Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

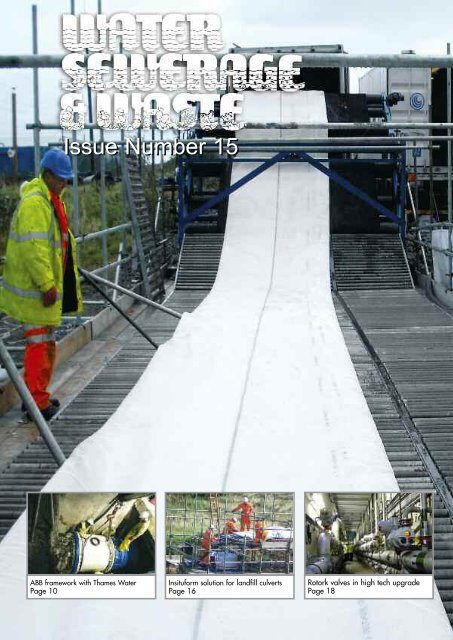

<strong>Issue</strong> Number <strong>15</strong><br />

ABB framework with Thames <strong>Water</strong><br />

Page 10<br />

Insituform solution for landfill culverts<br />

Page 16<br />

Rotork valves in high tech upgrade<br />

Page 18

Sira Test & Cert<br />

Janet Middlehurst from Sira Test and<br />

Certification Limited exhibited with “<strong>Water</strong>,<br />

<strong>Sewerage</strong> & <strong>Waste</strong>” Exhibitions at three<br />

venues last year, held competitions for a bottle<br />

of Champagne at each. Here are her winners.<br />

At our Manchester show in March Stewart<br />

Measures, a familiar face to our shows was<br />

very pleased to win the champagne.<br />

At our Warrington show in October regular<br />

exhibitor Peter Wood from Aquasystems was<br />

lucky enough to win the champagne.<br />

Mr George J Deans from Scottish Boders<br />

Abatoir Limited won the champagne at our<br />

last show of the year in Newcatsle.<br />

2 WSW 2010<br />

WINNERS!<br />

Exhibitors Visitors<br />

At each show exhibitors compete to attract the<br />

highest number of visitors to the exhibition. The<br />

winning exhibitor is presented with a case of<br />

wine supplied by the “Wine Society”. Below are<br />

some of this year’s winners.<br />

Rob Baldwin, Sales Manager for Prominent<br />

Fluid Controls succeeded in attracting the most<br />

visitors to the Warrington show.<br />

Nigel Wilson, Managing Director for Mini-<br />

Cam attracted the most visitors to the Bradford<br />

exhibition.<br />

Bob White, Quality Manager for John<br />

Davidson Pipes, succeeded in attracting the<br />

most visitors to the Newcastle show.<br />

<strong>Water</strong> and wastewater<br />

treatment solutions<br />

For information<br />

please<br />

ccall<br />

all 0 01782 578650,<br />

email enquir enquiries@as-h.com ies@as-h.com<br />

or visit<br />

www.as-h.com<br />

As an added attraction to our popular series of<br />

exhibitions visitors are entered on the day into<br />

a raffle for £250 which is always drawn at<br />

2.30pm at each show. Below are some of this<br />

year’s winners.<br />

Kristina Holcroft from United Utilities generously<br />

decided to treat her whole team to a pub lunch<br />

in the near future.<br />

We are delighted to announce that Mr John<br />

Haigh of Yorkshire <strong>Water</strong> donated entire<br />

amount to "<strong>Water</strong>aid" - What a lovely chap!<br />

Mrs Gillian Davies Gateshead City Council will<br />

be spending her winnings on a Nintendo Wii for<br />

her sons aged 10 and 6.<br />

WARRINGTON BRADFORD<br />

NEWCASTLE

04 Landia to the rescue in<br />

hospital emergency<br />

08 Saint Gobain win<br />

Construction Products Ass<br />

award<br />

10 ABB five year framework<br />

with Thames <strong>Water</strong><br />

12 Royal train yard recovering<br />

thanks to Onsite<br />

16 On time and on budget -<br />

Insituform<br />

21 Steelway Brickhouse<br />

framework with Anglian<br />

<strong>Water</strong><br />

23 Fixed-Film from Eimco<br />

24 Fuel oil storage in Scotland<br />

deadline looms<br />

26 Exhibitors Directory<br />

“<strong>Water</strong> <strong>Sewerage</strong> & <strong>Waste</strong>” Magazine<br />

30 Home Close<br />

Kibworth<br />

Leicester<br />

LE8 0JT<br />

Tel: 0116 279 2066<br />

Fax: 0116 279 6208<br />

www.pse.co.uk<br />

Editor<br />

Olivia Sanderson<br />

olivia@pse.co.uk<br />

Advertisement Manager<br />

Rosanna Rodgers<br />

rodgers@pse.co.uk<br />

Publisher<br />

Terry Rodgers<br />

terry@pse.co.uk<br />

While every effort is taken to ensure the accuracy of<br />

all editorial content, the publishers do not accept<br />

liability for an error printed or otherwise, that may<br />

occur. All articles are copyright of Media Link PR Ltd<br />

and may not be reproduced either in full or part<br />

without the Editor’s permission.<strong>Water</strong>, <strong>Sewerage</strong> &<br />

<strong>Waste</strong> magazine is part of Public Sector Exhibitions<br />

which in turn is part of Media Link PR Limited.<br />

Please recycle this magazine once you have read it.<br />

Going against the flow…<br />

You can easily slip into the wrong frame of mind. All around you hear doom and<br />

gloom and even the Chancellor warning of “tough times ahead” but there is always<br />

business to be done, especially in our industry.<br />

<strong>Water</strong> and drainage will always be around and we must visualise it getting<br />

much better with more jobs on the horizon.<br />

For instance, one project that is coming along is that Thames <strong>Water</strong> is looking<br />

to spend some £600M undertaking the biggest project in the water industry since<br />

privatisation in 1989.<br />

They have awarded the contact to a consortium of construction and engineering<br />

firms that will start work shortly on a 4.3mile tunnel designed to divert half the raw<br />

sewage that is dumped into the capital’s river.<br />

The Abbey Mills pumping station which takes sewage from north and east<br />

London to the sewage treatment works in Beckton, East London is regularly overwhelmed<br />

in heavy rains.<br />

Rather than allowing untreated sewage to seep up through the manholes and<br />

gullies, the overflows are released untreated into the River Lee, a tributary of the Thames.<br />

The tunnel will be as wide as three double-decker buses and Thames will eventually spend<br />

another £220million upgrading the Beckton plant so it can take the increased load.<br />

Thames is also looking to build a second more complex tunnel basically<br />

following the path of the Thames for 20 miles through the heart of the capital. It will<br />

intercept 34 sewage overflow points and like the Lee tunnel, take the sewage to Beckton.<br />

The project will require the permission of 13 councils and cost more that £2 billion. So<br />

although other industries may well be in the doldrums, it would seem that water is on the<br />

up and up…<br />

As always if you have any interesting articles or a<br />

point of view please feel free to contact the editor by email,<br />

olivia@pse.co.uk and just to let you know the next edition<br />

will be out in the middle of June 2010.<br />

Publisher<br />

Cover picture shows Roller beds being utilised to feed the impregnated Insituform Liners from the<br />

transport vehicles to the culvert installation site at Ballyogan Landfill and Recycling Park, Jamestown,<br />

Dublin 18, Ireland.<br />

2010 WSW 3

New digital<br />

chlorine<br />

dioxide testing<br />

from Palintest<br />

P<br />

alintest Ltd, a leading water analysis technology company, has<br />

developed a completely new method for testing Chlorine Dioxide levels<br />

in water. The ChlordioXense provides accurate testing without relying<br />

on subjective analysis for results. The instrument eliminates the potential for<br />

user error giving precise, consistent results whatever the operator’s level of<br />

experience.<br />

Developed from the successful electrochemical sensing technology in their<br />

ChloroSense digital chlorine sensor (now EPA approved), the ChlordioXense<br />

is very easy to operate. Simply insert a disposable electrode along with the<br />

water sample and close the lid to start a test. The instrument works for a wide<br />

range of concentrations, from 0.02 - 50 mg/l, with sample temperatures up<br />

to 40 degrees Celsius, with results given clearly on the LCD screen in less<br />

than a minute.<br />

Compared to the US EPA-approved Lissamine Green test method, the<br />

ChlordioXense gives accurate results with greater consistency. This means<br />

that the time taken and the training needed to get results is significantly<br />

reduced, benefiting a wide range of applications from food processing to<br />

paper mills and building services.<br />

The unit stores up to 500 results in its on-board memory, and can be<br />

connected by USB to a PC for simple downloading. Powered by AA batteries<br />

and weighing less than 1kg, it is truly portable and offers effortless Chlorine<br />

