Download PDF - FloraCulture International

Download PDF - FloraCulture International

Download PDF - FloraCulture International

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

October 2009 www.fl oracultureinternational.com<br />

Plant P<br />

Breeders’ B<br />

Rights R<br />

A ray of hope<br />

in i Ethiopia 14<br />

‘Concordia res parvae crescunt’<br />

The business magazine for fl oriculture worldwide<br />

Advanced actions<br />

reap rewards<br />

Plant<br />

Nurseries<br />

Competition<br />

warms up in<br />

Uruguay 24<br />

Certifi cations<br />

AEO secures<br />

swift customs<br />

clearance 46

Container Centralen A/S<br />

Egegårdsvej 20<br />

Postbox 479<br />

DK–5260 Odense S<br />

Tel. +45 6591 0002<br />

Fax +45 6591 3784<br />

ccinfo@container-centralen.com<br />

www.container-centralen.com<br />

Get ready for<br />

Operation Chip It 2010!<br />

The CC Containers will get new ID tags with built-in RFID*<br />

The unique and well-functioning CC pool system<br />

offers you the possibility of a smooth product<br />

�ow. To protect the system from illegal low-quality<br />

copies, CC Containers will soon get new tags.<br />

��������������������������<br />

����������������������������������������������<br />

������������������������������������������<br />

�����<br />

������<br />

RFID in the horticultural industry is powered by IBM.<br />

NEW TAG!<br />

In 2010, we will send new RFID tags to everybody who has<br />

CC Containers under contract with Container Centralen (CC).<br />

The new tags have a built-in RFID*, that will make identi�cation<br />

of genuine CC Containers even easier. Please make sure<br />

that the amount of CC Containers you have corresponds<br />

to the number stated in your CC contracts. If not, please<br />

contact your local CC of�ce.<br />

After the cut off date, only CC Containers<br />

with the new RFID tags will be accepted in<br />

the CC Pool System! You can easily check<br />

your tags with an RFID reader (“scanner”).<br />

“Operation Chip It” – a joint horticultural project<br />

Container Centralen and our partners in this project,<br />

Landgard, GASA Group, FloraHolland, and VGB, have come<br />

together to develop the new RFID tag for CC Containers.<br />

Also, retailers and other parties in the horticultural industry<br />

are increasingly demanding optimised logistics in general.<br />

RFID is an important step in this direction.<br />

* RFID = Radio Frequency Identi�cation<br />

For more information: www.operation-chip-it.com<br />

OPERATION:����<br />

ON: ���<br />

With W RFID into the future

One stop<br />

shopping!<br />

for the horticultural<br />

industry worldwide<br />

Gärtnereinkauf Münchingen GmbH<br />

Korntal Münchingen/ Deutschland<br />

Tel.: +49 7150 9123-0<br />

Fax: +49 7150 9123-23<br />

E-mail: info@gem-bedarf.de<br />

Horticoop België bvba<br />

Beveren (Waas)/ België<br />

Tel.: +32 499 706 343<br />

E-mail: info@horticoop.be<br />

Horticoop Scandinavia A/S<br />

Tilst/ Danmark<br />

Tel.: +45 87 369900<br />

Fax: +45 87 369909<br />

E-mail: info@horticoop.dk<br />

Sistemas Agricolas Hortisur s.l.<br />

Roquetas de Mar/ Almeria España<br />

Tel.: +34 950 338622<br />

Fax: +34 950 338621<br />

E-mail: horticoop@cajamar.es<br />

Horticoop Andina S.A.<br />

Quito/ Ecuador<br />

Tel.: +593 22483141/ 22483142<br />

E-mail: sales@horticoop.ec<br />

Horticoop Ethiopia PLC<br />

Debre Zeyt/ Ethiopia<br />

Tel.: 00251-910-195284<br />

E-mail: info@horticoop.et<br />

Hort Americas llc<br />

DFW/ Texas<br />

Tel.: + 1 469 532 2261<br />

Fax: + 1 469 375 2479<br />

info@hortamericas.com<br />

Horti Horti Fair Fair 2009 2009<br />

booth booth 02.0102 02.0102<br />

Your total horticultural supplier!<br />

Klappolder 150, 2665 LP Bleiswijk, Holland<br />

Tel.: +31 (0)10 52 41 620<br />

E-mail: export@horticoop.nl<br />

WWW.HORTICOOP.NL<br />

Partners of <strong>FloraCulture</strong> <strong>International</strong><br />

- AIPH<br />

- AFIF<br />

- Arava Flowers Export Company<br />

- Asbindo<br />

- BGI<br />

- China Intex Shanghai<br />

- Danish Ornamentals<br />

- Expofl ores<br />

- Flowers and Cents<br />

- HBAG<br />

- Kenya Flower Council<br />

- NZ Export Growers Orchid<br />

Association Inc.<br />

- Orchid<br />

Growers of Hawaii<br />

- Plantum<br />

- SAFEC<br />

- SAF<br />

- Wildfl owers Australia

Table of Contents<br />

Too little too late?<br />

“Without water we have no horticulture,<br />

without the Lake we have no water.” Words of<br />

wisdom or words of doom? Lake Naivasha is<br />

probably at its lowest level for about 60 years,<br />

and whilst it is all too easy to blame the fl ower<br />

growers for this situation, a more balanced<br />

view is called for, and indeed, is beginning<br />

to come to the fore in discussion.<br />

by David Gray<br />

A ray of hope in Ethiopia<br />

Th e backbone of the fl oriculture industry<br />

is the varieties, which are available for<br />

production, and new varieties will only<br />

be introduced to Ethiopia when suffi<br />

cient Plant Breeders’ Rights protection<br />

exists. Th is is not (yet) the case.<br />

by Dr Edgar Krieger<br />

VKC embarks on a new course<br />

Th e Permanent Judging Committee VKC, the<br />

Netherlands’ leading organization dedicated to<br />

judging and registering ornamental crops is to<br />

embark on a course of action that will provide<br />

new and improved customer service.<br />

by Ron van der Ploeg<br />

You can always do better…<br />

With this motto the Dane Torben<br />

Moth Madsen is running his nursery<br />

RosaDanica, convinced that if you don’t<br />

constantly look for new ways of working,<br />

you will never get anywhere.<br />

by Lotte Bjarke<br />

12<br />

14<br />

16<br />

20<br />

October 2009 Volume 19 Number 10<br />

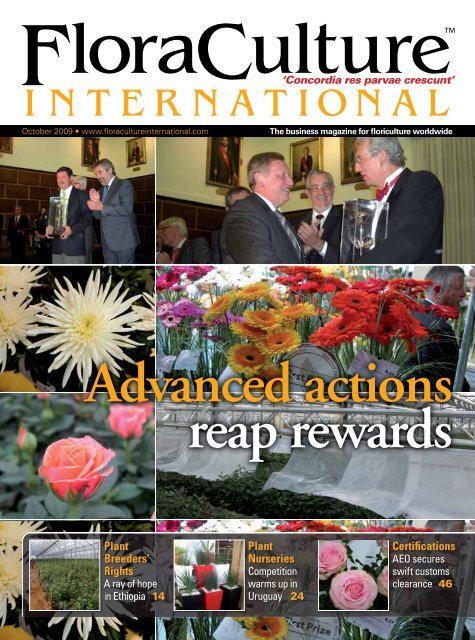

<strong>International</strong> Grower of the Year 2009<br />

During the 61st AIPH Annual Congress six grower candidates from six countries participated in<br />

the fi rst “<strong>International</strong> Grower of the Year” contest, organised by the AIPH and FCI. The reactions<br />

of the 2009 winners illustrates the high level of team satisfaction gained from the awards – the<br />

victory translating into an extra impulse for their advanced professional strategies<br />

by Anabel Evans 08<br />

GAP for disease management<br />

Powdery mildew and Botrytis control<br />

normally occurs under diff erent climatic<br />

conditions but both are good examples of<br />

how the principles of Good Agricultural<br />

Practices (GAP) can contribute to not<br />

only improved crop protection, but also<br />

reduce input costs and improve yield,<br />

quality and profi tability.<br />

by Louise Labuschagne<br />

Competition warms<br />

up in Uruguay<br />

Uruguayan plant nurseries are well positioned<br />

to take advantage of new money fl owing<br />

into their country as rich Europeans and<br />

Americans discover the ‘Provence’ of South<br />

America.<br />

by Jennifer Neujahr<br />

Access and Benefi t-Sharing<br />

Solutions<br />

Th e access to genetic resources is becoming<br />

increasingly diffi cult and subject to formalized<br />

administrative procedures. CIOPORA has<br />

subsequently adopted a Position Paper on<br />

Biodiversity, which recommends unrestricted<br />

access; underlines that benefi ts are already<br />

shared in a suffi cient way; and queries the<br />

manageability of any additional formalized<br />

ABS-instruments.<br />

by Dr Birte Lorenzen<br />

22<br />

24<br />

42<br />

Swift customs clearance<br />

secured with AEO<br />

Four Seasons Quality (FSQ), a leading<br />

importer of premium quality roses from<br />

Ecuador, is the fi rst fl ower company to be<br />

awarded with the ‘Authorised Economic<br />

Operator’ customs security and safety<br />

certifi cate, which enables a swifter clearance<br />

of fl owers at the border.<br />

by Ron van der Ploeg<br />

Departments<br />

46<br />

<strong>International</strong> Events 27<br />

World News 28<br />

Prices 39<br />

Advertising Index 49<br />

Columns<br />

In My Opinion 6<br />

Dust 23<br />

Miami 35<br />

Touch 45<br />

Stuff 47<br />

October 2009 | www.<strong>FloraCulture</strong><strong>International</strong>.com 05

