Centrifugal Fans direct driven with scroll - Nicotra Gebhardt

Centrifugal Fans direct driven with scroll - Nicotra Gebhardt

Centrifugal Fans direct driven with scroll - Nicotra Gebhardt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Centrifugal</strong> <strong>Fans</strong><br />

<strong>direct</strong> <strong>driven</strong><br />

<strong>with</strong> <strong>scroll</strong><br />

Issue 1.3<br />

November 2012<br />

2

The overall picture will decide<br />

Depending on the model of the fan, the efficiency grade “N” set in<br />

accordance <strong>with</strong> the ErP Directive must be achieved from 2013 and<br />

2015 respectively.<br />

Efficiency grade “N” to ErP-Directive<br />

Year<br />

<strong>Centrifugal</strong> fans<br />

<strong>with</strong> backward curved blades<br />

<strong>with</strong>out<br />

housing<br />

static<br />

2013 58 58 61 37 42<br />

2015 62 61 64 44 49<br />

The efficiency grade designates a parameter in the calculation<br />

of the target energy efficiency of a fan depending on the electric<br />

input power when operating at the optimal energy efficiency point.<br />

The figure of parameter “N” corresponds to the target energy<br />

efficiency <strong>with</strong> a power of 10 kW.<br />

To make the selection easier for our customers, we offer<br />

complete systems as defined by the ErP Directive!<br />

In order to compare the systems, the total efficiency ηe of the fan<br />

<strong>with</strong>out speed regulation is considered.<br />

η e = P u(s) / P e<br />

If the system has speed regulation, it will be taken into account <strong>with</strong><br />

the “part load compensation factor” Cc (see below):<br />

η e = P u(s) / P e(d) · C c<br />

<strong>with</strong><br />

housing<br />

static total<br />

<strong>Centrifugal</strong> fans <strong>with</strong> forward<br />

curved blades<br />

<strong>with</strong><br />

housing<br />

static total<br />

ηe = Total efficiency<br />

Pu(s) = Fan gas power when operating at the optimal<br />

energy efficiency point<br />

Pe = Electric input power when operating at the<br />

optimal energy efficiency point<br />

Ped = Input power of speed regulator when operating<br />

at the optimal energy efficiency point<br />

Cc = part load compensation factor<br />

<strong>with</strong>out speed regulation: Cc = 1<br />

<strong>with</strong> speed regulation Ped ≥ 5 kW: Cc = 1.04<br />

<strong>with</strong> speed regulation Ped < 5 kW: Cc = -0.03 ln(Ped ) + 1.088<br />

In order to take the speed regulation into account via the part load<br />

compensation factor Cc , the following mathematical losses arise<br />

in accordance <strong>with</strong> the formula prescribed by ErP for the following<br />

typical motor powers:<br />

Ped = 4.00 kW: Cc = 1.05 (5 %)<br />

Ped = 2.20 kW: Cc = 1.06 (6 %)<br />

Ped = 0.75 kW: Cc = 1.10 (10 %)<br />

Complete systems by <strong>Nicotra</strong> <strong>Gebhardt</strong><br />

<strong>Nicotra</strong> <strong>Gebhardt</strong> can supply complete systems in all product<br />

categories which meet the ErP requirements. We offer highly efficient<br />

fan systems<br />

<strong>with</strong> matching components and “high efficiency drives” –<br />

belt and <strong>direct</strong> drive.<br />

<strong>with</strong> integrated or external control to regulate speed.<br />

<strong>with</strong> IEC standard motors (IE2) or internal rotor motors <strong>with</strong><br />

brushless DC technology.<br />

and <strong>with</strong> AC external rotor motors or brushless DC external<br />

rotor motors.<br />

Building blocks for best values<br />

Thanks to the decades-long experience of <strong>Nicotra</strong> <strong>Gebhardt</strong> all the<br />

components of our fans contribute to their high performance.<br />

Impellers and blades are optimised for turbulence and therefore<br />

particularly efficient. An example: With the latest development,<br />

the RLM Evo impeller, the free-running centrifugal fans of<br />

<strong>Nicotra</strong> <strong>Gebhardt</strong> achieve system efficiency grades never reached<br />

before.<br />

In addition, the brushless DC drives which <strong>Nicotra</strong> <strong>Gebhardt</strong><br />

offers for its <strong>direct</strong> drive fans improve the system efficiency grades.<br />

The fan technology of <strong>Nicotra</strong> <strong>Gebhardt</strong> delivers highly<br />

