SCISSORS_MEERUT_DESIGN_CLINIC_ WORKSHOP_Full_Report

SCISSORS_MEERUT_DESIGN_CLINIC_ WORKSHOP_Full_Report

SCISSORS_MEERUT_DESIGN_CLINIC_ WORKSHOP_Full_Report

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

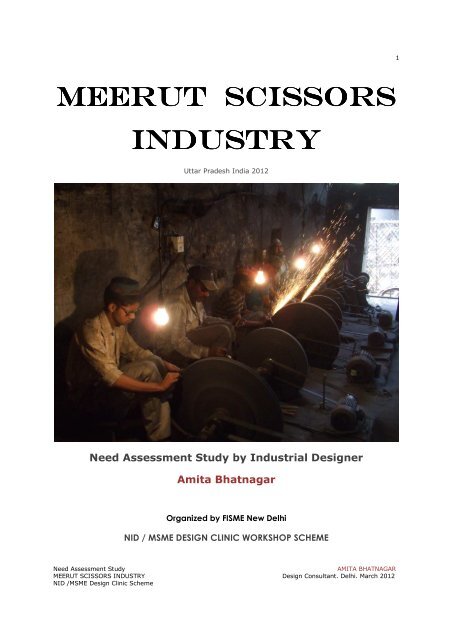

Meerut<br />

Meerut Meerut Scissors<br />

Scissors<br />

Industry<br />

Industry<br />

Uttar Pradesh India 2012<br />

Need Assessment Study by Industrial Designer<br />

Amita Bhatnagar<br />

Organized by FISME New Delhi<br />

NID / MSME <strong>DESIGN</strong> <strong>CLINIC</strong> <strong>WORKSHOP</strong> SCHEME<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

1

Index Pgs<br />

1. Acknowledgements 3<br />

2. Meerut City - A Geographical Analysis 4<br />

3. Industrial Product - A Functional Analysis 5-6<br />

4. Scissors - A Short History 6<br />

5. Product Variety – Meerut Scissors Industry MESMA (SPV) 7-8<br />

6. Raw Materials - Meerut Scissors Industry MESMA (SPV) 9-10<br />

7. Existing Technology Overview - Meerut Scissors Industry 11-14<br />

8. Production - Meerut Scissors Industry MESMA (SPV) 16-23<br />

9. Labeling & Packaging - Meerut Scissors Industry 24<br />

10. A macro perspective - Cluster Business model 25-26<br />

11. Design Analysis 27-29<br />

12. Design Intervention areas 30-31<br />

13. Future Design Research & Marketing & Competition 32-33<br />

14. Design Audit of Scissors manufacturing Units of Meerut 34-41<br />

15. Suggestions for Industry & Business growth 42<br />

* Note : Design suggestions on every page given in Italics, Bold<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

2

Acknowledgements<br />

I would like to thank The MSME Director as well as<br />

The Director of NID Mr. Pradyumna Vyas and<br />

Project Head Mr. Shashank for giving me this<br />

opportunity to work for the Meerut Scissors Industry.<br />

I would also like to thank Mr. Girish Kumar M. D.<br />

of Sai Electricals for his keen interest in the Design<br />

Survey of the Meerut Scissors Industry.<br />

Mr. Anil Bharadwaj Secretary General FISME<br />

Delhi, for his valuable guidance. Mr. V. M Sastry<br />

and Mr. Samuel from FISME Delhi for taking care of<br />

the Introductions to the Scissors association in<br />

Meerut and logistics and other arrangements for the<br />

Meerut Scissors Industry Need Assessment survey as<br />

a Designer.<br />

I would also like to thank all the Meerut Scissors<br />

manufacturers MESMA (SPV), its President Mr.<br />

Farmanuddin and its members for extending their<br />

assistance and Co-Operation at all times during the<br />

survey.<br />

I am especially grateful to Mr. Sajid and Mr. Sharif<br />

from the Meerut Scissors manufacturers MESMA<br />

(SPV) for their co-operation and taking out time<br />

from their busy schedules to accompany me to all<br />

the units in Meerut and providing me with valuable<br />

information and material available with them.<br />

Mr. Farmanuddin and Mr. Sharif have also been able<br />

to make available the relevant figures and specific<br />

Macro level statistics.<br />

I am grateful to Mr. Farmanuddin the President<br />

and all the other members of the Meerut scissors<br />

manufacturers MESMA (SPV) who allowed me to<br />

visit their manufacturing units for this study, and<br />

shared their problems, issues and concerns.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

3

Meerut - A Geographical Analysis<br />

Meerut is a metropolitan city in the Indian state of Uttar Pradesh. It is an ancient city located 70 km (43 mi)<br />

northeast of the national capital New Delhi, and 453 km (281 mi) northwest of the state capital, Lucknow. It is the<br />

second largest city in the National Capital Region of India (the largest being Delhi), the 16th largest metropolitan<br />

area and 17 th largest city in India. It ranked 292 in 2006 and 242 in 2010 in the list of largest cities and urban<br />

areas in the world and is the second fastest developing city in Uttar Pradesh (after Noida). The city covers an area<br />

of about 172 km 2 (66 sq mi) while the total metropolitan area is 198 km 2 (76 sq mi), third largest in Uttar Pradesh<br />

after Lucknow and Kanpur. It has the 2 nd largest army cantonment in the country.<br />

Meerut has a monsoon influenced humid subtropical climate characterized by very hot summers and cool winters.<br />

Summers last from early April to late June and are extremely hot, with temperatures reaching 43 °C (109 °F). The<br />

monsoon arrives in late June and continues till the middle of September. Temperatures drop slightly, with plenty of<br />

cloud cover but with higher humidity. Temperatures rise again in October and the city then has a mild, dry winter<br />

season from late October to the middle of March Lowest temperature recorded is 0.5 °C (32.9 °F) Rainfall is about<br />

80 cm to 100 cm per annum, which is suitable for growing crops. Most of the rainfall is received during<br />

the monsoon. Humidity varies from 30 to 100%.<br />

Meerut is famously associated with the Indian Rebellion of 1857 against the British East India Company. [19] The<br />

famous slogan "Dilli Chalo" ("Let's march to Delhi!") was first raised here. Meerut cantonment is the place where<br />

the rebellion started when Hindu and Muslim soldiers were given rifle cartridges rumored to have a coating made of<br />

animal fat.<br />

The city is one of the largest producers of Scissors, Sports goods, and the largest producer of musical instruments<br />

in India.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

4

Scissors<br />

The Product – A Functional Analysis<br />

Scissor is a cutting device which is used to cut various materials. It is made up of two blades which rotate on an<br />

axis against each other and divide the placed material in two parts. Scissors function when two blades under<br />

tension are closed against one another.<br />

Scissors are probably some of the first tools a person learns to use. Children can amuse themselves for hours<br />

cutting shapes out of construction paper. It's a safe bet that most people use scissors for something several times<br />

a week, if not every day.<br />

Scissors are cutting tools. They have to cut - always evenly, without problems, and with a minimum of effort.<br />

