Economic Impact Study (PDF) - Owensboro Riverport Authority

Economic Impact Study (PDF) - Owensboro Riverport Authority

Economic Impact Study (PDF) - Owensboro Riverport Authority

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

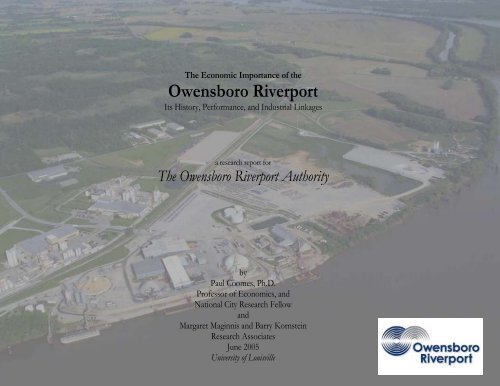

The <strong>Economic</strong> Importance of the<br />

<strong>Owensboro</strong> <strong>Riverport</strong><br />

Its History, Performance, and Industrial Linkages<br />

a research report for<br />

The <strong>Owensboro</strong> <strong>Riverport</strong> <strong>Authority</strong><br />

by<br />

Paul Coomes, Ph.D.<br />

Professor of <strong>Economic</strong>s, and<br />

National City Research Fellow<br />

and<br />

Margaret Maginnis and Barry Kornstein<br />

Research Associates<br />

June 2005<br />

University of Louisville

T Indiana<br />

he <strong>Owensboro</strong> <strong>Riverport</strong> was founded in the mid-1970s by a<br />

group of visionary community leaders. They recognized that the<br />

river is a special and permanent asset for <strong>Owensboro</strong>, and that<br />

industrial river traffic was already quite heavy. They also recognized the<br />

city’s geographic advantage in the coming growth of grain, fertilizer,<br />

steel, and aluminum businesses. Their goal was to help <strong>Owensboro</strong><br />

anchor and benefit from that growth by providing a critical piece of<br />

transportation and logistics infrastructure. Starting with some grants and<br />

a modest City investment, they acquired land that had recently become<br />

available, and built the initial configuration – a dock, an unloading facility<br />

and a 32,000 square foot warehouse on a few of the property’s 400 acres.<br />

Today, the facility is ten times larger and activity dwarfs that of twentyfive<br />

years ago.<br />

In this report we pull together historical information on the <strong>Riverport</strong>,<br />

organize more general data on important linked industries, and explain<br />

its importance to the <strong>Owensboro</strong> regional economy. This is a story of a<br />

strategic piece of public infrastructure, positioned to send, accept and<br />

store bulky commodities used pervasively in farming, automobile<br />

manufacturing, construction materials, and consumer goods. It is part of<br />

the logistics and distribution network for hundreds of farmers and<br />

dozens of manufacturing operations in the region, several of worldwide<br />

reach.<br />

The <strong>Riverport</strong>, as currently configured, is composed of a two-tiered<br />

flood wall, eight mooring dolphins, four pile cells, tug/fleeting service,<br />

two 110-ton cranes for barge loading and unloading, 500,000 square feet<br />

of modern warehouse space, a CSX main rail line with four spurs, a<br />

650,000 bushel grain storage facility, 75 acres of compacted rock for<br />

outdoor storage, two climate controlled pods to store up to 14,000 tons<br />

of fertilizer, and an office with state of the art inventory management<br />

systems. There are 45 employees, with jobs ranging from forklift<br />

operator to mechanic to inventory manager. The <strong>Riverport</strong> moved over<br />

1 million tons of cargo last year.<br />

rail line<br />

warehouses<br />

Dart Polymer<br />

fertilizer pods<br />

barge loading<br />

and unloading<br />

One’s first impression on a tour of the <strong>Riverport</strong> is its idyllic view of<br />

downtown <strong>Owensboro</strong> just several miles to the east - the long lazy curve<br />

of the river, the riverfront park, and the surrounding forest canopy<br />

create a flattering view of the city. Looking out on the river, one typically<br />

sees a set of barges, a tugboat or two, and some recreational boat traffic.<br />

The <strong>Riverport</strong>’s large cranes can load or unload a barge in one workshift.<br />

Fields of aluminum slabs and t-bars are organized and stacked in long<br />

rows, almost like houses along streets, and are carefully marked by both<br />

the manufacturer and by the <strong>Riverport</strong>’s inventory managers. A majority<br />

of the inventory is eligible for either the New York Mercantile Exchange<br />

or the London Metal Exchange, and must be tracked. Paper pulp arrives<br />

from Canada by rail, is moved to one of the warehouses, and is picked<br />

up on a daily basis by Kimberly Clark truckers. As the trucks pick up<br />

pulp they deliver pallets of paper towel products that are then stored at<br />

the <strong>Riverport</strong> before final delivery to customers.