efficient systems for all applications.<br />

C c<br />

η e<br />

η m η T η r<br />

P e(d) P e P u(s)<br />

A

DDM<br />

DDMB<br />

DD<br />

RZA<br />

RZP<br />

RZM<br />

TEM/REM<br />

B<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

6.000 m³/h<br />

P<br />

P<br />

P<br />

P<br />

P<br />

10.000 m³/h<br />

P<br />

P<br />

P<br />

P<br />

18.000 m³/h<br />

P<br />

P<br />

REM: 22.000 m³/h<br />

35.000 m³/h<br />

P<br />

100.000 m³/h<br />

P<br />

200.000 m³/h<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

40 °C<br />

P<br />

P<br />

60 °C<br />

Flow rate Media<br />

temperature<br />

P<br />

80 °C<br />

P<br />

P<br />

ATEX<br />

P<br />

P<br />

Voltage<br />

P<br />

P<br />

Brushless-DC<br />

Speed<br />

control<br />

P<br />

P<br />

P<br />

External Inverter<br />

P<br />

P<br />

P<br />

TEM: P<br />

P<br />

P<br />

P<br />

REM: P<br />

Forward curved blades<br />

galvanised sheet steel<br />

Backward curved<br />

blades<br />

coated steel<br />

P<br />

P<br />

P<br />

P<br />

≤ 0280<br />

P<br />

≥ 0315<br />

P<br />

P<br />

≤ 1000<br />

P<br />

≥ 1120<br />

P<br />

Galvanised steel<br />

P<br />

Coated steel<br />

Impeller Casing<br />

material<br />

P<br />

Single inlet<br />

Inlet<br />

type<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

Double inlet<br />

ErP status

2<br />

<strong>Nicotra</strong> <strong>Gebhardt</strong> technologies like ...<br />

Automated manufacture of compact <strong>scroll</strong> and impeller <strong>with</strong> forward<br />

curved blades<br />

proSELECTA II<br />

proSELECTA II is a technical selection program that allows you to<br />

configure your own individually designed fan. It provides you <strong>with</strong><br />

the opportunity to choose from the entire range of fan types and<br />

their associated options.<br />

Own AC and Brushless-DC motor production<br />

for optimal tuniung of motor and fan!<br />

Simple and reliable selection<br />

The result from proSELECTA II is the provision of all the technical<br />

data for your fan, including sound level data, dimension<br />

specifications and accessories. Apart from that, as a registered<br />

user, your purchase prices are provided. Additionally fully<br />

dimensioned drawings in dxf format are available, which can be<br />

downloaded and transferred straight into your CAD system.<br />

So that you can be sure. Models and options that are technically<br />

not permissible, are automatically excluded in proSELECTA II.<br />

So there is no chance that you will configure a “wrong” device<br />

option.<br />

You can register as a proSELECTA II user <strong>with</strong> us, which enables<br />

us to offer you faster order processing. What this means for you is:<br />

The complete configuration of your fan <strong>with</strong> its associated system<br />

accessories and belt drive layout.<br />

The possibility to produce fans that operate via a frequency<br />

inverter.<br />

The option of saving your own fan configuration on our server.<br />

The opportunity to modify your saved configuration, even over the<br />

phone to your <strong>Nicotra</strong> <strong>Gebhardt</strong> representative.

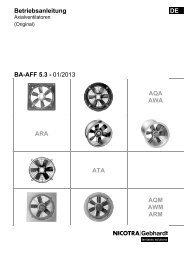

High performance centrifugal fans DDM<br />

double width, double inlet, (DWDI),<br />

<strong>with</strong> built-in, optimised external rotor motor,<br />

made of galvanised sheet steel;<br />

available in various models;<br />

Impeller <strong>with</strong> forward curved blades of galvanised steel plate<br />

High performance centrifugal fans DDMB<br />

double width, double inlet, (DWDI),<br />

<strong>with</strong> built-in, brushless DC external rotor motor and external commutation unit,<br />

made of galvanised sheet steel;<br />

available in various models;<br />

Impeller <strong>with</strong> forward curved blades of galvanised steel plate<br />

High performance centrifugal fans DD<br />

double width, double inlet, (DWDI),<br />

built-in, optimised internal rotor motor,<br />

made of galvanised sheet steel;<br />

available in various models;<br />

Impeller <strong>with</strong> forward curved blades of galvanised steel plate<br />

High performance centrifugal fans RZA rotavent<br />

double inlet,<br />

<strong>with</strong> built-in, low-slip external rotor motor,<br />

made of galvanised sheet steel or welded and coated,<br />

<strong>with</strong> multi position feet and connecting flange at discharge;<br />

Impeller <strong>with</strong> true aerofoil blades, welded and painted – system rotavent<br />

High performance centrifugal fans RZP rotavent<br />

double inlet,<br />

<strong>with</strong> built-in, brushless DC external rotor motor and external commutation unit,<br />

made of galvanised sheet steel;<br />

<strong>with</strong> multi position feet and connecting flange at discharge;<br />

Impeller <strong>with</strong> true aerofoil blades, welded and painted – system rotavent<br />

High performance centrifugal fans RZM rotavent<br />

double inlet,<br />

fan <strong>with</strong> <strong>direct</strong>ly coupled motor fitted on pedestal and base frame,<br />

made of galvanised sheet steel <strong>with</strong> heavy duty reinforced side frame,<br />

connecting flange at discharge,<br />

Impeller <strong>with</strong> true aerofoil blades, welded and painted – system rotavent<br />

High performance centrifugal fans REM/TEM<br />

single inlet, <strong>with</strong> flanged IEC standard motor out of air stream,<br />

in unterschiedlichen Ausführungsvarianten,<br />

Impeller <strong>with</strong> true aerofoil blades, welded and painted (REM)<br />

or forward curved blades of galvanised steel plate (TEM),<br />

<strong>with</strong> or <strong>with</strong>out pedestal for horizontal or vertical mounting<br />