Colofon<br />

<strong>FloraCulture</strong> <strong>International</strong> (ISSN1051-9076) is published monthly.Worldwide distribution.<br />

© 2009 <strong>FloraCulture</strong> <strong>International</strong> magazine. All rights reserved. No portion of editorial may<br />

be reproduced in any form without written permission of the publisher. Publisher is not liable<br />

for advertisements using illegally obtained images. Send address changes to <strong>FloraCulture</strong><br />

<strong>International</strong> magazine, Vondelstraat 162, 1054 GV Amsterdam, the Netherlands.<br />

Ron van<br />

der Ploeg<br />

Dennis<br />

Seriese<br />

Claudia<br />

Stokreef<br />

Arturo<br />

Croci<br />

Lotte<br />

Bjarke<br />

Marta Pizanode<br />

Marque<br />

William<br />

Armellini<br />

Paul<br />

Black<br />

Lucas<br />

Nicholas<br />

Eyal<br />

Policar<br />

Editorial & Administration Offi ces<br />

<strong>FloraCulture</strong> <strong>International</strong> B.V.<br />

Vondelstraat 162, 1054 GV Amsterdam, the Netherlands<br />

T (31) 20 618 2 666 F (31) 20 618 1 333<br />

Circulation Administration: FBW Woerden P.O. Box 612,<br />

3440 AP Woerden, the Netherlands<br />

T (31) 34 84 31 393 F (31) 34 84 32 552 info@fbw-woerden.nl<br />

Editors: Anabel Evans (anabel@fl oracultureinternational.com)<br />

Ron van der Ploeg (ron@fl oracultureinternational.com)<br />

Editorial team: Chris Beytes, Lotte Bjarke, Arturo Croci, Hans De Vries,<br />

David Gray, Kerry Herndon, Marie-Françoise Petitjean, Marta Pizano,<br />

Leaora Policar, Jennifer White<br />

Founding editor: Debbie Hamrick<br />

Publisher: <strong>FloraCulture</strong> <strong>International</strong> B.V.<br />

(jaap@fl oracultureinternational.com)<br />

T (31) 20 61 82 666 F (31) 20 61 81 333<br />

Printer: Habo DaCosta<br />

Designer: Stadsdrukkerij Amsterdam, Aryen Bouwmeester<br />

Advertising Sales Offi ces<br />

Europe, Africa, Asia/Pacifi c<br />

<strong>International</strong> Accounts Management:<br />

<strong>FloraCulture</strong> <strong>International</strong>, Vondelstraat 162,<br />

1054 GV Amsterdam, the Netherlands<br />

T (31) 20 618 2 666 F (31) 20 618 1 333<br />

Dennis Seriese (dennis@fl oracultureinternational.com) M (31) 62 21 65 220<br />

Angie Duff ree (angie@fl oracultureinternational.com)<br />

Claudia Stokreef (claudia@fl oracultureinternational.com) M (31) 63 03 99 450<br />

Italy, Southern France:<br />

Arturo Croci (arturo@fl oracultureinternational.com)<br />

Scandinavia: Lotte Bjarke (lotte@fl oracultureinternational.com)<br />

LB Text & Idé, Søndervej 10, 8350 Hundslund, Denmark T(45) 21 48 75 30<br />

South America: Marta Pizano de Marquez (marta@fl oracultureinternational.com)<br />

Horti Tecnia Ltda., Calle 85 No20-25 Of. 202B, Bogotá, Colombia<br />

T (57) 15 30 20 36 F (57) 12 36 25 54 hortitec@unete.com<br />

Miami: William Armellini(William@fl oracultureinternational.com)<br />

USA, Canada, Central America:<br />

Paul Black (pblack@ballpublishing.com) Lucas Nicholas<br />

(lnicholas@ballpublishing.com) Ball Publishing, 622 Town Road,<br />

PO Box 1660, West Chicago, IL 60186, United States<br />

T(1)6 30 23 13 675 F(1)6 30 23 15 254<br />

Middle East: Eyal Policar (eyal@fl oracultureinternational.com)<br />

T (972) 54 42 97 002 F (972) 86 58 19 07<br />

Japan: Eiji Yoshikawa (callems@world.odn.ne.jp)<br />

EMS Inc., 2-22-8 Matsubara, Setagaya-ku,Tokyo 156-0043, Japan<br />

T (81) 33 32 75 756 F (81) 33 32 27 933<br />

East Africa: David Gray (gray@africaonline.co.ke)<br />

South Africa: Cilla Lowen (cilla@fl oracultureinternational.com)<br />

T (27) 22 4857058 F (27) 22 4857415<br />

In my opinion<br />

Expos and People<br />

In the middle of a peak season for professional trade<br />

exhibitions and horticultural congresses around the world,<br />

from North to South and East to West, at the <strong>International</strong><br />

Association of Horticultural Producers (AIPH) Annual<br />

Congress, which was held this year in the fi fth largest Spanish<br />

city, Zaragoza, special attention was also being given to<br />

the plans for the horticultural and garden expositions for<br />

consumers. Th ese international events are renowned for their<br />

modern landscape designs and imaginative, very beautiful<br />

fl oriculture displays – all aiming to both educate citizens about<br />

fl oriculture and greenery and promote the value of fl owers and<br />

plants in homes, gardens and urban areas.<br />

In the pipeline are Expos for Taipei (Chinese Taipei) in<br />

2010/11; Xi’an (China) in 2011; Venlo (Th e Netherlands) in<br />

2012; Chiang Mai (Th ailand) in 2011/12; Suncheon (Republic<br />

of Korea) in 2103; Zaragoza (Spain) in 2014; Qingdao (China)<br />

in 2014; and, Antalya (Turkey) in 2016. Estimated visitor<br />

numbers, especially in the Asian countries, are mind-boggling<br />

and run into the millions.<br />

It seems a just reward that amid these bustling promotion<br />

plans, due attention was also given to six nurseries, the<br />

owners of which can only be described as leading industry<br />

entrepreneurs. From Belgium, Colombia, England, Germany,<br />

Holland and Spain, they were the candidates for the fi rst<br />

<strong>International</strong> Grower of the Year contest organized by the<br />

AIPH and FCI. Th e international jury was challenged to<br />

make a selection of the Gold, Silver and Bronze Rose winners<br />

(the full report can be read in our lead article); in all cases an<br />

advanced level of professionalism is evident.<br />

Undoubtedly, these companies have the skills to produce<br />

high quality ornamentals. Th e target of their modern<br />

business strategies is a strengthening of the relationship<br />

between their products and society. Th e company mission<br />

therefore emphasizes quality, sustainability and people.<br />

All three are fi nally determined by a multitude of complex<br />

factors – the latter is perhaps the most diffi cult of all?<br />

It starts with the people working at the heart of<br />

the industry in the greenhouses, fi elds, sales<br />

offi ces etc., expands along the supply chain<br />

to B2B contacts and ultimately, aims to<br />

reach the people on the street… especially<br />

those inquisitive enough to visit an Expo.<br />

Anabel Evans, editor<br />

anabel@fl oracultureinternational.com<br />

Eiji<br />

Yoshikawa<br />

<strong>FloraCulture</strong> <strong>International</strong> (ISSN1051-9076) is published monthly.<br />

WWorldwide<br />

distribution. ©2009 <strong>FloraCulture</strong> <strong>International</strong> magazine.<br />