1. Friction and twist<br />

Tension between the blades is in essence achieved through a slight bowing of the blades. In technical terms the<br />

blades are in friction mode to one another. This means that there is an arching in the blades towards the inside of<br />

the scissors. In addition both blades are turned along the side towards the cutting edge. In technical terms this is<br />

known as "twist". Friction and twist create such a force on the point of convergence of the cutting edge that the<br />

material gives and is severed.<br />

2. Sharpness<br />

What is usually called "sharpness" is technically defined as the angle of the cutting edge. The smaller the angle of<br />

the cutting edge - technical term the bevel or edge - the sharper the scissors will be. The disadvantage is that the<br />

more acute the angle, the greater the instability of the edge, and the scissors will dull faster. Therefore the shape<br />

and type of cutting edge are paramount in the manufacture of scissors. Grinding the cutting edge of their scissors<br />

at a variety of different angles depending on their final application. Finally there is the precision grinding of the<br />

cutting edge. Through this process microscopic flaws on the edge are completely eliminated. A straight edge is<br />

"sharper" than a ragged one. The cutting process is further enhanced through the wedge shape of the blade, which<br />

allows the material to glide away and thus magnify the sharpness.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

5

Based on their function, scissors tend to push the material being cut forward when the two blades close. Depending<br />

on the application, a serrated edge could be required to prevent the material from sliding. The basics described<br />

above are also applicable here. More important than the serration is the actual cutting action. The ideal closing<br />

angle of the blades to one another is approximately 21°. Based on their construction the angle changes during the<br />

closing action, and this is why high quality scissors have a bowed cutting edge, for the specific purpose of<br />

maintaining an even cutting action with a consistent closing angle.<br />

The insides of the blades of high quality scissors are concave ground. This hollow grinding not only reduces the<br />

friction resistance but also allows the material to smoothly slip away after being cut, without being hindered by<br />

jamming of the material when the blades are separated.<br />

History<br />

Scissors date from before the first century A.D. They can be seen in various forms in Egyptian art and have been<br />

the tools for tailors and barbers for at least 2,000 years. In Greek mythology, when Atropos of the Three Fates cut<br />

the thread of a life, she did it with "shears" or scissors.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

6

Types of Scissors manufactured in Meerut<br />

Scissors cluster, Meerut (India) is a 360 years old cluster. Main types of products are Barber scissors, Tailor<br />

scissors, General scissors and Paper scissors. Some Manufacturing has been switched over from hand work<br />

to mechanized processes through the Common Facility Centre established with the assistance of NIESBUD,<br />

Ministry of MSME, Government of India.<br />

Barber Scissors: Polished / Electroplated / with Plastic handles<br />

Barber Scissors: Polished / Powder coated / electroplated / serrated<br />

Scissors: Plastic handles / Black Powder coated / Red Powder coated / electroplated<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

7

Paper Scissors General Scissors<br />

* Better Raw material is required for a better quality final product<br />

Normal Tailors Scissor Heavy Tailors Scissor<br />

* Packaging and Graphic Design require contentious development at Meerut Scissors Industry<br />

Advantages of Scissors manufactured in Meerut<br />

1. The scissors manufactured in Meerut can be resharpened and have a long life.<br />

2. The Meerut scissors Industry is Labor Intensive.<br />

3. The scissors manufactured in Meerut are comparatively inexpensive.<br />

4. Maximum utilization of Space during processing and manufacturing<br />

5. The Industry is 360 yrs old.<br />

6. 50,000 people are directly involved in the Industry.<br />

7. 20,000 people are involved indirectly in the Industry.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

8

Raw Material<br />

Steel scissors exist in two basic forms. Carbon steel is used to make scissors in which the blade and the handle<br />

form one continuous piece. Carbon steel is manufactured from iron and about 1% carbon. It has the advantages of<br />

being strong and staying sharp. Scissors made from carbon steel are usually plated with nickel or chromium to<br />

prevent them from rusting.<br />

Stainless steel is used to make scissors in which a plastic handle is fitted to the metal blade. Stainless steel is<br />

manufactured from iron, about 1% carbon, and at least 10% chromium. It has the advantages of being light and<br />

rustproof. Stainless steel is not used in Meerut. The Plastic handles of scissors are made from a strong, light<br />

substance such as ABS (acrylonitrile-butadiene-styrene) plastic as well as PVC.<br />

* Raw material Storage systems and Space Design for better efficiency<br />

The Meerut scissor manufactures use scrap steel bought from the railways or automobile Industries. As these are<br />

cheaper than buying fresh metal stocks. (Stainless Steel Scissors production need a different scale and technology,<br />

and can be manufactured in large Industrial set ups.) The scrap metal is collected and roller machines used to<br />

make them into plates. These metal plates are then used for either Press cutting, or hand forging . Where brass<br />

handles have to be added for increasing the weight and give finishing, the handles are casted after the steel blade<br />

ends are fitted into the moulds.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

9

Scrap Carbon steel<br />

Scissors are generally made from Steel but as per<br />

the requirement of uses it may be manufactured<br />

with other metals too. Steel Scissors are<br />

manufactured using three kinds of materials.<br />

• Carbon Steel<br />

• Mild steel<br />

• Stainless steel<br />

Carbon Steel Scissors are made with single piece.<br />

Carbon Steel Scissors handles and blades are<br />

made with an undivided slice of carbon steel bar.<br />

Carbon Steel Scissors are robust and its blade has<br />

long lasting sharpness. Application of a layer of<br />

nickel or chromium increases their rust<br />

resistance.<br />

Steel Scissor is also sometimes fitted with plastic<br />

handles. Stainless steel Scissors have high rust<br />

resistance. The use of chromium makes them<br />

highly rustproof. Stainless steel Scissors are light<br />

in weight and offer a comfortable handling weight<br />

*Inconsistent quality Raw material needs to<br />

be controlled<br />

Metal scrap<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

10<br />

Old utensils are melted as Brass scrap and used for<br />

making Handles for certain kind of Scissors which are<br />

produced in Meerut.<br />

Brass Scrap

Meerut Scissor Industry Technology Overview<br />

Roller Machines at Meerut to prepare the Metal Sheet from Scrap Metal<br />

* Heavy Machinery Installations and fittings to be designed for reducing vibrations during<br />

operations as well as reduction in consumption of power.<br />

Press Machine Dies used for cutting Blanks<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