Fittings / Accessories<br />

complete system accessories<br />

fittings and options<br />

Technical Description<br />

Descriptions<br />

Operating limits<br />

Notes<br />

3<br />

DDM<br />

DDMB<br />

DD<br />

RZA<br />

RZP<br />

RZM<br />

TEM<br />

REM<br />

Fittings<br />

Accessories<br />

Technical<br />

Description

228<br />

Highest system performance and best energy efficiency:<br />

The RZM rotavent serie.<br />

Economic, quiet and compact:<br />

Through the combination of two high technologies - the aerodynamics of the rotavent<br />

impeller combined <strong>with</strong> energy efficient IEC motors - <strong>Nicotra</strong> <strong>Gebhardt</strong> has developed<br />

a series of coupled <strong>direct</strong> <strong>driven</strong> centrifugal fans setting new standards for economy<br />

and quiet operation.<br />

Your benefits:<br />

• powerful fan range <strong>direct</strong> <strong>driven</strong> <strong>with</strong> coupling<br />

• maintenance and wear free drive (no V-belts)<br />

• short payback time due to high energy saving, especially <strong>with</strong> long operating<br />

periods<br />

• higher comfort levels through particularly low noise fans and motors<br />

• problem free speed control from <strong>with</strong> frequency inverter<br />

Top quality for performance and a long service life!<br />

Alongside an intelligent construction, aspects such as the quality of materials and<br />

workmanship play a crucial role in ensuring a long life cycle.<br />

Apart from that, the tried and tested quality of our successful, long-standing RZR series<br />

remains the same. And that means robust impeller constructions, non-corrosive<br />

impeller shafts and quality bearings – for a long life <strong>with</strong> minimum noise.

<strong>Nicotra</strong> <strong>Gebhardt</strong> RZM rotavent<br />

The powerful high technologie!<br />

Optimal aerodynamics<br />

Low turbulance velocity for both inlet and discharge due to the large<br />

free cross section and minimal flow restraint of the impeller, an example<br />

of aerodynamics and performance of the rotavent.<br />

Acoustics<br />

Reduction of high frequency noise levels is just one of the advantages<br />

of the rotavent, together <strong>with</strong> optimised AC-motors.<br />

Minimal sound levels due to low blade passing frequencies from the<br />

optimised impeller geometry of the rotavent. The impeller has obliquely<br />

inclined blades <strong>with</strong> trailing edges, and the throat plate is inclined<br />

opposingly.<br />

Your benefits:<br />

• negligible sensitivity to built in disturbances<br />

• minor pressure loss <strong>with</strong> free discharge operation<br />

• smaller, yet greater energy performance<br />

Your benefits:<br />

• reduced size and costs of attenuation and silencers<br />

High efficiencies<br />

<strong>Nicotra</strong> <strong>Gebhardt</strong> fans of the RZM rotavent range are operating at high Your benefits:<br />

efficiency in wide area of the fan curve.<br />

• low running costs<br />

Wear-free drive by <strong>direct</strong> coupling<br />

• high efficiency<br />

The use of <strong>direct</strong> coupling drive avoids wear of the drive as this is the Your benefits:<br />

case <strong>with</strong> belt <strong>driven</strong> fans.<br />

• no subsequent filter necessary<br />

The benefits of rotavent RZM<br />

• less dust in the system<br />

The high value and precisely manufactured components of rotavent, manufactured <strong>with</strong> most modern machinery for demanding tolerance standards,<br />

are the basis for a product range satisfying highest quality requirements.<br />

Version Description Figure<br />

RZM 15-0400/-1000<br />

RZM 18-0630/-1000<br />

RZM 13-1120/-1400<br />

Lap jointed <strong>scroll</strong> of galvanised steel sheet <strong>with</strong> discharge flange and heavy duty reinforced<br />

side frames.Medium-heavy duty bearing execution <strong>with</strong> cast iron housing/strut assemblies.<br />

High performance impeller <strong>with</strong> hollow section true aerofoil blades, welded and epoxy coated.<br />

Fan <strong>with</strong> motor and elastic coupling mounted on a robust base frame.<br />

Lap jointed <strong>scroll</strong> of galvanised steel sheet <strong>with</strong> discharge flange and heavy duty reinforced<br />

side frames.Heavy duty bearing execution <strong>with</strong> split-type plummer block, mounted on robust<br />

pedestal.High performance impeller <strong>with</strong> hollow section true aerofoil blades, welded and epoxy<br />

coated.Fan <strong>with</strong> motor and elastic coupling mounted on a robust base frame.<br />

Heavy duty casing of sheet steel <strong>with</strong> stiffening members, step welded and coated, <strong>with</strong><br />

discharge flange. Casing is split on one axis (Size 1120), split on two axis (Sizes 1250/-1400).<br />

Heavy duty bearing execution <strong>with</strong> split-type plummer blocks, mounted on robust pedestal.<br />

High performance impeller <strong>with</strong> hollow section true aerofoil blades, welded and epoxy coated.<br />

Fan <strong>with</strong> motor and elastic coupling mounted on a robust base frame.<br />