Dioxide measurement for any situation.<br />

•<br />

•<br />

•<br />

•<br />

•<br />

4 WSW 2010<br />

SLD pumps and power have a wealth of knowledge and experience<br />

in the field of waste water and sewage. SLD have a highly invested<br />

fleet of equipment ranging from submersible, hydraulic submersible, standard<br />

versatile diesel pumps to extreme specialist high head diesel pumps, which are<br />

excellent units for this specialist field.<br />

Clients of SLD also take advantage of the in-house generator service which enables them to gain cost effective<br />

total solutions for their pumping and power needs.<br />

Pumps with high head capability<br />

Pumps with excellent solids<br />

handling<br />

Fuel efficient pumps<br />

Extensive depot network<br />

ISO 9001, ISO14001, OHSAS 18001<br />

Accredited<br />

In-house turnkey solutions<br />

In-house generator service<br />

Bespoke pump solutions<br />

Genuine 24/7 fast response<br />

Free site survey<br />

For hire or sale call us now!<br />

0800 146 763<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Landia to the<br />

rescue in<br />

hospital<br />

emergency<br />

P<br />

ump breakdowns and a six-week waiting time for new parts left a<br />

hospital in Shropshire with a costly and difficult effluent problem until<br />

Landia stepped in to help.<br />

Nuffield Health Shrewsbury Hospital were let down by the failure of one<br />

pump, followed almost immediately by the second – only to be told by<br />

their supplier that replacement parts needed for repair would take at least<br />

six weeks.<br />

In the meantime, the Nuffield maintenance team were forced to bring in<br />

two tankers per day to remove the effluent - at a cost of well over £600<br />

per load. Brian Forster, Resident Engineer for Norland Managed Services,<br />

commented: “We felt very let down, but Landia restored our faith by<br />

rolling up their sleeves and immediately getting stuck in to help find a<br />

quick yet long term economic solution”.<br />

Landia’s rapid turnaround saw the installation of a 5.5kW MPTK Cutter<br />

Pump with external knife system, which can handle hospital waste with a<br />

high content of solids, without breaking down.<br />

Brian Forster added: “Not only do we now have a first class pumping<br />

system in place, but importantly we have the peace of mind of Landia’s<br />

fast turnaround and back service up to help us out if necessary”.<br />

As well as designing in the interface for the retrofit to the existing pumping<br />

system, Landia also fitted a submersible well pump for Nuffield Health<br />

Shrewsbury Hospital to keep the dry well clear of water.<br />

Turn urn to<br />

to o the the rental rental experts eexperts<br />

experrts

Radicon Service & Repair<br />

Turn to us when the clock is ticking.<br />

In industry, the clock is always ticking. Whether it’s a tight deadline that has to be met or the need to avoid costly downtime, it’s vital that your<br />

processes run on time, all the time. Which is why it’s good to know that you can rely on the total support of David Brown Radicon Service & Repair,<br />

our team of technical experts are on call 24 hours a day to provide you with the very best in repair and support services. Time waits for no one,<br />

but David Brown Radicon Service & Repair are ready and waiting for your call.<br />

For further information call 01484 465752, email radicon@davidbrown.com<br />

or visit www.davidbrown.com/radicon-service<br />

www.davidbrown.com<br />

Radicon | Service & Repair<br />

2010 WSW 5

EnviroChamber the recycled composite chamber solution<br />

PDS-Plc are an established company and have<br />

for a number of years been supplying<br />

drainage and associated products to the<br />

highways authorities, building contractors<br />

and local councils.<br />

PDS-Plc also offer as part of the customer<br />

service a design facility to ensure that the<br />

correct product is supplied to meet the design<br />

criteria and it is fit for purpose.<br />

To compliment the existing range of products<br />

and to allow the company to move into areas<br />

which service the utility companies such as<br />

gas, telephone and especially the water<br />

industry, PDS-Plc have extended their range<br />

of products to include various sizes of one<br />

piece moulded under ground chamber<br />

sections.<br />

After listening to, and working with, four UK<br />

water companies and their contractors, the<br />

chamber sections were designed to be made<br />

as a one-piece moulding, are lighter than<br />

concrete and stronger than concrete and most<br />

importantly cost effective when compared with<br />

traditional materials and meet all of the<br />

existing future specifications.<br />

They also had to overcome most or all of the<br />

health and safety problems associated with<br />

traditional chamber sections. The most<br />

important being they could be handled by one<br />

6 WSW 2010<br />

person except for the very largest of the<br />

section which is 33kg, this heavier section<br />

would still only require a two-man lift and no<br />

mechanical handling systems. This would<br />

result in a quicker installation time and<br />

improved labour efficiency.<br />

As each section is lighter to transport, more<br />

chambers can be carried on each wagon,<br />

therefore there will be fewer trips and the end<br />

result is a lower carbon footprint and reduced<br />

transport costs.<br />

EnviroChambers sections are made using the<br />

compression moulding technique at two<br />

manufacturing plants in the UK both sited in<br />

the north west of England.<br />

The chamber sections are made from 100%<br />

recycled material obtained purely from UK<br />

sources from the post consumer waste stream.<br />

This waste would normally end up in landfill<br />

sites or incinerators and can, unlike<br />

traditional materials at the end of its useful<br />

life, be recycled to make new products.<br />

The one-piece moulded design gives them<br />

exceptional compressive strength and rigidity<br />

and therefore they are not susceptible to<br />

breaking either during installation or during<br />

transportation like traditionally made concrete<br />

sections.<br />

This results in a cost saving to the end user by<br />

not having to budget for breakages by<br />

ordering extra products and additional<br />

transport.<br />

The material used is impervious to moisture<br />

and therefore not susceptible to frost damage<br />

and crumbling when in use.<br />

All chambers throughout the different size<br />

ranges have a positive interlocking system to<br />

locate the sections one on top of the other and<br />

prevent any movement of the individual<br />

sections when finishing the chamber with<br />

backfill. They also incorporate a positive<br />

location for any of the cast iron or composite<br />

covers used in this industry.

Enviro Env<br />

v viroc<br />

chamber<br />

o a<br />

The Th The Recycled R Recycl<br />

l lled d Composite C Composite<br />

i Chamber C Ch Chamber b Solution SSolutio l ion<br />

A COMPREHENSIVE COMMPREHENNSIVE<br />

RANGE RA ANGE OF ONE-PIECE<br />

O ONE-PIEC CE<br />

MOULDED MOUL OUL DED MANHOLE MAN NHOL OL E CHAMBER CH C HAMBER BE SECTIONS SECTION SEC O NS S<br />

FOR THE T HE WATER WAT<br />

TE<br />

ER INDUSTRY<br />

INDUSSTRRY<br />

Y<br />

ADVANTAGES ADVAN ANTAA<br />

GES OVER<br />

TRADITIONAL TRA ADITIONAL<br />

MATERIALS MA T TERIALS<br />

INCLUDE INCLU<br />

UDE<br />

LIGHTWEIGHT, LIGHTWEIG<br />

GHT, , STRONGER, STRONGE<br />

ER, EASIER TO<br />

HANDLE<br />

AND INSTALL, INSTAA<br />

LL,<br />

MADE MAD DE<br />

FR FROM OM 100% 100 0% R RRECYCLED<br />

ECY CL ED MATERIAL, MMA<br />

MMA<br />

AT T ERIA ERIAL<br />

L, NO BREAKAGES, BR EAKA GES GES,<br />

REDUCES R<br />

EDUCES<br />

TRANSPO<br />

TRANSPORTATION RTAA<br />

TION COSTS COSTTS<br />

HYDRANT, HYDR RANT,<br />

, SV AND LAR<br />

LARGE GE<br />

CHAMBERS CHAM MBERS AAVAILABLE<br />

VAILABL AILAB BLE<br />

HYDRANT HYDRA ANT<br />

AND SV RANGE<br />

E<br />

ONE PIECE PIE ECE MOULDING, IN N VARIOUS VVARIOUS<br />

ARIOUS DEPTHS<br />

DEPTHSS<br />

Fully<br />

y Interlocking Units<br />

Purp Purpose ose Made Base Units<br />

ts<br />

Light Lightweight tweight For One-man an Lift<br />

Spee Speedier edier Installation<br />

Cost<br />

Effective<br />

LARGE<br />

E CHAMBER SECTIONS SE ECTIONS<br />

Range ange o<br />

of f siz sizes es fr from om 450m 450mm mm tto<br />

o 900mm in 7 75mm -<br />

100mm 00mm m depths<br />

Stron Strong ng and Robust<br />

Light<br />

t for Easy Installation<br />

on<br />

Posit Positive tive and Secure Interlock erlock between units<br />

ts<br />

Heav Heavy vy Duty Tested To E EN124 D400 Loading<br />

ng<br />

Hand<br />

d Holes for manual lifting<br />

No B Breakages reakages so reduced ed cost of Installation<br />

on<br />

Can be b be installed with reduced duced backfill backfill/concrete / conc rete<br />