AAll<br />

rights reserved. No portion of editorial may be reproduced in any<br />

fform<br />

without written permission of the publisher. Publisher is not<br />

liable for advertisements using illegally obtained images. Send address changes<br />

to <strong>FloraCulture</strong> <strong>International</strong> magazine, Vondelstraat 162, 1054 GV Amsterdam,<br />

01554_06_Colofon.indd 6 27-04-2009 13:08:58<br />

the Netherlands.<br />

Cilla Lowen

AIPH and FCI<br />

The AIPH and FCI<br />

“<strong>International</strong> Grower<br />

of the Year” initiative<br />

aims to give the<br />

deserved recognition<br />

to those growers<br />

who are striving to<br />

create a sustainable<br />

business in a highly<br />

competitive market,<br />

whether local and/<br />

or international. The<br />

remarks of the 2009<br />

winners illustrates<br />

the high level of<br />

team satisfaction<br />

gained from the<br />

awards – the victory<br />

translating into an<br />

extra impulse for their<br />

advanced professional<br />

strategies.<br />

by Anabel Evans<br />

The Bronze Rose winner was Pieter van de Berk from<br />

Van den Berk Nurseries in the Netherlands. Right: A 2009<br />

innovation from Van den Berk, the Swing Tree.<br />

8 www.<strong>FloraCulture</strong><strong>International</strong>.com | October 2009<br />

<strong>International</strong> Grower<br />

All six nominees, who are<br />

each the winners of their<br />

respective national contests,<br />

were highly commended by the<br />

international jury members with the<br />

fi rst prize and Gold Rose awarded<br />

to Marc van Hulle from the forest<br />

nursery Sylva van Hulle in Belgium.<br />

An outstanding aspect in the jury’s<br />

motivation is the company’s attitude<br />

to quality, which encompasses not<br />

only the end product but also the<br />

people in their business and market<br />

knowledge. Sylva is commended<br />

for not being afraid of the cost of<br />

quality.<br />

Marc van Hulle says, “We have<br />

the ability to grow good quality<br />

products, but the production system<br />

has to be controlled carefully and<br />

the products do have to be sold.<br />

In this respect our business relies<br />

on human resources and market<br />

knowledge. Our staff are the most<br />

important asset in the company<br />

and we promote a friendly working<br />

environment to motivate the whole<br />

team and enable us to ask for the<br />

highest output. Th is strategy is<br />

incorporated into our company<br />

mission and is called the BARK<br />

values, which translated into<br />

English refer to culturing a pride<br />

in being a nurseryman/woman<br />

and showing a high level of respect<br />

for all colleagues and customers.”<br />

Th e HR management program at<br />

Sylva actually received a Pioneer<br />

in HR Diversity Management<br />

prize in 2008. Th e actions range<br />

from regular meetings and training<br />

courses to self-managed innovation<br />

projects, an informative personnel<br />

newsletter including a ‘who’s who’<br />

section, a welcome-brochure and<br />

a DVD to illustrate production<br />

practices (including quality aspects)<br />

for new employees.<br />

Th e close cooperation is not<br />

restricted to internal management<br />

alone; Sylva has active contacts<br />

with a number of universities<br />

and research institutions to stay<br />

well informed about current<br />

trends in innovative production<br />

and commercial techniques. In<br />

combination with the inherited<br />

family knowledge, production<br />

systems are continually<br />

developing based on advanced<br />

environmentally-friendly and<br />

mechanized techniques. Th e MPS-<br />

VMS A-label was achieved in 1997.<br />

Th e family Van Hulle has been the<br />

owner of a forest nursery in Flanders,<br />

Belgium, since 1750. In 2003, the<br />

7th generation of the Van Hulle<br />

family arrived; Marc Van Hulle took

of the Year 2009<br />

over the company from his brothers<br />

together with his sons, Bram and<br />

Tim. Spread over 80 ha, Sylva<br />

produces 25 million plants annually;<br />

150 diff erent types of plants from<br />

the acer, fagus, populus, prunus,<br />

quercus, etc. forest species to buxus,<br />

taxus etc. hedging plants and shrubs<br />

can be found in the nursery, all<br />

cultivated on market demand with<br />

90% of the production exported to<br />

27 countries. Marc van Hulle ends,<br />

“Knowledge and service is highly<br />

important, especially with export<br />

to diff erent climatic conditions.<br />

Th e quality starts with the seed<br />

and together with our investments<br />

in quality guarantees throughout<br />

production, we want to hold our<br />

value in the market of forest and<br />

hedging plants with a socially<br />

responsible and highly qualitative<br />

image.”<br />

Colombia takes<br />

Silver Rose<br />

Th e Silver Rose winner is the fl ower<br />

producer and exporter Silvino<br />

Marc van Hulle from<br />

the Belgian nursery<br />

Sylva van Hulle<br />

proudly receives the<br />

Gold Rose from AIPH<br />

President Doeke<br />

Faber.<br />

Salguero from Flores de Tenjo Ltd<br />

in Colombia. Th e jury’s motivations<br />

related to: the consistent and high<br />

level of personnel care, training and<br />

education; initiatives in the breeding<br />

of varieties suited to local growing<br />

conditions; eff ective environmental<br />

practices, in particular the effi cient<br />

use of water.<br />

Flores de Tenjo has 28 years of<br />

experience in producing and<br />

exporting fl owers with roses,<br />

alstroemeria, hydrangea, freesias<br />

and ranunculus cultivated on 55<br />

ha. Th e company history is marked<br />

by innovation, constantly seeking<br />

new methods and tools to improve<br />

effi ciency of processes as well as the<br />

quality of the fl owers, along with<br />

the welfare of the workers and the<br />

environment. It was one of the fi rst<br />

nine farms to receive the Florverde®<br />

certifi cation created by Asocolfl ores.<br />

Being one of the farms in the<br />

Esmeralda Group Flores de Tenjo<br />

has also worked with Primacide (a<br />

company of the Esmeralda Group)<br />

on production techniques where<br />

improvements have been achieved<br />

in soil conditions (using organic<br />

products) and plant pathogen<br />

The Silver Rose was presented to Silvino Salguero from Flores de<br />

Tenjo in Colombia by the Mayor of Zaragoza.<br />

control. Another, more recent<br />

initiative is the creation of the<br />

company Bella Breeding with a<br />

grant from the Dutch government<br />

in a program oriented towards<br />

the creation of local employment.<br />

Th e breeding goals are focused<br />

on developing new alstroemeria<br />

varieties suited to the particular<br />

growing conditions of Colombia.<br />

Since its start in 2006, Bella<br />

Breeding has already developed<br />

seven varieties, all of which meet the<br />

environmental and legal standards<br />

required of export fl owers.<br />

Total production from the Flores<br />

de Tenjo facilities reached 22<br />

million stems in 2008 with over<br />

95% consumed in the USA. One<br />

further noteworthy process in the<br />

farm’s production system, with a<br />

very important socio-environmental<br />

impact, is the effi cient rainwater<br />

collection system. Th is system<br />

captures 90% of the rainwater to<br />

ensure an adequate farm water<br />

source throughout the year.<br />

No tree is too strange<br />

Th e third prize Bronze Rose goes<br />

to Pieter van den Berk, managing<br />

director of the semi-mature and<br />

mature trees specialist Van den Berk<br />

Nurseries in the Netherlands. Th e<br />

company product range covers 1700<br />

varieties of deciduous trees, conifers,<br />

shrubs and rhododendrons. Th e<br />

business areas that impressed the<br />

jury are: the company’s engineering<br />

innovations to complement<br />

progressive production techniques<br />

in a specialised business; compliance<br />

with environmental standards;<br />

its professional marketing and<br />

promotion activities including a<br />

multilingual website, Tree Book,<br />

guides and newsletter.<br />

Winning both the 2009 Dutch<br />

Horticultural Business Prize and<br />

the <strong>International</strong> Bronze Rose is,<br />

in Pieter van den Berk’s opinion,<br />

a real victory – recognition for the<br />

work of his uncle and father and<br />

the company staff . Being unafraid<br />

of the unusual is a management<br />

characteristic that has resulted in the >>><br />

October 2009 | www.<strong>FloraCulture</strong><strong>International</strong>.com m 9

AIPH and FCI<br />

Organisers and Jury<br />

Jury Members (left to right): Lionel Mills, England; Augusto<br />

Solano, Colombia; Secretariat Gerard de Wagt; Karl Heinz<br />

Compes, Germany; Gery Heungens, Belgium; Chairman<br />

Doeke Faber; Rob Bogers, The Netherlands.<br />

During the 61st Annual Congress of the <strong>International</strong><br />

Association of Horticultural Producers (AIPH) six<br />

grower candidates from six countries participated in<br />

the fi rst “<strong>International</strong> Grower of the Year” contest.<br />

Doeke Faber from the AIPH, Jaap N. Kras from<br />

<strong>FloraCulture</strong> <strong>International</strong> and invited secretary<br />