229

RZM ..-0400<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 406 mm<br />

Number of blades z 12<br />

Moment of Inertia J 0.33 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

� do not use in this area<br />

p F<br />

230<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

40<br />

Speed<br />

P a<br />

1.0<br />

0.4<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

1.0<br />

4.0<br />

f pd<br />

5.0<br />

8.0<br />

7.0<br />

6.0<br />

1.05<br />

72<br />

1.1<br />

Impeller Data<br />

Impeller weight m 10.5 kg<br />

Density of media r 1 1.2 kg/m³<br />

10<br />

kW<br />

75<br />

1.2<br />

1.3<br />

66%<br />

78<br />

A – 1.4<br />

0.5 0.6 0.7 0.8 0.9 1.0 1.5 2.0<br />

qV v 2<br />

2<br />

pd2 �1882 1/min<br />

Speed<br />

>1882 1/min<br />

2<br />

2000 3000 4000 5000 6000 8000<br />

15<br />

81<br />

75<br />

84<br />

87<br />

L WA 4;7<br />

80<br />

20<br />

90<br />

81<br />

93<br />

80<br />

96<br />

99<br />

� a (N max )<br />

70<br />

102<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

105<br />

50<br />

40<br />

A<br />

25<br />

108 dB<br />

m³/h<br />

4.0 5.0 6.0 7.0 8.0 9.0 m³/s<br />

3 4 5 6 7 8 9 10 15 20 30<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800 Pa<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

10000<br />

3.0<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

15000 20000<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

30000<br />

m/s<br />

1/min m/s<br />

3760 80<br />

3200<br />

2800<br />

2400<br />

2100<br />

1800<br />

1600<br />

1400<br />

1200<br />

1100<br />

N<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.99<br />

0.98<br />

0.97<br />

0.96<br />

0.95<br />

f�<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0400<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0400-4D-16 2.20 4 100La 400 3~ 50 D 4.75 1425 1760 62 164<br />

0400-4D-17 3.00 4 100Lb 400 3~ 50 D 6.30 1425 1950 68 192<br />

0400-4D-19 4.00 4 112M 400 3~ 50 D 8.20 1435 2160 75 192<br />

0400-4D-21 5.50 4 132Sa 400 3~ 50 D 11.40 1450 2390 82 264<br />

0400-4D-23 7.50 4 132Ma 400 3~ 50 D 15.40 1450 2650 91 264<br />

0400-2D-26 11.00 2 160Ma 400 3~ 50 D 21.50 2920 2970 51 151<br />

0400-2D-27 15.00 2 160Mb 400 3~ 50 D 29.00 2930 3300 56 151<br />

Dimensions in mm, subject to change.<br />

RZM 15-0400<br />

� 4×100<br />

Accessories<br />

G<br />

Ø10<br />

390<br />

� 504<br />

� 541<br />

� 567<br />

560<br />

526<br />

ZSR 51-0400 ZSG 01-0400 WBS 01-0400<br />

ZSG 15-2222<br />

ZKE 15-2222<br />

ZKF 15-2222<br />

� 507<br />

130<br />

30<br />

775<br />

667 767<br />

667<br />

302 463<br />

302<br />

179<br />

310<br />

263 263 263<br />

65<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

100<br />

112<br />

132<br />

160<br />

179<br />

773<br />

G<br />

1203<br />

1210<br />

1299<br />

1398<br />

RD 0 RD 90 RD 270<br />

Frequency Inverter Unit MM420<br />

for 3~ Line Choke for 3~ Frequency Inverter 6SE6430-<br />

369<br />

65<br />

671<br />

775<br />

179<br />

286<br />

65<br />

LG 0 LG 90 LG 270<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430-<br />

RZM 15-<br />

0400-4D-16 MM420 3AC 400V 2.20KW EMV B 6SE6400-3CC01-0BD3 - -<br />

0400-4D-17 MM420 3AC 400V 3.00KW EMV B 6SE6400-3CC01-0BD3 - -<br />

0400-4D-19 MM420 3AC 400V 4.00KW EMV B 6SE6400-3CC01-4BD3 - -<br />

0400-4D-21 MM420 3AC 400V 5.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0400-4D-23 MM420 3AC 400V 7.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0400-2D-26 MM420 3AC 400V 11.0KW EMV B 6SE6400-3CC02-5CD3 - -<br />

0400-2D-27 - 6SE6400-3CC03-5CD3 6SE6430-2AD31-5CA0 6SE6400-0BE00-0AA0<br />

231

RZM ..-0450<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 455 mm<br />

Number of blades z 12<br />

Moment of Inertia J 0.6 kgm²<br />

Technical Data<br />

Pa<br />

p F<br />

232<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

40<br />

Speed<br />

P a<br />

1.0<br />

0.5<br />

0.8<br />

0.7<br />

0.6<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

1.0<br />

4.0<br />

f pd<br />

8.0<br />

7.0<br />

6.0<br />

5.0<br />

72<br />

1.05<br />

10<br />

1.1<br />

0.6 0.7 0.8 0.9 1.0 1.5 2.0<br />

qV v 2<br />

2<br />

pd2 �1679 1/min<br />

Speed<br />

>1679 1/min<br />

2<br />

Impeller Data<br />

Impeller weight m 15.8 kg<br />

Density of media r 1 1.2 kg/m³<br />

75<br />

1.2<br />

kW<br />

15<br />

3000 4000 5000 6000 8000<br />

1.3<br />

66%<br />

78<br />

A – 1.4<br />

20<br />

81<br />

75<br />

84<br />

87<br />

L WA 4;7<br />

80<br />

25<br />

90<br />

81<br />

93<br />

80<br />

96<br />

99<br />

� a (N max )<br />

3 4 5 6 7 8 9 10 15 20 30<br />

70<br />

102<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

50<br />

105<br />

40<br />

25<br />

A<br />

108 dB<br />

40000 m³/h<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800 Pa<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