surro surround ound<br />

Environmentally nviro<br />

onmentally Frien Friendly ndly<br />

Call l oour<br />

ur<br />

ttechnical<br />

e echnical<br />

tteam<br />

eam<br />

tto<br />

o ddiscuss<br />

isc<br />

u uss<br />

aall<br />

ll<br />

yyour<br />

our<br />

ddesign<br />

esign<br />

requirements require<br />

m ments<br />

oon<br />

n 00844<br />

844<br />

848<br />

9400 94<br />

0 00<br />

or or<br />

go<br />

tto<br />

o wwww.pds–plc.com<br />

ww.<br />

pds<br />

– plc.<br />

com<br />

This<br />

pproduct<br />

roduct<br />

is<br />

ppart<br />

art<br />

oof<br />

f PPDS<br />

DS<br />

inovative<br />

rrange<br />

a n nge<br />

oof<br />

f recycled<br />

products.<br />

PIPELINE & DRAINAGE DRAINAA<br />

GE SY SYSTEMS YSTEMS<br />

PLC<br />

2010 WSW 7

Innovation celebrated in construction products industry<br />

S<br />

aint-Gobain PAM UK has been<br />

recognised for its innovative Hydraulic<br />

Pipe Unloading Beam in the<br />

Construction Products Association’s 2009<br />

edition of Construction Products Innovation<br />

and Achievement (CPIA).<br />

The Unloading Beams achievement in the<br />

category of Health, Safety and Security is<br />

one of only 24 products nationwide, to be<br />

chosen for last year’s publication, which<br />

annually showcases the most innovative<br />

products and processes created by the<br />

construction products industry during the<br />

last twelve months or so.<br />

Commenting on the achievement, Simon<br />

Storer, Communications and External Affairs<br />

Director, for the Construction Products<br />

Association said: “We are delighted that<br />

the construction products industry has once<br />

again shown an enormous desire to<br />

introduce a variety of new and exciting<br />

solutions. Despite the economic downturn in<br />

the UK, and the construction industry<br />

suffering more than most, you only need<br />

look at the products and processes<br />

showcased in CPIA to highlight the huge<br />

input the industry is making towards<br />

change.<br />

The industry has not always been good at<br />

trumpeting its own achievements. However,<br />

8 WSW 2010<br />

publication. Our Unloading Beam will bring<br />

enormous benefits to the construction<br />

industry by optimising safety in the pipe<br />

unloading process on sites across the UK.<br />

The beam is a ground-breaking means of<br />

unloading pipes as it completely removes<br />

the need to work at height and also<br />

eliminates the expense and inconvenience of<br />

crane hire. It is very important that our<br />

industry recognises and showcases<br />

innovation and we are grateful that CPIA<br />

2009 does this.”<br />

It is the fi rst premium-effi ciency pump in the world.<br />

Anditsgreaterenergysaving<br />

isanothergood<br />

reasontochooseit chooseit<br />

Our greater energy saving gives you:<br />

The ABS EffeX range of submersible sewage pumps<br />

has built-in IE3 premium-effi ciency motors in accordance<br />

with IEC60034-30 to optimise motor effi ciency.<br />

The main benefi t of this is the highest effi ciency<br />

available without any impact on the risk of increased<br />

blockage often associated with hydraulic effi ciency.<br />

Moreover, the ABS EffeX range boosts impeller<br />

design to the next level and achieves some of the<br />

highest hydraulic effi ciencies in the market, while still<br />

maintaining a minimum 75 mm free solid passage.<br />

CPIA demonstrates how the construction<br />

products industry is continuously developing<br />

and improving by creating innovative<br />

solutions which make a significant impact to<br />

all aspects of construction”.<br />

The 24 entries in CPIA are under four key<br />

headings; Energy and Carbon Saving;<br />

Health, Safety and Security; Improvements<br />

in Site Safety; and Resource Efficiency. By<br />

delivering these efficiencies, these new<br />

ideas bring a range of benefits to everyone<br />

including clients and end users, company<br />

employees and especially the environment<br />

we live in.<br />

The products featured in the publication<br />

cover a wide range and include processes<br />

designed to save energy and reduce<br />

emissions, providing safer operations on<br />

site for employees and contractors and<br />

provide a full sustainability appraisal of<br />

manufacturing operations. This creative and<br />

innovative approach is not confined just to a<br />

select few in one or two sectors, but can be<br />

seen as a key driver for an industry that is<br />

continuously improving and constantly<br />

changing.<br />

Andy Burnham, Supply Chain and<br />

Distribution Manager from Saint-Gobain<br />

PAM UK added, “We are very pleased to<br />

have been chosen for last year’s CPIA<br />

�� Reduced energy costs<br />

�� Smaller CO2<br />

footprint<br />

�� Qualifi cation for capital allowance schemes<br />

Everything considered, the ABS EffeX range of<br />

submersible sewage pumps offers you the highest<br />

performance for this product class.<br />

Now you can make the right choice if you want to be fi rst...<br />

...or more importantly, the fi rst choice if you want to be right!<br />

Visit www.ABSEffeX.com for the full picture<br />

and to request a demonstration.<br />

2

Sewage treatment works Struvite<br />

T<br />

hames <strong>Water</strong> Utilities sewage treatment<br />

works at Stanstead Abbotts, Hertfordshire<br />

handles all the sewage from the conurbation<br />

of Harlow and surrounding areas. The sewage<br />

works dispose of cake, a by-product, either by<br />

drying and then incinerating to produce green<br />

energy, or, as in the case of Beckton and<br />

Crossness, with the remainder of the sewage<br />

treatment works mixing the cake with straw for<br />

use as fertiliser. Prior to drying, liquid is removed<br />

from the cake with a Klampress using a belt and<br />

central drum to squeeze the substance.<br />

Struvite, a hard crystalline scale consisting of<br />

mainly magnesium and ammonium phosphate,<br />

built-up on the drum and belt, making removal<br />

with conventional high pressure washing<br />

BIO-BLOK ® ®<br />

®<br />

BIO-BLOK ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

����<br />

��<br />

BIO-BL BIO BL LOK ������������<br />

����������<br />

����������� � �� ��� ��� ������� ��� ����� ��� ���<br />

��������� ��������������������� �� �� ��������������������������� �� � ������������������������������� � �� � ������������� �� � ��<br />

