CLEANASCOPE System Enhances Endoscope Transport & Handling

CLEANASCOPE System Enhances Endoscope Transport & Handling

CLEANASCOPE System Enhances Endoscope Transport & Handling

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Expert Insights<br />

<strong>CLEANASCOPE</strong> <strong>System</strong> <strong>Enhances</strong> <strong>Endoscope</strong><br />

<strong>Transport</strong> & <strong>Handling</strong><br />

<strong>System</strong> Helps Minimize Risk of Cross Contamination,<br />

Improve Efficiency & Reduce Repair Costs<br />

With the number of endoscopy procedures<br />

growing around the world, it is vital that<br />

endoscopes are processed correctly in<br />

order to keep patients and staff safe from the spread<br />

of infection. Along with adhering to rigorous cleaning<br />

and decontamination practices, proper transport and<br />

storage of expensive, delicate endoscopes are crucial<br />

to ensure patient and staff safety and maintain optimal<br />

function. To address the many challenges associated<br />

with the handling of endoscopes, the <strong>CLEANASCOPE</strong><br />

<strong>System</strong> from Advanced Sterilization Products was<br />

designed as a unique storage and transportation<br />

system that reduces the risk of cross contamination<br />

and offers easy visual identification of clean versus<br />

contaminated endoscopes. Benefits of the <strong>CLEANASCOPE</strong><br />

<strong>System</strong> include improved reprocessing safety and<br />

efficiency, and a reduction in equipment repair costs.<br />

Improving <strong>Endoscope</strong> <strong>Handling</strong><br />

According to Libby Thomson, formerly the lead nurse<br />

in the Bowel Cancer Screening Centre and nurse<br />

endoscopist at a leading hospital in the United<br />

Kingdom, hospitals are increasingly focused on<br />

patient and staff safety and providing the highest<br />

level of care. This includes minimizing the risk of<br />

infection associated with endoscopy procedures.<br />

During clinical use, endoscopes are contaminated by<br />

multiple microorganisms, and failure to appropriately<br />

reprocess and handle endoscopes—both contaminated<br />

and clean—can result in nosocomial outbreaks and<br />

serious infections. However, these efforts are<br />

sometimes hampered by insufficient endoscope<br />

handling and transportation practices such as<br />

hospital staff members using open containers to<br />

move dirty endoscopes to the decontamination room.<br />

“<strong>Handling</strong> practices vary widely,” Thomson said. “For<br />

example, in some facilities endoscopes are transported<br />

in open buckets or other containers, which is<br />

inadequate. There is the potential to contaminate<br />

the environment by allowing secretions to fall to the<br />

floor or contaminants to become airborne because the<br />

containers aren’t covered. In addition, because it often<br />

is difficult to hold the container, some staff members<br />

might carry it close to their faces, potentially exposing<br />

them to the risk of infection from contaminated<br />

endoscopes. Similarly, when moving clean endoscopes<br />

back to procedure rooms in open containers, there is<br />

the potential for contamination of the disinfected<br />

instruments.”<br />

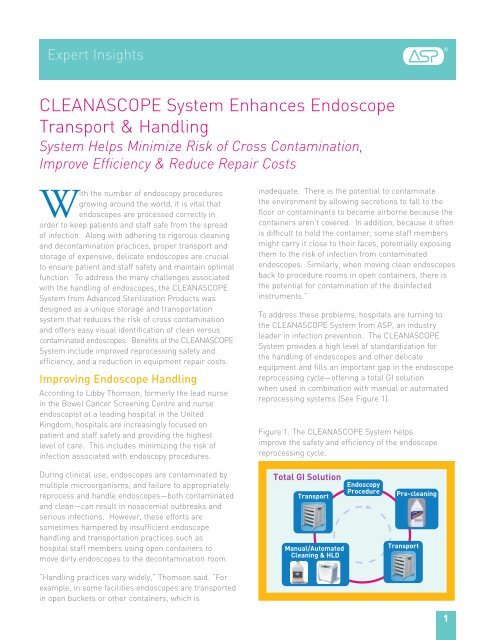

To address these problems, hospitals are turning to<br />

the <strong>CLEANASCOPE</strong> <strong>System</strong> from ASP, an industry<br />