$70<br />

$60<br />

$50<br />

$40<br />

$30<br />

$20<br />

$10<br />

$0<br />

$59.61<br />

Aluminum Shipping Cost per Ton<br />

New Orleans to <strong>Owensboro</strong>, March 2005<br />

$33.81<br />

Much of the economic story is related to the cost advantage that water<br />

transportation has over alternatives such as rail and truck. For inland<br />

transportation of nonperishable and bulky commodities, barges have no<br />

equal. Consider aluminum. Price quotes from major truck, rail, and barge<br />

shippers show that the water mode is nearly one-third the cost of rail,<br />

and one-fifth that of truck. The price difference is caused both by the<br />

energy and labor efficiency differences of the modes, but also by the<br />

great differences in volume typically hauled at once. A barge will carry<br />

1,500 tons of aluminum, rail 75 tons, and a truck only 22 tons. The<br />

<strong>Riverport</strong> helps local industries take advantage of this great cost<br />

difference, and make them more competitive in their respective markets.<br />

The state, federal, and city governments invested about $10 million<br />

in the <strong>Riverport</strong> facility during its first twenty years. Since then,<br />

there has been no public subsidy. Over the last twenty years, the<br />

<strong>Riverport</strong> <strong>Authority</strong> has plowed back a large portion of its revenues into<br />

improved facilities and equipment, investing another $20 million of self-<br />

$12.66<br />

Truck Rail Barge<br />

generated funds. And in the last few years the <strong>Riverport</strong> has been<br />

returning $150,000 annually to the City government general fund.<br />

The chart shows the full history of public investments in the <strong>Riverport</strong>.<br />

Between 1976 and 1996, the City of <strong>Owensboro</strong> contributed $2.6 million<br />

in bond payments and about $400,000 in operating subsidies. The City<br />

bonds were paid off five years before maturity. The federal government,<br />

including the Army Corps of Engineers, has contributed $2.5 million,<br />

and the State of Kentucky has contributed $4.3 million. Federal and state<br />

investments were primarily in the form of grants for land acquisition,<br />

building costs, infrastructure development and equipment purchases.<br />

$3,500,000<br />

$3,000,000<br />

$2,500,000<br />

$2,000,000<br />

$1,500,000<br />

$1,000,000<br />

$500,000<br />

$0<br />

Public Investments in the <strong>Owensboro</strong> <strong>Riverport</strong><br />

First Twenty Years<br />

City bond payments and subsidies<br />

State government grants<br />

Federal government grants<br />

1975 1976 1977 1978 1979 1980 1981 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996

Since opening in 1976, the <strong>Riverport</strong> has greatly expanded its capacity. It<br />

has added four warehouses, and now has over ten times the storage<br />

capacity as it did in 1976. Moreover, the newest warehouse was paid for<br />

completely out of self-generated revenues. Though no comparable<br />

published data exist, we believe <strong>Owensboro</strong> now has the greatest amount<br />

of public warehouse space along the rivers between Louisville and<br />

Memphis.<br />

square feet<br />

500,000<br />

450,000<br />

400,000<br />

350,000<br />

300,000<br />

250,000<br />

200,000<br />

150,000<br />

100,000<br />

50,000<br />

0<br />

1976<br />

1978<br />

1980<br />

1982<br />

Warehouse Capacity, 1976 to Present<br />

<strong>Owensboro</strong> <strong>Riverport</strong><br />

1984<br />

1986<br />

1988<br />

A majority of the warehouse space is now used to store incoming pulp<br />

and outgoing paper products manufactured by the Kimberly Clark plant<br />

near Stanley. The company made a decision when it built the plant to not<br />

construct its own warehouse facility. Given the huge scale of paper<br />

products to be stored, this created an opportunity for <strong>Owensboro</strong> area<br />

entrepreneurs. When no one stepped forward, <strong>Owensboro</strong> <strong>Riverport</strong><br />

constructed the large new warehouse.<br />

1990<br />

1992<br />

1994<br />

1996<br />

1998<br />

2000<br />

2002<br />

2004<br />

H<br />

ow and why do <strong>Owensboro</strong> area businesses, workers, and<br />

taxpayers benefit from the <strong>Riverport</strong>? This is a more<br />

complicated and interesting question than, say, what is the<br />

regional economic impact of the Ragu tomato processing plant. Whereas<br />

a particular firm has easily quantifiable impacts through its employment,<br />

vendors and tax payments, operations like <strong>Riverport</strong> impact their<br />

communities in more subtle but pervasive ways. It is useful to think of<br />

the <strong>Riverport</strong> much in the same way as one thinks about a major<br />

highway or an airport. It is not their direct employment that matters<br />

most. What matters is their ability to support commerce, which then in<br />

turn generates employment and income.<br />

Certainly the private sector is capable of providing infrastructure as well.<br />

Indeed, most warehouse space and logistics operations are located onsite<br />

at major manufacturers. <strong>Owensboro</strong> Grain is perhaps the largest<br />

handler of soybeans and corn in the state. Electric utilities routinely<br />

unload and store coal. Yet, until the <strong>Riverport</strong> was built, there was no<br />

place in the region that could load, unload, and store large volumes of<br />

heterogeneous commodities. This is of tremendous value to firms that<br />

need to move between water, rail, and truck transportation, and which<br />

for good business reasons might not want to themselves invest in the<br />

loading and storage facilities. Much as the private sector provides the<br />

airplanes and passengers that use public airports, firms around the world<br />

provide the barges, trucks, rail cars and commodities that use public<br />

ports, such as the <strong>Riverport</strong>.<br />

The public infrastructure that supports commerce along the Ohio River<br />

in western Kentucky needs to be customized to the particular strengths<br />

and opportunities of the area. We consider several of these here, and<br />

explain the <strong>Riverport</strong>’s place in the regional value chain. We start with<br />

the sector probably most familiar to Daviess County residents,<br />

agriculture.