� �������� ������<br />

������������������������������<br />

�������� � � �<br />

®<br />

������������<br />

���������������<br />

�� ��� � �������������������<br />

®<br />

®<br />

�� �����������������������<br />

� � � � �<br />

���� �������� ��� ���<br />

������� ��������� ���� ���<br />

� � � ��������<br />

impossible. The struvite caused the holes on the<br />

belt of the Klampress to block, resulting in the<br />

press becoming less efficient.<br />

High-pressure water washing was unable to<br />

remove the struvite and the use of chemicals was<br />

rejected, as the fertiliser by-product is used in the<br />

farming industry. Estimated costs, from the<br />

manufacturer of the system, for removing the<br />

two-ton drum and acid cleaning were given at<br />

around £7,000.<br />

Following a site survey by an engineer,<br />

Scalewatcher ENiGMA systems were installed<br />

on the main feed and the wash water. Since<br />

then, employees of Thames <strong>Water</strong> Utilities,<br />

carrying out high pressure water cleaning of the<br />

Klampress have reported to Stephen Payne,<br />

Area Support Engineer, that the struvite is much<br />

softer and far easier to remove from both the<br />

drum and belt.<br />

Commenting, Stephen Payne, says: “The cost of<br />

sending the drum back to the manufacturers was<br />

prohibitive and the Scalewatcher ENiGMA<br />

system has proved a cost effective and<br />

environmental solution to the problem”.<br />

Such has been the success of the ScaleWatcher<br />

Enigma, Thames <strong>Water</strong> Utilities is planning to<br />

purchase further units for the other two<br />

Klampresses located at the site<br />

BIO-BLOK ® �������������������� ����� �������������������������������������� ����<br />

����������������������������������������������������������������� �� ������������-<br />

����������� ��������������������� ���������������������� ��������������������� ®<br />

��� ���� �������<br />

������� ��������� ������� ���� ������� ������ ����������<br />

�� ���� ����������� ��� ��������� ���������������<br />

���������� ����<br />

��� -<br />

®<br />

��������� ���������� �� ���� ������������<br />

�������� ���� ������������ ��� ���� ���������<br />

���� ��������� ������ ������ �������� ��� ������ �������������� �����<br />

���������� ���� ���������������� ��� ��� ��� �� ������� ������������������� ����������� ����<br />

����� ����<br />

���������������������� ����������������������� � � ���������������������������������<br />

��������������� � � ���������� � ������ �<br />

������������<br />

® ��������������������������<br />

® ����� ������������������� ����������������������������� ����� ���������� ��� �������� ����� ����������������������������������������<br />

��� �� ����� ���� �����<br />

������������� ����������������������������������� ����� ������� ��� ��� ����� ��������� ��������������� ��� ���� ����������������<br />

���������� ���<br />

������ ������������������<br />

���������� �� �� ����� �����������������������������������������<br />

�� ����������������������������������������� �� �� �� �� �� ��������������<br />

������������� ��<br />

�<br />

The EXPO-NET BIO-BLOK<br />

������������������������������<br />

�������������<br />

������������������������������������<br />

�����������������<br />

���������������������� ��������<br />

�����������������������������<br />

����<br />

���������������������������������<br />

����������<br />

�����������������������������<br />

����������������������<br />

®<br />

The EXPO-NET BIO-BLOK elements are suitable for:<br />

���� ���������������������<br />

������������������������������������������������<br />

� ���������������������������������<br />

� � � � �<br />

�����������������������<br />

� �� �������� �������������<br />

�������������������������<br />

����������������<br />

� ����������<br />

�<br />

�������������������������<br />

� � � � �������������<br />

� � �����������������<br />

����������������<br />

����������������<br />

������������������<br />

� � � �����<br />

��������<br />

�������������<br />

�������������<br />

��������������<br />

� � �������������������������������<br />

���������������<br />

����<br />

����������������<br />

� ������������������<br />

��<br />

��������������������������������������������������<br />

������������������� � ���������������������������������<br />

�<br />

����������<br />

����������<br />

�������������<br />

�������������<br />

�� �����������������<br />

����������������<br />

�� �� ��<br />

���������������������������������������<br />

���������������� ���������������� ��������������������������<br />

��������������������������<br />

�� ��<br />

��������� � �������������<br />

� �<br />

�������������������<br />

�����������������<br />

� ��<br />

���������������<br />

�������<br />

���������������<br />

���������<br />

���� ���� ��<br />

������������<br />

The BIO-BLOK<br />

��������������<br />

�����������<br />

������������<br />

�������������������<br />

�������������������������<br />

�������������������<br />

������������������<br />

����������������<br />

�����������������������������<br />

���������������������������<br />

������������� ���������������������������������������������<br />

����������������������<br />

® elements are:<br />

������� ���������� ������������������������������������������������������-<br />

������������ ������� ��������� ��������������������������������������������<br />

���� ����������������� ������������������������������������� ���������������� ��<br />

�������������������������������������������������<br />

BIO-BLOK ® 2 �<br />

��������������������������������������������<br />

��<br />

BIO-BLOK ® 2 �<br />

��������������������������������������������<br />

��<br />

BIO-BLOK ® 2 �<br />

��������������������������������������������<br />

��<br />

BIO-BLOK ® ���������������<br />

�������<br />

���������������<br />

������ ����<br />

������ ����<br />

�������� ������<br />

®<br />

The BIO-BLOK elements are:<br />

������������� ���� ����������������<br />

���� ��� ���������� ����� ���� ������ ����<br />

���� -<br />

����������� ������ ������ ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

�����<br />

����� ��� �������� ���� ���� �������� �� ����� ��������<br />

��������������<br />

�����������<br />

������������� �<br />

�������� �� ��� ���� ���������� ����<br />

������ �������� ������ ���� ��� ������ ���� ��� ��������<br />

������������������<br />

� ��������������������������������<br />

� � � �<br />

® 2 �<br />

BIO-BLOK �������<br />

�� � ��� ������������������������������������������<br />

��� � �� � �� � �� � �� � �� ���������<br />

�� � ��<br />

� ��<br />

® 2 �<br />

BIO-BLOK �������<br />

�� � ��� ������������������������������������������<br />

��� � �� � �� � �� � �� � �� ���������<br />

�� � ��<br />

� ��<br />

® 2 �<br />

�������������������<br />

BIO-BLOK �������<br />

�� � ��� ������������������������������������������<br />

��� � �� � �� � �� � �� � �� ���������<br />

�� � ��<br />

� ��<br />

����������<br />

� ���������������<br />

� �<br />

® 2 ��<br />

�������������������<br />

BIO-BLOK ��������������������������������������������<br />

�������<br />

�� � ��� ������������������������������������������<br />

��� � �� � �� � �� � �� � �� ���������<br />

�� � ��<br />

� �� ��<br />

�������� �����������<br />

�<br />

����������������<br />

������������ �������������������<br />

� �<br />

������������ ���� ������������ ����������� ����������� � ��� ����������<br />

�� ����������������������� ���� ���� ���������� ������� ��� ������ ���������- ��������<br />

-<br />

���������������<br />

� ������������<br />

�<br />

�������������������������������������������������������<br />

��������������������<br />

� � ��������������������������������������<br />

�� � � �<br />

��������<br />

�������� ������ ������ ������������������������������<br />

������������������������������<br />

�� �� �� �� �� �����������������<br />

�����������������<br />

�� �� ��<br />

������������������<br />

� � �����<br />

���������������������������������������������������������<br />

���������������������<br />

� � ��������������������������������������������<br />

� � � � � � ���� ���������������<br />

�<br />

����� ������������������<br />

�� ��������������� �� � ������������������������������������<br />

�� �� ������������ �� �� �� �� ��� ��������������� �� �� �� �� � �� ������������������������������������ ��� �� �� �������������� �� �� �� �� � � � ������ �� � � ������� �� �� ������������������������������<br />

�������� �� � ���������� �� �� �� �� ����������������� ����� ��������� ��<br />

2010 WSW 9

ABB has won a new five year framework with Thames <strong>Water</strong><br />

A<br />

BB has broadened the scope of its sole<br />

supply arrangement with Thames <strong>Water</strong><br />

to include an extended range of major<br />

instrument categories.<br />

Traditionally ABB has been a flow partner to<br />

Thames <strong>Water</strong>, providing flow equipment<br />

alongside a group of favoured suppliers. Under<br />

New reed bed technology treats stronger effluents<br />

A<br />

wider range of effluents - including those<br />

with high strength contaminants such as<br />

ammonia, petrochemicals, agricultural<br />

wastes and capped landfill leachate – can now<br />

be treated by reed beds due to new Forced Bed<br />

AerationTM (FBA) technology.<br />

Currently undergoing UK trials, ARM Ltd joined<br />

forces with US-based Naturally Wallace which<br />

has proven the system internationally.<br />

“Case studies show when air is forced through<br />

the system to increase the oxygen availability,<br />

the greater the volume of oxygen in the system,<br />

the more efficient the treatment becomes. A<br />

Rotary Lobe Pumps I Macerating Technology<br />

Börger UK Limited | East Wing-Old School, Watling St. Gailey, Staffordshire | T: +44 1902 798977 | E: uk@boerger-pumps.com | I: www.boerger-pumps.com<br />