10000<br />

3.0<br />

15000 20000<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

4.0 5.0 6.0 7.0 8.0 9.0 10<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

30000<br />

m³/s<br />

m/s<br />

1/min m/s<br />

3360 80<br />

2800<br />

2400<br />

2100<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

N<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.99<br />

0.98<br />

0.97<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0450<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0450-4D-19 4.00 4 112M 400 3~ 50 D 8.20 1435 1770 61 182<br />

0450-4D-21 5.50 4 132Sa 400 3~ 50 D 11.40 1450 1960 67 210<br />

0450-4D-23 7.50 4 132Ma 400 3~ 50 D 15.40 1450 2180 75 210<br />

0450-4D-26 11.00 4 160Ma 400 3~ 50 D 22.00 1460 2480 85 281<br />

0450-4D-28 15.00 4 160L 400 3~ 50 D 30.00 1460 2760 94 281<br />

0450-2D-28 18.50 2 160L 400 3~ 50 D 35.00 2935 2940 50 281<br />

0450-2D-28 22.00 2 180M 400 3~ 50 D 41.00 2945 3080 52 319<br />

Dimensions in mm, subject to change.<br />

RZM 15-0450<br />

� 4×112<br />

k2<br />

Accessories<br />

G<br />

Ø12<br />

423<br />

� 566<br />

� 605<br />

� 640<br />

640<br />

606<br />

ZSR 51-0450 ZSG 01-0450 WBS 01-0450<br />

ZSG 15-2424<br />

ZKE 15-2424<br />

ZKF 15-2424<br />

� 569<br />

130<br />

35<br />

868<br />

750 863<br />

750<br />

342 522<br />

342<br />

202<br />

346<br />

303 303 303<br />

65<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

112<br />

132<br />

160<br />

180<br />

202<br />

868<br />

G<br />

1273<br />

1362<br />

1499<br />

1499<br />

RD 0 RD 90 RD 270<br />

Frequency Inverter Unit MM420<br />

for 3~ Line Choke for 3~ Frequency Inverter 6SE6430-<br />

413<br />

65<br />

755<br />

868<br />

202<br />

320<br />

65<br />

k2<br />

–<br />

–<br />

–<br />

78<br />

LG 0 LG 90 LG 270<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430-<br />

RZM 15-<br />

0450-4D-19 MM420 3AC 400V 4.00KW EMV B 6SE6400-3CC01-4BD3 - -<br />

0450-4D-21 MM420 3AC 400V 5.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0450-4D-23 MM420 3AC 400V 7.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0450-4D-26 MM420 3AC 400V 11.0KW EMV B 6SE6400-3CC02-5CD3 - -<br />

0450-4D-28 - 6SE6400-3CC03-5CD3 6SE6430-2AD31-5CA0 6SE6400-0BE00-0AA0<br />

0450-2D-28 - 6SE6400-3CC04-4DD0 6SE6430-2AD31-8DA0 6SE6400-0BE00-0AA0<br />

0450-2D-30 - 6SE6400-3CC04-4DD0 6SE6430-2AD32-2DA0 6SE6400-0BE00-0AA0<br />

233

RZM ..-0500<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 510 mm<br />

Number of blades z 12<br />

Moment of Inertia J 0.9 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

� do not use in this area<br />

p F<br />

234<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

40<br />

Speed<br />

P a<br />

1.0<br />

0.8<br />

0.7<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

4.0<br />

5.0<br />

1.0<br />

8.0<br />

7.0<br />

6.0<br />

0.8 0.9 1.0 1.5 2.0<br />

qV v 2<br />

2<br />

pd2 f pd<br />

10<br />

1.05<br />

3000 4000 5000 6000 8000<br />

2<br />

�1498 1/min<br />

Speed<br />

>1498 1/min<br />

72<br />

1.1<br />

Impeller Data<br />

Impeller weight m 19.9 kg<br />

Density of media r 1 1.2 kg/m³<br />

15<br />

20<br />

75<br />

1.2<br />

kW<br />

1.3<br />

68%<br />

78<br />

A – 1.4<br />

25<br />

81<br />

75<br />

30<br />

84<br />

87<br />

80<br />

L WA 4;7<br />

90<br />

82<br />

93<br />

80<br />

96<br />

99<br />

� a (N max )<br />

3 4 5 6 7 8 9 10 15 20 30<br />

70<br />

102<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

50<br />

105<br />

40<br />

25<br />

A<br />

108 dB<br />

40000 50000 m³/h<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

10000<br />

3.0<br />

15000 20000<br />

4.0 5.0 6.0 7.0 8.0 9.0 10<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

30000<br />

15 m³/s<br />

m/s<br />

Pa<br />

1/min m/s<br />

3000<br />

2700<br />

2400<br />

2100<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

900<br />

N<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.99<br />

0.98<br />

f�<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0500<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0500-4D-19 4.00 4 112M 400 3~ 50 D 8.20 1435 1470 51 205<br />