Topographically, <strong>Owensboro</strong> is part of the Great Interior<br />

Plains of the US, a vast area that extends from Western<br />

Kentucky and Tennessee north to Canada and west to the<br />

Rocky Mountains. Because of its relatively flat terrain and the rich<br />

nutrients of the soil, this area contains some of the best soil for<br />

agriculture anywhere in the country. From a more local perspective,<br />

the <strong>Owensboro</strong> area is part of the Western Coalfield region of<br />

Kentucky, bounded to the north by the Ohio River, and to the<br />

south, east, and west by the Western Sandstone of the Pennyroyal.<br />

Originally part of the Eastern Interior Coalfields of the US, the<br />

East St. Louis<br />

# # #<br />

#<br />

Cahokia #<br />

St. Clair<br />

W<br />

Corn Production<br />

71,500 - 2,691,000 bushels<br />

2,691,001 - 6,523,200 bushels<br />

6,523,201 - 12,168,000 bushels<br />

N<br />

S<br />

E<br />

#<br />

Centralia<br />

#<br />

Herrin<br />

#<br />

#<br />

Carbondale<br />

#<br />

Mount Vernon<br />

#<br />

Paducah<br />

#<br />

Murray<br />

#<br />

#<br />

Vincennes Washington<br />

# Evansville<br />

#<br />

Henderson<br />

# ÊÚ<br />

#<br />

Madisonville<br />

#<br />

Hopkinsville<br />

#<br />

Jasper<br />

Fort Campbell<br />

#<br />

70 0 70 Miles<br />

Corn Production by County, 2003<br />

#<br />

Bedford<br />

<strong>Owensboro</strong><br />

#<br />

Bowling Green<br />

Western Kentucky Coalfield<br />

was cut off from the larger<br />

region when the Ohio River<br />

was formed at the end of the<br />

last ice age. At that time,<br />

melting glaciers flattened land<br />

in southern Indiana while<br />

millennia of floods did the<br />

same for much of western<br />

Kentucky, creating the broad<br />

alluvial plains that extend south<br />

and west beyond <strong>Owensboro</strong>.<br />

Today, the Ohio River serves as<br />

one part of a major river<br />

transportation system linking the eastern US and Midwest to<br />

southern states and the Gulf of Mexico. Within this network, the<br />

area encompassing western Kentucky, southern Illinois and Indiana,<br />

is an important center for both agriculture and mining.<br />

The city of <strong>Owensboro</strong> itself is located among low hills and<br />

bottomlands on a large southward bend in the Ohio River, amidst<br />

some of the richest farmland in Kentucky. A humid continental<br />

climate, wide flat expanses of land, and rich alluvial soils make this<br />

an excellent region for growing soybeans, corn, wheat, hay, and<br />

tobacco and indeed this area has been a traditional leader in grain<br />

production for the state.<br />

One can see from the maps how production in Kentucky is<br />

concentrated in the counties around and to the west of <strong>Owensboro</strong>,<br />

and how Indiana and Illinois production concentrates in the south<br />

and west, particularly along the Wabash River basin. This<br />

concentration of corn and soybean production means that there is a<br />

perennial need to get fertilizer into the region and grain out to<br />

customers. There is no more inexpensive form of transportation than

arge, and hence there is great regional demand for loading,<br />

unloading, and storing agricultural products along the river. The<br />

<strong>Owensboro</strong> <strong>Riverport</strong> serves farm operations over a 75 to 100 mile<br />

radius. Nearly 200,000 tons of fertilizer were brought in by barge and<br />

rail to <strong>Riverport</strong> last year, where it was then trucked out to farm<br />