10 WSW 2010<br />

the new agreement, ABB has extended its sole<br />

supplier status to encompass mains and battery<br />

powered electromagnetic flowmeters, insertion<br />

electromagnetic flowmeters, absolute and<br />

differential pressure transmitters and coriolis<br />

mass flowmeters.<br />

The agreement follows a stringent 18 month<br />

FBA reed bed can improve the treatment<br />

capabilities of a traditional reed bed by up to <strong>15</strong><br />

times thus allowing the reed beds to have a<br />

smaller footprint,” said Tori Widdas of ARM.<br />

“FBA has been used successfully in the US for<br />

a number of years for the treatment of<br />

hydrocarbons and glycols. It’s just one of the<br />

ways in which we’re making environmental<br />

advances to open up entirely new applications.<br />

For instance, when we were in Leeds at the<br />

European Biosolids Conference last week, we<br />

were talking to both waste management<br />

companies and local authorities who need help<br />

technical review, looking at equipment<br />

performance, whole-life maintenance costs and<br />

software upgrades.<br />

Says Steve Wilding, Area Sales Manager, ABB<br />

UK instrumentation: "ABB has had a longstanding<br />

relationship with Thames <strong>Water</strong>,<br />

spanning over 20 years. During this time, we<br />

have established a good reputation for the<br />

accuracy of our flow measurement equipment.<br />

Our new agreement with Thames <strong>Water</strong> is an<br />

exciting opportunity for us to demonstrate how<br />

our equipment can help the company to realise<br />

new levels of measurement accuracy across a<br />

broader range of parameters."<br />

The flow instrumentation will be primarily used<br />

on Thames <strong>Water</strong>'s large water and wastewater<br />

treatment works pipelines ranging 50mm-2.2m<br />

and out on the district metered areas to help<br />

identify and counteract leakages in its mains.<br />

The Pressure transmitters will be used to measure<br />

pressure surges within the network, and critical<br />

pressures at pumping stations and treatment<br />

process plants.<br />

Thames <strong>Water</strong> is the largest water & wastewater<br />

service provider in England, supplying water<br />

treatment services to over 13 million customers in<br />

London and the surrounding counties. It invests<br />

around £500,000 a day on reducing leakage, with<br />

levels now 24 per cent lower than four years ago.<br />

treating biogas digestate – a by-product of the<br />

anaerobic treatment of waste - which FBA<br />

processes can treat,” said Tori Widdas.<br />

ARM Reed Beds is the UK’s sole supplier of<br />

FBA technology for waste water treatment..<br />

Innovation<br />

Each Börger pump is really<br />

custom made<br />

Thanks to an excellent dialogue between you and our Sales and<br />

Technical Staff.<br />

We guarantee only the best engineering and materials.<br />

Börger Rotary Lobe pumps can be used in many<br />

applications especially in the <strong>Waste</strong> <strong>Water</strong> Industry.<br />

Various fluids can be pumped: e.g. Primary Sludge, Activated<br />

Sludge, Screenings, Raw Sewage, Lime, Poly & Wash <strong>Water</strong>

New premises for Teekay<br />

U<br />

K specialist pipe coupling manufacturer Teekay Couplings Ltd. has<br />

recently acquired new premises in Milton Keynes, UK, increasing<br />

current manufacturing floor-space by 80%. The new premises will<br />

accommodate Final Assembly, Production Testing and Despatch<br />

Departments and will also include storage facilities suitable for housing a<br />

stock in excess of 20,000 pipe couplings. According to joint MD Ian<br />

Webb, the new acquisition meets the expanding global business potential<br />

in five key sectors – marine, water, civil engineering, building services<br />

and industrial. “Our customer base in all key commercial areas will<br />

benefit directly, being able to order standard items off-the-shelf.<br />

Shortened lead times and increased product availability will offer greater<br />

purchasing flexibility to our customers.” The Teekay Couplings Visitor<br />

Centre will provide a unique working environment where customer<br />

product training and project analysis can be easily undertaken. The<br />

company was formed in 1961 and began producing pipe couplings in<br />

1975. Today it produces more than 250,000 couplings a year.<br />

E<br />

FPSO’s fresh water supply from Eimco<br />

<strong>Water</strong> Technologies<br />

imco <strong>Water</strong> Technologies have been awarded a significant order by BP to<br />

supply and install a fresh water manufacturing plant on the FPSO (Floating<br />

Production, Storage and Offloading vessel) Schiehallion.<br />

Located in the Schiehallion oil field in the North East Atlantic Ocean to the west<br />

of the Shetland Islands, the high operating costs for the FPSO’s existing fresh<br />

water making plant led BP to evaluate the payback of replacing the old system<br />

with the latest development in Reverse Osmosis (RO) Technology, as designed<br />

by Eimco <strong>Water</strong> Technologies.<br />

The new design had to meet very tight transportation criteria, including the<br />

need for it to fit into the existing footprint to minimise pipe-work and<br />

modification during installation.<br />

The RO system replaces traditional methodologies and components with latest<br />

developments that include maintenance-free Axial Piston Pumps, guaranteed<br />

for three years, which have also significantly reduced the amount of space<br />

required.<br />

By introducing a new Proportional Chemical Dosing Technique, Eimco <strong>Water</strong><br />

Technologies is expected to also reduce chemical refill frequency from a daily<br />

task to just once every 50 days, eliminating the need to dilute chemicals.<br />

A PLC/HMI Interface allows the plant to operate automatically and the<br />

installation of the latest membrane technology should save on costs by reducing<br />

the actual number of membranes required.<br />

The lifetime of the RO<br />

membrane is expected to<br />

greatly increase by the<br />

utilisation of new advanced<br />

filters that eliminate the need<br />

for sand cartridge filters and<br />

ensure a high quality feed<br />

water.<br />

The cost e�cient way to join pipes<br />

tel:<br />

+44 (0)1494 ( 0) 1494 679500 6679500<br />

www.teekaycouplings.com<br />

www.<br />

tee<br />

k kaycouplings.<br />

comm<br />

2010 WSW 11

T<br />

Royal train yard recovering thanks to Onsite<br />

Andy Buckley Civil Asset Engineer with Anglian <strong>Water</strong> observes the 900 mm diameter Premier<br />