11

Multiple head ‘ H ‘ Press Machine Single head ‘ C ’ Press Machine<br />

Open oven for Hand forging of Blanks Hand tools used for Hand Forging<br />

* Redesign of process and systems required for volume quality production<br />

Hand Files Hand Tools<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

12

List of Hand Tools and Machines<br />

The Hand tools most commonly used are :<br />

1. Hammer 100gm head<br />

2. Hammer 800gm head<br />

3. Square File<br />

4. Round File<br />

5. Half Round File<br />

6. Rindge<br />

7. Plus<br />

8. Pincers<br />

9. Crucible<br />

10. Anvil<br />

11. Iron Round Plate<br />

12. Chaeni<br />

The Machines most commonly used are :<br />

1. Rolling Machine<br />

2. Lathe<br />

3. Die Tools<br />

4. Hand Drill<br />

5. Press H<br />

6. Press C<br />

7. Grinding Blade<br />

8. Furnace hard coke<br />

9. Milling Cutter<br />

10. Surface Grinder<br />

11. Polishing Machine<br />

12. Buffing Machine<br />

13. Tool Grinder<br />

14. Chamfering Machine<br />

15. Nickel Plating Plant<br />

16. Gold Plating Plant<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

13

Fan & forge Crucible Furnace Mould for casting the Brass handles<br />

* An enclosure designed around the furnace would help in reducing heat in the adjoining work area<br />

Hand Drill Grinding machines<br />

*A container for residue shrapnel could be effective<br />

designed to fit the space below the hand drill<br />

Sharpening the Grinder Processing after Press cutting<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

14

Local Sizing Machine Local Machine for Chamfering of Edge<br />

* Lighting and working area systems planning Design required<br />

Buffing and Polishing Electroplating<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

15

Production<br />

The manufacture of scissors is a rigorous precision work. The selection of materials is just as important as the<br />

actual production process on precision equipment. Specialists highly skilled in their field of work are required.<br />

Meerut Scissors are among the top specialists in India for Handmade scissors. What is needed is greater ongoing<br />

development of products and production methods which needs to be brought about a know-how that is yet to<br />

improve the present product.<br />

Making the blanks<br />

1. Before they are sharpened and attached, the two halves of a pair of scissors are known as blanks. A blank<br />

may consist of a blade and a handle in one piece or it may consist of only the blade. In the latter case, a<br />

metal handle will be welded to the blade or a plastic handle will be attached to it.<br />

• 2. Inexpensive scissors may be made from blanks formed by cold stamping. In this process, a sharp die in<br />

the shape of the blank is stamped into a sheet of unheated steel. The die cuts through the steel to form<br />

the blank.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

16

• 3. Blanks may also be made by molding. Molten steel is poured into a mold in the shape of the blank. The<br />

steel cools back into a solid and the blank are removed.<br />

• 4. Most quality scissors are made from blanks formed by drop forging. Like cold stamping, this process<br />

involves shaping the blanks with a die. This die, known as a drop hammer, pounds into a bar of red-hot<br />

steel to form the blank. The pressure of the drop hammer also strengthens the steel.<br />

* Raw material Wastage control systems and Die designs required<br />

Processing the blanks<br />

• 5. The blanks are trimmed to the proper shape by cutting away excess metal. A hole is drilled through the<br />

blank. This hole will later allow two completed blades to be attached to each other.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

17

• 6. The trimmed blanks are hardened by heating them, then cooling them quickly in cold air, water, oil, or<br />

another substance. The temperature to which they are heated and the medium in which they are cooled<br />

varies depending on the type of steel from which they are made and the desired characteristics of the<br />

blade.<br />

• 7. The hardened blanks are heated again and allowed to cool slowly in air. This second heating, known as<br />

tempering, gives the blank a uniform hardness. If the blades of a pair of scissors did not have uniform<br />

hardness, the harder places on one blade would soon wear out the softer places on the other blade.<br />

• 8. The repeated heating and cooling causes the blanks to warp. They are straightened by being placed on<br />

an anvil and lightly tapped with a hammer. This process is known as peening.<br />

* Work station Designs for Man power maximization required<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

18

Grinding and polishing<br />

• The blank is ground into a blade by applying the edge to a rapidly moving sanding belt or abrasive wheel.<br />

The surface of the belt or wheel is covered with small particles of an abrasive substance and works in the<br />

same way as sandpaper. The hard abrasive grinds away enough steel to form a sharp edge. During this<br />

process, the blade is cooled with water or various liquids known as cutting fluids to prevent it from heating<br />

and warping. The sharpened blade is then polished in a similar manner using belts or wheels, containing<br />

much smaller particles of abrasive.<br />

*Design of Safety gear for hands, feet, eyes and face for the workers using the grinders needed<br />

Making the handles<br />

• 10. For many scissors, the handles are formed from the start as part of the blank. If not, they may be<br />

made of a metal alloy or from plastic. If they are metal, they are made in the same way as the blanks and<br />

then welded to them. If they are plastic, they are made by injection molding. In this process, molten<br />

plastic is forced under pressure into a mold in the shape of the handles. It is allowed to cool and the mold<br />

is opened to remove the handles. The handles contain hollow slots into which the end of the blanks can be<br />

inserted. A strong adhesive is used to keep the handle firmly attached.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

19

Preparing Moulds for Casting of Brass Handles Moulds being set with blade blanks<br />

* Design of in flow and out flow to improve man power performance<br />

Fan and Forge crucible oven Casting in process pouring molten Brass<br />

* Design of crucible with attached insulated handle to avoid slippage and accidents<br />

Emptying the moulds minutes after casting Removing the Blanks with casted handles<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

20

Brass scrap for handles for Tailor’s scissors Grinder * Leg and Hand guard Designs required<br />

Ready Casted Blanks<br />

Filing the inner edges with a hand file Curvature adjustment in process<br />

* The Design of Upgraded Moulds can help in better finishing<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

