 1.00<br />

Moderate Shock 1.75<br />

Heavy Shock 2.50<br />

HP =<br />

T x RPM<br />

63,025

INSERT (3-JAW) TYPE FC SERIES<br />

BORED AND SOLID HUBS<br />

KEYWAY<br />

O.D.<br />

BORE<br />

LENGTH<br />

OVERALL<br />

LENGTH<br />

SETSCREW<br />

BORE<br />

HUB<br />

PROJ.<br />

HUB<br />

DIA.<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

To order complete coupling order two coupling halves and one coupling insert.<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.001 –.000<br />

Over- Assem- Coupling Coupling Inserts<br />

Coup- Bore all Hub bly Halves Bost-Bronz Rubber Polyurethane<br />

ling Length + Length Clear- Catalog Item Catalog Item Catalog Item Catalog Item<br />

Size Bore O.D. ++ Dia. Proj. ance † Number Code Number Code Number Code Number Code<br />

— — FC12 SOLID 47448<br />

3/8 FC12–3/8 08246<br />

FC12 7/16 .94 1.25 2.32 1.00 .62 3.19 FC12–7/16 08248 XFCBB12 08064 XFCR12 08078 XFCA12 08050<br />

1/2 FC12–1/2 08250<br />

5/8 FC12-5/8 52405<br />

— — FC15 SOLID 47449<br />

1/2 FC15–1/2 08252<br />

FC15<br />

9/16<br />

5/8<br />

1.13 1.50 2.76 1.25 .75 3.75<br />

FC15–9/16<br />

FC15–5/8<br />

61421 XFCBB15 08066<br />

08254<br />

XFCR15 08080 XFCA15 08052<br />

3/4 FC15–3/4 08256<br />

7/8 FC15–7/8 61422<br />

— — FC20 SOLID 47450<br />

1/2 FC20–1/2 08258<br />

9/16 FC20–9/16 66063<br />

5/8 FC20–5/8 08260<br />

FC20 3/4 1.57 2.00 3.69 1.75 1.12 4.81 FC20–3/4 08262 XFCBB20 08068 XFCR20 08082 XFCA20 08054<br />

7/8 FC20–7/8 08264<br />

15/16 FC20–15/16 08266<br />

1 FC20–1 08268<br />

1-1/8 FC20-1-1/8 52406<br />

— — FC25 SOLID 47451<br />

3/4 FC25–3/4 08270<br />

7/8 FC25–7/8 08272<br />

FC25<br />

1<br />

1-1/8<br />

1.76 2.50 4.13 2.25 1.25 5.38<br />

FC25–1<br />

FC25–1-1/8<br />

08274<br />

XFCBB25 08070<br />

08276<br />

XFCR25 08084 XFCA25 08056<br />

1-3/16 FC25–1-3/16 08278<br />

1-1/4 FC25–1-1/4 08280<br />

1-3/8 FC25-1-3/8 52408<br />

— — FC30 SOLID 47452<br />

1 FC30–1 08282<br />

1-1/8 FC30–1-1/8 08284<br />

FC30<br />

1-1/4<br />

1-3/8<br />

2.35 3.00 5.48 2.75 1.69 7.00<br />

FC30–1-1/4<br />

FC30–1-3/8<br />

08286<br />

XFCBB30 08072<br />

08288<br />

XFCR30 08086 XFCA30 08058<br />

1-7/16 FC30–1-7/16 08290<br />

1-1/2 FC30–1-1/2 08292<br />

1-5/8 FC30-1-5/8 52409<br />

— — FC38 SOLID 24650<br />

1-1/4 FC38–1-1/4 08294<br />

1-1/2 FC38–1-1/2 08296<br />

FC38 1-9/16<br />

1-5/8<br />

2.69<br />

3.75 6.32 3.50 1.88 8.19 FC38–1-9/16 08298 XFCBB38 08074<br />

FC38–1-5/8 08300<br />

XFCR38 08088 XFCA38 08060<br />

1-3/4 FC38–1-3/4 08302<br />

1-7/8 FC38–1-7/8 08304<br />

— — FC45 SOLID 24816<br />

1-3/4 FC45–1-3/4 08306<br />

FC45 1-7/8<br />

2<br />

3.07<br />

4.50 7.19 4.00 2.12 9.31 FC45–1-7/8<br />

FC45–2<br />

08308 XFCBB45 08076<br />

08310<br />

XFCR45 08090 XFCA45 08062<br />

2-1/8 FC45–2-1/8 08312<br />

+Length of hole in each half.<br />

++Total length of coupling with jaws engaged full depth.<br />

†Total length of coupling with jaws completely disengaged for insert assembly.<br />

SHAFT COUPLINGS<br />

REFERENCE PAGES<br />

Alignment—148<br />

Keyways and Setscrews—150<br />

<strong>Gear</strong> Catalog 93<br />

®

SPIDER RING (3-JAW) TYPE BF SERIES<br />

BOST-FLEX ®<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.001 –.000<br />

REFERENCE PAGES<br />

Alignment—148<br />

Keyways and Setscrews—150<br />

SELECTION PROCEDURE<br />

For Service Factors and Procedure, refer to<br />

FC Couplings (Page 92).<br />

94 <strong>Gear</strong> Catalog<br />

®<br />

SHAFT COUPLINGS<br />

ECONOMICAL 3-JAW COUPLING<br />

SPIDER RING URETHANE INSERTS absorb shock and vibration.<br />

Provides thru-bore opening for close coupling of shafts.<br />

BORE SIZES FROM 3/8" TO 1-1/4"<br />

COMPLETE WITH KEYWAY AND SETSCREW<br />

O.D.<br />

OVERALL<br />

LENGTH<br />

E F<br />

KEYWAY<br />

BORE<br />

SETSCREW<br />

Coup-<br />

Bore<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

(Includes two coupling halves and one coupling insert.)<br />

Approx.<br />

Coupling<br />

Replacement<br />

Insert<br />

ling Hub Overall Assem. Weight Catalog Item Item<br />

Size A B Dia. O.D. Length E F Clear. (Oz.) Number Code Code<br />

BF7<br />

3/8<br />

3/8<br />

1/2 .88 1.22 1.35 .50 .34 1.66 2<br />

BF7 3/8–3/8<br />

BF7 3/8–1/2<br />

11730<br />

11734 11722<br />

1/2 1/2 BF7 1/2–1/2 11732<br />

1/2 BF10 1/2–1/2 11736<br />

1/2 5/8 BF10 1/2–5/8 11742<br />

BF10<br />

5/8<br />

3/4<br />

5/8<br />

3/4<br />

1.26 1.59 1.97 .75 .46 2.41 6.5 BF10 1/2–3/4<br />

BF10 5/8–5/8<br />

BF10 5/8–3/4<br />

11744<br />

11738<br />

11746<br />

11724<br />

3/4 3/4 BF10 3/4–3/4 11740<br />

3/4 BF13 3/4–3/4 11748<br />

3/4 7/8 BF13 3/4–7/8 11754<br />

BF13<br />

7/8<br />

1<br />

7/8<br />

1<br />

1.62 1.97 2.47 .94 .59 3.00 14 BF13 3/4–1<br />

BF13 7/8–7/8<br />

BF13 7/8–1<br />

11756<br />

11750<br />

11758<br />

11726<br />

1 1 BF13 1–1 11752<br />

1 BF18 1–1 11760<br />

1 1-1/8 BF18 1–1-1/8 11766<br />

BF18<br />

1-1/8<br />

1-1/4<br />

1-1/8<br />

1-1/4<br />

2.25 2.72 2.97 1.13 .71 3.66 37 BF18 1–1-1/4<br />

BF18 1-1/8–1-1/8<br />

BF18 1-1/8–1-1/4<br />

11768<br />

11762<br />

11770<br />

11728<br />

1-1/4 1-1/4 BF18 1-1/4–1-1/4 11764<br />

HUB<br />

DIA.<br />

HORSEPOWER AND TORQUE RATING AT<br />

RECOMMENDED SPEEDS FOR INSERTS INDICATED<br />

Maximum Horsepower Rating at RPM of * Max<br />

Torque<br />

Size 100 300 690 870 1150 1750 3450 (Lb. Ins.)<br />

BF 7 .044 .13 .31 .39 .51 .78 1.5 28<br />

BF 10 .11 .34 .78 1.00 1.30 2.00 3.9 72<br />

BF 13 .25 .76 1.70 2.20 2.90 4.40 8.8 160<br />

BF 18 .48 1.40 3.30 4.10 5.50 8.30 16.4 300<br />

*For uniform load.

SHEAR TYPE BG SERIES<br />

O.D.<br />

BORE<br />

A<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

1/8–3/8 +.001 –.000<br />

BORE 1/2–5/8 +.0015 –.000<br />

3/4–1 +.002 –.000<br />

REFERENCE PAGES<br />

Alignment—148<br />

LOAD DATA<br />

OVERALL<br />

LENGTH<br />

F<br />

SETSCREW<br />

BORE<br />

B<br />

SHAFT COUPLINGS<br />

HUB<br />

DIA.<br />

HORSEPOWER AND TORQUE RATING AT<br />

RECOMMENDED SPEEDS FOR INSERTS INDICATED<br />

Maximum Horsepower Rating at RPM of * Max<br />

Torque<br />

Size 100 300 690 870 1150 1750 3450 (Lb. Ins.)<br />

BG-47 .001 .003 .008 .010 .013 .020 .039 .72<br />

BG11-1 .004 .011 .025 .031 .041 .062 .123 2.25<br />

BG11-2 .007 .021 .049 .062 .082 .125 .246 4.50<br />

BG11-3 .014 .043 .099 .124 .164 .250 .493 9.00<br />

BG11-4 .019 .057 .131 .166 .219 .333 .657 12.00<br />

BG11-5 .029 .086 .197 .248 .328 .500 .985 18.00<br />

BG11-6 .043 .129 .296 .313 .493 .750 1.478 27.00<br />

BG11-7 .057 .171 .394 .497 .657 1.000 1.971 36.00<br />

*For uniform load.<br />

METAL HUBS JOINED BY PERMANENTLY BONDED ELASTOMER<br />

require no lubrication. Flexible in any direction—accommodates<br />

misalignment up to 1/32" parallel, 2° angular.<br />

HIGH TORSIONAL DEFLECTION isolates low frequency vibration.<br />

BORE SIZES FROM 1/8" TO 1"<br />

COMPLETE WITH STANDARD SETSCREWS (Not installed).<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Coupling Bore Hub Overall Catalog Item<br />