Gerard de Wagt from the VKC Permanent Judging<br />

Committee organized the event in cooperation with<br />

national organizations in Belgium (AVBS), Colombia<br />

(Asocolfl ores/Cenifl ores), England (NFU), Germany<br />

(Taspo/ZVG), The Netherlands (Horticultural Business<br />

Prize) and Spain (FEPEX).<br />

Each of the candidates were judged on four main<br />

criteria; (1) economic performance, (2) sustainable<br />

business strategy (including social responsibility),<br />

(3) innovation and (4) overall company image.<br />

The Award Ceremony took place during the AIPH<br />

Gala Dinner on Tuesday 15 September in the grand<br />

city hall of Zaragoza, Spain, which was the host city<br />

of the 2009 AIPH Congress.<br />

A special thank you goes to the members of the<br />

international jury, who represented the national<br />

associations of the individual country candidates:<br />

• Gery Heungens, AVBS Belgium<br />

• Augusto Solano, Asocolfl ores Colombia<br />

• Lionel Mills, NFU England<br />

• Karl Heinz Compes, ZVG Germany<br />

• Rob Bogers, ISHS The Netherlands<br />

• Josep Pages, Girona Association<br />

of Nurseries Spain<br />

Chairman: Doeke Faber<br />

Secretariat: Gerard de Wagt<br />

10 www.<strong>FloraCulture</strong><strong>International</strong>.com | October 2009<br />

diversity of products, gleaned from<br />

his uncle Paulus van den Berk, who<br />

together with his father, Jan, has<br />

helped build up the family nursery<br />

into the current international<br />

company. Th e latest product<br />

innovation is the Swing Tree.<br />

Mechanization of production has<br />

also been critical to Van den Berk<br />

Nurseries’ development, allowing<br />

digging out and delivery to be<br />

carried out rapidly and adding<br />

to the job satisfaction of the staff<br />

team. Van den Berk adds, “Using<br />

an overlapping design of the knives<br />

fi tted to the mammoth digging<br />

machine, we can work with rootballs<br />

of varying diameters (up<br />

to a maximum of 2.6 m).” Th e<br />

timing and targeted quality of the<br />

service in the wide-ranging projects<br />

undertaken by Van den Berk has<br />

also led to an extension of the<br />

planting season by using containers,<br />

Spring Ring and especially coconut<br />

fi bre root-balls. Th e coconut fi bre<br />

root-ball method is a relatively<br />

unknown method that involves<br />

wrapping the root-ball with a mat<br />

that consists of two layers of coconut<br />

fi bres that sandwich a biologically<br />

degradable plastic; as a result mature<br />

trees can be planted in the summer.<br />

Van den Berk Nurseries has been<br />

ISO certifi cated since 1997 and is<br />

further committed to the sustainable<br />

Geoff Caesar from Bransford Webbs Plant Company in England.<br />

and environmentally friendly<br />

production of trees according to the<br />

requirements of the ‘Milieukeur’<br />

Ecolabel. Th is has resulted in a<br />

number of soil, cultivation and<br />

landscaping measures, such as<br />

sowing grass in between the trees –<br />

good for the insects while reducing<br />

the need for weed killers.<br />

Honorary Plaques<br />

Honorary plaques were awarded<br />

to Geoff Caesar from Bransford<br />

Webbs Plant Company, the<br />

wholesale nursery of garden plants<br />

(nursery stock) in England; Markus<br />

Wittmann from the pot plant<br />

nursery Gartenbau Wittmann in<br />

Germany; and Joan Roig Mas from<br />

Grup Roig, the ornamental plant<br />

nurseries (specialising in geranium)<br />

in Spain.<br />

Geoff Caesar commented that<br />

choosing the right products and<br />

marketing them in an imaginative<br />

manner has been a rewarding sales<br />

strategy for Bransford Webbs.<br />

He referred in particular to their<br />

Campaign Plants initiative, which<br />

quadrupled the sales of timed<br />

plant deliveries from February to<br />

August in 2008 (primula, dianthus,<br />

fuchsia, dahlia, leucanthemum<br />

and sedum). Caesar adds, “Th e<br />

initiative has allowed us to build a<br />

relationship with our garden centre

customers but it is critical that the<br />

POS material, which targets the<br />

customer’s emotions and involves<br />

plants in their lifestyle aspirations,<br />

is used professionally; the centres<br />

are encouraged to create a large hot<br />

spot display.” Bransford Webbs is<br />

also renowned for having a dynamic<br />

and strong management style with<br />

an emphasis on personnel input and<br />

creating a team spirit. Caesar says,<br />

“It is people that make the business.<br />

Th e Investor in People assessment<br />

is extremely worthwhile: through<br />

a system of business planning,<br />

objectives and staff reviews, we<br />

maintain a proactive training and<br />

development program across the<br />

whole business.”<br />

Th e German candidate, Markus<br />

Wittmann from Gartenbau<br />

Wittmann, was highly commended<br />

by the jury for the continual<br />

modernisation of the company:<br />

adapting to specifi c market<br />

opportunities; the close attention<br />

paid to customer demands; the<br />

operational management actions<br />

implemented to minimise costs and<br />

increase revenues.<br />

All year round approximately 130<br />

diff erent pot plants are produced.<br />

In addition to the tried and tested<br />

Joan Roig Mas<br />

from Grup Roig<br />

in Spain.<br />

products, niche products such as<br />

Gomphrena globosa, Lobelia valida<br />

and Catharanthus are also produced<br />

in large quantities. Many other new<br />

varieties are tested every year, some<br />

of which enter the standard product<br />

range. Also, for several years, a wide<br />

variety of summer pot plants in<br />

13 cm pots have been produced<br />

and marketed as mixed containers.<br />

Th e purchasers are mainly owneroperated<br />

garden centres, garden<br />

centre chains, specialist shops, DIY<br />

stores and C&C. A large geographic<br />

area is served by the nurseries own<br />

fl eet of vehicles with extensive<br />

additional services available,<br />

such as plants labelled to clientspecifi<br />

cations.<br />

Grup Roig, a leading ornamental<br />

plant nursery specialising in<br />

geranium, was highly commended<br />

by the jury for: professional<br />

representation of the sector<br />

through technical customer<br />

services; its breeding innovation<br />

and research collaboration for<br />

genetic improvement; its socioenvironmental<br />

responsibility<br />

strategy. Th e company produces and<br />

commercializes about 25 million<br />

cuttings per year (20 million in the<br />

Iberian Peninsula). Geraniums, the<br />

Christmas poinsettia, petunias and<br />

the aromatic herbs are some of the<br />

most important crops off ered by<br />

the company. Th ese are sold with<br />

the support of a team of highly<br />

trained technicians. Th e idea is that<br />

the service the company provides<br />

to its customers does not stop at<br />

the door of their own nursery, but<br />

goes deep into the greenhouse of the<br />

buyer. Some of the basic breeding<br />

material is obtained in collaboration<br />

with an offi cial local research<br />

institution, the IRTA (Institute for<br />

the Development of Agricultural<br />

Technologies, run by the regional<br />

government of Catalonia). Th is<br />

collaboration produces results; one<br />

successful commercial project is<br />

the development of two lines of<br />

geraniums specially adapted for<br />

growing in high temperatures. Th e<br />

lines are called Costa Brava and<br />

Costa Daurada. Th e company also<br />

sources its material from prestigious<br />

breeders all across Europe. |||<br />

Please visit<br />

us at the<br />

Horti Fair 2009<br />

Stand 0510<br />

Hall 7<br />

FOUR<br />

SEASONS<br />

QUALITY BV<br />

FIRST<br />

FLOWER<br />

TRADER<br />

AEO-CERTIFIED<br />

ECUADOR ROSES,<br />

WWW.FSQ.NL

Lake Naivasha<br />

“Without water we<br />

have no horticulture,<br />

without the Lake<br />

we have no water.”<br />

Words of wisdom or<br />

words of doom? Lake<br />

Naivasha is probably<br />

at its lowest level<br />

for about 60 years,<br />

and whilst it is all<br />

too easy to blame<br />

the fl ower growers<br />

for this situation, a<br />

more balanced view<br />

is called for, and<br />

indeed, is beginning<br />

to come to the fore in<br />

discussion.<br />

by David Gray<br />

12 www.<strong>FloraCulture</strong><strong>International</strong>.com | October 2009<br />