21

Assembling the scissors<br />

Two polished blades are attached to each other by a<br />

rivet or screw through the previously drilled holes.<br />

Rivets, which cannot be adjusted by the consumer,<br />

are used to make less expensive scissors. Adjustable<br />

screws are used in more costly scissors. The scissors<br />

are adjusted to ensure that the two blades work<br />

together correctly. They may be painted or plated<br />

with nickel or chrome to protect them from rust.<br />

Joining the pair of blanks with a Nut and<br />

Bolt<br />

Blades are sharpened on the grinding<br />

wheel after assembling of the scissors<br />

Riveting pair of Blanks for Barber Scissors<br />

* Design of Adjustable upgraded screws for<br />

riveting required for long term functional<br />

betterment of a high grade Product<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

22<br />

The most important aspect of quality control for<br />

scissors is the proper alignment of the two blades. In<br />

order for scissors to cut smoothly, the blades must<br />

meet at two points only. These two points are the<br />

swivel (the point where the rivet or screw connects<br />

the blades) and the cutting point. The cutting point<br />

moves from just beyond the swivel to the tip as the<br />

scissors are closed. The blades are prevented from<br />

meeting at any other points by giving them a slight<br />

horizontal and vertical curve away from each other<br />

during manufacture.<br />

In order to ensure that the blades meet correctly,<br />

the holes must be drilled to within one tenthousandth<br />

of an inch (about one four-hundredth of<br />

a millimeter) of the correct position. The position of<br />

the blades is inspected visually to see if the blades<br />

meet evenly. If not, a portion of one blade will<br />

overlap the other. This defect is known as a wing.<br />

The tips are also inspected to ensure that they meet<br />

evenly, without a gap between them or any overlap.<br />

Because even dull scissors are able to cut paper<br />

adequately, quality scissors are tested on tough<br />

synthetic fabrics. Sharpness is tested by making sure<br />

the blades cut the fabric rather than tear it. Strength<br />

is tested by cutting through multiple layers of fabric.

The blades should come together with a constant<br />

pressure during cutting.<br />

The consumer is responsible for maintaining the<br />

quality of the scissors. Scissors should only be used<br />

to cut the materials for which they were designed.<br />

Electroplating<br />

Some of the scissors are Gold electroplated while<br />

some others are chromium or nickel plated.<br />

Gold plated Scissors<br />

They should be oiled and sharpened regularly, and<br />

the screw should be adjusted as necessary. Scissors<br />

should be stored in a closed position. Setting down<br />

scissors in an open position is the most common<br />

cause of dull blades.<br />

Containers for plating<br />

Nickel plating<br />

* Systems Design requirements<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

23

Labeling and Packaging<br />

Labeling and Packaging is done once the scissors are<br />

ready after polishing and Finishing. The Scissor<br />

blades are oiled for retaining the sharpness of the<br />

blades in a packed state.<br />

Printed Cardboard boxes with Company name are<br />

used for Packing.<br />

The company stickers are added and the scissors are<br />

Wrapped in butter paper and put into polybags.<br />

* Graphic Design and printing potential exists<br />

* The cardboard boxes need to be<br />

replaced by water proof and unbreakable<br />

material<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

24

Macro Parameters<br />

* Spatial and systems Design requirements for High grade / Volume manufacturing<br />

The Meerut Scissors Industry cluster has a 100 small-scale units employing around 1000 people. In addition, the<br />

cluster has around 300 household units employing another 1000-1500 people. The estimated turnover of the<br />

cluster is around Rs 10 crores. The cluster is located around Peeramal market, Kanch ka phool, Khair Nagar,<br />

Ghantaghar, Kareem Nagar, Kotla and Kareemwala areas. Scissors manufacturers are also present in nearby<br />

villages like Mawana, Vahasuma, Parikhitgarh adi, Bara Gaon and Chota Gaon. The major products are 8" to 18"<br />

copper and silver scissors. Copper, steel and silver are the main raw materials required for manufacturing of<br />

scissors, which are available near Meerut city. There are two associations of scissors manufacturers. The cluster<br />

has been growing at a slow rate of about 3-4 percent. The only association in the cluster is Scissor Manufacturers<br />

Association.<br />

Product Scope<br />

In the recent years, the cluster has seen a decline in the demand for scissors of sizes 10” and below, due to an<br />

inflow of imported scissors. The 10” and below segment is primarily of household users. On the other hand, the<br />

demand has increased for scissors of bigger sizes, which are supplied to garment manufacturers. The cluster has<br />

the potential for recapturing the household segment partially, provided the quality of scissors is improved. More<br />

specifically, hardness and sharpness are the two issues to be tackled.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

25

Challenges<br />

1. The cluster is heavily dependent on traders both for raw material and sales, often leading to distress sales<br />

2. The Raw materials being used are usually mixed metal scrap from Industries, resulting in quality issues.<br />

2. Shortage of electricity has also led to a problem of underutilized capacities, thereby reducing profits.<br />

3. The manufacturers are also concerned with fluctuation in raw material prices and inconsistent supplies, over the<br />

last two years.<br />

Potential for intervention<br />

The cluster is very tightly controlled by the traders. Intervention is required for technology up gradation and quality<br />

control for recapturing the lost market and future growth. Design development and Product diversification is also<br />

required.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

26

Design Analysis<br />

Ergonomics<br />

As a tool in daily use the ease of handling of scissors is given prime attention. The tool should feel comfortable in<br />

every user's hand, and the user should not get tired of utilizing the tool for hours on end. This is the role played by<br />

the shaping of the scissors. The shapes of the blades as well as that of the handles are designed with this goal in<br />

mind. This is why scissors with which the user is cutting on a table are angled, nail scissors follow the shape of the<br />

nail, and embroidery scissors are extremely pointed, etc. Furthermore the shape of the handle is crucial to insure<br />

that various user hands are equally at ease in performing the function for which the scissors were designed. Shape<br />

and material are the key contributors to ease of use.<br />

1. Shape of the blades<br />

Based on the need for a variety of applications numerous shapes of blades have been developed over time. So, for<br />

example, scissors to cut a wick have an area to catch the cut-off wick; hat maker's scissors are bent to<br />

accommodate the shape of the hat; wall papering scissors are angled in such a way that it becomes unnecessary to<br />

lift the scissors from the cutting surface.<br />

2. The handle<br />

The shape of the handle has to follow the shape of the hand and must be able to smoothly transfer the strength of<br />

the hand to the cutting edge. The large the area for the finger, the more comfortable the scissors will feel. The<br />

closer the shape of the handle is to the hand, the easier it is to "handle" the tool with utmost precision. In addition<br />

to ease of handling for a variety of users, the user's preference, left or right hand, also becomes a challenge. Some<br />

producers attempt to produce scissors that are truly ambidextrous. In particular the newest synthetic materials<br />

make it possible to produce a variety of very comfortable handles. Two-component handles with their fused soft<br />

rubber inserts offer a maximum of comfort for each individual hand.<br />

Durability<br />

Durability is not just an ethical and environmental issue for good scissors. Each and every tool has a price, and<br />

requires a certain getting used to. Simply from an economic point of view a tool should have a long life. Longevity<br />

in scissors is determined through meticulous manufacturing (precision, maximum hardness, minimal wear and<br />

tear) and servicing potential (grinding and adjusting).<br />

1. Meticulous manufacturing<br />

The manufacture of scissors is rigorous precision work. The selection of materials is just as important as the actual<br />

production process on precision equipment. Specialists highly skilled in their field of work are required in India for<br />