Size A B Dia. O.D. Length F * Number Code<br />

1/8 BG47-2-2 49887<br />

1/8 3/16 BG47-2-3 49888<br />

BG47<br />

3/16<br />

1/4<br />

3/16<br />

1/4<br />

7/16 9/16 13/16 3/16<br />

BG47-2-4<br />

BG47-3-3<br />

BG47-3-4<br />

49889<br />

49890<br />

49891<br />

1/4 1/4 BG47-4-4 49892<br />

3/16<br />

3/16<br />

1/4<br />

BG11-1-3-3<br />

BG11-1-3-4<br />

49893<br />

49894<br />

BG11-1<br />

1/4<br />

1/4<br />

5/16<br />

5/8 13/16 1-3/8 11/32 BG11-1-4-4<br />

BG11-1-4-5<br />

49895<br />

49896<br />

5/16 5/16 BG11-1-5-5 49897<br />

1/4 BG11-2-4-4 49898<br />

1/4 5/16 BG11-2-4-5 49899<br />

BG11-2<br />

5/16<br />

3/8<br />

5/16<br />

3/8<br />

3/4 1 1-3/4 13/32<br />

BG11-2-4-6<br />

BG11-2-5-5<br />

BG11-2-5-6<br />

49900<br />

49901<br />

49902<br />

3/8 3/8 BG11-2-6-6 49903<br />

5/16 BG11-3-5-5 49904<br />

5/16 3/8 BG11-3-5-6 49905<br />

BG11-3<br />

3/8<br />

1/2<br />

3/8<br />

1/2<br />

7/8 1-1/4 2-1/8 15/32<br />

BG11-3-5-8<br />

BG11-3-6-6<br />

BG11-3-6-8<br />

49906<br />

49907<br />

49908<br />

1/2 1/2 BG11-3-8-8 49909<br />

3/8 BG11-4-6-6 49910<br />

3/8 1/2 BG11-4-6-8 49911<br />

BG11-4<br />

1/2<br />

5/8<br />

1/2<br />

5/8<br />

1 1-3/8 2-1/4 17/32<br />

BG11-4-6-10<br />

BG11-4-8-8<br />

BG11-4-8-10<br />

49912<br />

49913<br />

49914<br />

5/8 5/8 BG11-4-10-10 49915<br />

1/2 BG11-5-8-8 49916<br />

1/2 5/8 BG11-5-8-10 49917<br />

BG11-5 3/4 1-1/8 1-5/8 2-1/2 19/32 BG11-5-8-12 49918<br />

5/8 5/8 BG11-5-10-10 49919<br />

3/4 3/4 BG11-5-12-12 49920<br />

1/2<br />

1/2<br />

3/4<br />

BG11-6-8-8<br />

BG11-6-8-12<br />

49921<br />

49922<br />

BG11-6<br />

5/8<br />

5/8<br />

3/4<br />

1-3/8 1-13/16 2-11/16 11/16 BG11-6-10-10<br />

BG11-6-10-12<br />

49923<br />

49924<br />

3/4 3/4 BG11-6-12-12 49925<br />

1/2 3/4 BG11-7-8-12 49926<br />

5/8 5/8 BG11-7-10-10 49927<br />

BG11-7<br />

3/4<br />

3/4<br />

7/8<br />

1-1/2 2 2-7/8 3/4 BG11-7-12-12<br />

BG11-7-12-14<br />

49929<br />

49930<br />

1 1 BG11-7-16-16 49931<br />

*Shafts should not extend into “F” dimension.<br />

<strong>Gear</strong> Catalog 95<br />

®

96 <strong>Gear</strong> Catalog<br />

®<br />

SHAFT COUPLINGS<br />

CLAMPING TYPE SCC SERIES<br />

OUTSIDE<br />

DIA.<br />

BORE<br />

(A)<br />

CLAMP SCREW<br />

LENGTH<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.003 – +.000<br />

BORE (B)<br />

LOAD DATA<br />

Capacity is based on a standard steel, onepiece<br />

coupling mounted with recommended<br />

screw torque on a dry shaft. Capacities<br />

shown are for general guidance only. In<br />

appl ications involving control of torque<br />

loads, capacity should be determined<br />

experi mentally on actual parts involved.<br />

LOW CARBON STEEL COUPLINGS with a black oxide finish.<br />

BORE SIZES FROM 1/4” TO 2”<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Bore Clamp Catalog Item<br />

A B O.D. Length Screws (4) Number Code<br />

1/4 1/4 13/16 1-1/4 4-40 SCC1/4x1/4 49289<br />

3/8<br />

1/4<br />

3/8<br />

1-1/16 1-5/8 6-32<br />

SCC3/8x1/4<br />

SCC3/8x3/8<br />

49290<br />

49291<br />

1/2<br />

3/8<br />

1/2<br />

1-1/4 1-7/8 8-32<br />

SCC1/2x3/8<br />

SCC1/2x1/2<br />

49292<br />

49293<br />

5/8<br />

1/2<br />

5/8<br />

1-1/2 2-1/4 10-32<br />

SCC5/8x1/2<br />

SCC5/8x5/8<br />

49294<br />

49295<br />

1/2 SCC3/4x1/2 49296<br />

3/4 5/8 1-3/4 2-5/8 1/4-28 SCC3/4x5/8 49297<br />

3/4 SCC3/4x3/4 49298<br />

7/8<br />

5/8<br />

7/8<br />

1-7/8 2-7/8 1/4-28<br />

SCC7/8x5/8<br />

SCC7/8x7/8<br />

49299<br />

49300<br />

1 1 2 3 1/4-28 SCC1x1 49302<br />

1-1/8<br />

1<br />

1-1/8<br />

2-1/8 3-1/4 1/4-28<br />

SCC1-1/8x1<br />

SCC1-1/8x1-1/8<br />

49303<br />

49304<br />

1-1/4<br />

1<br />

1-1/4<br />

2-1/4 3-3/8 1/4-28<br />

SCC1-1/4x1<br />

SCC1-1/4x1-1/4<br />

49305<br />

49306<br />

1-3/8<br />

1<br />

1-3/8<br />

2-3/8 3-5/8 1/4-28<br />

SCC1-3/8x1<br />

SCC1-3/8x1-3/8<br />

49307<br />

49308<br />

1-1/2<br />

1<br />

1-1/2<br />

2-1/2 3-3/4 1/4-28<br />

SCC1-1/2x1<br />

SCC1-1/2x1-1/2<br />

49309<br />

49310<br />

1-3/4 1-3/4 3 4-1/2 5/16-24 SCC1-3/4x1-3/4 49312<br />

2 2 3-1/4 4-7/8 5/16-24 SCC2x2 49314<br />

TORQUE CAPACITY<br />

Torque Recommended<br />

Capacity Screw Screw Torque<br />

Bore (Lb. Ins.) Size (Lb. Ins.)<br />

1/4 72 4-40 20<br />

3/8 192 6-32 30<br />

1/2 480 8-32 55<br />

5/8 1200 10-32 90<br />

3/4 1500<br />

7/8 1680<br />

1 1920<br />

1-1/8 2200 1/4-28 90<br />

1-1/4 3000<br />

1-3/8 3500<br />

1-1/2 4000<br />

1-3/4<br />

2<br />

5400<br />

6000<br />

5/16-24 435

MULTI-JAW TYPE FA SERIES<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All ±.0005<br />

REFERENCE PAGES<br />

Alignment—148<br />

Keyways and Setscrews—150<br />

UNTREATED STEEL COUPLINGS for use in light duty applications,<br />

require no lubrication.<br />

BORE SIZES FROM 3/16" TO 1/2"<br />

COMPLETE WITH STANDARD SETSCREWS<br />

O.D.<br />

BORE<br />

LENGTH<br />

OVERALL<br />

LENGTH<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

SETSCREW<br />

BORE<br />

HUB<br />

PROJ.<br />

Steel<br />

Coupling Bore Assembly Hub Catalog Item<br />

Size Bore O.D. Length † Length ++ Clearance ‡ Dia. Proj. Teeth Number Code<br />

3/16 FA5 3/16–3/16 07900<br />

FA5 7/32 1/2 1-1/8 .48 .48 7/16 7/16 10 FA5 7/32–7/32 07902<br />

1/4 FA5 1/4–1/4 07904<br />

FA75 5/16<br />

3/8<br />

3/4 1-1/2 5/8 1-3/4 11/16 33/64 10<br />

FA75 5/16–5/16<br />

FA75 3/8–3/8<br />

07910<br />

07912<br />

FA10<br />

7/16<br />

1/2<br />

1 2 .86 .86 15/16 3/4 12<br />

FA10 7/16–7/16<br />

FA10 1/2–1/2<br />

07908<br />

07906<br />

†Total length of coupling with jaws engaged full depth.<br />

++Length of hole in each half.<br />

‡Approximate total length of coupling with jaws completely disengaged.<br />

RIGID (ONE PIECE) TYPE CR SERIES<br />

BORE SIZES FROM 1/4" TO 1-1/4"<br />

COMPLETE WITH STANDARD SETSCREWS<br />

O.D.<br />

SETSCREW<br />

A<br />

BORE<br />

OVERALL<br />

LENGTH<br />

A<br />

SHAFT COUPLINGS<br />

REFERENCE PAGES<br />

Keyways and Setscrews—150<br />

HUB<br />

DIA.<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Overall Catalog Item<br />

Bore O.D. Length A Setscrew Number Code<br />

1/4 .48 3/4 3/16 #6-32 CR4 34200<br />

5/16 .60 1 1/4 #10-32 CR5 34202<br />

3/8 .72 1 1/4 #10-32 CR6 34204<br />

1/2 .97 1-1/2 3/8 1/4-20 CR8 34206<br />

5/8 1.21 2 1/2 1/4-20 CR10 34208<br />

3/4 1.47 2 1/2 3/8-16 CR12 34210<br />

7/8 1.72 2 1/2 3/8-16 CR14 34212<br />

1 1.96 3 3/4 3/8-16 CR16 34214<br />

1-1/4 2.21 4 1 1/2-13 CR20 34216<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.001 –.000<br />

<strong>Gear</strong> Catalog 97<br />

®

HORSEPOWER RATINGS (Maximum) AT 1750 RPM<br />

Size Horsepower<br />

FCP21 1/20<br />

FCP23 1/2<br />

98 <strong>Gear</strong> Catalog<br />

®<br />

SHAFT COUPLINGS<br />

SLEEVE TYPE FCP SERIES<br />

MATERIALS<br />

Urethane Sleeves<br />

Delrin Hubs<br />

Aluminum Alloy Inserts<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.001 –.000<br />