Too little<br />

too late?<br />

Naivasha has been described<br />

as the ‘hot bed’ or<br />

‘birthplace’ of Kenyan<br />

horticulture due to the fact that<br />

this is where most of the early,<br />

large scale development of the<br />

industry took place (not forgetting<br />

the famous DCK Masongaleni<br />

project in the late 1970s!). It is<br />

still assumed in some quarters that<br />

whatever happens in, and around,<br />

the Naivasha area is typical of the<br />

industry as a whole, and vice versa.<br />

Th ere has in fact been rapid and<br />

signifi cant development in other<br />

parts of Kenya around Kericho,<br />

Eldoret, Th ika, Athi and Nanyuki/<br />

Timau, which do not seem to attract<br />

as much publicity, perhaps because<br />

these areas are not as concentrated.<br />

Whilst only about 30 of Kenya’s<br />

approximately 120 commercial<br />

fl ower growers are located around<br />

the Lake, they are generally the<br />

larger units, proportionately<br />

producing more export product<br />

(over 50% of the national total),<br />

employing more staff and taking<br />

relatively more water than the rest<br />

of the industry as a whole. Th e<br />

Municipal Council of Naivasha<br />

reckons that the local population<br />

has increased from about 25,000<br />

to around 300,000, bringing<br />

serious strains on its resources in<br />

terms of basic town planning: road<br />

maintenance, housing, provision<br />

of domestic water and sanitation<br />

facilities. Contributing to the local<br />

social problems are: the increasingly<br />

heavy traffi c (Naivasha is on the<br />

main route from Mombasa to<br />

Uganda and Central Africa); the<br />

continuing development of the<br />

geothermal projects in the hills to<br />

the West of the Lake; the increasing<br />

investment in tourist hotels along<br />

the lakeshore.<br />

Directly or indirectly, all these<br />

seemingly local developments<br />

have had far reaching eff ects.<br />

Th e most obvious of which is the<br />

potentially disastrous lowering<br />

in the volume and quality of the<br />

water in Lake Naivasha, which the<br />

fl ower growers are constantly being<br />

blamed for in the press and by some<br />

environmental interest groups.<br />

As one local environmentalist<br />

points out, the critical point (not<br />

recognised by everyone concerned)<br />

is not the level of the water but<br />

the volume of water in the lake,<br />

which means the depth. Th e lake<br />

has always been rather shallow, and<br />

its depth has almost certainly been<br />

reduced very signifi cantly over the<br />

years by siltation, quite regardless of<br />

any off take by the fl ower growers or<br />

anyone else.<br />

Th e overall ecology and hydrology of<br />

Lake Naivasha are very complicated;<br />

as the only ‘clean water’ lake in<br />

this part of the Great Rift Valley,<br />

with subdued volcanic activity still<br />

ongoing in the surroundings (the<br />

Ken Gen geothermal project, which<br />

produces some 20% of Kenya’s<br />

electrical power, is alongside),<br />

and with few, and only small<br />

rivers fl owing into the lake, the<br />

intake volume depends heavily on<br />

underground seepage. Th is is directly<br />

from the Aberdare and Kinangop<br />

mountain ranges to the East and<br />

indirectly from the Mau and the<br />

Eburru ranges to the West. All these<br />

‘water towers’ have been largely<br />

denuded of vegetation in recent<br />

years; a situation exacerbated by the<br />

on going drought. Furthermore,<br />

the Malewa River (not large but<br />

an important and reliable source<br />

of surface intake) besides having its<br />

supply reduced considerably by the<br />

destruction of the upriver forests<br />

was further reduced some years<br />

ago by partial diversion to supply<br />

water to Nakuru Town and certain<br />

neighbouring estates.<br />

Th e intake has<br />

subsequently been drastically<br />

reduced in recent years and<br />

for one reason or another the<br />

lake bed is said to have risen<br />

through siltation. Th e volume of<br />

water is thus reduced; at the same<br />

time increasing volumes of water<br />

have been (and continue to be)<br />

removed from the system. Th ere<br />

are many forms of abstraction,<br />

and of course, the most recent and<br />

therefore the most ‘popular’ as far as<br />

the press and the ‘disaster merchants’<br />

are concerned, is laid at the feet<br />

of the fl ower growers. Somewhat<br />

belatedly, surveys are underway and<br />

it would seem that no real fi gures are<br />

available, but the following have to<br />

be noted as signifi cant removers of<br />

water from the system, of which the<br />

lake itself is only a part.<br />

Signifi cant water users<br />

• According to the Lake Naivasha<br />

Riparian Association’s (LNRA)<br />

recent newsletter there are<br />

560 surface water permits and<br />

945 groundwater permits (i.e.<br />

boreholes, wells etc), though there<br />

is very little real monitoring and<br />

control of actual water taken out.<br />

• Evaporation has always been<br />

considered a major factor; and<br />

though some discount this, it is<br />

obvious that as the volume of<br />

water reduces the ratio of surface<br />

to volume increases and therefore<br />

the relative eff ect of evaporation<br />

increases, and is likely to continue<br />

to increase as global warming<br />

continues.<br />

• Many boreholes in the<br />

surrounding area are deep enough<br />

to be actually draining the lake.

