Ductile cast iron pipes with a cement mortar coating (ZMU) - Duktus

Ductile cast iron pipes with a cement mortar coating (ZMU) - Duktus

Ductile cast iron pipes with a cement mortar coating (ZMU) - Duktus

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

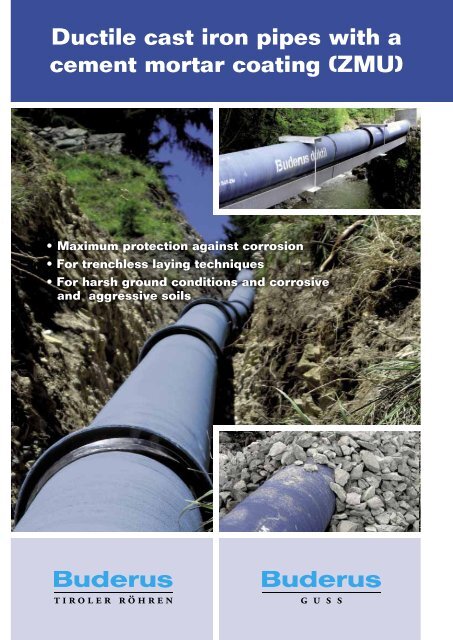

<strong>Ductile</strong> <strong>cast</strong> <strong>iron</strong> <strong>pipes</strong> <strong>with</strong> a<br />

<strong>cement</strong> <strong>mortar</strong> <strong>coating</strong> (<strong>ZMU</strong>)<br />

• Maximum protection against corrosion<br />

• For trenchless laying techniques<br />

• For harsh ground conditions and corrosive<br />

and aggressive soils

Why<br />

a <strong>cement</strong> <strong>mortar</strong> <strong>coating</strong> (<strong>ZMU</strong>)?<br />

What are <strong>ZMU</strong> <strong>pipes</strong>?<br />

As the zinc-plated pipe rotates, plastic-modifi ed <strong>cement</strong><br />

<strong>mortar</strong> based on blast furnace <strong>cement</strong> is applied to the pipe<br />

in a uniform thickness for a fi shtail nozzle. The <strong>cement</strong> <strong>mortar</strong><br />

is then reinforced <strong>with</strong> a bandage. <strong>ZMU</strong> is available for<br />

both drinking water (blue) and for waste water and sewage<br />

(reddish brown).<br />

An exhibit for an exhibition stand<br />

showing a traction head for<br />

trenchless applications<br />

Advantages of the <strong>ZMU</strong> <strong>coating</strong><br />

Resistant to chemicals<br />

• Under EN 545 and EN 15 542, ductile <strong>iron</strong> <strong>pipes</strong> <strong>with</strong> a<br />

<strong>ZMU</strong> <strong>coating</strong> can be used in any type of corrosive soil.<br />

Gives mechanical protection<br />

• <strong>ZMU</strong> <strong>pipes</strong> can be laid in existing backfi ll material <strong>with</strong> a<br />

maximum stone size of 100 mm. This is yet another reason<br />

why <strong>ZMU</strong> <strong>pipes</strong> <strong>with</strong> the BLS ® joint system are widely<br />

used for trenchless installation techniques.<br />

• Because of the high impact resistance of the <strong>ZMU</strong>, the<br />

<strong>pipes</strong> are particularly well suited to the usual rough treatment<br />

they can expect on building sites.<br />

Can be used for trenchless installation techniques<br />

For the press-pull, auxiliary pipe, burst lining, horizontal direc-<br />

tional drilling, rocket ploughing, and pipe relining techniques<br />

and many others.<br />

Economic advantages<br />

• No need for exchanges of soil or for<br />

additional bedding for the <strong>pipes</strong>, and the<br />

soil excavated can be re-used.<br />

• Major savings of time and money, because<br />

the soil excavated does not have<br />

to be taken away.<br />

• Long-term anti-corrosion protection<br />

(lasting for up to 140 years to DVGW<br />

(German Technical Association for Gas<br />

and Water) requirements) is obtained<br />

for the <strong>pipes</strong>.

Advantages of ductile <strong>iron</strong> <strong>pipes</strong><br />

• Durability measured in decades (up to 140 years)<br />

<strong>with</strong> the material properties unaffected.<br />

• High load-bearing capacity (for internal and external<br />

loads) <strong>with</strong> substantial safety margins.<br />

• Both deep and shallow top cover are possible.<br />

• Wall thicknesses, <strong>coating</strong>s and linings make the <strong>pipes</strong> suitable<br />

for use in a vast variety of applications.<br />

• A complete modular pipe and fitting system.<br />

• The innovative BLS ® restrained joint system eliminates<br />

the need for thrust blocks.<br />

• Pipes are env<strong>iron</strong>mentally-friendly (sustainable and<br />

recyclable and the materials used are inorganic).<br />

• Drinking water and ground water are protected<br />

by pipe walls which seal against diffusion.<br />

• Cement <strong>mortar</strong> linings are safe for drinking water.<br />

• Socket joints are capable of angular deflections<br />

of up to 5°. Therefore the number of fittings required can<br />

be reduced.<br />

• The most economical and practical solution<br />

on the market.<br />

• Easy to connect and install.<br />

• German quality.<br />

• Certified to DVGW (German Technical Association<br />

for Gas and Water) standard VP545, monitored by the<br />

MPA NRW (North-Rhine Westphalia Materials Testing<br />

Institute).<br />

Ready for anything!

Buderus Giesserei Wetzlar GmbH<br />

P.O. Box 12 40 • D–35573 Wetzlar<br />

Phone: +49 6441 49 14 10<br />

Fax: +49 6441 49 16 13<br />

export.gussrohrtechnik@gussrohre.com<br />

www.gussrohre.com<br />

Buderus Pipe Systems FZCO<br />

P.O. Box 262 446 • Dubai, UAE<br />

Phone: +971 (0) 4886 56-80<br />

Fax: +971 (0) 4886 56-40<br />

sales@buderuspipeme.com<br />

www.buderuspipeme.com<br />

Tiroler Röhren- und Metallwerke AG<br />

Innsbrucker Straße 51 • 6060 Hall in Tirol, Austria<br />

Phone: +43 5223 503<br />

Fax: +43 5223 43 619<br />

office@trm.at<br />

www.trm.at<br />

© · BGW/RV · 052 · 11/09 · e 1 000 · BD