REFERENCE PAGES<br />

Alignment—148<br />

SPLINED HUBS AND URETHANE SLEEVE accommodate<br />

misalignment to 5°.<br />

SLEEVE STOCK available for producing special lengths.<br />

NO LUBRICATION NEEDED<br />

COMPLETE WITH SETSCREWS<br />

A<br />

2<br />

O.D.<br />

A<br />

L<br />

E<br />

1<br />

16<br />

HUB<br />

SETSCREW<br />

BORE<br />

H<br />

INSERT<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Complete Coupling Insert and Hub Assembly Sleeve Only<br />

Catalog Item Catalog Item Catalog Item<br />

Bore O.D. A E H L Setscrew Number Code Number Code Number Code<br />

.125 4-40 FCP21-1/8 54893 XFCP21-1/8 54903<br />

.1875<br />

.250<br />

37/64 7/32 7/16 9/16 15/16<br />

6-32<br />

FCP21-3/16<br />

FCP21-1/4<br />

54894<br />

54895<br />

XFCP21-3/16<br />

XFCP21-1/4<br />

54904<br />

54905<br />

X5R21-16 54913<br />

.3125 8-32 FCP23-5/16 54899 XFCP23-5/16 54909<br />

.375<br />

.4375<br />

.500<br />

1-5/64 3/8 11/16 1 1-9/16 10-32<br />

1/4-20<br />

FCP23-3/8<br />

FCP23-7/16<br />

FCP23-1/2<br />

54900<br />

54901<br />

54902<br />

XFCP23-3/8<br />

XFCP23-7/16<br />

XFCP23-1/2<br />

54910<br />

54911<br />

54912<br />

X5R23-32 54915<br />

LOAD DATA SLEEVE STOCK<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

O.D. Length (Inches) Catalog Number Item Code<br />

1/2 10 5R21-16S 54916<br />

1 12 5R23-32S 54918

PIN AND BLOCK TYPE<br />

UNIVERSAL JOINTS<br />

GENERAL DESCRIPTION / SELECTION PROCEDURE ............................................................ 100<br />

STEEL & STAINLESS STEEL— BORED & SOLID HUBS............................................................101<br />

BOOT KITS ......................................................................................................................................101<br />

FORGED TYPE<br />

GENERAL DESCRIPTION / SELECTION PROCEDURE ..............................................................102<br />

STEEL — COMPLETE JOINTS.......................................................................................................103<br />

YOKES & CENTER KITS.................................................................................................................104<br />

MOLDED TYPE<br />

SECTION CONTENTS<br />

DELRIN — SINGLE & DOUBLE......................................................................................................105<br />

DELRIN — WITH SLIDE EXTENSION ............................................................................................106<br />

ENGINEERING INFORMATION...............................................................................................................148<br />

<strong>Gear</strong> Catalog 99<br />

®

100 <strong>Gear</strong> Catalog<br />

®<br />

UNIVERSAL JOINTS<br />

PIN AND BLOCK TYPE J/JS SERIES<br />

STEEL AND STAINLESS STEEL<br />

SELECTION<br />

Torque ratings may be calculated from data in tables. The<br />

tables indicate the Rated Static Torque (Lb. Ins.) of alloy and<br />

stainless steel joints and Speed-Angle factors suggested for<br />

various operating conditions.<br />

The approximate service torque rating of a particular joint is<br />

obtained by dividing the Rated Static Torque by the appropriate<br />

Speed-Angle factor.<br />

Selecting a universal joint to satisfy a specified torque requirement<br />

is also made convenient with the data provided.<br />

The designated torque load should be multiplied by the<br />

appropriate Speed-Angle factor to obtain an equivalent static<br />

torque load.<br />

A universal joint with a rated static torque equal to or greater<br />

than the calculated torque load would then be selected.<br />

<strong>Boston</strong> <strong>Gear</strong> precision machined J and JS Series Universal Joints are designed<br />

for connecting shafts at angles up to 30 degrees and speeds up to 2000 RPM.<br />

All sizes are stocked with both solid and bored hubs.<br />

Joints J100 and J100B and larger are equipped with self-closing, ball valve oilers,<br />

creating an oil reservoir to provide enclosed lubrication.<br />

The self-locking assembly ring on joints with 7/8" and larger hub diameter, fits<br />

into recess provided in center bearing block and snaps around groove in small<br />

bearing pin—assuring locking of entire assembly—allowing for quick and easy<br />

disassembly and reassembly. Joints with 3/4" and smaller hub diameters are<br />

locked by riveting the small bearing pin.<br />

Joint covers (boots) keep dirt and moisture out and lubricants in.<br />

SPEED ANGLE FACTORS<br />

EXAMPLE:<br />

A pair of universal joints are desired to transmit 1/2 HP from<br />

one shaft running at 500 RPM to another located at an angle<br />

of 10 degrees (from a straight line).<br />

The joints will be connected by an intermediate shaft and<br />

arranged to operate at equal angles of 5 degrees.<br />

A Speed-Angle factor of 9 is indicated in the table for an operating<br />

angle of 5 degrees and a speed of 500 RPM.<br />

Torque 63025 Load = x HP 63025 x = 1/2<br />

= 63 Lb. Ins.<br />

RPM<br />

500<br />

Equivalent Static Load = Torque load x Factor<br />

= 63 x 9 = 567 Lb. Ins.<br />

J100 size alloy steel or JS175 size stainless steel universals<br />

would be suggested for this application.<br />

Speed Operating Angle — Degrees (Deviation from Straight Line)<br />

in RPM 0 1/2 1 2 3 4 5 6 8 10 12 15 20 25 30<br />

2000 21 22 23.2 25.2 27.4 29.4 31.6 — — — — — — — —<br />

1800 19 20 21.0 22.8 24.8 26.6 28.6 30.4 — — — — — — —<br />

1600 17 17.8 18.8 20.4 22.2 23.8 25.6 27.2 — — — — — — —<br />

1400 15 15.8 16.6 18.0 19.6 21.0 22.6 24.0 27 — — — — — —<br />

1200 13 13.6 14.4 15.6 17.0 18.2 19.6 20.8 23.4 — — — — — —<br />

1000 11 11.6 12.2 13.2 14.4 15.4 16.6 17.6 19.8 22 — — — — —<br />

900 10 10.6 11.0 12.0 13.0 14.0 15.0 16.0 18.0 20 22 — — — —<br />

800 9.0 9.4 10.0 10.8 11.8 12.6 13.6 14.4 16.2 18 19.8 — — — —<br />

700 8.0 8.4 8.8 9.6 10.4 11.2 12.0 12.8 14.4 16 17.6 20 — — —<br />

600 7.0 7.4 7.8 8.4 9.2 9.8 10.6 11.2 12.6 14 15.4 17.6 — — —<br />

500 6.0 6.4 6.6 7.2 7.8 8.4 9.0 9.6 10.8 12 13.2 15.0 18 — —<br />

400 5.0 5.2 5.6 6.0 6.6 7.0 7.6 8.0 9.0 10 11.0 12.6 15 17.6 —<br />

300 4.0 4.2 4.4 4.8 5.2 5.6 6.0 6.4 7.2 8.0 8.8 10.0 12 14.0 16<br />

200 3.0 3.2 3.4 3.6 4.0 4.2 4.6 4.8 5.4 6.0 6.6 7.6 9.0 10.6 12<br />

100 2.0 2.2 2.2 2.4 2.6 2.8 3.0 3.2 3.6 4.0 4.4 5.0 6.0 7.0 8.0<br />

50 1.5 1.6 1.7 1.8 2.0 2.2 2.2 2.4 2.8 3.0 3.4 3.8 4.6 5.2 6.0<br />

25 1.3 1.3 1.4 1.5 1.6 1.8 1.9 2.0 2.2 2.6 2.8 3.2 3.8 4.4 5.0<br />

10 1.1 1.2 1.2 1.3 1.4 1.5 1.7 1.8 2.0 2.2 2.4 2.8 3.4 3.8 4.4<br />

0 1.0 1.1 1.1 1.2 1.3 1.4 1.5 1.6 1.8 2.0 2.2 2.6 3.0 3.6 4.0<br />

RATED STATIC TORQUE (LB. INS.) STRAIGHT LINE<br />

ALLOY STEEL UNIVERSAL JOINTS<br />

Catalog Number J37 J50 J62 J75 J87 J100 J112 J125 J150 J175 J200 J250 J300 J400<br />

Torque — Lb. Ins. 20 80 166 320 370 600 670 1040 1680 2500 4400 7000 11,000 26,400<br />

STAINLESS STEEL UNIVERSAL JOINTS<br />

Catalog Number JS37 JS50 JS62 JS75 JS87 JS100 JS112 JS125 JS150 JS175 JS200 JS250 JS300 JS400<br />

Torque — Lb. Ins. 6 24 50 96 110 180 200 310 500 750 1320 1900 3100 7360

PIN AND BLOCK TYPE J/JS SERIES<br />

STEEL AND STAINLESS STEEL BORED AND SOLID HUBS<br />

STANDARD TOLERANCES<br />

Dimensions Tolerance<br />

Steel Stainless<br />

Bore All ± .001 ±.001<br />

Hub Dia. All + .000 – .003 ±.020<br />

Bore Length All ±1/16 ±1/64<br />

Overall Length<br />

REFERENCE PAGES<br />

1-3/4 - 4-1/4 ±1/64 ±1/64<br />

5 - 10-5/8 ±1/32 ±1/32<br />

UNIVERSAL JOINTS<br />

OVERALL LENGTH<br />

OVERALL<br />

LENGTH<br />

2<br />

BORE<br />

LENGTH<br />

OVERALL<br />

LENGTH<br />

2<br />

A<br />

C B C<br />

Boot Kit<br />

Lubrication—148<br />

Mounting—148<br />

Universal Joints Boot Kits †<br />

Catalog Item Catalog Item Bore** Bore* Hub Overall Keyway Setscrew Approx. Catalog † ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

STEEL STAINLESS<br />

Number Code<br />

STEEL<br />

Number Code Length Dia. Length<br />

Weight<br />

Lbs.<br />

A B C<br />

Item<br />

Number Code<br />

J37A-3/16 72467 - - - 2-56NC .04<br />

J37B 08426 JS37B 08472 3/16 11/16 3/8 1-3/4 - - .04 1-1/32 1-1/32 9/32 UB37 47602<br />