Handmade scissors. What is needed is greater ongoing development of products and production methods which<br />

needs to be brought about a know-how that is yet to improve the present product.<br />

2. Maintenance<br />

Due to the fact that the blades of scissors are continuously in contact a certain wear and tear is inevitable, and<br />

sooner or later they need to be serviced. Just grinding the edges is not enough. In some cases the scissors need to<br />

be taken apart and re-adjusted. This is why good scissors have a screw that allows for disassembly and re-<br />

adjustment. Inexpensive scissors cannot be adjusted as the blades are riveted together. High quality scissors<br />

should be only scissors with screws.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

27

Technology<br />

The technology presently used is geared towards hand production of smaller volumes due to which prices of the<br />

Scissors made in Meerut are higher. While the market has seen cheaper and smarter scissors in striking packaging<br />

from China, Korea and Taiwan<br />

As the most important aspect of quality control for scissors is the proper alignment of the two blades. In order for<br />

scissors to cut smoothly, the blades must meet at two points only. These two points are the swivel (the point<br />

where the rivet or screw connects the blades) and the cutting point. The cutting point moves from just beyond the<br />

swivel to the tip as the scissors are closed. The blades are prevented from meeting at any other points by giving<br />

them a slight horizontal and vertical curve away from each other during manufacture.<br />

This is mainly controlled by Hand and Hand tools are used to adjust the balancing and setting of the two blades.<br />

Good scissors should always close smoothly with a minimum of effort. High quality hair scissors have a closing<br />

pressure of approximately 20 grams<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

28

To ensure the ease of handling, all imperfections have to be minimized. Friction occurs when two surfaces are<br />

moved against one another. In other words, the inside of the blades and the screw in its bearing. Through friction<br />

and twist (see above) the blades only come into contact in two places during the cutting action - at the shank, just<br />

behind the screw and at the point where the two blades meet. This function increases pressure on the cutting<br />

edges and considerably reduces friction resistance.<br />

To further decrease this friction, the points of contact are polished (smooth surface = minimal friction) and oiled.<br />

To further increase smoothness a bearing is placed between the screw head and the body. These bearings range<br />

from simple synthetic washers to elaborate mini roller bearings like those found in precision tools.<br />

Appearance<br />

Last but not least, visual impact is also the hallmark of good scissors. This criterion is not limited to the clean finish<br />

of the surface, but also to the total design concept.<br />

1. The finish<br />

Good scissors are always carefully and evenly ground and polished. The clean, brushed satin or high gloss polish of<br />

the steel surface is a clear indication of the care that has been taken throughout the entire production process.<br />

2. The design<br />

Presentation and appearance, the appealing good looks of scissors, which are used on a daily basis, should be<br />

enjoyable and pleasing to the eye. Also the manufacturers should have the courage to create new concepts<br />

3. The packaging<br />

Good quality packaging is crucial to sales and marketing in markets. The consumer is attracted to a product by its<br />

graphic design and packaging materials quality. Careful thought needs to be given to these by the Industry.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

29

Design Intervention Areas<br />

1. Raw Material<br />

The Meerut Scissors Industry mostly uses scrap metal for the scissors it produces. The scrap is collected from<br />

different sources and is not consistent in nature or quality. This needs insightful change, to match with other<br />

production technology changes.<br />

Use of improved quality Raw material in consistent lots, can give a quantum jump to the quality of the final<br />

product.<br />

2. Technology Development<br />

The technology in Meerut Scissors Industry presently used is developed for smaller volumes by using select hand<br />

processes and scrap material. Due to which the quality and selling price of the Scissors made in Meerut are lower.<br />

While the market has been flooded by inexpensive and smarter scissors in striking packaging from other countries,<br />

The sales of these have adversely affected the sales of the Scissors produced in Meerut. The technology for<br />

stainless steel scissors could also be one of the technologies developed.<br />

Possible Design development and product development, and process development projects in the Industry could<br />

yield marked results in bringing up the sales.<br />

3. Packaging and Graphic Design<br />

Packaging is crucial to sales and marketing in markets. The consumer is attracted to a product by its graphic<br />

design and packaging materials quality. Careful thought needs to be given to these by the Industry.<br />

Possible Packaging Design development and also Graphic design development projects in the Industry could yield<br />

remarkable results.<br />

4. Design for Compliance and Safety<br />

Design for Safety and Compliance, a very important area of the Industry anywhere is another area for Design<br />

Intervention in Meerut Scissors Industry.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

30

5. Design of Processes and Systems Design<br />

Developing workable processes, space and sequential planning for maximum output , maximum efficiency, better<br />

finishing and better accuracy to avoid manufacturing losses , man power losses, optimum working conditions and<br />

proper storage etc. are some other areas for Design Intervention.<br />

6. Design of Safety gear and Work Apparel<br />

Most hazardous work areas and jobs require proper working gear and safety measures for the different body parts.<br />

Especially the eyes, while grinding; the hands; the feet. This is another very important area of Design Intervention.<br />

7. Creative Designs using the Metal Scrap<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

31

Future Design & Development possibilities<br />

There are many different kinds of scissors, shears, blades and razors which are needed in the market- domestic as<br />

well as global, besides other metal products. The Meerut Scissors Industry can cater to these other similar product<br />

requirements by developing the capacity required to produce more specialized and specific function scissors, and<br />

by diversifying the product range.<br />

The Industry can also look at similar technology needing products in steel and Brass which can be manufactured in<br />

