Block Machines - RI MAC Maschinen & Anlagen GmbH

Block Machines - RI MAC Maschinen & Anlagen GmbH

Block Machines - RI MAC Maschinen & Anlagen GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

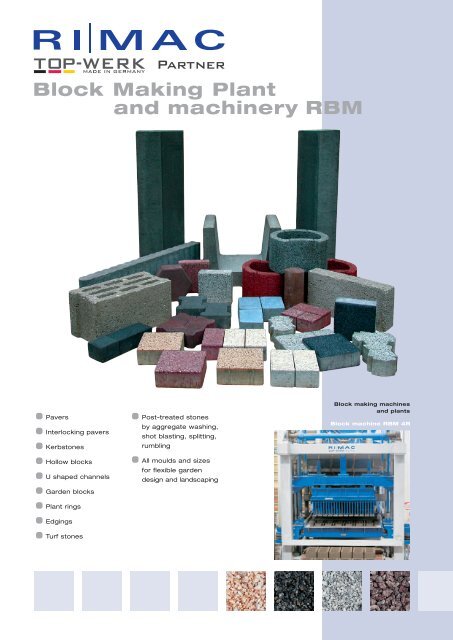

<strong>Block</strong> Making Plant<br />

and machinery RBM<br />

Pavers<br />

Interlocking pavers<br />

Kerbstones<br />

Hollow blocks<br />

U shaped channels<br />

Garden blocks<br />

Plant rings<br />

Edgings<br />

Turf stones<br />

Post-treated stones<br />

by aggregate washing,<br />

shot blasting, splitting,<br />

rumbling<br />

All moulds and sizes<br />

for flexible garden<br />

design and landscaping<br />

<strong>Block</strong> making machines<br />

and plants<br />

<strong>Block</strong> machine RBM 4R

Advantages of the<br />

<strong>RI</strong><strong>MAC</strong> <strong>Block</strong> Machine<br />

Quick start and stop because of frequencycontrolled<br />

vibrators (2 or 4)<br />

Adjust compaction to suit the product by specific<br />

unbalance setting (amplitude), frequency-control,<br />

adjustable top load and moulds clamping<br />

Careful product processing because of proportional<br />

valve technology<br />

With or without face mix<br />

Simple operation<br />

<strong>RI</strong>CS - <strong>RI</strong><strong>MAC</strong> Information and Control System /<br />

remote maintenance / data storage / error<br />

messages and fault diagnosis<br />

RFP Handling modular Step 1 simple start-up<br />

version of handling equipment at low cost<br />

RFP Handling Step 2 fully automatic circuit with<br />

buffer system between wet- and dry-end for rising<br />

up the total capacity<br />

RAS automated transfer car system<br />

Advantages of the plant:<br />

The customer can expand the modular plant set-up<br />

successively<br />

No need for racking system saves high investment<br />

and brings service costs down<br />

Excellent ambient temperature for high product<br />

quality and cement savings<br />

Use of concrete reaction heat and humidity of product<br />

stack in conjunction with the total housing of the<br />

whole storage area reduces climate and heating costs<br />

Flat building reduces investment and climatisation costs<br />

Extremely fast working dry-end because of patented<br />

rotor cuber RRO<br />

Economical automated transfer car system RAS<br />

Alternatively use of finger car and racking system as<br />

standard solution is possible<br />

Rotor transfer grab RRO for quick and<br />

gentle packaging of the products;<br />

no layer stacker necessary<br />

Adaption to individual customer<br />

demands<br />

Integration of partial elements originating<br />

from existing plants possible<br />

Extension for finishing options -<br />

washing, shot blasting,<br />

splitting, umbling equipment<br />

or other<br />

<strong>RI</strong><strong>MAC</strong> block machine RBM 2R

Proven <strong>RI</strong><strong>MAC</strong> vibration system<br />

4R 2R<br />

Handling Step 1+2standard 1400 x 900 - 1100 mm 1400 x 700 - 950 mm<br />

Handling Step 1+2legged pallet 1600 x 900 - 1100 mm 1600 x 700 - 950 mm<br />

Working surface max. 1300 x 1050 mm 1300 x 900 mm<br />

Design single vibrating table of rugged construction<br />

Frequency control option option<br />

Ouick start and stop option option<br />

RFH Fixed Handling – 1500 x 950 mm<br />

Frequency controlled vibrators 2R/4R<br />

<strong>RI</strong><strong>MAC</strong> transfer car system RAS<br />

<strong>Block</strong>-Machine RBM 2R or 4R<br />

4R 2R<br />

<strong>RI</strong><strong>MAC</strong> vibrator 4 x 13,2 kw 2 x 13,2 kw<br />

Top load vibrator 2 x 1,3 kw 2 x 1,3 kw<br />

Working cycle from 12 sec. from 14 sec.<br />

Product hight* 40 - 350 mm 40 - 350 mm<br />

Weight approx. 30 t approx. 24 t<br />

* keep legged pallet- or rack height in mind<br />

Legged pallet height 125, 225 or 325 / 132,5 mm

Bewährte Qualität<br />

<strong>RI</strong><strong>MAC</strong><br />

<strong>Maschinen</strong> + <strong>Anlagen</strong> <strong>GmbH</strong><br />

Im Bruch 4-10<br />

D-69256 Mauer bei Heidelberg<br />

Phone +49 (0) 6226-4291-0<br />

Fax +49 (0) 6226-4291-10<br />

Email info@ri-mac.de<br />

Internet www.ri-mac.de<br />

Subsidiary Weilheim:<br />

Paradeisstraße 56<br />

D-82362 Weilheim<br />

Phone +49 (0) 881-627-215<br />

Fax +49 (0) 881-627-278<br />

Email info@ri-mac.de<br />

Internet www.ri-mac.de<br />

<strong>Block</strong> <strong>Machines</strong><br />

Plant Layouts<br />

Modular plant set-up in steps 0-2<br />

Step 0 – start-up version Step 1 – fully automatic plant with<br />

forklift truck operation<br />

With plain standard pallet for<br />

forklift truck operation<br />

Step 2 – complete plant with buffer and<br />

transfer car system<br />

Right of technical modification reserved.<br />

Fixed handling RFH for legged pallets<br />

and forklift truck operation<br />

Rotor cuber RRO<br />

RFP Handling step 1 elevator/lowerator +<br />

RAS automated transfer system