J37 08400 JS37 08452 - - .05<br />

J50A-1/4 72468 - - - 4-40NC .08<br />

J50B 08428 JS50B 08474 1/4 3/4 1/2 2 - - .08 1-1/4 1-5/16 11/32 UB50 47603<br />

J50 08402 JS50 08454 - - .10<br />

J62A-5/16 72469 - - 3/32x3/64 10-32NF .14<br />

J62B 08430 JS62B 08476 5/16 13/16 5/8 2-1/4 - - .14 1-1/2 1-7/16 13/16 UB62 47604<br />

J62 08404 JS62 08456 - - .18<br />

J75A-3/8 72470 - - 3/32x3/64 10-32NF .24<br />

J75B 08432 JS75B 08478 3/8 31/32 3/4 2-11/16 - - .24 1-3/4 1-9/16 9/16 UB75 47605<br />

J75 08406 JS75 08458 - - .30<br />

J87A-7/16 72471 -- 3/32x3/64 10-32NF .31<br />

J87B 08434 JS87B 08480 7/16 1-1/32 7/8 3 - - .31 2 1-13/16 19/32 UB87 47606<br />

J87 08408 JS87 08460 - - .45<br />

J100A-1/2 72472 - - 1/8x1/16 1/4-20NC .50<br />

J100B 08436 JS100B 08482 1/2 1-3/16 1 3-3/8 - - .50 2-1/4 2-1/8 5/8 UB100 47607<br />

J100 08410 JS100 08462 - - .66<br />

J112A-9/16 72473 - - 1/8x1/16 1/4-20NC .69<br />

J112B 72474 JS112B 72483 9/16 1-7/32 1-1/8 3-1/2 - - .69 2-9/16 2-7/16 17/32 UB112 72491<br />

J112 72475 JS112 72484 - - .88<br />

J125A-5/8 72476 -- 3/16x3/32 5/16-18NC .88<br />

J125B 08438 JS125B 08484 5/8 1-1/4 1-1/4 3-3/4 - - .88 2-7/8 2-3/4 1/2 UB125 47608<br />

J125 08412 JS125 08464 - - 1.15<br />

J150A-3/4 72477 - - 3/16x3/32 5/16-18NC 1.44<br />

J150B 08440 JS150B 08486 3/4 1-11/32 1-1/2 4-1/4 - - 1.44 3-1/4 3-1/4 1/2 UB150 47609<br />

J150 08414 JS150 08466 - - 1.81<br />

J175A-7/8 72478 - - 3/16x3/32 5/16-18NC 2.31<br />

J175B 08442 JS175B 08488 7/8 1-9/16 1-3/4 5 - - 2.31 3-5/8 3-3/4 5/8 UB175 47610<br />

J175 08416 JS175 08468 - - 2.86<br />

J200A-1 72479 - - 1/4x1/8 3/8-16NC 3.31<br />

J200B 08444 JS200B 08490 1 1-5/8 2 5-7/16 - - 3.31 4-1/2 4-3/16 5/8 UB200 47611<br />

J200 08418 JS200 08470 - - 4.06<br />

J250A-1-1/4 72480 - - 1/4x1/8 3/8-16NC 6.81<br />

J250B 08446 JS250B 72485 1-1/4 2-3/32 2-1/2 7 - - 6.81 5-1/2 4-7/8 1-1/16 UB250 47612<br />

J250 08420 JS250 72486 - - 8.25<br />

J300A-1/1/2 72481 - - 3/8x3/16 1/2-13NC 12.5<br />

J300B 08448 JS300B 72487 1-1/2 2-27/32 3 9 - - 12.5 6 5-5/8 1-11/16 UB300 47613<br />

J300 08422 JS300 72488 - - 15.25<br />

J400A-2 72482 - - 1/2x1/4 1/2-13NC 25.8<br />

J400B 08450 JS400B 72489 2 3-1/8 4 10-5/8 - - 25.8 6-7/8 6-5/8 2 UB400 47614<br />

J400 08424 JS400 72490 - - 31.3<br />

*Approximate Hub Projection<br />

†Each Kit contains (2) Boots and (4) Ties together with complete instructions for installation and lubrication.<br />

**Style A includes bore, keyway and setscrew. Style B includes bore only<br />

HUB<br />

DIA.<br />

BORE DIA.<br />

<strong>Gear</strong> Catalog 101<br />

®

102 <strong>Gear</strong> Catalog<br />

®<br />

UNIVERSAL JOINTS<br />

FORGED/CAST UJNS/UJNL SERIES<br />

STEEL BOS-TRONG ®<br />

SELECTION<br />

LOAD DATA<br />

A BOS-trong ® joint is composed of two yokes and a center kit. BOS-trong joints<br />

may be purchased assembled, or as separate yokes and center kits. Individually<br />

boxed.<br />

AVAILABLE IN TWO SIZES<br />

EQUIPPED WITH NEEDLE BEARINGS<br />

PRECISION MACHINED FOR LONG, SMOOTH OPERATION<br />

CONTINUOUS OR INTERMITTENT SERVICE<br />

HIGH CAPACITY WITH MINIMUM SWING DIAMETER<br />

BROAD RANGE OF HOLE DIAMETERS<br />

AVAILABLE WITH ROUND, SQUARE OR HEXAGON HOLES<br />

COMPLETE WITH KEYWAY AND SETSCREW<br />

REPLACEABLE CENTER KITS<br />

FITTING FOR LUBRICATION<br />

Universal Joints are used in many different types of applications and under a wide variety of operating conditions.<br />

No convenient method can be presented for determining ratings for all possible circumstances.<br />

Performance will be affected by vibration, shock loading, high temperature, dusty environment, etc.<br />

The simplest solution to this problem is to provide approximate ratings of universal joints operating at various<br />

angles and speeds under normal service conditions.<br />

The suggested ratings are for general use in applications where two joints are arranged at equal angles with the<br />

bearing pins of the intermediate yokes in line with each other.<br />

Service torque ratings of the two sizes of BOS-trong ® Needle Bearing universals are listed in tables. Ratings for<br />

intermediate speeds and/or angles not shown may be found by interpolation.<br />

APPROXIMATE TORQUE RATINGS (LB. INS.)<br />

UJNS Series UJNL Series<br />

Operating Angle *—Degrees (Deviation from Straight Line) Operating Angle †—Degrees (Deviation from Straight Line)<br />