Meerut. To tide over lean periods or slump in orders for scissors.<br />

Specialized scissors include sewing scissors, which often have one sharp point and one blunt point for intricate<br />

cutting of fabric, and nail scissors, which have curved blades for cutting fingernails and toenails. Special kinds of<br />

shears include pinking shears, which have notched blades that cut cloth to give it a wavy edge, and thinning<br />

shears, which have teeth that thin hair rather than trim it.<br />

Safety Scissors These have blunt ends and blades encased in plastic so the child cannot injure himself. The<br />

modern ones are a great improvement over the all metal school scissors that were once popular. The new ones are<br />

almost as good as "grown-up" scissors in their cutting capability.<br />

Larger scissors with sharper points are the standard office and home scissors. Most people use these scissors for<br />

tasks such as clipping coupons from the newspaper, as well as other general uses around the home. They may be<br />

plastic with steel blades or all metal<br />

Surgical scissors, a pair of surgical scissors has a design that facilitates sterilization, with no cracks or pits for<br />

bacteria to hide in, and construction durable enough to hold up to considerable heat in the autoclave. Some may<br />

have padded handles and other features to make them easier to use, including handles tailored to both left and<br />

Right handed surgeons. A high degree of control is critical with surgical instruments, and thus they are very<br />

carefully engineered to work optimally.<br />

Dissecting Scissors Metzenbaum scissors are a type of surgical tool typically used to cut delicate soft tissues. Not<br />

only are they the most commonly used scissors for cutting tissue, but they are designed only to be used for that<br />

purpose. Because of their specific function, they sometimes are called Metzenbaum<br />

Micro scissors are medical scissors that are mostly used for tissue or suture cutting. Unlike other medical<br />

scissors, they do not have right or left hoops, so any surgeon, whether right of left-handed, can use micro scissors.<br />

This versatility makes micro scissors an indispensable part of any operating room. In addition, these scissors are<br />

ideal for hard to reach places, since they are small and extremely sharp.<br />

Shears Scissors are cutting instruments consisting of a pair of metal blades connected in such a way that the<br />

blades meet and cut materials placed between them when the handles are brought together. The word shears is<br />

used to describe larger instruments of the same kind. As a general rule, scissors have blades less than 6 in (15 cm)<br />

long and usually have handles with finger holes of the same size. Shears have blades longer than 6 in (15 cm) and<br />

often have one small handle with a hole that fits the thumb and one large handle with a hole that will fit two or<br />

more fingers. There is a possibility for the Meerut to enter into the shears market.<br />

Razors Razors with Plastic or metal handles used by Barbers, which have a demand in local and rural markets can<br />

also be produced by the press cut methods in steel at Meerut.<br />

Metal Hand tools The Hand tools required for the production of Scissors and for other Industries , could also be<br />

manufactured in Meerut, with some machines and skills added to the already available technology.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

32

Metal Jewellery Metal scrap from Scissors production can be used for making New age jewellery and can be<br />

produced by the Meerut scissors manufacturers. There is a possibility of a very large market for jewellery of this<br />

kind.<br />

Metal Hardware for Bags and Fashion Accessories is another requirement area and Designers can play an<br />

important role in developing Quality Designs of Hardware in Brass and steel required by the markets can be<br />

produced by the Meerut Scissors Industry.<br />

Decorative Metal furniture can also be produced at Meerut, using metal as well as the scissors scrap.<br />

Catalogue and Website Design is a requirement and Designers can play an important role in developing<br />

graphics and communication materials for the Meerut Scissors Industry.<br />

Research and Development<br />

Constant Research and Development Is the strength of every Industry, and the only way to get ahead and make<br />

profits and sustained growth. The areas which require constant attention and up gradation in the Meerut Scissors<br />

Industry are:<br />

1. Product Design Development<br />

2. Product Diversification<br />

3. Product Up gradation<br />

4. Technology Up gradation<br />

5. Production processes Up gradation<br />

6. Die making<br />

7. Raw material alternatives<br />

8. Graphics<br />

9. Packaging<br />

10. Waste material use<br />

11. Development of Usage of Alternative sources of Energy<br />

12. Marketing strategies and Communication<br />

13. Training<br />

14. Power saving devices<br />

15. Time saving processes<br />

Marketing & Competition<br />

In the recent years, the cluster has seen a decline in the demand for scissors of sizes 10” and below, due to an<br />

inflow of imported scissors. The 10” and below segment is primarily of household users. On the other hand, the<br />

demand has increased for scissors of bigger sizes, which are supplied to garment manufacturers. The cluster has<br />

the potential for recapturing the household segment partially, provided the quality of scissors is improved. More<br />

specifically, hardness and sharpness are the two issues to be tackled.<br />

The household consumer looking for a better looking product, and better packaging, is attracted to the imported<br />

glistening steel and attractively packaged Imported product. The professional consumer and the highly specialized<br />

requirements of the Medical field, cannot find the technically perfect product they are looking for, from Meerut.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

33

Design Audit of Scissor manufacturing<br />

Units at Meerut<br />

1. Name : Munco Scissors<br />

Owner : Mr. Mohammad Alam<br />

Address : Zakir Colony, Meerut<br />

Product : Barber Scissors<br />

Turnover : 6 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is not consistent in nature or quality. This needs to change, to match with other<br />

production technology changes.<br />

2. Developing workable processes, space and sequential planning for maximum output, maximum<br />

efficiency, better finishing and better accuracy to avoid manufacturing losses, man power losses, optimum<br />

working conditions and proper storage etc. are some other areas for Design Intervention required by the<br />

Unit.<br />

3. Packaging is crucial to sales and marketing in the markets for the unit. The consumer is attracted to a<br />

product by its graphic design and packaging materials quality. Careful thought needs to be given to these<br />

by the Unit.<br />

4. The unit requires Designed workstations for working the blanks, as well as finishing and packing.<br />

5. The unit can also produce furniture or Jewellery from scissors waste.<br />

2. Name : 3 Star Scissors<br />

Owner : Mr. Zahid<br />

Address : Kotla street , Kanchi wali Gali, Meerut<br />

Product : Barber Scissors<br />

Turnover : 4 Lakhs / Annum<br />

Design Audit : 1. The manufacturing technology needs up gradation for a better product. Product<br />

diversification can be beneficial. Better grinding and chamfering machines are required by the unit.<br />

2. Developing efficient spaces and sequential planning for maximum output, maximum efficiency, better<br />

finishing and better accuracy to avoid manufacturing losses, man power losses, optimum working<br />

conditions and proper storage etc. are some other areas for Design Intervention required by the Unit.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