• Whilst most of the fl ower<br />

growers use drip irrigation under<br />

plastic greenhouse conditions<br />

(and therefore with very little<br />

wastage), the increase in number<br />

of centre pivot systems for outdoor<br />

vegetable growing is, by all<br />

accounts, becoming a serious drain<br />

on the aquifers as well as being<br />

wasteful (as with all overhead<br />

systems).<br />

• KenGen, the operator of the<br />

Ol Karia geothermal project is<br />

said, by some, to actually remove<br />

more water than any of the other<br />

‘culprits’, but fi gures do not seem<br />

to be available.<br />

Aside from volume, the quality of<br />

the water has also been aff ected,<br />

both from direct lake water and<br />

from boreholes; EC has been<br />

increasing as the lake level drops<br />

and growers are having to introduce<br />

reverse osmosis systems, aff ecting<br />

the quality of the lake water as the<br />

‘by product’ fi nds its way back into<br />

the lake. Add to these factors, the<br />

ever increasing population with the<br />

inevitable requirement for water and<br />

the less inevitable (in theory at least)<br />

production of waste, much of which<br />

fi nds its way back into the lake as a<br />

potent pollutant.<br />

However, recent newspaper headlines<br />

and newsletters of interested<br />

Kenya’s fl ower<br />

growing regions.<br />

parties (such as: ‘Lake Naivasha is<br />

dying: Government and users wake<br />

up to nightmare reality’; ‘Eff ects<br />

of forest destruction put lake at<br />

risk’; ‘Lake Naivasha is facing an<br />

environmental catastrophe’) have<br />

been bringing the situation out<br />

into the open after, it would be<br />

said by many, ‘too many years with<br />

our heads in the sand’.<br />

A Management Plan was drafted<br />

nearly 20 years ago, this was initially<br />

gazetted by the Government to<br />

make it ‘offi cial’ but has apparently<br />

been mired in political, legal<br />

and personal self interest so has<br />

still got be offi cially introduced.<br />

Naivasha Na N Fair<br />

The Naivasha Horticultural Fair, held in mid<br />

September, was instituted some six years ago to<br />

present the ‘friendly face of horticulture’ and to<br />

cement relations with the local population and<br />

authorities. Since then it has grown each year and<br />

has been able to contribute increasingly to local<br />

organisations and charities. In addition, some of the<br />

fl ower growers contribute individually, for instance,<br />

to a planned new maternity wing at the local<br />

hospital, and one contributes a signifi cant amount<br />

to the ‘Safe House’ project every month. The local<br />

Rotary Club, one of the benefi ciaries of the Fair, has,<br />

among other projects, set itself a target to plant at<br />

least 50,000 trees over the next year, desperately<br />

needed in an area that has been largely denuded of<br />

its rain-making, water-holding cover in recent years.<br />

Although the published program listed 98 exhibitors,<br />

there were in fact about 125 trade stands and 10<br />

‘social’ stands, in all slightly more than last year.<br />

There was a good mix of plant breeders (six of the<br />

locally based rose breeders); seed, equipment and<br />

input suppliers (such as Pannar, Hygrotech, Syngenta<br />

and Koppert); international organisations (like<br />

NAKTuinbouw); and, a plethora of local non- or semihorticultural<br />

companies and organisations ranging<br />

from cheese makers, various handicraft stalls and a<br />

charity football maker (next year’s World Cup in South<br />

Africa is very much the ‘talk of the town’ even though<br />

Now, at least (and at last) the local<br />

District Commissioner is trying<br />

to bring everyone and everything<br />

together to establish a proper<br />

working relationship of all the parties<br />

and hopefully, a proper workable<br />

plan with sensible monitoring,<br />

development limitations, and<br />

minimum corruption.<br />

All too little too late? Unless the<br />

ongoing rape of the surrounding<br />

environment can be stopped and<br />

unless the promised El Nino dumps<br />

a deluge on the catchment areas,<br />

many fear the worst... the economic<br />

and social eff ects could be a real<br />

nightmare. |||<br />

Kenya will not be participating). Slightly surprisingly,<br />

the rose breeders (a fair barometer of prospects?)<br />

were reasonably upbeat about the industry, reporting<br />

fairly good sales for replacement, but very little<br />

increase and virtually no new investment this year.<br />

Dilpack in conjunction with the fl ower trader, The<br />

Flower Hub, were launching their new cut fl ower<br />

food and reporting capacity expansion at their<br />

Nairobi factory, whilst UFO, representing Bartels and<br />

other suppliers, were launching their new marketing<br />

concept of scented bouquets.<br />

Probably slightly fewer visitors than last year<br />

attended the Fair, some perhaps discouraged by the<br />

looming threat of a thunderstorm, which actually<br />

fl ooded the Fair early on Saturday afternoon... most<br />

welcome it was too, though apparently localised.<br />

As a result of this year’s Fair (and with the help of<br />

some overseas well wishers) the organisers are<br />

hoping to be able to donate at least Ksh 6 million<br />

shillings ($80,000) to their usual local charities;<br />

support which, although perhaps modest by<br />

international standards, is always most welcome,<br />

particularly this year when so many lives have been<br />

disrupted by the still continuing tensions from last<br />

year’s election aftermath and exacerbated by the<br />

well documented drought.<br />

October 2009 | www.<strong>FloraCulture</strong><strong>International</strong>.com 13

Plant Breeders’ Rights<br />

Addis Ababa, the<br />

capital city of<br />

Ethiopia means<br />

“new fl ower” when<br />

translated into<br />

English - and is thus<br />

also a synonym for<br />

one of the main<br />

drivers of economic<br />

growth: horticulture.<br />

The backbone of<br />

the industry is the<br />

varieties, which<br />

are available for<br />

production, and new<br />

varieties will only be<br />

introduced to Ethiopia<br />

when suffi cient Plant<br />

Breeders’ Rights (PBR)<br />

protection exists. This<br />

is not (yet) the case.<br />

1 CIOPORA,<br />

the international community of<br />

breeders of asexually reproduced<br />

ornamental and fruit plants.<br />

by Dr Edgar Krieger,<br />

Secretary General of<br />

CIOPORA<br />

14 www.<strong>FloraCulture</strong><strong>International</strong>.com | October 2009<br />