supply operations around the region. Over 100,000 tons of grain are<br />

loaded on barges each year at <strong>Riverport</strong>.<br />

Unlike most of Kentucky, farming continues to be an<br />

important source of income in the <strong>Owensboro</strong><br />

region. Agriculture generated over $100 million in net<br />

income for farmers in Daviess and McLean counties<br />

in 2001, and farm workers earned about $7 million in<br />

wages and salaries. This was ten percent of the<br />

Kentucky state total. Certainly, the <strong>Riverport</strong> is one<br />

important factor keeping transportation costs down<br />

for area farmers, helping them stay competitive in the<br />

international grain markets. For example, the<br />

<strong>Riverport</strong> in the last year has shipped grain products<br />

to the United Kingdom, Israel, Brazil, Korea and<br />

Japan. Major shippers of corn at <strong>Riverport</strong> include<br />

<strong>Owensboro</strong> Grain Company, Scouler Grain, Inter-<br />

Grain and Louis Dreyfus. Fertilizer customers include<br />

Southern States Cooperative, Dyno-Nobel, Miles<br />

Enterprises, and Nelson Brothers, LLC.<br />

East St. Louis<br />

# # Fairview # Heights<br />

# O'Fallon<br />

Cahokia #<br />

Belleville<br />

W<br />

N<br />

S<br />

E<br />

Mississippi<br />

# Centralia<br />

#<br />

Cape Girardeau<br />

#<br />

Sikeston<br />

# Mount Vernon<br />

#<br />

Herrin<br />

#<br />

#<br />

Carbondale<br />

Marion<br />

Little<br />

Wabash River<br />

#<br />

Paducah<br />

#<br />

Murray<br />

Wabash<br />

River<br />

White<br />

River<br />

#<br />

#<br />

Vincennes Washington<br />

White River<br />

Evansville<br />

#<br />

#<br />

Henderson<br />

200 0 200 Miles<br />

ÊÚ<br />

#<br />

Madisonville<br />

#<br />

Hopkinsville<br />

Soybean Production by County, 2003<br />

#<br />

Jasper<br />

East Fork<br />

White River<br />

<strong>Owensboro</strong><br />

#<br />

Fort Campbell North<br />

#<br />

Clarksville<br />

#<br />

Springfield<br />

Green River<br />

Ohio<br />

#<br />

Bowling Green<br />

Soybean production<br />

192,000 - 1,347,00 bu<br />

1,347,901 - 2,763,600 bu<br />

2,763,601 - 5,101,800 bu

T<br />

he <strong>Riverport</strong> is also a major storage and distribution site for<br />

paper products. Incoming pulp, primarily from Canada,<br />

Alabama, and Washington, is unloaded from rail cars, stored, and<br />

is picked up by truck for delivery to paper manufacturers. The<br />

Kimberly-Clark plant near Stanley uses <strong>Riverport</strong> as its primary<br />

warehouse for finished paper products. On a given day, <strong>Riverport</strong> may<br />

have as many as 1,000,000 cases of paper towels, Kleenex and toilet<br />

paper on pallets in its new 300,000 square foot warehouse. These are<br />

trucked in daily from the Kimberly-Clark plant, and trucked out on<br />

demand to major customers around the United States.<br />

(X St. Charles<br />

W<br />

(X<br />

(X Peoria<br />

(X<br />

(X<br />

Rockford<br />

(X<br />

(X<br />

Elgin Chicago<br />

(X<br />

Aurora (X (X Naperville<br />

(X (X<br />

(X Hammond<br />

Joliet<br />

(X Decatur<br />

(X Springfield<br />

St. Louis<br />

N<br />

S<br />

E<br />

(X Champaign<br />

(X<br />

Terre Haute<br />

Evansville<br />

(X<br />

(X ÊÚ<br />

(X South Bend<br />

(X<br />

(X<br />

Clarksville<br />

(X<br />

Bloomington<br />

(X<br />

(X<br />

Fort Wayne<br />

(X Muncie<br />

(X Anderson<br />

Indianapolis<br />

(X<br />

<strong>Owensboro</strong><br />

Nashville<br />

Louisville<br />

(X<br />

Toledo<br />

(X<br />

(X<br />

(X (X<br />

(X (X<br />

(X<br />

(X Columbus<br />

(X Springfield<br />

(X Dayton<br />

(X<br />

Kettering<br />

(X Hamilton<br />

200 0 200 Miles<br />

(X<br />

Cincinnati<br />

(X<br />

Lexington<br />

Employment at Paper Mfg. Plants, 2001<br />

(X<br />

(X<br />

(X<br />

Akron<br />

(X Canton<br />

(X<br />

Youngstown<br />

(X Charleston<br />

Huntington<br />

Employment in Paper Manufacturing<br />

Knoxville Less than 100<br />

100-499<br />

500-999<br />

More than 1,000<br />

The map shows the distribution of employment at paper<br />

manufacturing plants in Kentucky and bordering states. Note the<br />

clear tendency for paper operations to locate along major rivers. They<br />

seek to take advantage of the inexpensive bulk transportation<br />

available by barge, and also the well-established rail connections<br />

located along the Ohio River valley.