34

3. Packaging is crucial to sales and marketing in the markets for the unit. The consumer is attracted to a<br />

product by its graphic design and packaging materials quality. Careful thought needs to be given to these<br />

by the Unit.<br />

4. The unit requires proper workstations for working the blanks, as well as finishing and packing<br />

3. Name : Ayub Scissors<br />

Owner : Mr. Ayub<br />

Address : Gram Hasanpur, Garh Road, Meerut<br />

Product : Barber Scissors<br />

Turnover : 3.5 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is not consistent in nature or quality.<br />

2. Developing workable processes, space and sequential planning for maximum output, maximum<br />

efficiency, better finishing and better accuracy to avoid manufacturing losses, man power losses, optimum<br />

working conditions and proper storage etc. are some other areas for Design Intervention required by the<br />

Unit.<br />

3. Research and development as well as better grinding machines are required<br />

4. Packaging is crucial to sales and marketing in the markets for the unit. The consumer is attracted to a<br />

product by its graphic design and packaging materials quality.<br />

5. The unit requires Designed workstations and safety clothing<br />

6. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

4. Name : Shiekh Scissors<br />

Owner : Mr. Sharif Ahmed<br />

Address : 136 Sabun Giran, Meerut<br />

Product : Tailors Scissors<br />

Turnover : 5 Lakhs / Annum<br />

Design Audit : 1. Developing workable processes, space and sequential planning for maximum output,<br />

maximum efficiency, better finishing and better accuracy to avoid manufacturing losses, man power<br />

losses, optimum working conditions and proper storage etc. are some other areas for Design Intervention<br />

required by the Unit.<br />

2. Safety clothing and better grinding machines required.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

35

3. The unit requires Designed workstations and safety clothing<br />

4. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

5. Product diversification can increase the demand for the products from the unit<br />

5. Name : Nasir Forz and Casting<br />

Owner : Mr.Mohammad Sadiq Faifi<br />

Address : 191 Hata Abdul Kyum, Bagpat Road, Meerut<br />

Product : Tailoring Scissors<br />

Turnover : 4 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is not consistent in nature or quality. The steel blanks are casted elsewhere<br />

and then brought to the unit for casting of handles in Brass, in the process adding to the cost per unit.<br />

2. Developing workable processes, space and sequential planning for maximum output, maximum<br />

efficiency, better finishing and better accuracy to avoid manufacturing losses, man power losses, optimum<br />

working conditions and proper storage etc. are some other areas for Design Intervention required by the<br />

Unit.<br />

3. The unit requires planned casting area and safety clothing.<br />

4. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

5. The Unit can diversify to make Hardware for fashion accessories and lifestyle products.<br />

6. Name : Unique Trading Company<br />

Owner : Mr. Naushad Ali<br />

Address : Islam Nagar, Maliana, Meerut<br />

Product : Barber Scissors<br />

Turnover : 6 Lakhs / Annum<br />

Design Audit : 1. The manufacturing technology needs up gradation for a better product. Product<br />

diversification can be beneficial. advanced Injection molding machine might be introduced for good quality<br />

plastic handles, giving competition to the Chinese product in the market.<br />

2. Developing efficient spaces and sequential planning for maximum output, maximum efficiency, better<br />

finishing and better accuracy to avoid manufacturing losses, man power losses, optimum working<br />

conditions and proper storage etc. are some other areas for Design Intervention required by the Unit.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

36

3. Packaging is crucial to sales and marketing in the markets for the unit. The consumer is attracted to a<br />

product by its graphic design and packaging materials quality. Careful thought needs to be given to these<br />

by the Unit.<br />

4. The unit needs to invest in safety measures and special clothing for the workers<br />

7. Name : Eagle Manufacturing Company<br />

Owner : Mr. Mohammad Nadeem<br />

Address : Pillckhri Road, Meerut<br />

Product : Tailoring Scissors<br />

Turnover : 7 Lakhs / Annum<br />

Design Audit : 1. Developing workable processes, space and sequential planning for maximum output,<br />

maximum efficiency, better finishing and better accuracy to avoid manufacturing losses, man power<br />

losses, optimum working conditions and proper storage etc. are some other areas for Design Intervention<br />

required by the Unit.<br />

2. The unit requires Designed workstations and safety clothing<br />

3. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

4. Product diversification can increase the demand for the products from the unit<br />

8. Name : Farman Kanchi Udyog<br />

Owner : Mr. Farmanuddin<br />

Address : Shyam Nagar, Meerut<br />

Product : Tailoring Scissors<br />

Turnover : 6 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is not consistent in nature or quality.<br />

2. Developing workable processes, space and sequential planning for maximum output, maximum<br />

efficiency, better finishing and better accuracy to avoid manufacturing losses, man power losses, optimum<br />

working conditions and proper storage etc. are some other areas for Design Intervention required by the<br />

Unit.<br />

3. Packaging is crucial to sales and marketing in the markets for the unit. Careful thought needs to be<br />

given to this by the Unit.<br />

4. The unit requires Designed workstations for working the blanks, as well as finishing and packing.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

37

5. The unit can also produce high quality hardware for fashion accessories, as well as jewellery , to<br />

diversify.<br />

9. Name : Roxy Scissors Company<br />

Owner : Mr. Mustaq Ahmed<br />

Address : Guzri Bazaar, Meerut<br />

Product : Tailoring Scissors<br />

Turnover : 4 Lakhs / Annum<br />

Design Audit : 1. Developing workable processes, space and sequential planning for maximum output,<br />

maximum efficiency, better finishing and better accuracy to avoid manufacturing losses, man power<br />

losses, optimum working conditions and proper storage etc. are some other areas for Design Intervention<br />

required by the Unit.<br />

2. The unit requires Designed workstations and safety clothing<br />

3. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

4. Product diversification can increase the demand for the products from the unit<br />

5. Metal furniture can be manufactured by the unit for further growth<br />

10. Name : Fancy Scissors<br />

Owner : Mr. Irshad<br />

Address : Tarapuri, Meerut<br />

Product : General Scissors, Tailoring , Barber Scissors, Electroplating<br />

Turnover : 4 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is inconsistent in nature and quality.<br />