A ray of hope<br />

in Ethiopia<br />

Horticulture is one of the<br />

fastest growing industries<br />

in Ethiopia with a fi vefold<br />

increase in export earnings<br />

from 2005 to 2007. In 2008<br />

US$186 million were generated<br />

by export of horticultural products<br />

and 60,000 people are working<br />

in this industry already. Today,<br />

Ethiopia is ranked behind Kenya<br />

as Africa’s No.2 in the fl ower industry,<br />

and given its climatic and<br />

geographical conditions chances for<br />

further growth are good. But good<br />

climatic and geographical conditions<br />

are not the only prerequisite<br />

for a strong horticultural industry.<br />

Th e Ethiopian Plant Breeders’<br />

Right law went into force in 2006.<br />

However, from 2006 until today no<br />

PBR offi ce has been established in<br />

Ethiopia, which in practice means<br />

that breeders cannot obtain PBR<br />

rights for their varieties. Additionally,<br />

the law focuses, as in many<br />

– especially developing – countries,<br />

on agricultural farming and misses<br />

the chance to effi ciently protect<br />

PBR and thereby strengthen one<br />

of the very important industries in<br />

Ethiopia. Ethiopia is thus another<br />

example where adequate consideration<br />

is not given to tension areas<br />

between the (alleged) requirements<br />

of small agricultural farmers on the<br />

one hand and the needs of growers<br />

of ornamental and fruit varieties on<br />

the other hand.<br />

Many loopholes<br />

in protection<br />

Th e main reason for CIOPORA’s 1<br />

concern is the very limited scope<br />

of rights in the Ethiopian PBR<br />

law, combined with an extremely<br />

broad interpretation of the so called<br />

“farmers’ privilege” (which in fact<br />

is a farmers’ exemption) - also applicable<br />

to vegetatively reproduced<br />

ornamental and fruit varieties. In<br />

eff ect, these rulings more or less<br />

completely erode away the protection,<br />

especially for vegetatively<br />

reproduced ornamental and fruit<br />

varieties. Th e natural process of vegetative<br />

propagation means that these<br />

varieties are very easy to reproduce<br />

true to type. Th us, the permission to<br />

use – without the prior authorisation<br />

of the title holder - harvested<br />

material for further propagation<br />

and even more to sell such material<br />

for propagation purposes make the<br />

“protection” of the varieties ineff ective.<br />

As a result the current PBR law<br />

of Ethiopia does not comply with<br />

the TRIPS agreement: this requires<br />

that WTO-members (Ethiopia<br />

applied for membership to WTO in<br />

January 2003) protect plant varieties<br />

by either patents or an eff ective sui<br />

generis system or any combination<br />

thereof.<br />

Many other loopholes exist in the<br />

Ethiopian law, such as: the limited<br />

number of species eligible for pro-<br />

tection; the lack of protection for<br />

Essentially Derived Varieties (EDV);<br />

the omission of a suffi cient transitional<br />

period for PBR applications;<br />

and, a lack of enforcement tools.<br />

CIOPORA has recently provided<br />

the Ethiopian government with its<br />

detailed comments and proposals<br />

for its PBR law. CIOPORA has also<br />

engaged in a workshop on Plant<br />

Breeders’ Rights in May 2009,<br />

organized by the Ethiopian government<br />

and the Dutch Agricultural<br />

Attaché in Ethiopia. All participants<br />

at the workshop agreed that the<br />

level of PBR protection must be<br />

increased soon. As a result of the<br />

discussions CIOPORA developed<br />

a roadmap for the establishment of<br />

an eff ective PBR system in Ethiopia<br />

and is in close communication with<br />

the Ethiopian government about the<br />

implementation of this roadmap.<br />

From CIOPORA’s point of view it<br />

would be benefi cial and is feasible to<br />

improve the PBR law and establish<br />

the Ethiopian PBR offi ce within<br />

the next 12 months. Furthermore,<br />

CIOPORA recommended that<br />

an international network for cooperation<br />

is built up for the DUS<br />

(Distinctness, Uniformity, Stability)<br />

examination, for example, and to<br />

establish an eff ective enforcementstructure.<br />

Urgent priority<br />

More and more disputes occur in<br />

the Ethiopian fl ower industry due<br />

to the economic crisis but also, to<br />

a large extent, because of the complete<br />

lack of eff ective protection for<br />

plant varieties. Th e disputes often<br />

escalate at the borders or in the<br />

consuming regions, where breeders<br />

enforce their PBR rights in these<br />

territories. For the benefi t of their<br />

national fl ower and fruit business,<br />

Ethiopian politicians should give<br />

this matter a high priority and solve<br />

the issues as soon as possible. |||

yyyyyyyyyy<br />

Raspberry<br />

Raspberry Ice Ice<br />

ica R RRRaa<br />

a ppppppber ppp<br />

RRRRRRRRa RRaaa aa<br />

South America<br />

ss<br />

RR RRRRRRRRRRRRRRRRRRRR<br />

spppppppb<br />

ass<br />

OUR BEST SELECTIONS 2010<br />

eer eeeeeeeer rrr rr IIc<br />

yyyyyy r Icee yyyy<br />

beeerr r<br />

ppbbe<br />

IIcce cceeee e eeeeeeeeeee<br />

®®®® ®®<br />

eee<br />

c cc ®® ®®<br />

®<br />

Europe ©GW 9/09<br />

® Rosebreeding since 1906<br />

Visit us at the Horti Fair 2009,<br />

Stand-No. 0604, Hall 7<br />

Whisky ®<br />

Whisky ® Deep Water ®<br />

Kenya<br />

Deep Water ®<br />

DDee eeeeeeeeeee eeeeeeeeeeeeeee WWWWW tt ® ®<br />

DDDee DDee<br />

DDDDDDDDDDD ee<br />

eeeeeeep eepp<br />

e p W W t ®<br />

Tel.: +49 (0) 41 22 / 70 84 · Fax: 70 87 · Internet: www.rosen-tantau.com<br />

RosenTantau_178x124.indd 1 21-09-2009 14:48:53<br />

Visit us at<br />

the Horti Fair<br />

in Amsterdam,<br />

13. - 16.10.2009<br />

Innovations for Growing Success<br />

Our customers expect superior quality<br />

and reliable service with competitive prices.<br />

You can depend on us. Always.<br />

Pöppelmann GmbH & Co. KG · Kunststoffwerk-Werkzeugbau<br />

Bakumer Straße 73 · 49393 Lohne · Germany<br />

Phone +49 4442 982-1600 · Fax +49 4442 982-1607<br />

teku@poeppelmann.com · www.poeppelmann.com<br />

Poppelman_178x124.indd 1 21-09-2009 14:56:24<br />

©G GW 9/09

Quality Measure<br />

The Permanent<br />

Judging Committee<br />

VKC, the Netherlands’<br />

leading organization<br />

dedicated to judging<br />

and registering<br />

ornamental crops<br />

is to embark on a<br />

course of action that<br />

will provide new and<br />

improved customer<br />

service. VKC<br />

coordinator Gerard<br />

de Wagt unveils some<br />

details of VKC’s<br />

ambitious 10 year<br />

plan featuring product<br />

judging with added<br />

value for both grower<br />

and trade, as well<br />

as an <strong>International</strong><br />

Grower of the Year<br />

competition.<br />

VKC coordinator Gerard de Wagt unveils<br />

some details of VKC’s ambitious 10 year<br />

plan featuring product judging with<br />

added value for both grower and trade.<br />

by Ron van der Ploeg<br />

16 www.<strong>FloraCulture</strong><strong>International</strong>.com | October 2009<br />

VKC embarks<br />

on a new course<br />

No time for this, no time for<br />

that. In our hurried society<br />

even growers of fl owers<br />

and plants tend to work faster than<br />

the rhythm of nature, having not<br />

much time left to participate in<br />

fl ower shows and the associated<br />

quality competitions. “Th ese shows<br />

will continue to exist but the grower<br />

who zestfully marks, selects, harvest,<br />

transports and displays his best<br />

fl ower at a fl ower show will become<br />

increasingly rare. Growers are less<br />

content with the mere honour of<br />

winning a prize, they want more<br />

added value,” says VKC coordinator<br />

Gerard de Wagt.<br />

A new style of<br />

trial judging<br />

Analyzing these facts the management<br />

of the VKC has opted for a<br />

new style of trial judging; a strong<br />

focus will be put on the trade sector<br />

and the presentation and performance<br />

of the fl ower and plants<br />

throughout the supply chain.<br />

In order to limit the amount of<br />

work for the grower, the VKC will<br />

be taking care of the product selection<br />

by picking out two to three A1<br />

quality bunches stored in the cool<br />

rooms of the auctions. One bunch<br />

will be used for a vase presentation,<br />

the two remaining bunches will<br />

be displayed in the usual auction<br />

container.<br />

“At the top of the grower’s list of<br />

wishes is better communication<br />

with buyers. Th e VKC judging new<br />

style aims to build a bridge between<br />

production and trade. New judging<br />

committees and new criteria will<br />

be formed: the main criteria to be<br />

checked being bud presentation,<br />

overall freshness of the product,<br />

transportability, packaging, product<br />

information and product images,”<br />

says De Wagt.<br />

Th e VKC plans to organize its new<br />

quality competition per product<br />

during its supply period, two to four<br />

times a year during trade fairs and<br />

auction shows. Year-round crops like<br />

roses or gerberas could possibly be<br />

judged on more occasions. “Consequently<br />

the buyers will acquire a<br />

clear image of the diff erent producers.<br />

A list of growers will appear. As<br />

a grower you’d better be listed at<br />

the top rather than at the bottom.<br />

Th is list should be stimulating less<br />

competent growers to gain a higher<br />

ranking.”<br />

Asked if this list should be interpreted<br />

as a sign of distrust towards<br />

the quality controllers at the Dutch<br />

fl ower auction, De Wagt says, “Th e<br />

promised A1 quality is not always a<br />

reality. In this context the new VKC<br />

quality competition is an example<br />

of added value for both growers and<br />

buyers. In the end the grower will<br />

receive a better price for his products<br />

giving the buyer premium quality<br />

in return.”<br />

Role outside national<br />

boundaries<br />

Facing sky-high production costs, the<br />

Netherlands sees its production area

of ornamentals clearly decreasing:<br />

in 2007 the total area of ornamental<br />

greenhouse crops was 5,743<br />

ha which has decreased by 5.1%<br />

to 5,452 ha. Th is has resulted in a<br />

decrease in the total number of VKC<br />

judgings from 7,901 in 2006 to<br />

6,550 in 2008. “Th e signifi cant decrease<br />

in Dutch production raises the<br />

question whether the VKC should be<br />

increasing its role outside its national<br />

boundaries? An increasing number of<br />

Dutch growers have already moved<br />

half of their production to Africa<br />

or South America. Why not set up<br />

a local quality competition in these<br />

countries using their international<br />

trade shows as a platform? One good<br />

example would be the Colombian<br />

trade show Profl ora where this year<br />

we have been organizing for the<br />

fourth time a quality contest for<br />

breeders and growers. In Colombia a<br />

committee of four judges will assess<br />

roses, bulb fl owers, alstroemeria,<br />

carnations and lots of greens. Th e<br />

VKC would like to kick off a similar<br />

contest at the upcoming Hortec<br />

trade fair in Kenya.”<br />

<strong>International</strong> Grower<br />

of the Year Award<br />

Th e internationalisation of the VKC<br />

is also progressing with the new<br />

<strong>International</strong> Grower of the Year<br />

contest. “Th e VKC has been chosen<br />

to become the offi cial secretariat<br />

for this new competition which<br />

is organized by the <strong>International</strong><br />

Association of Horticulture Producers<br />

(AIPH) and the <strong>FloraCulture</strong><br />

<strong>International</strong> magazine. Each of<br />

the candidates, who are each the<br />

winners of their respective national<br />

contests, are judged on four main<br />

criteria: economic performance, sustainable<br />

business strategy innovation<br />

and overall company image.”<br />

Th e nominees already represent the<br />

top ranked horticultural businesses.<br />

“Special attention is given to the<br />

economic performance. Every<br />

candidate has to provide an audit<br />

certifi cate. We are really looking<br />

for fi nancially healthy companies,”<br />

stresses De Wagt.<br />

In this year’s fi rst edition of the<br />

contest, six countries participated.<br />

From the UK is the Worcester-based<br />

Bransford Webbs Plant Company;<br />

the Netherlands is represented by<br />

Van den Berk Boomkwekerijen;<br />

while the Joan Roig Mas plant<br />

company is representing the Spanish<br />

fl ag. Belgium sends in the tree nursery<br />

run by Marc van Hulle, while<br />

German born Markus Wittman<br />

is defending the German honour.<br />

Finally, Flores de Tenjo represents<br />

Colombia.<br />

“Th e award ceremony took place<br />

during the gala dinner of the 2009<br />

Annual AIPH Congress in Zaragoza,<br />

Spain. It is an event where we<br />

will be striving to encourage more<br />

participants year-on-year with the<br />

target for 2010 being 10 countries.<br />

We strongly believe that the nominees<br />

should not only originate from<br />

the big producing countries, but also<br />

from the large consumer markets<br />

like China and Japan - these growers<br />

should also be participating,”<br />

concludes De Wagt. |||<br />

A new style of trial judging will put a strong focus on the trade sector and the presentation<br />

and performance of the fl ower and plants throughout the supply chain.<br />

THE SHADING<br />

STANDARD!<br />

Durable high-tech shading agent for a<br />

favourable light/heat balance, diff use<br />

light and an optimal climate.<br />

Weather-resistant universal shading<br />

agent for use in greenhouse horticulture.<br />

For simple removal of ReduHeat and<br />

ReduSol from glass, polycarbonate,<br />

acrylic and plastic fi lm.<br />

www. .com<br />

Mardenkro B.V.<br />

Geerstraat 8 / Postbus 280<br />

5110 AG Baarle Nassau (NL)<br />

We welcome you<br />

on our stand<br />

01.03.24 (HAL 1)<br />

Tel.: +31(0) 13 507 70 69<br />

Fax: +31(0) 13 507 73 43<br />

E-mail: info@mardenkro.com

Born in Holland<br />

Lex+ Quality selection<br />

Visit the Lex+ Rose Experience in Kudelstaart.<br />

www.lex.nl

Lex+, the Rose Factory BV<br />

Hoofdweg 148<br />

1433 JX Kudelstaart<br />

The Netherlands<br />

T. +31 297 361 422<br />

F. +31 297 361 420<br />

W. www.lex.nl E. info@lex.nl

Potted Plants<br />

“Don’t fear the<br />

unknown. Check it<br />

out.” With this motto<br />

the Dane Torben Moth<br />

Madsen is running his<br />

nursery RosaDanica,<br />

convinced that if<br />

you don’t constantly<br />

look for new ways<br />

of working, you will<br />

never get anywhere.<br />

by Lotte Bjarke<br />

20 www.<strong>FloraCulture</strong><strong>International</strong>.com | October 2009<br />