The <strong>Riverport</strong> is also a major handler of metals, including scrap,<br />

finished steel, and aluminum. These products are highly linked<br />

with the automobile, truck and parts manufacturing firms that<br />

have clustered along a north-south corridor between Michigan and<br />

Alabama. There are hundreds of such firms within a 200 mile radius of<br />

<strong>Owensboro</strong>. <strong>Riverport</strong> handled 48,000 tons of steel and 440,000 tons<br />

of aluminum in 2004. The metals arrive by barge and rail, and are<br />

shipped out by barge, rail and truck. Most of the aluminum leaves by<br />

truck, for example, to the Logan Aluminum plant near Russellville, one<br />

hundred miles to the south, where it is turned into sheet products for<br />

buildings, automotive components, and food can stock.<br />

W<br />

N<br />

S<br />

#S<br />

#S<br />

Sikeston #S<br />

E<br />

#S<br />

Chicago<br />

#S<br />

#S<br />

Toledo<br />

#S<br />

Hammond #S Gary<br />

#S<br />

#S<br />

Joliet<br />

Valparaiso<br />

Fostoria #S #S Tiffin<br />

#S<br />

Findlay<br />

#S<br />

Effingham<br />

#S<br />

Carbondale<br />

#S<br />

Henderson<br />

#S<br />

Paducah<br />

Peru #S Wabash<br />

#S<br />

#S<br />

#S<br />

Richmond<br />

#S<br />

Columbia #S<br />

Shelbyville<br />

#S<br />

Tullahoma #S<br />

#S<br />

#S #S<br />

Lawrenceburg<br />

#S<br />

#S<br />

Lima<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S Lafayette<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

#S<br />

Kokomo<br />

Peoria<br />

Bloomington<br />

Champaign<br />

Bellefontaine<br />

Sidney<br />

Newark<br />

Piqua<br />

Troy<br />

Columbus<br />

Huber Heights<br />

Dayton<br />

Indianapolis<br />

Shelbyville<br />

Middletown<br />

Terre Haute<br />

Cincinnati<br />

St. Louis<br />

Evansville<br />

#S<br />

#S<br />

Jackson<br />

#S ÊÚ<br />

#S<br />

Clarksville<br />

Nashville<br />

#S<br />

#S<br />

<strong>Owensboro</strong><br />

Louisville<br />

Bowling Green<br />

#S<br />

#S<br />

Murfreesboro<br />

#S<br />

Lexington<br />

Knoxville #S<br />

#S Maryville<br />

#S<br />

#S<br />

#S Euclid<br />

Cleveland Heights<br />

#S<br />

#S<br />

Amherst Parma<br />

#S Cuyahoga #S Falls<br />

Youngstown<br />

#S Akron<br />

#S<br />

Canton<br />

#S #S<br />

Johnson City<br />

Elizabethton<br />

200 0 200 Miles<br />

Employment at Aluminum Companies, 2001<br />

#S<br />

Fairmont<br />

#S #S<br />

Marietta Clarksburg<br />

#S<br />

#S Charleston<br />

Huntington<br />

Employment in Aluminum Industry<br />

Less than 100<br />

100-249<br />

250-499<br />

More than 500<br />

Aluminum is perhaps<br />

the most interesting and<br />

important of the metals<br />

handled at <strong>Riverport</strong>.<br />

Few <strong>Owensboro</strong><br />

residents likely know<br />

that on most days their<br />

home town contains the<br />

largest stock of publicly<br />

traded aluminum bars in<br />

the United States. On a<br />

recent day, there<br />

were 140,000<br />

pieces stored on site, with a total market value of $185 million.<br />

<strong>Riverport</strong> is the only site in the US to handle aluminum for both<br />

the New York Mercantile Exchange and the London Metal<br />

Exchange. The stored aluminum may have been made in the US,<br />

Russia, Canada, Brazil or South Africa. It is traded as a<br />

commodity on NYMEX or LME, with the ultimate buyers<br />

representing auto manufacturing, aircraft, construction, beverage<br />

can, and wiring industries. <strong>Owensboro</strong> is a natural site for large<br />

scale aluminum storage, because of the <strong>Riverport</strong>’s barge loading<br />

and unloading facilities, its indoor and outdoor storage capacity,<br />

and because its location is so close to the center of the key users<br />

of aluminum.<br />

The aluminum industry is very important to the <strong>Owensboro</strong><br />

regional economy. There are major aluminum plants at Hawesville,<br />

Lewisport, Sebree and Evansville, with many aluminum fabricating<br />

operations in Henderson. Indeed, these aluminum plants have<br />

long been a source of some of the highest paying jobs for<br />

<strong>Owensboro</strong> residents. According to the 2000 Census, 1,545<br />

Daviess County residents commuted to Hancock County to work,<br />

664 commuted to Vanderburgh County, 660 to Spencer County,

447 to Henderson County, and 419 to Warrick County. These were<br />

the top five destinations for Daviess County out-commuters, and the<br />

counties are all dominated by metal and auto-related manufacturing<br />

operations. Indeed about one half of the $240 million in industrial<br />

payrolls in Hancock County are earned by workers who reside in<br />

another county, especially Daviess County.<br />

About 36 percent of all aluminum production and processing in<br />

United States occurs in Kentucky and adjacent states. As is evident<br />

from the map, much of that activity is clustered along the Ohio<br />

River. Major aluminum customers using <strong>Riverport</strong> include Aleris<br />