Speed Up to Up to<br />

RPM 3° 5° 8° 12° 20° 30° 3° 5° 8° 12° 20° 30°<br />

1800 610 515 440 — — — 845 710 610 — — —<br />

1200 700 590 505 435 — — 965 815 695 600 — —<br />

900 770 650 555 480 365 — 1060 895 765 660 500 —<br />

600 880 740 635 545 415 260 1210 1020 875 755 575 355<br />

300 1110 935 800 690 525 325 1530 1290 1100 950 725 450<br />

200 1270 1070 915 790 600 370 1750 1480 1260 1090 825 515<br />

100 1600 1350 1150 995 755 470 2210 1860 1590 1370 1040 645<br />

50 2020 1700 1450 1250 950 590 2780 2350 2000 1730 1310 815<br />

25 2540 2140 1830 1580 1200 745 3500 2960 2530 2180 1650 1020<br />

10 3450 2900 2480 2140 1630 1010 4760 4010 3430 2960 2250 1390<br />

Non Operating Flex angle—90°<br />

*Maximum Angles (Momentary)—45°<br />

†Maximum Angles (Momentary)—35°

FORGED/CAST UJNS/UJNL SERIES<br />

STEEL BOS-TRONG ®<br />

OVERALL<br />

LENGTH<br />

SETSCREW<br />

BORE<br />

HUB<br />

DIA.<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.002 –.000<br />

REFERENCE PAGES<br />

Mounting —148<br />

Lubrication — 148<br />

ORDERING INFORMATION<br />

KEYWAY<br />

Joints can also be ordered in various combinations<br />

of round, square or hex holes. To<br />

order the combination desired, specify<br />

“UJNS” or “UJNL” and hole size and type as<br />

listed in table of Yokes, Page 104. Use “S”<br />

for square and “H” for hexagon.<br />

UNIVERSAL JOINTS<br />

All joints have round holes with standard keyways and 3/8–16 hex socket<br />

setscrews.<br />

ALL DIMENSIONS IN INCHES<br />

Approx.<br />

Overall Bore Hub Dia. Weight Catalog Item<br />

Length Hub-A Hub-B Hub-A Hub-B (Lbs.) Number Code<br />

UJNS SERIES SWING DIAMETER—2-1/2"<br />

5/8 1-5/8 UJNS 10-10 17300<br />

3/4 1-5/8 UJNS 10-12 17302<br />

13/16 1-5/8 UJNS 10-13 17304<br />

5 5/8 7/8 1-5/8 1-5/8 2 UJNS 10-14 17306<br />

15/16 1-5/8 UJNS 10-15 17308<br />

1 1-5/8 UJNS 10-16 17310<br />

1-1/8 2-1/4 UJNS 10-18 17312<br />

3/4 1-5/8 UJNS 12-12 17314<br />

13/16 1-5/8 UJNS 12-13 17316<br />

5 3/4 7/8 1-5/8 1-5/8 2 UJNS 12-14 17318<br />

15/16 1-5/8 UJNS 12-15 17320<br />

1 1-5/8 UJNS 12-16 17322<br />

1-1/8 2-1/4 UJNS 12-18 17324<br />

13/16 1-5/8 UJNS 13-13 17326<br />

7/8 1-5/8 UJNS 13-14 17328<br />

5 13/16 15/16 1-5/8 1-5/8 2 UJNS 13-15 17330<br />

1 1-5/8 UJNS 13-16 17332<br />

1-1/8 2-1/4 UJNS 13-18 17334<br />

7/8 1-5/8 UJNS 14-14 17336<br />

5 7/8<br />

15/16<br />

1<br />

1-5/8<br />

1-5/8<br />

1-5/8<br />

2<br />

UJNS 14-15<br />

UJNS 14-16<br />

17338<br />

17340<br />

1-1/8 2-1/4 UJNS 14-18 17342<br />

15/16 1-5/8 UJNS 15-15 17344<br />

5 15/16 1 1-5/8 1-5/8 2 UJNS 15-16 17346<br />

1-1/8 2-1/4 UJNS 15-18 17348<br />

5 1<br />

1<br />

1-1/8<br />

1-5/8<br />

1-5/8<br />

2-1/4<br />

2<br />

UJNS 16-16<br />

UJNS 16-18<br />

17350<br />

17352<br />

5 1-1/8 1-1/8 2-1/4 2-1/4 3 UJNS 18-18 17498<br />

UJNL SERIES SWING DIAMETER—2-3/4"<br />

1 2 UJNL 16-16 17354<br />

1-1/8 2-1/4 UJNL 16-18 17356<br />

1-3/16 2-1/4 UJNL 16-19 17358<br />

5-1/2 1 1-1/4 2 2-1/4 3-3/4 UJNL 16-20 17360<br />

1-3/8 2-1/4 UJNL 16-22 17362<br />

1-7/16 2-1/4 UJNL 16-23 17364<br />

1-1/2 2-1/4 UJNL 16-24 17366<br />

1-1/8 2-1/4 UJNL 18-18 17368<br />

1-3/16 2-1/4 UJNL 18-19 17370<br />

5-1/2 1-1/8<br />

1-1/4<br />

1-3/8<br />

2-1/4<br />

2-1/4<br />

2-1/4<br />

3-3/4<br />

UJNL 18-20<br />

UJNL 18-22<br />

17372<br />

17374<br />

1-7/16 2-1/4 UJNL 18-23 17376<br />

1-1/2 2-1/4 UJNL 18-24 17378<br />

1-3/16 2 UJNL 19-19 17380<br />

1-1/4 2-1/4 UJNL 19-20 17382<br />

5-1/2 1-3/16 1-3/8 2-1/4 2-1/4 3-1/4 UJNL 19-22 17384<br />

1-7/16 2-1/4 UJNL 19-23 17386<br />

1-1/2 2-1/4 UJNL 19-24 17388<br />

1-1/4 2 UJNL 20-20 17390<br />

5-1/2 1-1/4<br />

1-3/8<br />

1-7/16<br />

2-1/4<br />

2-1/4<br />

2-1/4<br />

3-1/4<br />

UJNL 20-22<br />

UJNL 20-23<br />

17392<br />

17394<br />

1-1/2 2-1/4 UJNL 20-24 17396<br />

1-3/8 2-1/4 UJNL 22-22 17398<br />

5-1/2 1-3/8 1-7/16 2-1/4 2-1/4 3-1/4 UJNL 22-23 17400<br />

1-1/2 2-1/4 UJNL 22-24 17402<br />

5-1/2 1-7/16<br />

1-7/16<br />

1-1/2<br />

2-1/4 2-1/4 3-1/4<br />

UJNL 23-23<br />

UJNL 23-24<br />

17404<br />

17406<br />

5-1/2 1-1/2 1-1/2 2-1/4 2-1/4 3-1/4 UJNL 24-24 17408<br />

<strong>Gear</strong> Catalog 103<br />

®

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

Round +.000–+.002<br />

Bore Square<br />

3/4–13/16 +.000–+.002<br />

7/8 –1-1/2 +.001 +.003<br />

Hexagon +.002 +.004<br />

104 <strong>Gear</strong> Catalog<br />

®<br />

UNIVERSAL JOINTS<br />

FORGED/CAST UJS/UJL SERIES<br />

STEEL<br />

A<br />

Bore<br />

Hub<br />

Dia.<br />

Keyway<br />

YOKES<br />

These yokes are for assembly with UJSC Center Kits.<br />

All yokes are furnished with 3/8–16 hex socket setscrew.<br />

UJS14H is 1/8 NPT straight.<br />

ALL DIMENSIONS IN INCHES<br />

A<br />

KEYWAY<br />

HUB<br />

BORE DIA.<br />

CENTER KITS DOUBLE YOKES<br />

DIM.<br />

ACROSS<br />

FLATS<br />

ALL DIMENSIONS IN INCHES<br />

Center Kits * Double Yokes<br />

Approx. Maximum Approx.<br />

Weight Catalog Item Operating Weight Catalog Item<br />

A B C D (Lbs.) Number Code J Angle (Lbs.) Number Code<br />

UJS Series UJS Series Forged<br />

1-61/64 35/64 19/32 31/32 1/2 UJSC 17464 2-1/2 15° 1 UJSD 17460<br />

UJL Series UJL Series Forged – 2 piece Welded Construction<br />

2-5/16 .644 5/8 1-1/16 3/4 UJLC 17466 4-7/16 35° 2-1/4 UJLD 17462<br />

*Center Kits include 1 cross, 4 bearings, 4 cork washers and 4 lock rings.<br />

Round Bores Square Bores Hexagon Bores<br />

Setscrew<br />

Location<br />

Approx.<br />

Weight<br />

(Lbs.)<br />

Catalog<br />

Number<br />

Item<br />

Code<br />

Dim.<br />

Across<br />

Flats<br />

Hub<br />

Dia.<br />

Approx.<br />

Weight<br />

(Lbs.)<br />

Catalog<br />

Number<br />

Item<br />

Code<br />

Catalog<br />

Number<br />

UJS Series<br />

.625<br />

(4)<br />

UJS10 17410 — — — — — — —<br />

2-1/2<br />

.750<br />

.813<br />

.875<br />

1.63<br />

3/16x3/32<br />

(1)<br />

(4)<br />

(5)<br />

(4)<br />

3/4<br />

UJS12<br />

UJS13<br />

UJS14<br />

17412<br />

17414<br />

17416<br />

.750<br />

.813<br />

.875 (7)<br />

1.63<br />

3/4<br />

UJS12S<br />

UJS13S<br />

UJS14S<br />

17438<br />

17440<br />

17442<br />

—<br />

—<br />

UJS14H (7)<br />

—<br />

—<br />

17454<br />

.938<br />

1.000<br />

1/4x1/8<br />

(1)<br />

(4)<br />

(4)<br />

UJS15<br />

UJS16<br />

17418<br />

17420<br />

.938<br />

1.000(7)<br />

2.25<br />

1-1/4<br />

UJS15S<br />

UJS16S<br />

17444<br />

17446<br />

—<br />

—<br />

—<br />

—<br />

1.125 2.25 (2) (4) 1-1/4 UJS18 17422 1.126 UJS18S 17448 UJS18H 17456<br />

UJL Series<br />

1.000 2.00 1/4x1/8 (3) (4) 1-1/2 UJL16 17424 1.000 2.00 1-1/2 UJL16S 17450 — —<br />

1.125<br />

UJL18 17426 1.126 2.25 1-1/2 UJL18S 17452 UJL18H 17458<br />

1.1875 1/4x1/8<br />

UJL19 17428 (1) Two keyways 180° apart, 3/16x3/32 and 1/4x1/8<br />

2-3/4 1.250<br />

1.375<br />

2.25<br />

5/16x5/32<br />

(5)<br />

1-1/4<br />

UJL20<br />

UJL22<br />

17430<br />

17432<br />

(2) Two keyways 180° apart, 1/4x1/8 and 5/16x5/32<br />

(3) Located 90° from shown<br />

(4) Located as shown<br />

1.4375<br />

1.500<br />

3/8x3/16<br />

(4)(6)<br />

UJL23<br />

UJL24<br />

17434<br />

17436<br />

(5) Located 180° from shown<br />

(6) Additional setscrew over keyway<br />

(7) Has both .875 and 1.000 square bores @ 45°<br />

Item<br />

Code

MOLDED TYPE JP SERIES<br />

SINGLE AND DOUBLE<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.001 –.000<br />

REFERENCE PAGES<br />

Mounting—148<br />

MATERIALS<br />

Delrin Body<br />

Nickel Plated Brass Spider and Insert<br />

MOLDED DELRIN BODY provides vibration dampening and electrical<br />

insulation.<br />

MAX. ANGULAR DISPLACEMENT—Single 45°, Double 90°<br />

MAX. AMBIENT TEMPERATURE—180°F<br />

COMPLETE WITH SETSCREWS<br />

C<br />

C<br />

O.D.<br />

O.D.<br />

BORE<br />

BORE<br />

(2) SETSCREWS<br />

EACH END (SEE NOTE)<br />

INSERT<br />

L<br />

BRASS<br />

SPIDER<br />

(2) SETSCREWS<br />

EACH END<br />

F<br />

L<br />

BRASS<br />

SPIDER<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

DOUBLE ONLY<br />

Bore L<br />

Max. SINGLE DOUBLE<br />

Depth<br />

Parallel Catalog Item Catalog Item<br />

Bore (Typical) O.D. C Single Double F Offset Setscrew Number Code Number Code<br />

1/8 .39 1/4 .27 1-3/64 1-23/64 5/16 .22 #4-40 JP25-1/8 * 54194 JPD25-1/8 54202<br />

1/8<br />

.52 3/8 .41 1-31/64 2 17/32 .36 #4-40<br />

JP37-1/8 * 3/16 JP37-3/16<br />

54195<br />

54196<br />

JPD37-1/8<br />

JPD37-3/16<br />

54203<br />

54204<br />

3/16<br />

1/4<br />

.63 1/2 .54 1-13/16 2-7/16 5/8 .43 #6-32<br />

JP50-3/16<br />

JP50-1/4<br />

54197<br />

54198<br />

JPD50-3/16<br />

JPD50-1/4<br />

54205<br />

54206<br />

1/4 JP62-1/4 54199 JPD62-1/4 54207<br />

5/16 .86 5/8 .68 2-41/64 3-33/64 7/8 .61 #8-32 JP62-5/16 54200 JPD62-5/16 54208<br />

3/8 JP62-3/8 54201 JPD62-3/8 54209<br />

*One setscrew each end.<br />

LOAD DATA<br />

Maximum Torque †<br />

Basic (Lb. Ins.)<br />

Size Single Double<br />

25 5 2.5<br />

37 16 7<br />

50 26 12<br />

62 60 47<br />

†This is the ultimate or breaking torque for static, zero angle conditions. Actual<br />

operating conditions will dictate use of significantly lower values.<br />

UNIVERSAL JOINTS<br />

SINGLE<br />

DOUBLE<br />

<strong>Gear</strong> Catalog 105<br />

®

106 <strong>Gear</strong> Catalog<br />

®<br />

UNIVERSAL JOINTS<br />

MOLDED TYPE JPE SERIES<br />

WITH SLIDE EXTENSION<br />

A<br />

BORE<br />

(2) SETSCREWS<br />

EACH END<br />

(SEE NOTE)<br />

B<br />

C IN CLOSED POSITION<br />

G<br />

O.D. F H<br />

D<br />

K IN CLOSED POSITION<br />

MOLDED DELRIN BODY provides vibration dampening and electrical<br />

insulation.<br />

MAX. ANGULAR DISPLACEMENT—90°<br />

MAX. AMBIENT TEMPERATURE—180°F<br />

MAX. EXTENSION—3/4"<br />

COMPLETE WITH SETSCREWS<br />

J<br />

BRASS<br />

SPIDERS<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.001 –.000<br />

REFERENCE PAGES<br />

Mounting —148<br />

MATERIALS<br />

Delrin Body<br />

Nickel Plated Brass Spider and Insert<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Bore<br />

Depth G Catalog Item<br />

Bore (Typical) O.D. A B C D E F (Sq.) H J K Setscrew Number Code<br />

1/8<br />

3/16<br />

.52 3/8 .41 .74 2-59/64 1-1/8 — 1-47/64 3/16 23/64 2-43/64 4-13/32 #4-40<br />

JPE37-1/8<br />

JPE37-3/16<br />

54210<br />

54211<br />

3/16<br />

1/4<br />

.63 1/2 .54 .91 2-23/64 1-1/8 3/8 1-34/64 3/16 23/64 2-9/16 4-11/64 #6-32<br />

JPE50-3/16<br />

JPE50-1/4<br />

54212<br />

54213<br />

LOAD DATA<br />

Basic<br />

Maximum Recommended<br />

Torque (Lb. Ins.) *<br />

Size Closed Open<br />

JPE37 8 5<br />

JPE50 14 10<br />

*This is the ultimate or breaking torque for static zero angle conditions.<br />

Actual operating conditions will dictate use of significantly lower values.

