Eco-Corr® Biodegradable VpCI® Film, Patented

Eco-Corr® Biodegradable VpCI® Film, Patented

Eco-Corr® Biodegradable VpCI® Film, Patented

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Eco</strong>-Corr ®<br />

<strong>Biodegradable</strong> VpCI ® <strong>Film</strong>, <strong>Patented</strong><br />

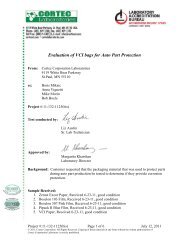

BIODEGRADATION TIMELINE<br />

t= 0 t= 15 days t= 30 days t= 76 days t= 93 days<br />

PRODUCT DESCRIPTION<br />

<strong>Eco</strong>-Corr ® is the first and only certified biodegradable<br />

corrosion inhibiting film. <strong>Eco</strong>-Corr ® contains Cortec’s<br />

proprietary VpCI technology and provides excellent<br />

contact, barrier and vapor-phase corrosion protection<br />

for ferrous and non-ferrous metals. Various formulations<br />

containing up to 40% biobased content are available and<br />

can be designed to fit required properties ranging from<br />

highly elastic to semi-rigid structures.<br />

<strong>Eco</strong>-Corr ® is certified 100% biodegradable and<br />

compostable by the <strong>Biodegradable</strong> Products Institute/<br />

United States Composting Council (BPI/USCC) according<br />

to ASTM D6400. When placed in a typical commercial<br />

composting environment, <strong>Eco</strong>-Corr ® films will fully<br />

biodegrade into carbon dioxide and water within a matter<br />

of weeks. There is no ecotoxicity to the soil, plants or<br />

microorganisms involved in this process. The exact time<br />

for films to biodegrade is dependent upon the conditions<br />

and activity of the disposal environment (temperature,<br />

soil quality, activity of microorganisms). <strong>Eco</strong>-Corr ® films<br />

are shelf stable and will not break down prematurely until<br />

disposed of in a proper composting environment.<br />

<strong>Eco</strong>-Corr ® is patented under US patents 6,028,160 and<br />

6,156,929.<br />

Applications<br />

Metal parts packaged in <strong>Eco</strong>-Corr ® receive continuous<br />

protection against salt, excessive humidity, condensation,<br />

moisture, aggressive industrial atmosphere and dissimilar<br />

metal corrosion. The Vapor phase Corrosion Inhibitors<br />

vaporize and then condense on all metal surfaces in the<br />

enclosed package. VpCI reaches every area of your<br />

part, protecting its exterior as well as hard to reach<br />

interior surfaces. You get complete product protection<br />

during storage as well as during domestic and overseas<br />

shipments, virtually eliminating any rust claims. Once the<br />

film is no longer needed, <strong>Eco</strong>-Corr ® can be composted<br />

and will degrade into carbon dioxide and water within<br />

weeks, certified under BPS guidelines.<br />

FEATURES<br />

• The first and only 100% biodegradable, 100%<br />

compostable packaging film that provides contact,<br />

barrier and vapor corrosion inhibition<br />

• Provides multimetal corrosion inhibitor protection<br />

• Meets NACE TM0208-2008 standard for corrosion<br />

protection. Conforms to NACE Standard Recommended<br />

Practice RP0487-2000 Considerations in the Selection<br />

of Vapor Corrosion Inhibitors.<br />

• Meets German TL-8135-002 standard for corrosion<br />

protection<br />

CONTROL SAMPLE #1 SAMPLE #2 SAMPLE #3<br />

VIA Test: Conforms to MIL-PRF-22019D

MECHANICAl PROPERTIES<br />

Property Test Method Units<br />

<strong>Eco</strong>-Corr (40% biobased<br />

content)<br />

Cortec Corporation warrants Cortec ® USER ASSUMES ALL RISK AND LIABILITY WHATSOEVER IN CONNECTION THEREWITH. No representation o<br />

recommendation not contained herein shall have any force or effect unless in a written document signed by a<br />

products will be free from defects when shipped to customer. Cortec Cor-<br />

officer of Cortec Corporation.<br />

poration’s obligation under this warranty shall be limited to replacement of product that proves to be defective.<br />