0500-4D-21 5.50 4 132Sa 400 3~ 50 D 11.40 1450 1630 56 234<br />

0500-4D-23 7.50 4 132Ma 400 3~ 50 D 15.40 1450 1820 62 234<br />

0500-4D-26 11.00 4 160Ma 400 3~ 50 D 22.00 1460 2070 70 298<br />

0500-4D-28 15.00 4 160L 400 3~ 50 D 30.00 1460 2300 78 298<br />

0500-4D-30 18.50 4 180M 400 3~ 50 D 35.50 1465 2470 84 336<br />

0500-4D-31 22.00 4 180L 400 3~ 50 D 42.00 1465 2610 89 336<br />

Dimensions in mm, subject to change.<br />

RZM 15-0500<br />

� 5×112<br />

k2<br />

Accessories<br />

G<br />

Ø12<br />

457<br />

� 635<br />

� 674<br />

� 708<br />

690<br />

656<br />

ZSR 51-0500 ZSG 01-0500 WBS 01-0500<br />

ZSG 15-2525<br />

ZKE 15-2525<br />

ZKF 15-2525<br />

� 638<br />

130<br />

35<br />

957<br />

821 950<br />

821<br />

370 574<br />

370<br />

220<br />

381<br />

328 328 328<br />

65<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

112<br />

132<br />

160<br />

180<br />

220<br />

955<br />

G<br />

1342<br />

1431<br />

1568<br />

1568<br />

RD 0 RD 90 RD 270<br />

Frequency Inverter Unit MM420<br />

for 3~ Line Choke for 3~ Frequency Inverter 6SE6430-<br />

457<br />

65<br />

827<br />

957<br />

220<br />

356<br />

65<br />

k2<br />

–<br />

–<br />

–<br />

27<br />

LG 0 LG 90 LG 270<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430-<br />

RZM 15-<br />

0500-4D-19 MM420 3AC 400V 4.00KW EMV B 6SE6400-3CC01-4BD3 - -<br />

0500-4D-21 MM420 3AC 400V 5.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0500-4D-23 MM420 3AC 400V 7.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0500-4D-26 MM420 3AC 400V 11.0KW EMV B 6SE6400-3CC02-5CD3 - -<br />

0500-4D-28 - 6SE6400-3CC03-5CD3 6SE6430-2AD31-5CA0 6SE6400-0BE00-0AA0<br />

0500-4D-30 - 6SE6400-3CC04-4DD0 6SE6430-2AD31-8DA0 6SE6400-0BE00-0AA0<br />

0500-4D-31 - 6SE6400-3CC04-4DD0 6SE6430-2AD32-2DA0 6SE6400-0BE00-0AA0<br />

235

RZM ..-0560<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 570 mm<br />

Number of blades z 12<br />

Moment of Inertia J 1.7 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

� do not use in this area<br />

236<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

p F<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

40<br />

Speed<br />

P a<br />

1.0<br />

0.8<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

4.0<br />

1.0 1.5 2.0<br />

qV v 2<br />

2<br />

pd2 �1340 1/min<br />

Speed<br />

>1340 1/min<br />

2<br />

8.0<br />

7.0<br />

6.0<br />

5.0<br />

1.0<br />

4000 5000 6000 8000<br />

f pd<br />

10<br />

72<br />

1.05<br />

15<br />

1.1<br />

Impeller Data<br />

Impeller weight m 30 kg<br />

Density of media r 1 1.2 kg/m³<br />

20<br />

75<br />

25<br />

1.2<br />

kW<br />

1.3<br />

78<br />

68%<br />

A – 1.4<br />

30<br />

81<br />

75<br />

84<br />

35<br />

87<br />

L WA 4;7<br />

80<br />

90<br />

82<br />

93<br />

96<br />

80<br />

99<br />

� a (N max )<br />

70<br />

102<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

105<br />

50<br />

40<br />

25<br />

A<br />

108 dB<br />

40000 50000 60000 m³/h<br />

3 4 5 6 7 8 9 10 15 20 30<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

10000<br />

3.0<br />

15000 20000<br />

30000<br />

4.0 5.0 6.0 7.0 8.0 9.0 10<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

15<br />

m³/s<br />

m/s<br />

Pa<br />

1/min m/s<br />

2680<br />

2400<br />

2100<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

900<br />

800<br />

N<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.99<br />

0.98<br />

0.97<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0560<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0560-4D-23 7.50 4 132Ma 400 3~ 50 D 15.40 1450 1500 51 276<br />