2. Developing workable processes, space and sequential planning for maximum output, maximum<br />

efficiency, better finishing and better accuracy, storage etc. are some other areas for Design Intervention<br />

required by the Unit.<br />

3. Research and development as well as better grinding machines are required<br />

4. Packaging is crucial to sales and marketing in the markets for the unit. The consumer is attracted to a<br />

product by its graphic design and packaging materials quality. Careful thought needs to be given to these<br />

by the Unit.<br />

5. The unit requires Designed workstations and safety clothing<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

38

6. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

11. Name : Insha Creations<br />

Owner : Mr. Tabassum<br />

Address : Islamabad, Meerut<br />

Product : Tailoring Scissors , Barber Scissors<br />

Turnover : 3.5 Lakhs / Annum<br />

Design Audit : 1. Developing workable processes, space and sequential planning for maximum output,<br />

maximum efficiency, better finishing and better accuracy to avoid manufacturing losses, man power<br />

losses, optimum working conditions and proper storage etc. are some other areas for Design Intervention<br />

required by the Unit.<br />

2. The unit requires Designed workstations and safety clothing<br />

3. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

4. Product diversification can increase the demand for the products from the unit<br />

12. Name : Myco Industries<br />

Owner : Mr. Irfan<br />

Address : Islamabad, Meerut<br />

Product : Kitchen, General Scissors with Plastic handle<br />

Turnover : 6 Lakhs / Annum<br />

Design Audit : 1. The manufacturing technology needs up gradation for a better product. Product<br />

diversification can be beneficial. advanced Injection molding machine might be introduced for good quality<br />

plastic handles, giving competition to the Chinese product in the market.<br />

2. Developing efficient spaces and sequential planning for maximum output, maximum efficiency, better<br />

finishing and better accuracy to avoid manufacturing losses, man power losses, optimum working<br />

conditions and proper storage etc. are some other areas for Design Intervention required by the Unit.<br />

3. Packaging is crucial to sales and marketing in the markets for the unit. The consumer is attracted to a<br />

product by its graphic design and packaging materials quality. Careful thought needs to be given to these<br />

by the Unit.<br />

4. The unit needs to invest in safety measures and special clothing for the workers<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

39

13. Name : Aamir Scissors<br />

Owner : Mr. Aamir<br />

Address : Teer Gran, Meerut<br />

Product : Tailoring Scissors<br />

Turnover : 7 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is not consistent in nature or quality. This needs to change, to match with other<br />

production technology changes.<br />

2. Developing workable processes, space and sequential planning for maximum output, maximum<br />

efficiency, better finishing and better accuracy to avoid manufacturing losses, man power losses, optimum<br />

working conditions and proper storage etc. are some other areas for Design Intervention required by the<br />

Unit.<br />

3. Packaging is crucial to sales and marketing in the markets for the unit. The consumer is attracted to a<br />

product by its graphic design and packaging materials quality. Careful thought needs to be given to these<br />

by the Unit.<br />

4. The unit requires Designed workstations for working the blanks, as well as finishing and packing.<br />

5. The unit can also produce high quality furniture , for further growth.<br />

14. Name : Ayub Rolling Mill<br />

Owner : Mr. Ayub<br />

Address : Partapur, Meerut<br />

Product : Barber Scissors<br />

Turnover : 5 Lakhs / Annum<br />

Design Audit : 1. Sequential planning for maximum output, maximum efficiency, better finishing and<br />

better accuracy to avoid manufacturing losses, man power losses, optimum working conditions and proper<br />

storage etc. are some other areas for Design Intervention required by the Unit.<br />

2. The unit requires Designed workstations and safety clothing<br />

3. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

4. Product diversification can increase the manufacturing from the unit, for increased turnover<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

40

15. Name : Max Trading Company<br />

Owner : Mr. Parvez<br />

Address : Nakkarchayan, Meerut<br />

Product : Barber , Tailor Scissors<br />

Turnover : 7 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is inconsistent in nature and quality.<br />

2. Developing workable processes, space and sequential planning for maximum output, and proper<br />

storage etc. are some other areas for Design Intervention required by the Unit.<br />

3. Research and development as well as better grinding machines are required<br />

4. Packaging is crucial to sales and marketing in the markets for the unit.<br />

5. The unit requires Designed workstations and safety clothing<br />

6. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

16. Name : Zig Zag Scissors<br />

Owner : Mr. Ashwaq<br />

Address : Gram Hasanpur, Meerut<br />

Product : Zig Zag Scissors<br />

Turnover : 3 Lakhs / Annum<br />

Design Audit : 1. The unit mostly uses scrap metal for the scissors it produces. The scrap is collected<br />

from different sources and is not consistent in nature or quality. This needs to change, to match with other<br />

production technology changes.<br />

2. Developing workable processes, space and sequential planning for maximum output, maximum<br />

efficiency, better finishing and better accuracy to avoid manufacturing losses, man power losses, optimum<br />

working conditions and proper storage etc. are some other areas for Design Intervention required by the<br />

Unit.<br />

3. The unit requires Designed workstations and safety clothing<br />

4. Packaging and Graphics designs can be used for enhancing the sales of the product.<br />

5. Product diversification can increase the manufacturing , for increased turnover.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

41

Suggestions for Industry and<br />

Business growth<br />

1. Credit facility should be made available to all the Manufacturers, on the same<br />

concept as the Kisan credit facility. Manufacturers should also be provided with credit cards<br />

for a limited amount, for buying Raw material or buying machines and equipment, giving<br />

them the advantage of picking up larger orders from the market.<br />

The Meerut Scissors manufacturers as well as the other Manufacturing associations from<br />

other sectors should work on this possibility.<br />

2. A Raw material Bank needs to be created for the Scissors producers.<br />

3. Electric Power supply situation needs improvement<br />

4. Business development Training; Machine operators training; Exposure to international<br />

manufacturing techniques; <strong>Full</strong> Automization of production for stainless steel Scissors ,as<br />

well as Die making and Tools making training needs to be organized for the sector.<br />

5. Testing Labs required in Meerut for Quality grading needed for exports of Scissors.<br />

6. Due to exposure to toxic substances and hazardous nature of the Industry proper<br />

Insurance coverage is required for the Labor in the form of subsidized Health<br />

cards .<br />

7. Technology Obsolescence needs to be planned for, with introduction of safer and<br />

better grinding, chamfering machines, forging chambers and processes etc.<br />

8. The growth of the local Industry depends on competitive prices in the markets vis a vis<br />

imported scissors . Recommendations are for increasing the Excise duty on the<br />

Imported scissors.<br />

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

42

Need Assessment Study AMITA BHATNAGAR<br />

<strong>MEERUT</strong> <strong>SCISSORS</strong> INDUSTRY Design Consultant. Delhi. March 2012<br />

NID /MSME Design Clinic Scheme<br />

43