To obtain replacement product under this warranty, the customer must notify Cortec Corporation of the claimed THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED O<br />

defect within six months after shipment of product to customer. All freight charges for replacement products shall STATUTORY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNES<br />

All be statements, paid by technical customer. information and recommendations contained herein are based on tests Cortec Corporation<br />

FOR A PARTICULAR PURPOSE. IN NO CASE SHALL CORTEC CORPORATION BE LIABLE FOR INCIDENTAL O<br />

believes to be reliable, but the accuracy or completeness thereof is not guaranteed.<br />

CONSEQUENTIAL DAMAGES.<br />

Cortec Corporation shall have no liability for any injury, loss or damage arising out of the use of or the inability<br />

Cortec to use Corporation the products. warrants Cortec ® lIMITED WARRANTY<br />

All statements, technical information and recommendations contained herein are based on tests Cortec Corporation<br />

believes to be reliable, but the accuracy or completeness thereof is not guaranteed.<br />

BEFORE USING, USER SHALL DETERMINE THE SUITABILITY OF THE PRODUCT FOR ITS INTENDED USE, AND<br />

USER ASSUMES ALL RISK AND LIABILITY WHATSOEVER IN CONNECTION THEREWITH. No representation or<br />

Cortec Corporation warrants Cortec recommendation not contained herein shall have any force or effect unless in a written document signed by an<br />

products will be free from defects when shipped to customer. Cortec Cor-<br />

officer of Cortec Corporation.<br />

poration’s obligation under this warranty shall be limited to replacement of product that proves to be defective.<br />

To obtain replacement product under this warranty, the customer must notify Cortec Corporation of the claimed THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED OR<br />

defect within six months after shipment of product to customer. All freight charges for replacement products shall STATUTORY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS<br />

be paid by customer.<br />

FOR A PARTICULAR PURPOSE. IN NO CASE SHALL CORTEC CORPORATION BE LIABLE FOR INCIDENTAL OR<br />

CONSEQUENTIAL DAMAGES.<br />

Cortec Corporation shall have no liability for any injury, loss or damage arising out of the use of or the inability<br />

to use the products.<br />

® lIMITED WARRANTY<br />

BEFORE All statements, USING, USER technical SHALL information DETERMINE and THE recommendations SUITABILITY OF contained THE PRODUCT herein FOR are based ITS INTENDED on tests Cortec USE, Corporation AND<br />

USER believes ASSUMES to be ALL reliable, RISK AND but the LIABILITY accuracy WHATSOEVER or completeness IN CONNECTION thereof is not guaranteed.<br />

THEREWITH. No representation or<br />

recommendation not contained herein shall have any force or effect unless in a written document signed by an<br />

products will be free from defects when shipped to customer. Cortec Cor-<br />

Cortec Corporation warrants Cortec<br />

officer of Cortec Corporation.<br />

poration’s obligation under this warranty shall be limited to replacement of product that proves to be defective.<br />

To obtain replacement product under this warranty, the customer must notify Cortec Corporation of the claimed THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED OR<br />

defect within six months after shipment of product to customer. All freight charges for replacement products shall STATUTORY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS<br />

be paid by customer.<br />

FOR A PARTICULAR PURPOSE. IN NO CASE SHALL CORTEC CORPORATION BE LIABLE FOR INCIDENTAL OR<br />

CONSEQUENTIAL DAMAGES.<br />

Cortec Corporation shall have no liability for any injury, loss or damage arising out of the use of or the inability<br />

to use the products.<br />

® lIMITED WARR<br />

BEFO<br />

USER<br />

recom<br />

products will be free from defects when shipped to customer. Cortec Cor-<br />

officer<br />

poration’s obligation under this warranty shall be limited to replacement of product that proves to be defective.<br />