(formerly Commonwealth Aluminum), Logan Aluminum, Alcan,<br />

Alcoa, Century, Hydro Aluminum, and General Motors.<br />

Steel is also an<br />

important industry<br />

that uses <strong>Riverport</strong>.<br />

Both scrap and<br />

rolled steel are<br />

moved through the<br />

facility. The map<br />

shows the<br />

distribution of iron<br />

and steel foundries<br />

around the Midwest<br />

and Kentucky.<br />

Firms are clearly clusters along the major rivers and near large<br />

urban areas – Chicago, Indianapolis, Cincinnati, and St. Louis.<br />

Major steel customers using <strong>Riverport</strong> include AK Steel, Adelphia<br />

Metals, Dahl and Groezinger, Stemcor, Lockwood International,<br />

and Tri-State Metals. The foundries are attracted to locations along<br />

large rivers, in order to take advantage of the lower shipping costs of<br />

barge and rail, and inexpensive electricity typically available.<br />

the<br />

The aluminum and steel companies are of course also attracted by the<br />

regional concentration of auto-related manufacturing plants. It is well<br />

known that the auto industry has moved south from its Michigan base<br />

along Interstates 65 and 75 towards Alabama and Georgia. Kentucky has<br />

been a major winner in this movement, particularly in the central<br />

bluegrass region and around Bowling Green.<br />

(X<br />

(X<br />

(X<br />

(X (X (X (X<br />

(X (X(X Chicago<br />

(X (X (X<br />

Oak (X (X Lawn<br />

(X<br />

Gary<br />

(X<br />

(X<br />

South Bend<br />

(X<br />

Fort Wayne<br />

(X<br />

Toledo<br />

(X<br />

(X (X (X<br />

(X<br />

(X<br />

(X<br />

Lorain<br />

Elyria Parma<br />

(X<br />

(X<br />

Youngstown<br />

Akron<br />

(X<br />

Canton<br />

(X<br />

Pittsburgh<br />

(X<br />

Peoria<br />

(X<br />

Muncie<br />

(X<br />

Anderson<br />

(X<br />

Champaign<br />

(X<br />

(X<br />

Indianapolis<br />

(X Decatur<br />

Springfield<br />

(X<br />

Terre Haute<br />

(X<br />

Bloomington<br />

(X<br />

Columbus<br />

(X<br />

Springfield<br />

(X<br />

(X Dayton<br />

Kettering<br />

(X<br />

Hamilton<br />

(X<br />

Cincinnati<br />

St. Charles<br />

(X<br />

Charleston<br />

(X<br />

(X<br />

Huntington<br />

(X<br />

St. Louis<br />

(X<br />

Louisville (X<br />

Lexington<br />

Evansville<br />

(X<br />

(X<br />

W<br />

N<br />

S<br />

E<br />

ÊÚ<br />

(X<br />

Clarksville<br />

Nashville (X<br />

<strong>Owensboro</strong><br />

(X<br />

(X<br />

Knoxville<br />

200 0 200 Miles<br />

Employment at Foundry Plants, 2001<br />

Employment in Foundries<br />

Less than 100<br />

100-499<br />

500-999<br />

More than 1000<br />

(X

The next two maps provide a satellite view of the geographic distribution<br />

of auto-related manufacturing activity in Kentucky and bordering states.<br />

The first is for motor vehicle assembly plants. These are typically<br />

anchors for many parts plants in their areas, and all of these are potential<br />