You can<br />

always<br />

do better...<br />

At RosaDanica pot roses are<br />

the key product. Every year<br />

12.5 million pot roses in fi ve<br />

diff erent pot sizes are produced in 8<br />

ha of greenhouses. Th e experience<br />

and know-how about pot roses goes<br />

back 20 years but this has never<br />

been an excuse to be indiff erent<br />

about innovation. A high priority is<br />

always given to the constant search<br />

for new and better products as well<br />

as new and improved production<br />

methods. “We are always hoping to<br />

fi nd what we didn’t even know we<br />

were looking for,” says Torben Moth<br />

Madsen. “And in order to achieve<br />

this we can’t leave any stone unturned.<br />

We have to check out ideas<br />

even if they seem crazy to begin<br />

with. Th is is the only way to be truly<br />

innovative and without innovation<br />

we as a company cannot expect to<br />

survive in the future.”<br />

Durability comes fi rst<br />

For Torben Moth Madsen the primary<br />

goal is to improve durability of<br />

the pot rose. Th is is a goal that has<br />

been pursued for years with remark-<br />

Diversifi cation, fi rst Heuchera<br />

able new standards as a result. But if<br />

you ask Torben Moth Madsen even<br />

longer durability can be achieved.<br />

“At RosaDanica we have seen new<br />

markets for our products growing in<br />

the Eastern part of Europe. Markets<br />

we can only service because our<br />

products can stand up to the long<br />

trip in the back of a truck and still<br />

keep their ornamental value at the<br />

point of destination. Th is is why<br />

durability is the key to success,” says<br />

Torben Moth Madsen.<br />

RosaDanica is doing all the testing<br />

of new pot roses from the German<br />

rose breeder Kordes Roses. A<br />

cooperation which goes back almost<br />

20 years.<br />

“Th e potential in rose breeding is<br />

enormous and there is still plenty<br />

to achieve. Basic objectives, such as<br />

the scented rose with long durability<br />

is still awaited. Not to mention the<br />

complete series of roses with special<br />

characteristics that we don’t yet see<br />

today. You are welcome to try and<br />

guess what these are!” says Gert<br />

Jensen, who is R&D manager at<br />

RosaDanica.<br />

Pot roses are, and will continue to be, the key product of RosaDanica. But since the demand for pot roses<br />

changes from season to season the nursery has adapted the amount produced to match the needs of the<br />

market. This strategy is resulting in unexploited greenhouse capacity during certain periods. In order to<br />

fi ll this gap the nursery is in the process of searching for new products, which will fi t into the schedule of<br />

the pot roses. The fi rst product under test is Heuchera and more will follow. “We are looking for something<br />

new and different, which is not too easy to handle, and we keep an open mind. We know that we need to do<br />

things differently from our colleagues to maintain our market space, and we know that this is not achieved<br />

overnight,” says Torben Moth Madsen.<br />

Fit for export<br />

Jensen is enthusiastic and when roses<br />

appear with specifi c potential during<br />

his trials, he couldn’t be more happy.<br />

But still one feature comes fi rst. Th e<br />

durability. Heartbroken, interesting<br />

varieties with special characteristics<br />

have been rejected simply because<br />

of their lack of durability. “It is<br />

tough, but it is better to make the<br />

decision at this point. It is better<br />

for both Kordes Roses as a breeder<br />

and RosaDanica as a nursery. Th e<br />

weak characteristics always show up<br />

sooner or later,” says Jensen.<br />

All the potential new varieties have<br />

to undergo a cooling period followed<br />

by simulated transport, retail<br />

presentation and fi nally, living room<br />

conditions to evaluate their durability.<br />

“We know that our plants are<br />

exposed to tough challenges, especially<br />

during transport. But in order<br />

to be of value to the fi nal consumer,<br />

they have to be able to withstand<br />

these conditions without loss of<br />

ornamental value,” says Jensen. His<br />

goal is to have a 21-day shelf life of<br />

a single fl ower after the simulations.<br />

Trials have proven that an even<br />

longer shelf life can be achieved, so<br />

the search for new, improved varieties<br />

has certainly not stopped.

Mechanical growthretarding<br />

effects<br />

Th e search for new and improved<br />

varieties is important but this is not<br />

a quality that stands alone. Even<br />

the best, most durable plant can<br />

be spoilt if it is not grown under<br />

optimal conditions. Th is means that<br />

also the research on improved growing<br />

techniques is an important issue<br />

at RosaDanica – and an area where<br />

interesting results have recently<br />

been found. A research project was<br />

A new, mechanical growth-retarding<br />

technique is resulting in stronger, more<br />

uniform plants, which have more fl owers<br />

due to the better growth of lower side<br />

shoots.<br />

(left) Torben<br />

Moth Madsen,<br />

RosaDanica owner,<br />

and Gert Jensen,<br />

R&D manager.<br />

Durability is the key to success of their Kordana® pot roses.<br />

initiated at the nursery to discover a<br />

means of saving energy, but out of<br />

the results a diff erent aspect of production<br />

management caught their<br />

attention and is now being further<br />

developed in the greenhouses. Pot<br />

roses need to be treated with growth<br />

retardants to achieve the presentation<br />

of attractive, compact plants.<br />

RosaDanica, however, is currently<br />

reducing dramatically the amount<br />

of chemical growth retardants applied.<br />

Th e research project, which<br />

is carried out in cooperation with<br />

the Universities at Copenhagen and<br />

Aarhus, proved that a mechanical<br />

treatment can do the trick and not<br />

only keeps the plants compact but<br />

also results in a better quality of<br />

roses.<br />

“It is known that the movement of<br />

plants, for instance by wind breezes,<br />

makes them less tall, but it is new<br />

to use this knowledge for keeping<br />

ornamental pot plants compact,”<br />

says Torben Moth Madsen, who<br />

has been surprised by the potential<br />

of the method. So far 30-40% of<br />

applied chemical growth retardants<br />

have been saved while new results<br />

indicate that maybe almost all<br />

chemical growth retardants can be<br />

dispensed with, if the right method<br />

and strategy is developed.<br />

Environmentally friendly<br />

At RosaDanica the plants are<br />

brought into movement by plastic<br />

sheets, which are pulled through the<br />

greenhouse by the spraying boom<br />

installation, which is normally used<br />

for spraying several times a day. Th e<br />

results are remarkable. Not only are<br />

the treated plants compact, they are<br />

also stronger, more uniform and<br />

have more fl owers due to the better<br />

growth of lower side shoots, which<br />

are not eff ected by the plastic sheet<br />

as they would have been by chemicals.<br />

Actually, so far the results have<br />

been so promising that RosaDanica<br />

has implemented the new method<br />

for production in a large part of the<br />

nursery.<br />

“Not all of the results have been<br />

scientifi cally documented, but<br />

there is no doubt that we are onto<br />

something here. We have to develop<br />

the method with regards to the sheet<br />

material and the mechanical-drive<br />

solution. We also have to improve<br />

our understanding because to get<br />

optimal results from the new technique<br />

there is a matter of adapting,<br />

for instance, our strategies of climate<br />

control, fertilization and even take<br />

into consideration the time of the<br />

year. But we are ready to take up the<br />

challenge as we can clearly see the<br />

potential for pot rose production,<br />

and also probably many other pot<br />

plants,” underlines Torben Moth<br />

Madsen. He is also enthusiastic<br />

about the improvements to the<br />

working environment, which are<br />

made possible by the introduction<br />

of mechanical growth-retarding<br />

eff ects. Not to mention that further<br />

introduction of the system might be<br />