To obtain replacement product under this warranty, the customer must notify Cortec Corporation of the claimed THE F<br />

defect within six months after shipment of product to customer. All freight charges for replacement products shall STATU<br />

be paid by customer.<br />

FOR A<br />

CON<br />

Cortec Corporation shall have no liability for any injury, loss or damage arising out of the use of or the inability<br />

to use the products.<br />

Distributed by:<br />

<strong>Eco</strong>-Corr (0% biobased<br />

content)<br />

VpCI-126<br />

Caliper ASTM D6988 mil 2.00 2.00 2.00<br />

• Complete replacement for non-degradable and inferior<br />

blend films<br />

Packaging<br />

<strong>Eco</strong>-Corr ® MD<br />

11.77 10.40 18.88<br />

Breaking Factor<br />

ASTM D882-02 lbs/in MECHANICAl PROPERTIES<br />

MECHANICAl TD 9.32 10.81 18.25<br />

MECHANICAl<br />

PROPERTIES<br />

PROPERTIES<br />

<strong>Eco</strong>-<br />

MD<br />

<strong>Eco</strong>-Corr (40% 5774.65 Property bio- <strong>Eco</strong>-Corr (0% bio- 4728.20Test Method 3184.35 Units<br />

Tensile Property Strength at Break<br />

Test ASTM Method D882-02Units psi <strong>Eco</strong>-Corr (40% bio- <strong>Eco</strong>-Corr (0% bio- VpCI-126<br />

ba<br />

Property Test Method Units based content) based content) VpCI-126<br />

TD based content) 4451.90 Caliper based content) 4699.10ASTM D6988 3109.60 mil<br />

Caliper ASTM D6988 mil 2.00 2.00 2.00<br />

Caliper MD ASTM D6988 mil 2.00 300.21 2.00 MD 759.38 2.00 770.37<br />

Elongation at Break MD ASTM D882-02 % 11.77 Breaking Factor 10.40 ASTM 18.88D882-02<br />

lbs/in<br />

Breaking Factor<br />

MD<br />

TD ASTM D882-02 lbs/in<br />

11.77 10.40<br />

340.68 TD 18.88<br />

Breaking Factor<br />

795.89 833.65<br />

TD ASTM D882-02 lbs/in 9.32 10.81 18.25<br />

TD 9.32 10.81<br />

MD<br />

2321.62 MD 18.25<br />

Yield Strength<br />

MD<br />

ASTM D882-02 psi<br />

5774.65<br />

991.44 793.85<br />

Tensile Strength at Break 4728.20 3184.35 ASTM D882-02 psi<br />

Tensile Strength at Break MD ASTM D882-02 psi<br />

5774.65 4728.20<br />

Tensile Strength at Break CD ASTM D882-02 psi<br />

2285.99<br />

TD 3184.35<br />

TD 4451.90 4699.10 1093.163109.60 1425.18<br />

TD 4451.90 4699.10 3109.60<br />

MD<br />

156.96 MD<br />

MD<br />

300.21 3719.95 15852.96<br />

Tear Strength MD ASTM D1922-06a mN 300.21<br />

Elongation at Break 759.38<br />

759.38<br />

ASTM 770.37<br />

770.37<br />

D882-02 %<br />

Elongation at Break<br />

ASTM D882-02 %<br />

Elongation at Break<br />

CD ASTM D882-02 %<br />

470.88 TD<br />

TD 340.68 795.89 4959.94833.65 20279.24<br />

TD 340.68 795.89<br />

MD<br />

833.65<br />

MD ASTM D1709-04,<br />

2321.62<br />

Dart Drop Impact Resistance MD<br />

grams 2321.62 Yield 573.30 Strength 991.44<br />

991.44 >1300ASTM 793.85<br />

793.85 D882-02 753.28 psi<br />

Yield Strength<br />

ASTM D882-02 Test Method A psi<br />

Yield Strength<br />

ASTM D882-02 psi<br />

CD<br />

CD 2285.99 1093.16 1425.18<br />

CD 2285.99 1093.16 1425.18<br />

* Typical mechanical properties represent average laboratory values and are intended as guides only, not<br />

MD<br />

MD<br />

156.96 as specifications. <strong>Film</strong><br />

MD<br />

156.96Tear Strength 3719.95<br />

3719.95 ASTM 15852.96<br />

15852.96 D1922-06a mN<br />

properties Tear are Strength typical of blown film extruded ASTM D1922-06a at a blowup ratio mN<br />