Pipe liner as it is being installed.<br />

he Royal Train Yard at Wolverton Rail Works in<br />

Milton Keynes was aquired by housing<br />

developer Willmott Dixon in order to create<br />

300 new homes. The project was to tackle a very<br />

complex refurbishment of the 200 year-old<br />

building.<br />

There was a requirement to stabilise an area of<br />

potentially unstable ground under the existing<br />

building which investigations showed carried a<br />

900mm diameter surface water sewer. The sewer<br />

ran at a depth of 14m below the historic Grade II<br />

listed building and the Grand Union Canal<br />

connection London to Birmingham. The sewer was<br />

the responsibility of Anglian <strong>Water</strong>.<br />

Historical drawings showed the sewer running in a<br />

straight line between two manholes for a distance<br />

of just over 100m. With this information of the<br />

location of the sewer, Willmott Dixon’s engineers<br />

drilled a bore hole which was pumped full of<br />

concrete to stabilise the ground below. In the event,<br />

the drawing was found not to be complete. The<br />

sewer had in fact been constructed, not in a straight<br />

line as shown on the drawing, but as a long slow<br />

bend with part of its course running directly below<br />

where the bore hole operation had taken place.<br />

This meant that the bore hole had been drilled<br />

Specialist contractors for the water, sewerage and waste industry<br />

The most successful water<br />

loss specialists in the UK<br />

l Advanced Leak Detection<br />

l Hydraulic Analysis<br />

l <strong>Water</strong> Conservation<br />

l Asset Management<br />

For UK <strong>Water</strong> Companies &<br />

Industrial Customers World Wide<br />

12 WSW 2010<br />

water management specialists<br />

Tel: 0<strong>15</strong>36 5<strong>15</strong>110<br />

www.hydrosave.co.uk<br />

directly into the sewer which had subsequently<br />

been completely filled with concrete.<br />

Once aware of the situation Willmott Dixon, with<br />

Anglian <strong>Water</strong>’s approval, attempted to remove the<br />

concrete using high pressure jetting. Unfortunately<br />

this proved ineffective.<br />

Subsequent attempts were made to remove the<br />

concrete using man-entry methods and water<br />

lances. Whilst this achieved the removal of some<br />

2m of concrete, the operation was abandoned on<br />

health and safety grounds because the pipe<br />

structure was compromised by cracking found near<br />

to where it was believed the bore hole had passed<br />

through it.<br />

Anglian <strong>Water</strong>’s Steve Jones, the company’s Asset<br />

Engineering Manager, along with Andy Buckley,<br />

Civil Asset Engineer, who oversaw the project, then<br />

approach ed specialist underground construction<br />

contractor OnSite to see if the company’s ‘No-Dig’<br />

expertise could be utilised in resolving this difficult<br />

problem.<br />

OnSite initially proposed to use its highspecification<br />

robot cutter unit to grind out the<br />

concrete. Initial attempts with this system<br />

progressed very slowly. The company then came up<br />

with a unique and safe method of man entry<br />

The UK’s leading sewer<br />

rehabilitation & maintenance<br />

contractors<br />

l Flow Monitoring<br />

l Sewer Cleaning<br />

l CCTV Sewer Surveying<br />

l Premier-Pipe Full Length CIPP Lining<br />

l Premier-Patch Localised Repairs,<br />

l Connection & Lateral Lining<br />

Tel: 01235 772882<br />

www.onsite.co.uk<br />

Hydrosave, Onsite & Perco are all members of South Staffordshire Plc<br />

working which would enable crews to work within<br />

the pipe whilst remaining fully protected during the<br />

cutting operations.<br />

The method involved installing a series of structural<br />

CIPP repair patches inside the pipe up to the face of<br />

the concrete. The concrete excavation team could<br />

then work safely within the ‘patched’, and therefore<br />

supported, area of the pipe whilst further concrete<br />

was removed. A new patch was installed after<br />

every 0.5 m of concrete was removed, enabling<br />

safe working to continue.<br />

As the operation progressed a constant appraisal<br />

of procedures was carried out with new ideas and<br />

suggestions being put forward all the time. Such<br />

suggestions included the installation of a temporary<br />

support heading where the concrete had been<br />

poured into the pipe. After just seven days the<br />

teams working within the pipe had completely<br />

removed the 8m long concrete obstruction.<br />

Subsequently, and to ensure the long term structural<br />

integrity of the pipe particularly around the<br />

damaged area caused by the bore hole, Anglian<br />

<strong>Water</strong> accepted OnSite’s proposal to fully line the<br />

damaged area using its structural Premier-Pipe<br />

CIPP lining system.<br />

Whilst an alternative GRP lining method had been<br />

considered it was ultimately rejected by Anglian<br />

<strong>Water</strong> on the grounds that, once installed, the<br />

sewer pipe flow capacity could be insufficient with<br />

the loss of so much cross sectional area, which<br />

concerned Anglian <strong>Water</strong>’s engineers.<br />

The new lining ran under the Royal Train Yard<br />

and Grand Union canal bridge.<br />

‘No-dig’ pipe installation<br />

& sewer replacement<br />

l Auger Boring<br />

l Microtunnelling<br />

l Shaft Sinking<br />

l Directional Drilling<br />

l Headings<br />

l Pipe Bursting<br />

l Slip Lining<br />

Tel: 01604 590200<br />

www.perco.co.uk

TT-UK / TT Middle East presents Burstfoam<br />

A<br />

t the first Underground Infrastructure<br />

Middle East Conference held in<br />

Bahrain TT-UK/TT Middle East<br />

presented for the first time in the Region their<br />

NEW Burstform, Tight in Pipe Trenchless<br />

renewal pipe system. Burstform is a<br />

deformation unit, which deforms the circular<br />

high quality PE 100 pipe into an oval shape<br />

and allows the pipe to be pulled around two<br />

90 degree bends from the surface into the<br />

manhole and from the manhole into the host<br />

pipe using the advanced QuickLock rod<br />

technology.<br />

Before the pipe enters the host pipe a<br />

reshaping mechanism forms the pipe back<br />

Because Becaus se water shoul should ld never go to waste ...<br />

Heliscreen ® He CSO<br />

Sc Screening System<br />

Burstform Pipe deformation<br />

into a circular pipe. This process avoids the<br />

expensive pipe launching pit.<br />

The technical paper was presented by Daniel<br />

Toms to a receptive audience including high<br />

ranking officials from the Bahrain Ministry of<br />

Works and the Bahrain Society of Engineers.<br />

TT-UK/TT Middle East‘s sales partner, Abbas<br />

Biljeek, were also in attendance to assist with<br />

the varied Trenchless application exhibition<br />

enquiries generated during the course of the<br />

event.<br />

TT-UK/TTME takes this opportunity to thank<br />

the organisers EITEP for their great efforts in<br />

organising this inaugural event where 250<br />

visitors from 13 nations were in attendance.<br />

��������������������������� ������ �� �� �� �� �� �� �� ������� �������<br />

����� ����� ����� ����� ����� ����� ����� ����� ����� ����� ����� ����� ����� ����� ���<br />

��� � � �� ����������<br />

��������� ����� ������������� ����������<br />

P<br />

Hydro International<br />

������������<br />

�������������������������������������� ����� �������<br />

����� ������<br />

�����������������<br />

����������������� ������<br />

� ���� ��� �<br />

��� � ���� ������������������������������������<br />

������<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

����� ��� ��������<br />

������ ������<br />

Prominent Fluid<br />

Controls<br />

roMinent’s business unit Chemical Fluid<br />

Handling (CFH) develops, produces and<br />

markets components and complete systems for<br />

storage, transfer, metering, and neutralization of<br />

liquid chemicals. Products are chemical storage<br />

tanks, chemical transfer pumps, metering pumps,<br />

instrumentation for monitoring, measurement, and<br />

control, complete metering systems and polymer<br />

preparation systems.<br />

ProMaqua is focused on the following sectors and<br />

applications: Food and beverage industry, drinking<br />

water supply, swimming pool and wellness industry,<br />

hotels as well as cooling water disinfection and<br />

combating legionella. The company offers complete<br />

system solutions making use of all current methods<br />

to treat water. The range of products and services<br />

includes chlorine dioxide systems, electrolysis<br />

systems, UV systems, ozone systems and membrane<br />

filtration systems as well as measurement, control<br />

and dosing technology.<br />

Reliability is their main virtue. Therefore they heavily<br />

invest in research and development and keep a high<br />

degree of in-house production depth. This ensures<br />

an optimum standard of quality in their <strong>15</strong><br />

manufacturing locations and makes them<br />

independent of fluctuations in the supplier market.<br />

All internal processes are certified in accordance<br />

with DIN EN ISO 9001:2000. F<br />

��� ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

�� �������������� ���������<br />

��� ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��������������� ��������������<br />

����������� ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

�����������������������<br />

��� ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��������������������������<br />

��� ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

���������������� ���������������<br />

��� ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

���������������<br />

�������������������<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

�� ����<br />

�� �� �����������<br />

����������<br />

���������������������������������<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