SETSCREW COLLARS<br />

SHAFT COLLARS<br />

STEEL & STAINLESS STEEL.........................................................................................................108<br />

CLAMPING COLLARS<br />

SECTION CONTENTS<br />

THREADED — STEEL & STAINLESS STEEL...............................................................................109<br />

1 PIECE — STEEL, STAINLESS STEEL & ALUMINUM ...............................................................110<br />

2 PIECE — STEEL & STAINLESS STEEL .....................................................................................111<br />

<strong>Gear</strong> Catalog 107

108 <strong>Gear</strong> Catalog<br />

SETSCREW COLLARS<br />

STEEL AND STAINLESS STEEL SC/SSC SERIES<br />

WIDTH<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE<br />

1/8-1/2<br />

9/16-2<br />

+.0005/ +.0025<br />

+.0005 /+.0030<br />

Over 2 +.0010/ +.0040<br />

MATERIAL<br />

SETSCREWS<br />

BORE OUTSIDE<br />

DIA.<br />

Stainless Steel—Type 303 Austenitic<br />

Steel—Low Carbon, Zinc Plated Finish<br />

STEEL BORE SIZES FROM 1/8" TO 3"<br />

STAINLESS STEEL BORE SIZES FROM 1/8" TO 2"<br />

STAINLESS STEEL COLLARS ARE CORROSION-RESISTANT AND<br />

NON-MAGNETIC suitable for temperatures up to 800°F. Ideal for applications<br />

requiring hygienic cleanliness.<br />

ALL COLLARS COMPLETE WITH STANDARD HOLLOW POINT<br />

SETSCREWS.<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Alloy Steel Stainless Steel<br />

Outside Catalog Item Catalog Item<br />

Bore Dia. Width Number Code Number Code<br />

-1/8 3/8 1/4 SC12 67697 SSC12 67740<br />

-3/16 7/16 1/4 SC18 67698 SSC18 67741<br />

-1/4 1/2 5/16 SC25 67699 SSC25 67742<br />

-5/16 5/8 5/16 SC31 67700 SSC31 67743<br />

-3/8 3/4 3/8 SC37 67701 SSC37 67744<br />

-7/16 7/8 7/16 SC43 67702 — —<br />

-1/2<br />

-9/16<br />

1 7/16<br />

SC50<br />

SC56<br />

67703<br />

67704<br />

SSC50<br />

—<br />

67745<br />

—<br />

-5/8 1-1/8 1/2 SC62 67705 SSC62 67746<br />

-11/16<br />

-3/4<br />

1-1/4 9/16<br />

SC68<br />

SC75<br />

67706<br />

67707<br />

—<br />

SSC75<br />

—<br />

67747<br />

-13/16 1-1/4 9/16 SC81 67708 — —<br />

-7/8 1-1/2 9/16 SC87 67709 SSC87 67748<br />

-15/16<br />

1<br />

1-1/2<br />

9/16<br />

5/8<br />

SC93<br />

SC100<br />

67710<br />

67711<br />

—<br />

SSC100<br />

—<br />

67749<br />

1-1/16<br />

1-1/8<br />

1-3/4 5/8<br />

SC106<br />

SC112<br />

67712<br />

67713<br />

—<br />

SSC112<br />

—<br />

67784<br />

1-3/16<br />

1-1/4<br />

2 11/16<br />

SC118<br />

SC125<br />

67714<br />

67715<br />

—<br />

SSC125<br />

—<br />

67785<br />

1-5/16<br />

1-3/8<br />

2-1/8<br />

11/16<br />

3/4<br />

SC131<br />

SC137<br />

67716<br />

67717<br />

—<br />

—<br />

—<br />

—<br />

1-7/16<br />

1-1/2<br />

2-1/4 3/4<br />

SC143<br />

SC150<br />

67718<br />

67719<br />

—<br />

SSC150<br />

—<br />

67788<br />

1-9/16 SC156 67720 — —<br />

1-5/8 2-1/2 13/16 SC162 67721 — —<br />

1-11/16 SC168 67722 — —<br />

1-3/4 SC175 67723 SSC175 67789<br />

1-13/16 2-5/8 7/8 SC181 67724 — —<br />

1-7/8 SC187 67725 — —<br />

1-15/16 SC193 67726 — —<br />

2 3 7/8 SC200 67727 SSC200 67790<br />

2-1/8 SC212 67728 — —<br />

2-3/16 SC218 67729 — —<br />

2-1/4<br />

2-5/16<br />

3-1/4 15/16<br />

SC225<br />

SC231<br />

67730<br />

67731<br />

—<br />

—<br />

—<br />

—<br />

2-3/8 SC237 67732 — —<br />

2-7/16<br />

2-1/2<br />

3-1/2 1<br />

SC243<br />

SC250<br />

67733<br />

67734<br />

—<br />

—<br />

—<br />

—<br />

2-9/16 3-3/4 1 SC256 67735 — —<br />

2-11/16<br />

2-3/4<br />

4 1-1/8<br />

SC268<br />

SC275<br />

67736<br />

67737<br />

—<br />

—<br />

—<br />

—<br />

2-15/16<br />

3<br />

4 1-1/8<br />

SC293<br />

SC300<br />

67738<br />

67739<br />

—<br />

—<br />

—<br />

—

THREADED TYPE CSC/CSSC SERIES<br />

STEEL AND STAINLESS STEEL<br />

MATERIAL<br />

OUTSIDE<br />

DIA. WIDTH<br />

CLAMP SCREW<br />

Steel—Low Carbon, Black Oxide Finish<br />

Stainless—Type 303 Austenitic<br />

SETSCREW COLLARS<br />

BORE<br />

DESIGN PROVIDES CONVENIENT SETTING, ADJUSTING AND<br />

REMOVAL - prevents shaft damage.<br />

OSHA CONFORMANCE - collars have completely recessed screw<br />

head.<br />

BORE THREADS FROM 10-32 TO 1 1/4-12<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Steel Stainless Steel<br />

Bore Outside Clamp Catalog Item Catalog Item<br />

Thread Dia. Width Screws Number Code Number Code<br />

1/4-20 CSC25-20 49238 CSSC25-20 49265<br />

1/4-28<br />

5/16-18<br />

13/16 1/4 4-40<br />

CSC25-28<br />

CSC31-18<br />

49239<br />

49240<br />

—<br />

—<br />

—<br />

—<br />

5/16-24 CSC31-24 49241 — —<br />

3/8-16<br />

3/8-24<br />

1-1/16 5/16 6-32<br />

CSC37-16<br />

CSC37-24<br />

49242<br />

49243<br />

CSSC37-16<br />

CSSC37-24<br />

49269<br />

49270<br />

1/2-13<br />

1/2-20<br />

1-1/4 3/8 8-32<br />

CSC50-13<br />

CSC50-20<br />

49244<br />

49245<br />

CSSC50-13<br />

CSSC50-20<br />

49271<br />

49272<br />

5/8-11<br />

5/8-18<br />

1-1/2 13/32 10-32<br />

CSC62-11<br />

CSC62-18<br />

49246<br />

49247<br />

CSSC62-11<br />

CSSC62-18<br />

49273<br />

49274<br />

3/4-10<br />

3/4-16<br />

1-3/4 1/2 1/4-28<br />

CSC75-10<br />

CSC75-16<br />

49248<br />

49249<br />

CSSC75-10<br />

CSSC75-16<br />

49275<br />

49276<br />

7/8-9<br />

7/8-14<br />

1-7/8 1/2 1/4-28<br />

CSC87-9<br />

CSC87-14<br />

49250<br />

49251<br />

—<br />

—<br />

—<br />

—<br />

1-8<br />

1-14<br />

2 1/2 1/4-28<br />

CSC100-8<br />

CSC100-14<br />

49252<br />

49253<br />

CSSC100-8<br />

CSSC100-14<br />

49279<br />

49280<br />

1-1/8-7<br />

1-1/8-12<br />

2-1/8 1/2 1/4-28<br />

CSC112-7<br />

CSC112-12<br />

49254<br />

49255<br />

—<br />

—<br />

—<br />

—<br />

1-1/4-7<br />

1-1/4-12<br />

2-1/4 1/2 1/4-28<br />

CSC125-7<br />

CSC125-12<br />

49256<br />

49257<br />

—<br />

CSSC125-12<br />

—<br />

49284<br />

<strong>Gear</strong> Catalog 109

1-PIECE TYPE CSC/CSSC/CASC SERIES<br />

STEEL, STAINLESS STEEL AND ALUMINUM<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.003 –.000<br />