Tear Strength<br />

ASTM D1922-06a mNof<br />

2.5:1, but are dependent upon operating CDconditions.<br />

CD 470.88 4959.94 20279.24<br />

CD 470.88 4959.94 20279.24<br />

ASTM D1709-04,<br />

ASTM D1709-04,<br />

Dart Drop Impact Resistance<br />

grams<br />

PACKAGING<br />

Dart Drop Impact Resistance<br />

ASTM D1709-04, grams 573.30 SHElF lIFE >1300 753.28 Test Method A<br />

Dart Drop Impact Resistance<br />

Test Method A grams Shelf 573.30 Life<br />

>1300 753.28<br />

Test Method A<br />

<strong>Eco</strong>-Corr is available in standard length 36” (91.4cm) For shipping and storage applications, <strong>Eco</strong>-Corr is a<br />

* Typical mechanical properties represent average laboratory values and are For * Typical<br />

intended shipping mechanical<br />

as guides and only, storage properties<br />

not as applications, represent average<br />

specifications. <strong>Film</strong> <strong>Eco</strong>-Corr laboratory values and are inte<br />

* and Typical 48” mechanical (122 cm) properties rolls represent as well average as a wide laboratory variety values of and are intended properties great as are guides alternative typical only, of not blown as to specifications. film conventional extruded at <strong>Film</strong> a polyethylene blowup ratio of 2.5:1, films. but <strong>Eco</strong> are<br />

properties are typical of blown film extruded at a blowup ratio of 2.5:1, but are dependent upon operating conditions.<br />

properties are typical of blown film extruded at a blowup ratio of 2.5:1, but are dependent<br />

custom sizes and forms. Custom products include single Corr has upon a operating shelf life conditions. of up to two years, when sealed in<br />

PACKAGING<br />

wound sheeting, is available double in standard wound length sheeting, 36” (91.4cm) U-sheets, M- SHElF PACKAGING original packaging.<br />

and<br />

PACKAGING<br />

SHElF<br />

lIFE<br />

SH<br />

lIFE<br />

<strong>Eco</strong>-Corr sheets, 48” (122 center cm) folds, rolls gusset as well tubes, as a wide converted variety bags of custom made<br />