consumers of the aluminum and steel products made around the region.<br />

The dark red splotches indicate major plants. The Georgetown KY<br />

Toyota plant, the Ford plants in Louisville, and the Toyota truck plant<br />

above Evansville are all clearly indicated. To the south, one can see the<br />

employment range for the Corvette plant in Bowling Green, the Nissan<br />

truck plant in Murfreesboro, and the GM Saturn plant below Nashville.<br />

Note that, except for the Evansville-area facility, all of the assembly<br />

plants are along the I-65 or I-75 corridors. This allows for quick<br />

Charles<br />

W<br />

N<br />

S<br />

(X<br />

E<br />

Rockford (X<br />

(X<br />

(X<br />

(X<br />

Elgin (X<br />

## (X<br />

(X (X<br />

Aurora<br />

Nape rville<br />

(X # (X #<br />

(X Gary<br />

Joliet<br />

(X<br />

# Peoria<br />

#<br />

Normal<br />

(X<br />

(X # Decatur<br />

Springfield<br />

St. Louis<br />

Chicago<br />

(X<br />

Champaign<br />

# (X<br />

South Bend<br />

#<br />

Lafayette<br />

(X #<br />

(X<br />

Terre Haute<br />

# Columbus<br />

(X<br />

Bloom ington<br />

Evansville<br />

(X<br />

(X ÊÚ<br />

<strong>Owensboro</strong><br />

(X #<br />

Fort Wayne<br />

#<br />

Bowling Green<br />

#<br />

Hopkinsville<br />

Clarksville<br />

(X # Springfield<br />

(X #<br />

Nashville<br />

#<br />

Columbia<br />

(X Muncie<br />

(X<br />

Ander son<br />

Indianapolis<br />

200 0 200 Miles<br />

(X Euclid<br />

(X Toledo<br />

(X #<br />

(X<br />

Lorain Cleveland Heights<br />

(X<br />

(X<br />

(X #<br />

(X Cleveland<br />

Parma # Warren<br />

(X<br />

#<br />

Elyria<br />

Bowling Green<br />

(X Youngstown<br />

Akron<br />

(X # Columbus<br />

(X #<br />

Springfield<br />

# (X<br />

(X Dayton<br />

#<br />

(X # Louisville (X # Lexington<br />

Georgetown<br />

#<br />

Murfreesboro<br />

(X<br />

(X<br />

Cincinnati<br />

#<br />

#<br />

Chillicothe<br />

Portsmouth<br />

#<br />

(X<br />

Canton<br />

#<br />

# (X #<br />

(X<br />

Ashlan d Huntington<br />

(X Knoxville<br />

Charleston<br />

Employment in Auto Manufacturing<br />

Less than 100<br />

100-499<br />

500-999<br />

More than 1,000<br />

#<br />

P<br />

shipment of finished cars and trucks to all the major consumer markets,<br />

particularly those east of the Rocky Mountains. In fact, the exact center<br />

of the US population east of the Rockies just passed through Lexington<br />

KY, and is moving along a southwestern line. Putting auto assembly<br />

plants along that vector is the best way to minimize transportation costs,<br />

and this is the primary reason this region has attracted so many plants<br />

the last two decades.<br />

Parts plants are typically smaller and more ubiquitous. The second map<br />

shows the distribution of employment at motor vehicle parts plants in<br />

Kentucky and bordering states. One can see the north-south pattern<br />

along and between the primary interstate corridors – from Michigan<br />

olumbia<br />

(X<br />

St. Charles<br />

(X<br />

(X<br />

Rockford<br />

(X<br />

X(<br />

Peoria<br />

(X<br />

Aurora (X (X<br />

Hammond(X<br />

(X<br />

(X<br />

Joliet<br />

(X Decatur<br />

(X Springfield<br />

St. Louis<br />

(X<br />

(X<br />

(X<br />

Chicago<br />

Gary<br />

(X Champaign<br />

(X<br />

Terre Haute<br />

Evansville<br />

(X<br />

(X ÊÚ<br />

(X South Bend<br />

(X<br />

Fort Wayne<br />

(X<br />

(X Muncie<br />

(X Anderson<br />

(X<br />

Bloomington<br />

(X Clarksville<br />

(X<br />

Indianapolis<br />

<strong>Owensboro</strong><br />

(X Louisville<br />

Nashville<br />

(X Toledo<br />

(X Columbus<br />

(X Springfield<br />

(X Dayton<br />

(X<br />

Kettering<br />

(X Hamilton<br />

200 0 200 Miles<br />

(X<br />

(X<br />

Cincinnati<br />

(X<br />

Lexington<br />

(X<br />

Chattanooga<br />

(X<br />

(X<br />

(X (X<br />

(X<br />

(X<br />

(X<br />

(X Akron<br />

(X Youngstown<br />

Knoxville<br />

(X<br />

(X Canton<br />

(X Charleston<br />

Huntington<br />

Employment in Auto Parts Manufacturing<br />

Less than 100<br />

100-499<br />

500-999<br />

More than 1,000<br />

Employment at Motor Vehicle Mfg. Plants, 2001 Employment at Motor Vehicle Parts Mfg. Plants, 2001<br />

W<br />

N<br />

S<br />

E<br />

(X

through Indianapolis, Louisville and Nashville, and through Columbus,<br />

Cincinnati, Lexington, and Knoxville. The southern portion of this<br />

automobile alley has been the fastest growing in the industry<br />

nationwide. Kentucky was a major winner during the past fifteen years,<br />

as especially the Japanese manufacturers looked for greenfield sites in<br />

smaller communities, in the center of the population, and below<br />

historically unionized markets to the north.<br />

Other important <strong>Riverport</strong> customers include Dart Polymers, Quality<br />

Containment, Hausner Hard Chrome, and Hendrick Screen Company.<br />

Dart is located adjacent to the <strong>Riverport</strong> terminal and utilizes a pipeline<br />

to unload styrene from barges to make Styrofoam pellets for packaging.<br />

T<br />

he <strong>Owensboro</strong> economy and the City government now receive<br />

annual dividends on its past investments. The <strong>Riverport</strong> has<br />

been financially self-supporting since 1996, and directly<br />

contributes City $150,000 each year to the City’s general fund.<br />

Revenues earned from loading and storage at the <strong>Riverport</strong> are used to<br />

pay the salaries of its employees.<br />

These are dollars earned from selling<br />

a service to firms around the<br />

world and hence can be considered ‘new’ to the <strong>Owensboro</strong> economy.<br />