leader in infection prevention. The <strong>CLEANASCOPE</strong><br />

<strong>System</strong> provides a high level of standardization for<br />

the handling of endoscopes and other delicate<br />

equipment and fills an important gap in the endoscope<br />

reprocessing cycle—offering a total GI solution<br />

when used in combination with manual or automated<br />

reprocessing systems (See Figure 1).<br />

Figure 1. The <strong>CLEANASCOPE</strong> <strong>System</strong> helps<br />

improve the safety and efficiency of the endoscope<br />

reprocessing cycle.<br />

Total GI Solution Endoscopy<br />

Procedure<br />

<strong>Transport</strong><br />

Manual/Automated<br />

Cleaning & HLD<br />

Pre-cleaning<br />

<strong>Transport</strong><br />

1

“The liner system is one of the most important reasons why many facilities<br />

are adopting the <strong>CLEANASCOPE</strong> <strong>System</strong>—the color-coded liners take the<br />

guesswork out of endoscope reprocessing.”<br />

According to Thomson, the <strong>CLEANASCOPE</strong> <strong>System</strong><br />

quickly resolves endoscope transport problems. The<br />

closed, reusable transport trays, carts, and liner<br />

system reduce the risk of cross-contamination from<br />

droplet or airborne contaminants and allow secure<br />

transportation to and from decontamination rooms.<br />

“With the <strong>CLEANASCOPE</strong> trays and mobile cart,<br />

instruments are safely contained, and it is no longer<br />

necessary to carry around soiled equipment in open<br />

containers,” she said.<br />

Eliminating the Guesswork<br />

The <strong>CLEANASCOPE</strong> <strong>System</strong> helps ensure that patients<br />

are not inadvertently exposed to infection risks. The<br />

patented, single-use liner system offers a protective<br />

environment for a disinfected endoscope and provides<br />

clear identification for staff of whether the equipment<br />

is clean or contaminated. After a patient procedure,<br />

the endoscope is wiped down, flushed, and placed in a<br />

<strong>CLEANASCOPE</strong> tray. A red liner cover then is placed<br />

over the tray, ensuring that the endoscope can be<br />

Red & Green Liners Identify Clean<br />

Versus Contaminated <strong>Endoscope</strong>s,<br />

Improving Patient Safety<br />

The <strong>CLEANASCOPE</strong> <strong>System</strong>’s unique colored liners<br />

improve patient safety by signaling to staff whether an<br />

endoscope is clean or dirty. A contaminated endoscope<br />

is placed in a tray and covered with a red liner,<br />

indicating that it is contaminated. Once reprocessed,<br />

the endoscope is covered with a green liner, letting<br />

staff know that is safe to use.<br />

2<br />

Benefits of the<br />

<strong>CLEANASCOPE</strong><br />

Liner <strong>System</strong>:<br />

• Reduces risk<br />

of crosscontamination<br />

• Offers a protective<br />

environment for<br />

endoscopes<br />

• Provides clear<br />

identification<br />

of whether<br />

equipment is clean<br />

or contaminated<br />

• Protects patients<br />

and improves the<br />

efficiency of the<br />

reprocessing cycle<br />

safely and hygienically transported back to the cleaning<br />

room—and alerting staff members that the endoscope<br />

is contaminated. Once the endoscope is reprocessed,<br />

it is placed in a <strong>CLEANASCOPE</strong> tray, with a clean liner,<br />

and covered with a green liner cover, signaling to staff<br />

that it is safe to use for procedures. This unique<br />

liner system helps protect patients and improve the<br />

efficiency of the endoscope reprocessing cycle. (See<br />

Sidebar: Red & Green Liners Identify Clean Versus<br />

Contaminated <strong>Endoscope</strong>s, Improving Patient Safety)<br />

According to Thomson, it can be difficult to differentiate<br />

between clean and dirty endoscopes when a facility<br />

uses open containers. “Equipment can be placed in a<br />

receptacle that isn’t easily identifiable as being dirty,”<br />

she said. “In a busy endoscopy environment, there is<br />

the potential risk of someone picking up that scope<br />

and using it on another patient. Now with the<br />

<strong>CLEANASCOPE</strong> <strong>System</strong>, there is a fail-safe way of<br />

telling whether scopes are clean or dirty, and staff can<br />

make sure instruments are in the appropriate area—<br />

especially important in hectic endoscopy departments.”<br />

The <strong>CLEANASCOPE</strong> <strong>System</strong> also contributes to<br />