sizes<br />

<strong>Eco</strong>-Corr<br />

is<br />

from and<br />

is<br />

available<br />

these forms.<br />

available<br />

in<br />

types Custom<br />

in<br />

standard<br />

standard<br />

length<br />

of film products<br />

length<br />

36”<br />

and perforated include<br />

36”<br />

(91.4cm) For <strong>Eco</strong>-Corr<br />

single<br />

(91.4cm) For<br />

shipping is<br />

shipping<br />

and available<br />

and<br />

storage in standard<br />

storage<br />

applications, length<br />

applications,<br />

<strong>Eco</strong>-Corr 36” (91.4cm)<br />

<strong>Eco</strong>-Corr<br />

is<br />

is<br />

a For<br />

a<br />

and or bag-on-a-roll<br />

wound<br />

Once removed and put to use, <strong>Eco</strong>-Corr will remain<br />

sheeting,<br />

and<br />

48”<br />

48”<br />

(122<br />

(122<br />

cm)<br />

products. double<br />

cm)<br />

rolls<br />

wound<br />

rolls<br />

as<br />

as<br />

well<br />

sheeting,<br />

well<br />

as<br />

as<br />

a wide<br />

U-sheets,<br />

wide<br />

variety<br />

variety<br />

of<br />

great and 48”<br />

Msheets,<br />

of<br />

great<br />

alternative (122 cm)<br />

alternative<br />

to<br />

to<br />

conventional rolls as well as<br />

conventional<br />

polyethylene a wide variety<br />

polyethylene<br />

films. of<br />

films.<br />

<strong>Eco</strong>- gre<br />

<strong>Eco</strong>custom<br />

effective with regard to mechanical strength until film is<br />

center<br />

custom<br />

sizes<br />

folds,<br />

sizes<br />

and<br />

gusset<br />

and<br />

forms.<br />

forms.<br />

Custom<br />

tubes,<br />

Custom<br />

products<br />

converted<br />

products<br />

include<br />

bags made<br />

include<br />

single Corr custom<br />

from<br />

single Corr<br />

has sizes<br />

has<br />

a shelf and<br />

shelf<br />

life forms.<br />

life<br />

of<br />

of<br />

up Custom<br />

up<br />

to<br />

to<br />

two<br />

two<br />

years, products<br />

years,<br />

when include<br />

when<br />

sealed single<br />

sealed<br />

in Co<br />

in<br />

wound these placed in contact with material containing microorgan-<br />

types<br />

wound<br />

sheeting,<br />

FOR of<br />

sheeting,<br />

double<br />

INDUSTRIAl film and perforated<br />

double<br />

wound<br />

wound<br />

sheeting,<br />

USE ONlY or bag-on-a-roll<br />

sheeting,<br />

U-sheets,<br />

U-sheets,<br />

M- original wound<br />

products.<br />

M- original<br />

packaging. sheeting, double wound sheeting, U-sheets, M- orig<br />

packaging.<br />

sheets,sheets,<br />

center<br />

center<br />

folds,<br />

folds,<br />

gusset<br />

gusset<br />

tubes,<br />

tubes,<br />

converted<br />

converted<br />

bags<br />

bags<br />

made sheets,<br />

made<br />

isms, center such folds, as certain gusset tubes, types converted of waste, soil, bags and made compost.<br />

from<br />

from KEEP<br />

these<br />

these OUT<br />

types<br />

types OF<br />

of<br />

of REACH<br />

film<br />

film<br />

and<br />

and OF<br />

perforated<br />

perforated CHIlDREN<br />

or<br />

or<br />

bag-on-a-roll Once from<br />

bag-on-a-roll Once<br />

removed Under these types<br />

removed these and of<br />

and<br />

put conditions, film<br />

put<br />

to and<br />

to<br />

use, perforated<br />

use,<br />

<strong>Eco</strong>-Corr<br />

<strong>Eco</strong>-Corr 100% disintegration will or bag-on-a-roll<br />

will<br />

remain<br />

On<br />

remain will occur<br />

products.<br />

effective products.<br />

products.<br />

effective within<br />

with<br />

with<br />

regard<br />

a regard few weeks<br />

to<br />

to<br />

mechanical<br />

mechanical with no<br />

strength<br />

residual strength<br />

until<br />

until contamination<br />

film<br />

film<br />

is effe<br />

is of the<br />

KEEP CONTAINER TIGHTlY ClOSED<br />

placed<br />

placed<br />

in<br />

soil. in<br />

contact<br />

contact<br />

with<br />

with<br />

material<br />

material<br />

containing<br />

containing<br />

microorgan- pla<br />

microorgan-<br />

FOR<br />

FOR NOT INDUSTRIAl<br />

INDUSTRIAl FOR INTERNAl USE ONlY<br />

USE ONlY CONSUMPTION<br />

isms, FOR<br />

isms,<br />

such INDUSTRIAl<br />

such<br />

as<br />

as<br />

certain USE<br />

certain<br />

types ONlY<br />

types<br />

of<br />

of<br />

waste,<br />

waste,<br />

soil,<br />

soil,<br />

and<br />

and<br />

compost. ism<br />

compost.<br />

KEEP<br />

KEEP CONSUlT<br />

OUT OF<br />

OUT OF MATERIAl<br />

REACH OF<br />

REACH OF SAFETY<br />

CHIlDREN<br />

Under<br />

CHIlDREN DATA SHEET FOR MORE Under KEEP these OUT these<br />

conditions, OF conditions, REACH 100% OF 100% CHIlDREN disintegration<br />

disintegration<br />

will<br />

will<br />

occur Un<br />

occur<br />

within<br />

KEEP<br />

KEEP INFORMATION<br />

CONTAINER TIGHTlY ClOSED<br />

within KEEP<br />

a CONTAINER<br />

few<br />

few<br />

weeks<br />

weeks<br />

with<br />

with TIGHTlY<br />

no<br />

no<br />

residual<br />

residual ClOSED<br />

contamination<br />

contamination<br />

of<br />

of<br />

the wit<br />

the<br />

CONTAINER TIGHTlY ClOSED<br />

soil.<br />

soi<br />

NOT FOR INTERNAl CONSUMPTION<br />

soil. NOT FOR INTERNAl CONSUMPTION<br />

NOT FOR INTERNAl CONSUMPTION<br />

CONSUlT MATERIAl SAFETY DATA SHEET FOR MORE lIMITED CONSUlT WARRANTY MATERIAl SAFETY DATA SHEET FOR MORE<br />

CONSUlT MATERIAl SAFETY DATA SHEET FOR MORE<br />

All statements, technical information and recommendations contained herein are based on tests Cortec Corporation BEFORE USING, USER SHALL DETERMINE THE SUITABILITY OF THE PRODUCT FOR ITS INTENDED USE, AND<br />