����<br />

����<br />

�������� ����� ���������<br />

�������������� �� ��<br />

��<br />

��<br />

��<br />

��<br />

��<br />

���������<br />

��� ��������<br />

����������������������<br />

��������� �������<br />

turning water around ... ®<br />

turning water around ...<br />

2010 WSW 13

The upstream end of the twin 1,350 mm<br />

diameter culverts being rehabilitated.<br />

A<br />

growth area for the use of Insituform<br />

Technologies Ltd. (ITL)s lining products<br />

has been that of culvert rehabilitation.<br />

A recent project in Ireland demonstrated just<br />

how effective renovation of existing systems<br />

can be even in difficult-to-access<br />

circumstances.<br />

The project as part of the Ballyogan Landfill<br />

Stage 2 Capping contract. The culvert<br />

rehabilitation project was designated as the<br />

Ballyogan Landfill Site Carrickmines Dublin<br />

18 works. The client was Dun Laoghaire<br />

Rathdown County Council with RPS<br />

Consulting Engineers acting as its<br />

engineering consultant. The main contractor<br />

for the project was Priority Construction, and<br />

the lining works were subcontracted to<br />

specialist contractor Insituform Environmental<br />

Watch out for the brand new innovation in peristaltic pumping<br />

What is Air G A P?<br />

Guaranteed Added Protection<br />

��Total separation of pump and drive<br />

��Complete isolation, no contamination<br />

��Up to 70% space reduction<br />

�� �������������� ������<br />

16 WSW 2010<br />

On time and on budget - Insituform<br />

Heavy duty scaffolding was required to install<br />

the CIPP liners.<br />

Techniques, a subsidiary of ITL (IET).<br />

The Ballyogan Landfill and Recycling Park<br />

(BRP) surrounding area is characterised by a<br />

mixture of agricultural, recreational,<br />

residential, commercial and industrial land<br />

use. The total site area is approximately 62<br />

hectares, 43 of which were used for landfill.<br />

The BRP currently occupies approximately 11<br />

hectares. The remaining area consists of the<br />

landfill site entrance and service roads, site<br />

compound, landfill gas combustion plant,<br />

methane stripping plant and other services.<br />

The permanent cap is in place on one part of<br />

the landfill. This area is defined as the Stage<br />

1 Area. The remainder of the area is<br />

currently being capped under the Stage 2<br />

Capping Contract, the contract under which<br />

the culvert lining sub-contract is designated.<br />

The installation site was beside the Arklow<br />

Carrickmines 220kV electricity substation.<br />

As part of these works a Strategic<br />

Improvement Plan (SIP) was carried out for<br />

the landfill which highlighted the fact that the<br />

twin 1,350mm diameter culverts were at a<br />

risk of structural failure due to their location<br />

and age, and required rehabilitation.<br />

The twin culverts, which extend through the<br />

body of the landfill site, convey the Ballyogan<br />

Stream through the landfill.<br />

After careful consideration of the options<br />

available it was decided that rehabilitation<br />

would be most efficiently and cost effectively<br />

achieved by using two single shot<br />

installations, each 271m long, using curedin-place<br />

pipe (CIPP) lining technology, a form<br />

of lining in which IET specialises.<br />

Before beginning the installation of<br />

Insituform® CIPP, the culverts were cleaned<br />

T: 0113 222 0250 E: info@verder.co.uk W: www.verder.co.uk

solution for landfill culverts in Ireland<br />

Roller beds were used to feed the impregnated<br />

liners into the culvert installation site.<br />

and CCTV surveys were undertaken in order<br />

to assess the extent of any existing damage to<br />

the pipe structure. The closed-circuit<br />

television report detailed a number of<br />

structural faults along the length of the<br />

culverts which ranged from Grade 1 to<br />

Grade 4 status. Whilst it was thought that<br />

these cracks did not pose a short-term risk to<br />

the structural integrity of the culverts, it was<br />

considered prudent to take early remedial<br />

action to ensure that the culverts did not<br />

deteriorate any further and that they remain<br />

structurally sound into the future.<br />

One of the main obstacles to a simple<br />

installation solution was the proximity of the<br />

installation site to the Arklow Carrickmines<br />

220 kV electricity substation. Power lines<br />

from the substation are known to pass directly<br />

Setting up a liner at the start of an installation. The twin culverts lined and ready for<br />