increased efficiency. “The ability to quickly, easily, and<br />

safely transport instruments from the procedure room<br />

to the decontamination area and back greatly improves<br />

efficiency,” she said.<br />

“The system works very well. Facilities can place<br />

carts near the endoscopy rooms stocked with clean<br />

endoscopes, and clinical staff members will know<br />

exactly where to go to find what they need. When a<br />

procedure is complete, scopes can be immediately<br />

transported in a covered, color-coded tray to the<br />

decontamination area. Everyone will know what they<br />

are doing, and people in the decontamination room<br />

can quickly see what needs to be cleaned. The liner<br />

system is one of the most important reasons why<br />

many facilities are adopting the <strong>CLEANASCOPE</strong><br />

<strong>System</strong>—the color-coded liners take the guesswork<br />

out of endoscope reprocessing.”<br />

Cutting Repair Costs<br />

Thomson said that another key feature of the<br />

<strong>CLEANASCOPE</strong> <strong>System</strong> is its reusable trays, which<br />

guard against costly equipment repairs by protecting<br />

endoscopes from accidental damage during transport.

This benefit is especially important as hospitals<br />

face growing financial pressures and must safeguard<br />

expensive instrumentation, including flexible<br />

endoscopes, which are prone to handling damage<br />

and costly to repair. According to the literature:<br />

• At least half of endoscopes in hospital settings may<br />

be unavailable for use because of repair needs. 1<br />

• Damaged endoscopes can be expensive to repair,<br />

disrupt a facility’s capacity to provide endoscopy<br />

services, and potentially compromise patient safety. 2<br />

• Approximately 70-90% of endoscope damage may be<br />

attributed to improper handling. 3–5<br />

• Proper endoscope care and handling can dramatically<br />

improve the lifespan of an endoscope. 3<br />

According to Thomson, the <strong>CLEANASCOPE</strong> <strong>System</strong><br />

trays help reduce endoscope damage. “The trays<br />

are well-sized, so you don’t need to tightly coil the<br />

endoscope for transport, reducing damage,” she said.<br />

“Also, having endoscopes safely in individual covered<br />

trays prevents accidental damage during transport to and<br />

from the decontamination area. That’s very important in<br />

busy endoscopy departments. Facilities have experienced<br />

less repair time and cost for endoscopes since they<br />

started using the <strong>CLEANASCOPE</strong> <strong>System</strong>.”<br />

This is critical, Thomson said, as the instruments are<br />

expensive, with endoscopes costing from $20,000 to<br />

more than $80,000 each. 3,6 The financial impact is<br />

exacerbated because damaged endoscopes can lead to<br />

canceled procedures and delays in patient treatment.<br />

Focus on Standards<br />

According to Thomson, the positive experience of<br />

hospitals with the <strong>CLEANASCOPE</strong> <strong>System</strong> is<br />

indicative of a growing focus on instrument processing<br />

standards and infection prevention in the United<br />

States, Europe, and around the world.<br />

Many professional organizations, hospitals, and endoscopy<br />

centers have developed guidelines to govern the transport<br />

and handling of these fragile, high-priced instruments.<br />

Professional organizations in the U.S., including the<br />

Association of Perioperative Registered Nurses (AORN)<br />

and the Society of Gastroenterology Nurses and<br />

Associates (SGNA), have issued guidelines or recommended<br />

practices calling for the transport of endoscopes<br />

in a covered receptacle at all times. 7,8 In the United<br />

Kingdom, the Joint Advisory Group (JAG) on GI Endoscopy<br />

also has issued similar standards regarding the<br />

transport of endoscopes. 9 (See Sidebar: Guidelines for<br />

<strong>Transport</strong>ing and <strong>Handling</strong> Flexible <strong>Endoscope</strong>s)<br />

In the United Kingdom, Thomson served as a JAG lead<br />

nurse advisor and said that in recent accreditation visits<br />

to facilities, there has been an increased concentration<br />

on reviewing and improving decontamination practices,<br />

including endoscope transport and storage. “When we<br />

started decontamination assessments, things were not<br />

in good shape,” she said. “Now, most units have made<br />

significant investments to improve their practices, and<br />

standards are rapidly rising. Endoscopy departments<br />

worldwide are spending the money to improve services,<br />

and there is more emphasis on using equipment such<br />

as the <strong>CLEANASCOPE</strong> <strong>System</strong>.<br />

“With endoscopy, we must be vigilant to prevent<br />

putting patients and staff at risk,” Thomson continued.<br />

“As a result, we want to always minimize exposure to<br />

infections, and the <strong>CLEANASCOPE</strong> <strong>System</strong> provides a<br />

