EPPINGER Manual - ESA Eppinger GmbH

EPPINGER Manual - ESA Eppinger GmbH

EPPINGER Manual - ESA Eppinger GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>EPPINGER</strong> <strong>Manual</strong> (Assembling and Handling) for<br />

Driven Toolholder DIN 69880 (VDI)<br />

With a <strong>Eppinger</strong> VDI driven toolholder every customer gets a high quality product that<br />

provides outstanding technical characteristics:<br />

PRECI-FLEX® adapter system or standard collet chuck<br />

Different kinds of couplings, ref. turret type (e.g. DIN 5480, DIN 1809, etc.)<br />

Adjusting block, ref. toolholder version<br />

Tapered roller bearings<br />

GENERALLY<br />

1. Each driven toolholder has got his own test protocol, that documents the proven<br />

geometrical accuracy .<br />

2. Our tools are completely maintenance-free owing to the used Long-Life-Grease.<br />

Bearings and gears are greased with: Make Klüber, NBU15 Isoflex.<br />

3. Every driven unit was checked for temperature and ride disturbance. This means, that<br />

the toolholder are immediately ready for working processes!<br />

4. Technical information and individual equipment for each tool are available at our<br />

online-database: (http://katalog.eppinger.de).<br />

INSTRUCTIONS FOR TOOLHOLDER CHANGE<br />

Basically: To guarantee an optimal function of the toolholder we require a clean<br />

tooling interface. Only this ensures the highest possible precision of the<br />

handling process.<br />

Loose the serrated VDI-locking wedge of the toolholder station inside the turret.<br />

The coupling of the toolholder should be aligned to the counterpart of the turret<br />

interface.<br />

Insert the toolholder into the turret until it get in contact with the turret surface.<br />

Tighten the serrated VDI-locking wedge*<br />

<strong>ESA</strong> <strong>Eppinger</strong> <strong>GmbH</strong><br />

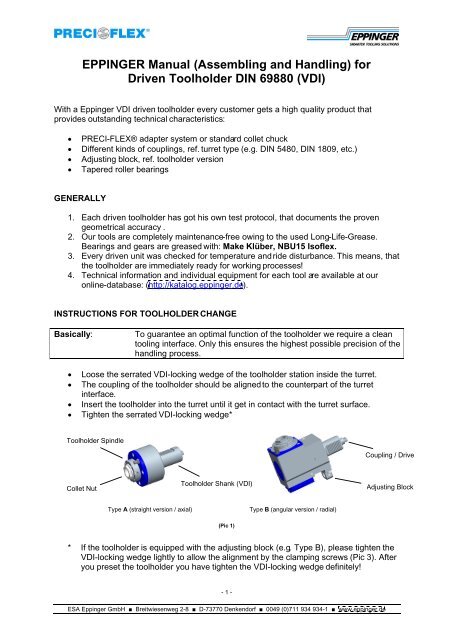

Type A (straight version / axial) Type B (angular version / radial)<br />

Breitwiesenweg 2-8<br />

(Pic 1)<br />

* If the toolholder is equipped with the adjusting block (e.g. Type B), please tighten the<br />

VDI-locking wedge lightly to allow the alignment by the clamping screws (Pic 3). After<br />

you preset the toolholder you have tighten the VDI-locking wedge definitely!<br />

- 1 -<br />

D-73770 Denkendorf<br />

0049 (0)711 934 934-1<br />

www.eppinger.de

INSTRUCTIONS FOR ADAPTER CHANGE (PRECI-FLEX® - Interface)<br />

1. Remove the four screws (a) from the base holder.<br />

2. Clean the taper and flat mounting surface from the adapter and the base holder.<br />

3. Install and tighten the four screws (b) with the T-wrench (c)<br />

4. Use the hook wrench (d) to detain the spindle from rotating<br />

The conical and flat face planar interface ensures highest accuracy and rigidity!<br />

ADJUSTING BLOCK<br />

<strong>ESA</strong> <strong>Eppinger</strong> <strong>GmbH</strong><br />

Breitwiesenweg 2-8<br />

(Pic 2)<br />

For example angular (radial) driven tools (Type B / Pic 1) can be positioned on the turret by<br />

the adjusting block.<br />

Type C (Disc/Face contact-Turret) Type D (Star-Turret)<br />

(Pic 3)<br />

TECHNICAL INFORMATION FOR DRIVEN UNITS WITH INTERNAL COOLANT SUPPLY<br />

1. Don´t run the toolholder without coolant! Danger of overheating!<br />

2. Permitted coolant pressure = 70 bar / 1000 psi.<br />

3. Coolant fluid has to be filtered with minimum 30 micron!<br />

4. In general you are able to modify the toolholder into external coolant supply.<br />

5. Coolant tubes, sealing rings for collet nuts and spindle-sealings are available at our<br />

online-database: (http://katalog.eppinger.de).<br />

BASIC NOTES FOR USAGE<br />

Remove all resources for the assembling (Spanner-Wench, etc.) from the toolholder even<br />

from the working area of the CNC-lathe, BEFORE you start the working process!<br />

MAINTENANCE AND SERVICE<br />

To reach a long lifetime of the driven units, please don´t use strong chemical cleaning<br />

agents. Even don´t use compressed air for wiping the tools and protect all the surfaces with<br />

oil or other anticorrosives.<br />

- 2 -<br />

D-73770 Denkendorf<br />

0049 (0)711 934 934-1<br />

www.eppinger.de