MATERIAL<br />

Steel—Low Carbon, Black Oxide FInish<br />

Stainless—Type 303 Austenitic<br />

Aluminum—T6061<br />

LOAD DATA<br />

OUTSIDE<br />

DIA. WIDTH<br />

CLAMP SCREW<br />

Capacity is based on a standard steel,<br />

one-piece collar mounted with recommended<br />

screw torque on a lightly oiled<br />

shaft. Capacity is load to move collar<br />

.010". Data shown is for guidance only.<br />

In applications involving control of axial<br />

loads, capacity should be determined<br />

experimentally on actual parts involved.<br />

Axial<br />

Recommended<br />

Screw<br />

Torque<br />

Load (Lb. Ins.)<br />

Capacity Screw Stainless<br />

Bore (Lbs.) Size Steel Steel<br />

1/8–5/16 400 4-40 20 16<br />

3/8–7/16 600 6-32 30 24<br />

1/2–9/16 1400 8-32 55 35<br />

5/8–11/16 1800 10-32 90 72<br />

3/4–1-9/16 4000 1/4-28 220 170<br />

1-5/8–2-3/8 6500 5/16-24 435 340<br />

2-7/16–3 8500 3/8-24 710 550<br />

110 <strong>Gear</strong> Catalog<br />

BORE<br />

CLAMPING COLLARS<br />

DESIGN PROVIDES CONVENIENT SETTING, ADJUSTING AND<br />

REMOVAL prevents shaft damage.<br />

OSHA CONFORMANCE collars have completely recessed screw head.<br />

BORE SIZES FROM 1/8" TO 3"<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Steel Stainless Steel Aluminum<br />

Outside Clamp Catalog Item Catalog Item Catalog Item<br />

Bore Dia. Width Screws Number Code Number Code Number Code<br />

1/8 CSC12 49000 CSSC12 49094 — —<br />

3/16<br />

1/4<br />

13/16 1/4 4-40<br />

CSC18<br />

CSC25<br />

49001<br />

49002<br />

CSSC18<br />

CSSC25<br />

49095<br />

49096<br />

CASC18<br />

CASC25<br />

49048<br />

49049<br />

5/16 CSC31 49003 CSSC31 49097 CASC31 49050<br />

3/8<br />

7/16<br />

1-1/16 5/16 6-32<br />

CSC37<br />

CSC43<br />

49004<br />

49005<br />

CSSC37<br />

CSSC43<br />

49098<br />

49099<br />

CASC37<br />

—<br />

49051<br />

—<br />

1/2<br />

9/16<br />

1-1/4 3/8 8-32<br />

CSC50<br />

CSC56<br />

49006<br />

49007<br />

CSSC50<br />

CSSC56<br />

49100<br />

49101<br />

CASC50<br />

CASC56<br />

49053<br />

49054<br />

5/8<br />

11/16<br />

1-1/2 13/32 10-32<br />

CSC62<br />

CSC68<br />

49008<br />

49009<br />

CSSC62<br />

—<br />

49102<br />

—<br />

CASC62<br />

—<br />

49055<br />

—<br />

3/4<br />

13/16<br />

1-3/4<br />

CSC75<br />

CSC81<br />

49010<br />

49011<br />

CSSC75<br />

—<br />

49104<br />

—<br />

CASC75<br />

—<br />

49057<br />

—<br />

7/8<br />

15/16<br />

1-7/8<br />

CSC87<br />

CSC93<br />

49012<br />

49013<br />

CSSC87<br />

CSSC93<br />

49106<br />

49107<br />

CASC87<br />

—<br />

49059<br />

—<br />

1<br />

1-1/16<br />

2<br />

CSC100<br />

CSC106<br />

49014<br />

49015<br />

CSSC100 49108 CASC100 49061<br />

CSSC106 49109 — —<br />

1-1/8<br />

1-3/16<br />

2-1/8 1/2 1/4-28<br />

CSC112<br />

CSC118<br />

49016<br />

49017<br />

CSSC112 49110<br />

CSSC118 49111<br />

—<br />

—<br />

—<br />

—<br />

1-1/4<br />

1-5/16<br />

2-1/4<br />

CSC125<br />

CSC131<br />

49018<br />

49019<br />

CSSC125 49112 CASC125 49065<br />

CSSC131 49113 — —<br />

1-3/8<br />

1-7/16<br />

2 3/8<br />

CSC137<br />

CSC143<br />

49020<br />

49021<br />

— —<br />

CSSC143 49115<br />

—<br />

—<br />

—<br />

—<br />

1-1/2<br />

1-9/16<br />

2-1/2<br />

CSC150<br />

CSC156<br />

49022<br />

49023<br />

CSSC150 49116 CASC150 49069<br />

— — — —<br />

1-5/8 CSC162 49024 — — — —<br />

1-11/16 3 CSC168 49025 — — — —<br />

1-3/4 CSC175 49026 — — CASC175 49073<br />

1-7/8 CSC187 49028 — — — —<br />

1-15/16 3-1/4 5/8 5/16-24 CSC193 49029 CSSC193 49123 — —<br />

2 CSC200 49030 CSSC200 49124 CASC200 49077<br />

2-3/16 CSC218 49033 — — — —<br />

2-1/4 3-1/2 CSC225 49034 — — — —<br />

2-3/8 CSC237 49036 — — — —<br />

2-7/16<br />

2-1/2<br />

4<br />

CSC243<br />

CSC250<br />

49037<br />

49038<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

2-5/8 CSC262 49040 — — — —<br />

2-11/16 4-1/4 3/4 3/8-24 CSC268 49041 — — — —<br />

2-3/4 CSC275 49042 — — — —<br />

2-7/8 CSC287 49044 — — — —<br />

2-15/16 4-1/2 CSC293 49045 — — — —<br />

3 CSC300 49046 — — — —

CLAMPING COLLARS<br />

2-PIECE TYPE 2SC/2SSC SERIES<br />

STEEL AND STAINLESS STEEL<br />

OUTSIDE<br />

DIA.<br />

CLAMP SCREWS<br />

WIDTH<br />

BORE<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.003 –.000<br />

MATERIAL<br />

Steel—Low Carbon, Black Oxide Finish<br />

Stainless—Type 303 Austenitic<br />

LOAD DATA<br />

Capacity is based on a standard steel, onepiece<br />

collar mounted with recommended<br />

screw torque on a lightly oiled shaft.<br />

Capacity is load to move collar .010”. Data<br />

shown is for guidance only. In applications<br />

involving control of axial loads, capacity<br />

should be determined experimentally on<br />

actual parts involved.<br />

Axial<br />

Recommended<br />

Screw<br />

Torque<br />

Load (Lb. Ins.)<br />

Capacity Screw Stainless<br />

Bore (Lbs.) Size Steel Steel<br />

1/8–5/16 400 4-40 20 16<br />

3/8–7/16 600 6-32 30 24<br />

1/2–9/16 1400 8-32 55 35<br />

5/8–11/16 1800 10-32 90 72<br />

3/4–1-9/16 4000 1/4-28 220 170<br />

1-5/8–2-3/8 6500 5/16-24 435 340<br />

2-7/16–3 8500 3/8-24 710 550<br />

DESIGN PROVIDES CONVENIENT SETTING, ADJUSTING AND<br />

REMOVAL prevents shaft damage.<br />

OSHA CONFORMANCE collars have completely recessed screw head.<br />

BORE SIZES FROM 1/8" TO 3"<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Steel Stainless Steel<br />

Outside Clamp Catalog Item Catalog Item<br />

Bore Dia. Width Screws Number Code Number Code<br />

1/8 2SC12 49141 — —<br />

3/16<br />

1/4<br />

13/16 1/4 4-40<br />

2SC18<br />

2SC25<br />

49142<br />

49143<br />

—<br />

2SSC25<br />

—<br />

49190<br />

5/16 2SC31 49144 2SSC31 49191<br />

3/8<br />

7/16<br />

1-1/16 5/16 6-32<br />

2SC37<br />

2SC43<br />

49145<br />

49146<br />

2SSC37<br />

2SSC43<br />

49192<br />

49193<br />

1/2<br />

9/16<br />

1-1/4 3/8 8-32<br />

2SC50<br />

2SC56<br />

49147<br />

49148<br />

2SSC50<br />

2SSC56<br />

49194<br />

49195<br />

5/8<br />

11/16<br />

1-1/2 13/32 10-32<br />

2SC62<br />

2SC68<br />

49149<br />

49150<br />

2SSC62<br />

2SSC68<br />

49196<br />

49197<br />

3/4<br />

13/16<br />

1-3/4<br />

2SC75<br />

2SC81<br />

49151<br />

49152<br />

2SSC75<br />

—<br />

49198<br />

—<br />

7/8<br />

15/16<br />

1-7/8<br />

2SC87<br />

2SC93<br />

49153<br />

49154<br />

2SSC87<br />

—<br />

49200<br />

—<br />

1<br />

1-1/16<br />

2<br />

2SC100<br />

2SC106<br />

49155<br />

49156<br />

2SSC100<br />

2SSC106<br />

49202<br />

49203<br />

1-1/8<br />

1-3/16<br />

2-1/8<br />

1/2 1/4-28 2SC112<br />

2SC118<br />

49157<br />

49158<br />

2SSC112<br />

2SSC118<br />

49204<br />

49205<br />

1-1/4<br />

1-5/16<br />

2-1/4<br />

2SC125<br />

2SC131<br />

49159<br />

49160<br />

2SSC125<br />

2SSC131<br />

49206<br />

49207<br />

1-3/8<br />

1-7/16<br />

2-3/8<br />

2SC137<br />

2SC143<br />

49161<br />

49162<br />

—<br />

2SSC143<br />

—<br />

49209<br />

1-1/2<br />

1-9/16<br />

2-1/2<br />

2SC150<br />

2SC156<br />

49163<br />

49164<br />

2SSC150<br />

—<br />

49210<br />

—<br />

1-5/8 2SC162 49165 — —<br />

1-11/16 3 2SC168 49166 — —<br />

1-3/4 2SC175 49167 — —<br />

1-7/8 2SC187 49169 2SSC187 49216<br />

1-15/16 3-1/4 5/8 5/16-24 2SC193 49170 2SSC193 49217<br />

2 2SC200 49171 2SSC200 49218<br />

2-1/8 2SC212 49173 — —<br />

2-3/16<br />

2-1/4<br />

3-1/2<br />

2SC218<br />

2SC225<br />

49174<br />

49175<br />

—<br />

—<br />

—<br />

—<br />

2-3/8 2SC237 49177 — —<br />

2-7/16<br />

2-1/2<br />

4<br />

2SC243<br />

2SC250<br />

49178<br />

49179<br />

—<br />

—<br />

—<br />

—<br />

2-5/8 2SC262 49181 — —<br />

2-11/16 4-1/4 3/4 3/8-24<br />

2SC268 49182 — —<br />

2-3/4 2SC275 49183 — —<br />

2-7/8 2SC287 49185 — —<br />

2-15/16 4-1/2 2SC293 49186 — —<br />

3 2SC300 49187 — —<br />

<strong>Gear</strong> Catalog 111

112 <strong>Gear</strong> Catalog<br />

NOTES

THRUST WASHERS<br />

WASHERS & BUSHINGS<br />

STEEL & STAINLESS STEEL.........................................................................................................114<br />