re-commissioning.<br />

over the inlet of the river culverts. This meant<br />

that there was a maximum permissible<br />

machinery reach and height restriction of 4.5<br />

m. Although a heavy duty scaffolding<br />

arrangement could be constructed at the liner<br />

launch site, no crane could be used to feed<br />

the impregnated liner to the scaffold.<br />

In all, the lining works were scheduled as a<br />

three week programme. Once the site was<br />

prepared and the liners were ready to invert,<br />

both of the liner installations took just three<br />

days each to complete - including installation<br />

and hot water curing.<br />

As previously mentioned, working in a river<br />

environment meant the flow had to be<br />

diverted on a continuous basis.<br />

Paul Smyth, Director of Insituform<br />

Environmental Techniques said: “In this<br />

project, we have carried out the largest CIPP<br />

lining job in Ireland to date in very difficult<br />

conditions while completing the work both on<br />

time and on budget. The close co-operation<br />

between the main contractor, Priority<br />

Construction and the project manager, RPS,<br />

resulted in a successful outcome of the project<br />

and complete client satisfaction.”<br />

For ITL, John Beech, Business Development<br />

Manager, commented: “These installations<br />

were not exactly ‘run-of-the-mill’ jobs. Access<br />

was tricky, particularly given the proximity of<br />

the substation. The lining operations<br />

themselves went very well, even with the<br />

logistics challenges of getting materials and<br />

supplies to relatively remote locations. It was<br />

a job well done.”<br />

Unnoticed in neighbourhoods<br />

around the world. From the U.K. and Europe to the USA<br />

and Asia, Insituform Blue ®<br />

is renewing<br />

drinking water pipelines with the<br />

most innovative, least disruptive<br />

trenchless technology available.<br />

We have helped communities around<br />

the world reduce leakage, improve<br />

water quality and restore structural<br />

integrity to their drinking water<br />

systems. Call or visit us online to<br />

learn what Insituform Blue ®<br />

can do for your neighbourhood,<br />

wherever you are.<br />

uksales@insituform.co.uk<br />

Tel 0 (44) 1924-277076<br />

www.insituform.co.uk<br />

© 2008 INA Acquisition Corp.<br />

2010 WSW 17

Rotork valve actuators assist high-tech upgrade<br />

Rotork IQT actuators installed on new pipework in the<br />

chambers between the membrane plants, operating the<br />

sewage inlet and outlet, air, sodium hypochlorite, wash<br />

water and permeate valves.<br />

T<br />

he Wessex <strong>Water</strong> sewage treatment works<br />

at Swanage utilises state-of-the-art<br />

membrane bioreactor technology to<br />

produce high quality effluent that exceeds EU<br />

standards and is cleaner than the sea into which<br />

it is discharged.<br />

Now nearing completion, a major plant<br />

upgrade at the site is introducing automation<br />

and energy saving measures, whilst increasing<br />

the size of the membrane treatment plant to<br />

provide spare capacity for future demand.<br />

Central to the upgrade, Profibus networkenabled<br />

Rotork IQT intelligent electric actuators<br />

have been installed to operate butterfly and plug<br />

valves on new pipework throughout the plant.<br />

Swanage STW treats sewage for a population of<br />

around 10,000 which can more than double<br />

when the area is busy with holidaymakers.<br />

Following preliminary screening and grit<br />

removal, sewage enters Kubota membrane<br />

plants installed in six large tanks for biological<br />

treatment and disinfection. The pores in the<br />

membranes are so small that they can prevent<br />

microscopic bacteria and viruses from passing<br />

through. The upgrade involves increasing the<br />

number of membrane packs in each tank to<br />

thirty-six, thus considerably increasing the<br />

���������������������������������������<br />

���<br />

���<br />

�<br />

18 WSW 2010<br />

Rotork IQT actuators controlling butterfly valves on the<br />

pipework carrying air to the membrane plants.<br />

treatment capacity without exceeding the<br />

confines of the existing works’ footprint.<br />

Automation of the treatment process also<br />

enables it to run with increased efficiency and<br />

reduced energy consumption.<br />

On each of the membrane plants, the Rotork IQT<br />

actuators operate inlet isolation and outlet<br />

modulating valves for the sewage, together with<br />

air, sodium hypochlorite and wash water<br />

injection valves. Additional IQT actuators control<br />

the permeate isolation valves used for<br />

automated sequential flushing to maintain<br />

membrane efficiency. In total, fifty-one actuators<br />

are installed on each tank to provide automatic<br />

sequencing of the sewage treatment, membrane<br />

cleaning and backwashing processes.<br />

Fourteen Profibus-DP two-wire networks link the<br />

actuators to PLCs in the site’s central MCC. These<br />

are controlled by a PLC and SCADA system<br />

written by Wessex <strong>Water</strong>’s in-house Automation<br />

Team. The control PLC is a twin CPU<br />

configuration, with one dedicated to the control<br />

and monitoring of more than 300 actuators,<br />

whilst the other runs the complex automation<br />

process, resulting in the collection of control,<br />

status and full diagnostic data from each<br />

actuator, without any PLC speed or memory<br />

�����������������<br />

����������������������������������������������� ��� ��� ��� ���<br />

���<br />

���<br />

������������<br />

One of the Rotork actuator diagnostic touch screen HMI<br />

displays on the site’s SCADA system.<br />

limitations. Diagnostic information is available,<br />

locally at the valve or nearby HMI, on the site<br />

SCADA system and at the regional operation<br />

centre at Bath. Remote diagnosis is a cost<br />

effective method of maintenance and service<br />

because the right operational staff can be sent to<br />

site when required.<br />

With the high level of process automation<br />

enabled by the Rotork actuators, come the<br />

added benefits of process integrity, audit ability<br />

and highly reliable and accurate process<br />

control. Running costs are expected to reduce<br />

due to more effective control of the plant, saving<br />

electrical power, cleaning agents and water. The<br />

effective use of Profibus technology has allowed<br />

significant installation savings in cabling,<br />

terminations, PLC hardware and labour.<br />

The Damar Group is the principal contractor for<br />

mechanical and electrical installation at the<br />

Swanage upgrade project, including the on-site<br />

fabrication and installation of pipework and<br />

actuated valves. The project manager is Wessex<br />

Engineering and Construction Services and the<br />

design consultant is Mott MacDonald. The<br />

Rotork actuators have been supplied in<br />

accordance with the framework agreement that<br />

the company holds with Wessex <strong>Water</strong>.<br />

� � � � � � � � � � � ������������������������������������������������������� ����������������������������������������������������������������������������������������������������������������������������������������������������<br />

��������� ��������� ��������� ��������� ��� ��� ��� ��� ��� ��� ��� ��� ��� ���<br />

���<br />

���

MiniRAE 3000 Portable Handheld PIDs<br />

W<br />

aterra are delighted to announce<br />

their appointment by RAE Systems to<br />

be their official environmental<br />

reseller of choice. This brings a whole new<br />

range of gas monitoring products to <strong>Water</strong>ra<br />

customers including the new MiniRAE 3000<br />

series of portable handheld photo-ionisation<br />

detector’s (PIDs).<br />

MiniRAE PIDs are one of the most advanced<br />

hand-held volatile organic compound (VOC)<br />

monitors on the market and are ideal for any<br />

application requiring broadband or<br />

compound specific VOC detection.<br />

Three portable PIDs are offered by <strong>Water</strong>ra<br />

including the MiniRAE LITE, MiniRAE 3000<br />

and UltraRAE 3000.<br />

The MinRAE LITE is one of the most reliable<br />

handheld volatile organic compound (VOC)<br />

monitors available. Its PID range of 0 to<br />

5,000ppm makes it an ideal instrument for<br />

routine site investigation, monitoring and<br />

construction projects. This entry level PID now<br />

includes ATEX certification as an option.<br />

The NEW MiniRAE 3000 is the successor to the<br />

MiniRAE 2000 and is their most advanced<br />

handheld volatile organic compound (VOC)<br />

monitor With an extended VOC range of 0 to<br />

��� ������� ������ ��� �� ������<br />

��� ������������������ ���������� ������� ��� �� ������ �����<br />

���� ������ ����� ���� ����������<br />

������� ���� �������� ���� ����� ������ ������� �������<br />

�������� ��� ������� ���� �� ���� �������<br />

���� ���� ���� ������� ������ ����� ��� ������� ���� ��� ���������<br />

���� ������ ��� ���� ���� ������<br />

����� ������ ������� ������ ���� ���������� ��� ������� �����<br />

�������� ����� ���� ������� ������������<br />

����� ������� ��� �� ����� �� ������� ���� ��������� �������<br />

���� �� ������ �� �� ������� ���� ������������� �������������<br />

����� ���� ������������� ���<br />

���� � ��������� ���� ��� ���<br />

���� ����� ������ ������ ������������������<br />

- a new standard in VOC monitoring from <strong>Water</strong>ra<br />

<strong>15</strong>,000ppm, logging capability at 1 minute<br />

intervals and optional wireless functionality<br />

this is an ideal instrument for situations<br />

requiring automated logging of results and for<br />

broader spectrum VOC detection.<br />

For compound specific detection at low<br />

concentrations, there is the UltraRAE 3000.<br />

This has the same exhanced features as the<br />

Since 1975 successfully growing through continuous product- and market extension.<br />

More than 8000 units in operation, equipped with the unique SCREWPELLER ® .<br />

AQUA TURBO ® AER-AS<br />

Direct drive floating surface aerator<br />

Headquarters<br />

Brusselsesteenweg 508<br />

B-<strong>15</strong>00 Halle – Belgium<br />

Tel. : 32 (0)2 362 02 62<br />

Fax : 32 (0)2 360 35 89<br />

E-mail : asi@aquaturbo.be<br />

www.aquaturbo.be<br />

European offices<br />

France<br />

Tel. : 33 (0)3 23 83 66 83<br />

Fax : 33 (0)3 23 83 68 41<br />

E-mail : aquaturbo@wanadoo.fr<br />

UK<br />

Tel. : 44 (0)1625 531 944<br />

Fax : 44 (0)1625 537 477<br />

E-mail : pwood@aquaturbo.demon.co.uk<br />

Germany<br />

Tel. : 49 (0)4392 913 772<br />

Fax : 49 (0)4392 913 776<br />

E-mail : ASIDeutschland@aol.com<br />

USA subsidiary and worldwide agents<br />

and distributors<br />

MiniRAE 3000 but with an extended detection<br />

range of 50 to 200ppb in benzene specific<br />

mode making it an ideal instrument for hazard<br />

assessment on contaminated land projects.<br />

It has rugged design features with the field user<br />

in mind. All MiniRAE units are built to last.<br />

They include a big graphic display, large<br />

function buttons which are operable with 3<br />

layers of gloves, a field-interchangeable<br />

battery pack and with easy access to the PID<br />

lamp and sensor which are easily replaceable<br />

without the need for any tools. Also included is<br />

an integrated flashlight for better visibility in<br />

low light, a rugged IP67 rated housing and a<br />

strong, protective removable rubber boot - and<br />

<strong>Water</strong>ra can provide service, maintenance<br />

and calibration at very competitive prices.<br />

ATEX certification is included as standard and<br />

the MiniRAE 3000 and UltraRAE 3000<br />

incorporate a built in 300 compound library<br />

allowing automatic correction of concentration<br />

units to specific gas type.<br />

<strong>Water</strong>ra are a specialist provider of<br />

groundwater and contaminated land<br />

monitoring products throughout the UK and<br />

Ireland.<br />

AQUA TURBO ® COVER TM<br />

Floating FRP spray cover for<br />

the AQUA TURBO ® AER-AS<br />

AQUA TURBO ® AER-GD<br />

Low speed surface aerator<br />

with floating rotor<br />

AQUA TURBO ® AER-SL<br />

Aspirator<br />

AQUA TURBO ® AER-SB/L<br />

Submersible aerator<br />

- either self aspirating<br />

- or connected to a surpressor<br />

AQUA TURBO ® MIX-SL<br />

Submersible mixer<br />

AQUA TURBO ® MIX-AS<br />

and MIX-BS<br />

Floating downdraft mixers<br />

with vertical shaft<br />

AQUA TURBO ® FB<br />

For foam aspiration and breaking<br />

AQUA TURBO ® FRED<br />

For both re-entrainment of<br />

floatables and basin mixing<br />

AQUA DECANT TM<br />

Floating weir for<br />

SBR reactor<br />

2010 WSW 19<br />

STUDIO DEWIT • 11/2008

Multiparameter colorimeter offers cost-effective clean and waste water testing<br />

A<br />

new, cost-effective instrument that lowers the<br />

cost of entry to multiparameter clean and<br />

waste water testing has been introduced by<br />

Camlab, one of the UK's leading scientific<br />

equipment suppliers.<br />

The Camlab <strong>Water</strong> MC500 multiparameter<br />

colorimeter is designed to test more than 70<br />

different clean and waste water testing parameters<br />

for the cost equivalent to two single parameter<br />

colorimeters.<br />

The MC500’s design combines the mobility of a<br />

portable photometer with the characteristics of a<br />

modern laboratory photometer. The instrument<br />

addresses all the important parameters of water<br />

analysis, from aluminium to zinc. The high level of<br />

accuracy of Camlab water reagents and the userfriendliness<br />

of the MC500 enable rapid and reliable<br />