0560-4D-26 11.00 4 160Ma 400 3~ 50 D 22.00 1460 1710 58 343<br />

0560-4D-28 15.00 4 160L 400 3~ 50 D 30.00 1460 1900 65 343<br />

0560-4D-30 18.50 4 180M 400 3~ 50 D 35.50 1465 2040 69 380<br />

0560-4D-31 22.00 4 180L 400 3~ 50 D 42.00 1465 2160 73 380<br />

0560-4D-33 30.00 4 200La 400 3~ 50 D 56.00 1465 2400 82 518<br />

Dimensions in mm, subject to change.<br />

RZM 15-0560<br />

� 6×112<br />

k2<br />

Accessories<br />

G<br />

Ø12<br />

G1<br />

� 712<br />

� 751<br />

� 785<br />

770<br />

730<br />

ZSR 51-0560 ZSG 01-0560 WBS 01-0560<br />

ZSG 15-2727<br />

ZKE 15-2727<br />

ZKF 15-2727<br />

� 715<br />

130<br />

35<br />

k1<br />

1083<br />

914 1061<br />

914<br />

409 639<br />

409<br />

247<br />

431<br />

365 365 365<br />

G3<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

132<br />

160<br />

180<br />

200<br />

247<br />

1071<br />

G<br />

1540<br />

1734<br />

1734<br />

1774<br />

G1<br />

497<br />

497<br />

497<br />

518<br />

RD 0 RD 90 RD 270<br />

Frequency Inverter Unit MM420<br />

for 3~ Line Choke for 3~ Frequency Inverter 6SE6430-<br />

512<br />

G3<br />

G3<br />

80<br />

80<br />

80<br />

100<br />

921<br />

1083<br />

247<br />

405<br />

G3<br />

k1<br />

15<br />

15<br />

15<br />

–<br />

k2<br />

–<br />

–<br />

–<br />

1<br />

LG 0 LG 90 LG 270<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430-<br />

RZM 15-<br />

0560-4D-23 MM420 3AC 400V 7.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0560-4D-26 MM420 3AC 400V 11.0KW EMV B 6SE6400-3CC02-5CD3 - -<br />

0560-4D-28 - 6SE6400-3CC03-5CD3 6SE6430-2AD31-5CA0 6SE6400-0BE00-0AA0<br />

0560-4D-30 - 6SE6400-3CC04-4DD0 6SE6430-2AD31-8DA0 6SE6400-0BE00-0AA0<br />

0560-4D-31 - 6SE6400-3CC04-4DD0 6SE6430-2AD32-2DA0 6SE6400-0BE00-0AA0<br />

0560-4D-33 - 6SE6400-3CC05-2DD0 6SE6430-2AD33-0DA0 6SE6400-0BE00-0AA0<br />

237

RZM ..-0630<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 640 mm<br />

Number of blades z 12<br />

Moment of Inertia J 2.4 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

3500<br />

� RZM 18 only<br />

� do not use in this area<br />

p F<br />

238<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

P a<br />

1.0<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

4.0<br />

6.0<br />

5.0<br />

8.0<br />

7.0<br />

1.0<br />

40<br />

4000 5000 6000 8000 10000<br />

Speed<br />

q V<br />

v 2<br />

2<br />

pd2 �1194 1/min<br />

Speed<br />

>1194 1/min<br />

2<br />

1.5 2.0<br />

f pd<br />

10<br />

1.05<br />

15<br />

72<br />

20<br />

1.1<br />

Impeller Data<br />

Impeller weight m 38 kg<br />

Density of media r 1 1.2 kg/m³<br />

25<br />

75<br />

30<br />

1.2<br />

kW<br />

78<br />

1.3<br />

A – 1.4<br />

69%<br />

40<br />

35<br />

81<br />

75<br />

84<br />

45<br />

87<br />

L WA 4;7<br />

80<br />

90<br />

93<br />

82<br />

96<br />

80<br />

99<br />

� a (N max )<br />

3 4 5 6 7 8 9 10 15 20 30<br />

102<br />

70<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

105<br />

50<br />

40<br />

A<br />

25<br />

108 dB<br />

80000 m³/h<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

3.0<br />

15000 20000<br />

30000<br />

40000<br />

4.0 5.0 6.0 7.0 8.0 9.0 10 15<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

60000<br />

20<br />

m³/s<br />

m/s<br />

Pa<br />

1/min m/s<br />

2380<br />

2100<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

900<br />

800<br />

700<br />

N<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.99<br />

0.98<br />

0.97<br />

f�<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0630<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0630-6D-23 4.00 6 132Ma 400 3~ 50 D 9.30 950 1000 52 312<br />

0630-6D-24 5.50 6 132Mb 400 3~ 50 D 12.80 950 1110 58 312<br />

0630-6D-26 7.50 6 160Ma 400 3~ 50 D 17.60 970 1240 64 386<br />

0630-4D-28 15.00 4 160L 400 3~ 50 D 30.00 1460 1540 52 312<br />

0630-4D-30 18.50 4 180M 400 3~ 50 D 35.50 1465 1660 56 424<br />

0630-4D-31 22.00 4 180L 400 3~ 50 D 42.00 1465 1760 60 424<br />

Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 18- kW – V Hz A 1/min 1/min Hz kg<br />