BUSHINGS<br />

SOFT STEEL....................................................................................................................................115<br />

GROOVED PULLEYS<br />

SECTION CONTENTS<br />

ROUND BELT................................................................................................................................116<br />

<strong>Gear</strong> Catalog 113

STEEL AND STAINLESS STEEL<br />

HARDENED STEEL<br />

Bore Outside Diameter Thickness Catalog No.<br />

9/32<br />

1/16<br />

3/32<br />

18800<br />

18802<br />

3/16<br />

3/8<br />

1/16<br />

3/32<br />

18804<br />

18806<br />

7/16 1/16 06724 *<br />

1/4<br />

1/2<br />

1/16<br />

3/32<br />

18808<br />

18810<br />

9/16 1/16 06726 *<br />

5/64 06728 *<br />

5/16 5/8 1/16 18812<br />

1/8 18814<br />

3/8<br />

5/8<br />

1/16<br />

1/8<br />

18816<br />

18818<br />

11/16 3/32 06730 *<br />

7/16 7/8<br />

1/16<br />

5/32<br />

18820<br />

18822<br />

3/4<br />

1/16<br />

1/8<br />

18824<br />

18826<br />

1/2<br />

7/8 1/8 06734 *<br />

1-1/8<br />

1/16<br />

5/32<br />

18828<br />

18830<br />

1-1/4 3/16 18832<br />

9/16 1-3/8<br />

3/32<br />

3/16<br />

18834<br />

18836<br />

25/32<br />

1/16<br />

1/8<br />

18838<br />

18840<br />

5/8<br />

1-1/4<br />

1-3/8<br />

3/32<br />

3/16<br />

3/16<br />

18842<br />

18844<br />

18846<br />

1-1/2<br />

3/32<br />

3/16<br />

18848<br />

18850<br />

1-3/4 3/16 18852<br />

1 3/32 18854<br />

1-5/16<br />

3/32<br />

3/16<br />

18856<br />

18858<br />

3/4<br />

1-5/8<br />

1/8<br />

3/16<br />

18860<br />

18862<br />

1-3/4 3/16 18864<br />

2 3/16 18866<br />

114 <strong>Gear</strong> Catalog<br />

THRUST WASHERS<br />

HARDENED AND GROUND<br />

STEEL BORE SIZES FROM 3/16" TO 2"<br />

STAINLESS STEEL BORE SIZES FROM 3/16" TO 1/2"<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE<br />

06700 Series<br />

18000 Series<br />

+.0015 – .007<br />

+.002 +.007<br />

O.D.<br />

06700 Series<br />

18000 Series<br />

+.000 – .005<br />

±.030<br />

Thickness All +.000 – .005<br />

HARDENED STEEL<br />

Bore Outside Diameter Thickness Catalog No.<br />

1-3/16 3/32 18868<br />

7/8<br />

2<br />

2<br />

1/8<br />

3/16<br />

18870<br />

18872<br />

2-1/4 3/16 18874<br />

7/16 13/16 3/32 06732 *<br />

1-9/16<br />

1/8<br />

3/16<br />

18876<br />

18878<br />

1<br />

2<br />

1/8<br />

3/16<br />

18880<br />

18882<br />

2-1/4<br />

9/64<br />

3/16<br />

18884<br />

18886<br />

2-1/2 1/4 18888<br />

1-1/16 2-1/2 1/4 18890<br />

1-1/8 2-1/2 1/4 18894<br />

1-3/16 2 3/16 18896<br />

2<br />

9/64<br />

3/16<br />

18898<br />

18922<br />

1-1/4 2-7/16<br />

9/64<br />

1/4<br />

18900<br />

18924<br />

2-3/4 9/64 18902<br />

3 1/4 18904<br />

1-5/16 2-3/4 1/4 18906<br />

1-3/8 3<br />

5/32<br />

1/4<br />

18908<br />

18910<br />

1-1/2<br />

3<br />

5/32<br />

1/4<br />

18912<br />

18914<br />

3-1/4 1/8 18916<br />

2 4<br />

5/32<br />

5/16<br />

18918<br />

18920<br />

STAINLESS STEEL †<br />

Bore Outside Diameter Thickness Catalog No.<br />

3/16 7/16 1/16 06760<br />

1/4 9/16 1/16 06762<br />

5/16 5/8 5/64 06764<br />

3/8 11/16 3/32 06766<br />

1/2 7/8 1/8 06770<br />

*These Washers also listed with AO Bearings.<br />

†These Washers also listed with SAO Bearings.

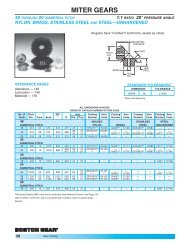

SOFT STEEL<br />

BORE<br />

OUTSIDE<br />

DIA.<br />

STANDARD TOLERANCES<br />

LENGTH<br />

DIMENSION TOLERANCE<br />

BORE All ±.0005<br />

O.D.<br />

Up to 1-1/4<br />

Over 1-1/4<br />

+.0005 +.0015<br />

+.001 +.002<br />

LENGTH<br />

Up to 1”<br />

Over 1”<br />

+.000 –.007<br />

+.000–.010<br />

BUSHINGS<br />

BORE SIZES FROM 3/16" TO 1-1/4"<br />

MULTI-PURPOSE BUSHINGS suitable for use as hole reducers,<br />

spacers, standoffs or slip bushings.<br />

ADAPTABLE FOR OTHER USES including wear sleeves, liners or<br />

cutting arbor studs.<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Bore Outside Diameter Length Catalog No.<br />

1/4 18510<br />

3/16 5/16 5/8 18512<br />

3/8 18516<br />

1/4<br />

5/16<br />

3/8<br />

1/2<br />

5/8<br />

3/4<br />

1<br />

18514<br />

18518<br />

18522<br />

18524<br />

3/8 5/8 18520<br />

5/16<br />

1/2<br />

3/4<br />

1<br />

18526<br />

18528<br />

3/8<br />

1/2<br />

5/8<br />

3/4<br />

1<br />

3/4<br />

1-1/4<br />

18530<br />

18532<br />

18534<br />

18536<br />

7/16 5/8<br />

3/4<br />

1-1/4<br />

18538<br />

18540<br />

3/4 18542<br />

5/8 1 18544<br />

1/2 1-1/4 18546<br />

3/4<br />

3/4<br />

1<br />

18554<br />

18556<br />

5/8<br />

3/4<br />

3/4<br />

1<br />

18560<br />

18562<br />

7/8 1-1/4 18566<br />

7/8 1-1/4 18568<br />

3/4<br />

1<br />

1-3/8<br />

1-1/2<br />

2<br />

18574<br />

18626<br />

1-1/2 1-1/2 18606<br />

7/8 1 1-1/2 18576<br />

1-1/4 18596<br />

1 1-3/8 2 18602<br />

2 18622<br />

1-1/8 1-1/4 2 18598<br />

1-3/8 2 18604<br />

1-1/4 1-1/2 1-1/2 18614<br />

2 2 18624<br />

<strong>Gear</strong> Catalog 115

ROUND BELT TYPE G1200<br />

FACE<br />

WIDTH<br />

OUTSIDE<br />

DIA.<br />

BORE<br />

STANDARD TOLERANCES<br />

DIMENSION TOLERANCE<br />

BORE All +.001 –.000<br />

116 <strong>Gear</strong> Catalog<br />

SETSCREW<br />

HUB<br />

PROJ.<br />

GROOVED PULLEYS<br />

HUB<br />

DIA.<br />

BRASS AND IRON<br />

BORE SIZES FROM 3/16" TO 3/4"<br />

COMPLETE WITH STANDARD SETSCREWS<br />

ALL DIMENSIONS IN INCHES<br />

ORDER BY CATALOG NUMBER OR ITEM CODE<br />

Outside Hub V Catalog Item<br />

Bore Dia. Dia. Proj. Groove Style Number Code<br />

BRASS—3/16" ROUND BELT (or smaller)—1/4" FACE<br />

3/16<br />

1/2<br />

7/8<br />

1/2<br />

5/8<br />

1/4<br />

74°<br />

46°<br />

Plain<br />

G1214<br />

G1215<br />

18700<br />

18702<br />

1/4<br />

1<br />

1-1/2<br />

5/8 5/16 46° Plain<br />

G1216<br />

G1217<br />

18704<br />

18706<br />

2 5/8 Webbed G1218 18708<br />

5/16 3 3/4 5/16 46° Spoked G1219 18710<br />

4 3/4 Spoked G1220 18712<br />

IRON †—3/8" ROUND BELTS (or smaller)—1/2" FACE<br />

1 15/16 G1202 * 18718<br />

1/2<br />

1-1/2 1<br />

1/2<br />

Plain G1203 * 2 1 G1204<br />

18720<br />

* 18722<br />

5/8<br />

3<br />

4<br />

5<br />

1-1/4<br />

1-5/8 3/4<br />

53°<br />

Webbed<br />

G1205<br />

G1206<br />

G1207<br />

18724<br />

18726<br />

18728<br />

3/4<br />

6<br />

8<br />

1-3/4 1<br />

Spoked<br />

G1208<br />

G1209<br />

18730<br />

18732<br />

†Outside diameter, sides, grooves, hole and ends of hub, finished.

MINIATURE TIMING BELTS & PULLEYS<br />

SECTION CONTENTS<br />

MINIATURE TIMING BELT & PULLEY SELECTION....................................................................118 – 120<br />

MINIATURE TIMING BELTS, 6 & 9mm WIDTHS....................................................................................121<br />

TIMING BELT PULLEYS, FOR 6 & 9mm WIDE BELTS...............................................................122 – 126<br />

MINIATURE TIMING BELTS, 9 & 15mm WIDTHS..................................................................................127<br />

TIMING BELT PULLEYS, FOR 9 & 15mm WIDE BELTS ............................................................128 – 131<br />

<strong>Gear</strong> Catalog 117

MINIATURE TIMING BELTS & PULLEYS<br />

MINIATURE HTD ® TIMING BELT DRIVES<br />

BASIC CONSTRUCTION<br />

Timing <strong>belt</strong>s are essentially flat <strong>belt</strong>s with the addition of evenly<br />

spaced teeth along the surface that contacts toothed <strong>pulleys</strong>.<br />

Power is transmitted smoothly and without slippage.<br />

Pulley pitch diameters are larger than their outside diameters<br />

and the <strong>belt</strong> pitch lines lie within the flat portion. Tension members<br />

are molded in the flat portion to serve as load-carrying<br />