key solution. Every time there’s an infection outbreak<br />

in a hospital, there is an investigation. When you<br />

have solid procedures in place so staff can look at<br />

an endoscope and know it is clean with a visual sign,<br />

you can reduce the chance that a contaminated<br />

endoscope is the cause. If the scopes are clean,<br />

you’re not transporting infections. Guidelines have<br />

been a big driver for change, and it’s a small price<br />

to pay to get something like this into place” ■<br />

Guidelines for <strong>Transport</strong>ing &<br />

<strong>Handling</strong> Flexible <strong>Endoscope</strong>s:<br />

• AORN recommends that endoscopes be transported<br />

“…in a manner that preserves the sterilization/<br />

disinfection status of the endoscope.” 7<br />

• SGNA recommends transporting endoscopes<br />

in closed containers to avoid chances for cross<br />

contamination. Its guidelines state that, when<br />

transporting an endoscope to the reprocessing<br />

area, an enclosed container will prevent escape<br />

of airborne and droplet contaminants. 8 Experts<br />

emphasize that it is important to consider both the<br />

protection of the apparatus and the environment<br />

during transport. 10<br />

• CDC guidelines state that, “A protocol should be<br />

developed that ensures the user knows whether<br />

an endoscope has been appropriately cleaned and<br />

disinfected,” and endoscopes should be stored<br />

“in a manner that will protect them from damage<br />

or contamination.” 11<br />

• The UK National Health Service’s National<br />

Endoscopy Programme guidelines require that<br />

“endoscopes are transported to the decontamination<br />

area in a covered receptacle that is of an appropriate<br />

size as to avoid contaminating the environment,”<br />

and when transporting an instrument to and from<br />

the endoscopy unit, “endoscopes are transferred<br />

in a receptacle with a hard lid that completely<br />

encloses the endoscope.” 9<br />

3

References<br />

1. Leiner D. Implementing cost-effective ways to reduce endoscope repair expenses. Biomed Instrum Technol.<br />

2003;37:201–204.<br />

2. Dix K. Scope cleaning and repair: top 10 ways to keep scopes happy. Infection Control Today. 2008.<br />

http://www.infectioncontroltoday.com/articles/scope-cleaning-and-repair.html. Accessed June 26, 2008.<br />

3. Dilulio R. Service solutions: protecting your endoscope investment. 24X7. October 2006.<br />

http://www.24x7mag.com/issues/articles/2006-10_05.asp. Accessed June 26, 2008.<br />

4. Ellis K. <strong>Endoscope</strong> cleaning and repair: keeping valuable scopes fit for duty. EndoNurse. 2006.<br />

http://www.endonurse.com/articles/2006/11/endoscope-cleaning-and-repair.aspx. Accessed April 30, 2009.<br />

5. Ellis K. <strong>Endoscope</strong> repair: perspectives and advice from industry experts. EndoNurse. 2005.<br />

http:/www.endonurse.com/articles/521feat1.html. Accessed June 26, 3008.<br />

6. Dix K. Scope leak testing. EndoNurse. 2007. http://www.endonurse.com/articles/07aprfeat2.html. Accessed<br />

Sept. 24, 2009.<br />

7. Conner R, Reno D. AORN Standards, Recommended Practices and Guidelines. Denver, CO: AORN; 2006.<br />

8. Society of Gastroenterology Nurses and Associates Inc (SGNA). Standards of Infection Control in Reprocessing of<br />

Flexible Gastrointestinal <strong>Endoscope</strong>s. 2007.<br />

9. National Endoscopy Programme: Decontamination Standards for Flexible <strong>Endoscope</strong>s. Leicester, England: Joint<br />

Advisory Group on GI Endoscopy; 2009.<br />

10. Thomas L. <strong>Transport</strong>ing the endoscope. Gastroenterol Nurs. 2005;28:145–146.<br />

11. Rutala W, Weber D. HICPAC Guideline for disinfection and sterilization in healthcare facilities, 2008: Centers for<br />

Disease Control and Prevention;16, 87.<br />

33 Technology Drive • Irvine CA 92618 • (888) 783-7723<br />

www.aspjj.com<br />

<strong>CLEANASCOPE</strong> is a registered trademark of Medicart International Limited.<br />

© Ethicon, Inc. 2010 AD-100319-01-US_A