INFORMATION<br />

INFORMATION<br />

INFORMATION<br />

believes to be reliable, but the accuracy or completeness thereof is not guaranteed.<br />

® is a<br />

great alternative to conventional polyethylene films. <strong>Eco</strong>-<br />

Corr ® has a shelf life of up to two years, when sealed<br />

in original packaging. Once removed and put to use,<br />

<strong>Eco</strong>-Corr ® will remain effective with regard to mechanical<br />

strength until film is placed in contact with material<br />

containing microorganisms, such as certain types of<br />

waste, soil, and compost. Under these conditions, 100%<br />

disintegration will occur within a few weeks with no<br />

residual contamination of the soil.<br />

Printing pattern for<br />

<strong>Eco</strong>-Corr ®<br />

Distributed by:<br />

Distributed by:<br />

printed on recycled paper 100% post consumer<br />

Revised 7/31/12. © Cortec Corporation 2002-2012. All rights reserved. Supersedes: 10/9/06.<br />

© 2012Cortec ® , <strong>Eco</strong>-Corr ® 4119 White Bear Parkway, St. Paul, MN 55110 USA<br />

Phone (651) 429-1100, Fax (651) 429-1122<br />

Toll Free (800) 4-CORTEC, E-mail info@cortecvci.com<br />

Internet http://www.CortecVCI.com<br />

and <strong>VpCI®</strong> are trademarks of Cortec Corporation. Copying of these materials in any<br />

form without the written authorization of Cortec Corporation is strictly prohibited.<br />

printed ISO accreditation on recycled applies paper to Cortec’s 100% processes post only. consumer<br />

Revised 7/31/12. © Cortec Corporation 2002-2012. All rights reserved. Supersedes: 10/9/06.<br />

© 2012Cortec ® , <strong>Eco</strong>-Corr ® 4119 White Bear Parkway, St. Paul, MN 55110 USA<br />

Phone (651) 429-1100, Fax (651) 429-1122<br />

Toll Free (800) 4-CORTEC, E-mail info@cortecvci.com<br />

Internet http://www.CortecVCI.com<br />

printed on recycled paper 100% post consumer<br />

Revised 7/31/12. © Cortec Corporation 2002-2012. All rights reserved. Supersedes: 10/9/06.<br />

© 2012Cortec<br />

and <strong>VpCI®</strong> are trademarks of Cortec Corporation. Copying of these materials in any<br />

form without the written authorization of Cortec Corporation is strictly prohibited.<br />

ISO accreditation applies to Cortec’s processes only.<br />

® , <strong>Eco</strong>-Corr ® 4119 White Bear Parkway, St. Paul, MN 55110 USA<br />

Phone (651) 429-1100, Fax (651) 429-1122<br />

Toll Free (800) 4-CORTEC, E-mail info@cortecvci.com<br />

Internet http://www.CortecVCI.com<br />

printed on recycled paper 100% post consumer<br />

Revised 7/31/12. © Cortec Corporation 2002-2012. All rights reserved. Supersedes: 10/9/06.<br />

and <strong>VpCI®</strong> are trademarks of Cortec Corporation. Copying of these materials in any<br />

© 2012Cortec<br />

form without the written authorization of Cortec Corporation is strictly prohibited.<br />

ISO accreditation applies to Cortec’s processes only.<br />

® , <strong>Eco</strong>-Corr ® 4119 White Bear Parkway, St. Paul, MN 55110 USA<br />

Phone (651) 429-1100, Fax (651) 429-1122<br />

Toll Free (800) 4-CORTEC, E-mail info@cortecvci.com<br />

Internet http://www.CortecVCI.com<br />

and <strong>VpCI®</strong> are trademarks of Cortec Corporation. Copying of these materials in any<br />

form without the written authorization of Cortec Corporation is strictly prohibited.<br />

ISO accreditation applies to Cortec’s processes only.<br />

Di