That is, unlike local grocery stores and doctors’ offices which simply<br />

absorb residents’ dollars in return for a service, the <strong>Riverport</strong> is a<br />

generator of dollars for the local economy. The wages and salaries of its<br />

employees create new purchasing power, which translates in new<br />

homes, car sales, and all the other retail items offered in <strong>Owensboro</strong>’s<br />

shops.<br />

<strong>Riverport</strong><br />

employees also pay local occupational and property taxes to<br />

the City and County governments, tax revenues that would not be<br />

available without the <strong>Riverport</strong> activity. In 2003, <strong>Riverport</strong> had on<br />

average 45 employees with a total payroll of $1.3 million. The payroll<br />

generated about $4,000 in occupational taxes to the City of<br />

<strong>Owensboro</strong>. Assuming an average home value of $125,000, and a<br />

typical residential location pattern, we can estimate that their property<br />

tax payments to City, County and the public schools are about $45,000<br />

annually.<br />

The box lists some of the<br />

major local vendors who sell<br />

goods and services to the<br />

<strong>Riverport</strong>. These companies<br />

receive part of their<br />

revenues due to <strong>Riverport</strong><br />

activity, and thus a portion<br />

of their employment,<br />

payrolls, and induced retail<br />

spending is due to the<br />

logistics activity there.<br />

The next box lists some of<br />

the major customers of<br />

<strong>Riverport</strong>. These regional<br />

and international companies<br />

use <strong>Riverport</strong> for bringing in<br />

fertilizer, steel, aluminum<br />

and other commodities, or<br />

to ship out grain, aluminum<br />

and other commodities to<br />

markets around the world.<br />

Note that the list includes<br />

many industrial powerhouse<br />

names, as well as less-known<br />

but dominant companies in<br />

the metals, grain, and<br />

logistics businesses.<br />

Major Local Vendors<br />

Alphatec<br />

Applied Industrial Technologies<br />

Builders Discount Lumber<br />

Cintas Corp.<br />

Commonwealth Storage<br />

Emmick Oil<br />

General Rubber & Plastics<br />

Gipe Automotive<br />

Greenwell Chisholm<br />

Junior Janatorial Services<br />

K&W Equipment<br />

May Electric<br />

Miles LP Gas<br />

NES Rentals<br />

Ohio Valley 2 Way Radio<br />

<strong>Owensboro</strong> Harbor Service<br />

<strong>Owensboro</strong> Manufacturing<br />

PeopleMark<br />

Quality Oil<br />

Sterett Crane<br />

T&T Forklift Repair<br />

Tire Mart<br />

Trophy House<br />

Yager Materials<br />

Yeiser's Warehouse Co.

Conclusion<br />

The <strong>Owensboro</strong> <strong>Riverport</strong> is a major economic asset to the region. It<br />

provides the infrastructure for inexpensive shipping and storage of<br />

heavy commodities produced and used by industries within a 100-mile<br />

and greater radius. The operation provides a cost advantage to many<br />

regional companies, allowing them to be competitive internationally,<br />

and thus provide high paying jobs. For example, over the last dozen<br />

years the <strong>Riverport</strong> has handled 1.8 million tons of aluminum. If the<br />

<strong>Riverport</strong> operations served to save aluminum customers but one<br />

penny per pound on freight, these companies gained a $36 million<br />

advantage in freight costs. Aluminum and aluminum-using companies,<br />

flourishing in the area due partly to this transportation cost<br />

advantage, provide among the best paying jobs in the region.<br />

There<br />

are some firms that can attribute their business viability to<br />

<strong>Riverport</strong>. For example, a manufacturer of steel reinforcement bars in<br />

southern Kentucky is able to purchase bulk steel through <strong>Riverport</strong> at<br />

such a cost savings that the company has built a major business selling<br />

to construction job sites over a 200-mile radius.<br />

Hopefully,<br />

this report will help shine the light on one of <strong>Owensboro</strong>’s<br />

strategic economic advantages.<br />

for more information contact<br />

<strong>Owensboro</strong> <strong>Riverport</strong> <strong>Authority</strong><br />

P.O. Box 21955, <strong>Owensboro</strong>, KY 43404-1955<br />

Toll free: (877) 599-7929 or direct (270) 926-4238<br />

Regional<br />

Major Customers<br />

<strong>Owensboro</strong> <strong>Riverport</strong><br />

International<br />

AK Steel ABN Amro<br />

Aleris Adelphia Metals<br />

Century Aluminum AIG Clearing Corp.<br />

Dahl & Groezinger Alcan<br />

Dart Polymers Alcoa<br />

Hagan & Stone BHP Billiton<br />

Kimberly Clark Calyon Financial<br />

Logan Aluminum David J. Joseph Company<br />

Miles Enterprises Dyno Nobel<br />

Nelson Brothers Fimat Futures<br />

Ohio Valley Aluminum General Motors<br />

<strong>Owensboro</strong> Grain Glencore<br />

Southern States Hunter Douglas<br />

Weyerhaeuser InterGrain<br />

Koch Supply and Trading<br />

Mitsubishi<br />

Prudential Securities<br />

Sempra Metals USA<br />

Stemcor<br />

The Scoular Company