10" Band Saw Model 3104 - Manual & Guides

10" Band Saw Model 3104 - Manual & Guides

10" Band Saw Model 3104 - Manual & Guides

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

miter gauge extension allows you to lower the<br />

blade guard within 1/8" of the material to be<br />

cut without any interference from the blade<br />

guard .<br />

RIPPING SLOT . . . Place miter gauge in ripping<br />

slot to desired width and tighten screw . (A rip<br />

scale is provided for a reference .<br />

HOUSING COVER LATCHES . . There are<br />

seven latches to remove the housing cover . To<br />

release latches, place your index finger at one<br />

end of the latch and gently lift the other end<br />

with your thumb. To lock the latch, press down<br />

until the open end of the latch snaps securely<br />

over the locking tab . Always make sure the<br />

latches are securely snapped before turning on<br />

the saw .<br />

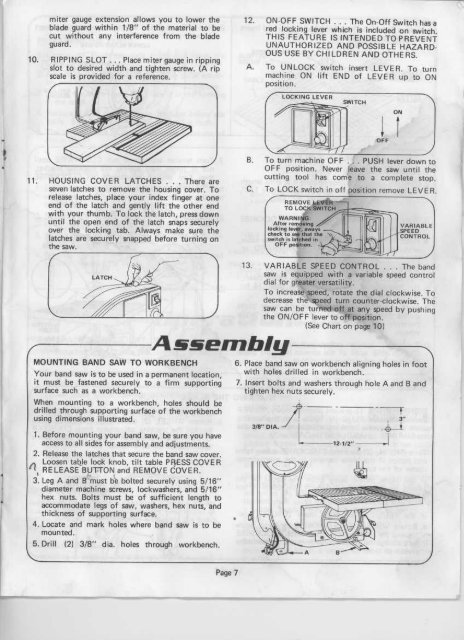

MOUNTING BAND SAW TO WORKBENCH<br />

Assembly<br />

Your band saw is to be used in a permanent location,<br />

it must be fastened securely to a firm supporting<br />

surface such as a workbench .<br />

When mounting to a workbench, holes should be<br />

drilled through supporting surface of the workbench<br />

using dimensions illustrated .<br />

1 . Before mounting your band saw, be sure you have<br />

access to all sides for assembly and adjustments .<br />

2 . Release the latches that secure the band saw cover .<br />

Loosen table lock knob, tilt table PRESS COVER<br />

t RELEASE BUTTON and REMOVE COVER .<br />

3 . Leg A and B 'must be bolted securely using 5/16"<br />

diameter machine screws, lockwashers, and 5/16"<br />

hex nuts . Bolts must be of sufficient length to<br />

accommodate legs of saw, washers, hex nuts, and<br />

thickness of supporting surface .<br />

4 . Locate and mark holes where band saw is<br />

mounted .<br />

to be<br />

5 . Drill (2) 3/8" dia . holes through workbench .<br />

Page 7<br />

12 . ON-OFF SWITCH . . . The On-Off Switch has a<br />

red locking lever which is included on switch .<br />

THIS FEATURE IS INTENDED TO PREVENT<br />

UNAUTHORIZED AND POSSIBLE HAZARD-<br />

OUS USE BY CHILDREN AND OTHERS .<br />

A . To UNLOCK switch insert LEVER . To turn<br />

machine ON lift END of LEVER up to ON<br />

position .<br />

LOCKING LEVER<br />

SWITCH<br />

B . To turn machine OFF . . . PUSH lever down to<br />

OFF position . Never leave the saw until the<br />

cutting tool has come to a complete stop .<br />

C . To LOCK switch in off position remove LEVER .<br />

3/B" DIA.<br />

REMOVE LEVER<br />

TO LOCK SWITCH<br />

WARNING :<br />

After removing<br />

locking lever awavs<br />

check to see that the N<br />

switch a latched in<br />

OFF position .<br />

13 . VARIABLE SPEED CONTROL . . . The band<br />

saw is equipped with a variable speed control<br />

dial for greater versatility .<br />

To increase speed, rotate the dial clockwise . To<br />

decrease the speed turn counter-clockwise . The<br />

saw can be turned off at any speed by pushing<br />

the ONiOF F lever to off position .<br />

(See Chart on page 10)<br />

6 . Place band saw on workbench aligning holes in foot<br />

with holes drilled in workbench .<br />

7 . Insert bolts and washers through hole A and B and<br />

tighten hex nuts securely .<br />

ON<br />

VARIABLE<br />

SPEED<br />

CONTROL<br />

OAF