0630-4D-34 30.00 4 200La 400 3~ 50 D 56.00 1465 1960 66 480<br />

0630-4D-36 37.00 4 225S 400 3~ 50 D 69.00 1475 2100 71 540<br />

Dimensions in mm, subject to change.<br />

RZM 15-0630<br />

RZM 18-0630<br />

� 6×112<br />

k2<br />

Accessories<br />

G<br />

Ø12<br />

G1<br />

� 798<br />

� 837<br />

� 871<br />

820<br />

780<br />

ZSR 51-0630 ZSG 01-0630 WBS 01-0630<br />

ZSG 15-2828<br />

ZKE 15-2828<br />

ZKF 15-2828<br />

� 801<br />

130<br />

35<br />

k1<br />

1204<br />

1021 1188<br />

1021<br />

454 715<br />

454<br />

279<br />

479<br />

390 390 390<br />

G3<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

132<br />

160<br />

180<br />

200<br />

225<br />

279<br />

1195<br />

G<br />

1629<br />

1766<br />

1766<br />

1940<br />

1964<br />

G1<br />

542<br />

542<br />

542<br />

561<br />

562<br />

RD 0 RD 90 RD 270<br />

Frequency Inverter Unit MM420<br />

for 3~ Line Choke for 3~ Frequency Inverter 6SE6430-<br />

574<br />

G3<br />

G3<br />

80<br />

80<br />

80<br />

100<br />

100<br />

1028<br />

1204<br />

279<br />

446<br />

G3<br />

k1<br />

16<br />

16<br />

16<br />

51<br />

51<br />

k2<br />

–<br />

–<br />

28<br />

–<br />

–<br />

LG 0 LG 90 LG 270<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430-<br />

RZM 15-<br />

0630-6D-23 MM420 3AC 400V 4.00KW EMV B 6SE6400-3CC01-4BD3 - -<br />

0630-6D-24 MM420 3AC 400V 5.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0630-6D-26 MM420 3AC 400V 7.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0630-4D-28 - 6SE6400-3CC03-5CD3 6SE6430-2AD31-5CA0 6SE6400-0BE00-0AA0<br />

0630-4D-30 - 6SE6400-3CC04-4DD0 6SE6430-2AD31-8DA0 6SE6400-0BE00-0AA0<br />

0630-4D-31 - 6SE6400-3CC04-4DD0 6SE6430-2AD32-2DA0 6SE6400-0BE00-0AA0<br />

RZM 18-<br />

0630-4D-34 - 6SE6400-3CC05-2DD0 6SE6430-2AD33-0DA0 6SE6400-0BE00-0AA0<br />

0630-4D-36 - 6SE6400-3CC08-3ED0 6SE6430-2AD33-7EA0 6SE6400-0BE00-0AA0<br />

239

RZM ..-0710<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 718 mm<br />

Number of blades z 12<br />

Moment of Inertia J 4.8 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

3500<br />

� RZM 18 only<br />

� do not use in this area<br />

p F<br />

240<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

P a<br />

1.0<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

4.0<br />

40<br />

5000 6000 8000 10000<br />

Speed<br />

1.5 2.0<br />

qV v 2<br />

2<br />

pd2 �1064 1/min<br />

Speed<br />

>1064 1/min<br />

2<br />

8.0<br />

7.0<br />

6.0<br />

5.0<br />

1.0<br />

10<br />

f pd<br />

15<br />

1.05<br />

72<br />

20<br />

1.1<br />

25<br />

Impeller Data<br />

Impeller weight m 52 kg<br />

Density of media r 1 1.2 kg/m³<br />

40<br />

35<br />

30<br />

75<br />

1.2<br />

78<br />

1.3<br />

kW<br />

A – 1.4<br />

69%<br />

45 50<br />

81<br />

75<br />

84<br />

60<br />

87<br />

90<br />

L WA 4;7<br />

80<br />

93<br />

83<br />

96<br />

99<br />

80<br />

102<br />

� a (N max )<br />

70<br />

105<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

50<br />

40<br />

108 dB<br />

3 4 5 6 7 8 9 10 15 20 30<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800 Pa<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

3.0<br />

15000 20000<br />

30000<br />

40000<br />

4.0 5.0 6.0 7.0 8.0 9.0 10 15<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

60000<br />

20<br />

80000<br />

A<br />

25<br />

m³/h<br />

m³/s<br />

m/s<br />

1/min m/s<br />

2120<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

N<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.99<br />

0.98<br />

0.97<br />

f�<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0710<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0710-6D-26 7.50 6 160Ma 400 3~ 50 D 17.60 970 1020 53 453<br />

0710-6D-28 11.00 6 160L 400 3~ 50 D 24.00 965 1160 60 453<br />

0710-6D-31 15.00 6 180L 400 3~ 50 D 29.50 965 1290 66 491<br />

0710-4D-31 22.00 4 180L 400 3~ 50 D 42.00 1465 1470 50 491<br />

0710-4D-33 30.00 4 200L 400 3~ 50 D 56.00 1465 1610 55 618<br />

0710-4D-36 37.00 4 225S 400 3~ 50 D 69.00 1475 1730 58 689<br />

0710-4D-36 45.00 4 225M 400 3~ 50 D 82.00 1475 1850 62 689<br />

Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 18- kW – V Hz A 1/min 1/min Hz kg<br />

0710-4D-39 55.00 4 250M 400 3~ 50 D 101.00 1480 1980 66 828<br />

Dimensions in mm, subject to change.<br />

RZM 15-0710<br />

RZM 18-0710<br />

� 7×112<br />

k2<br />

Accessories<br />

G<br />

Ø12<br />

610<br />

� 894<br />

� 934<br />

� 968<br />

940<br />

900<br />

ZSR 51-0710 ZSG 01-0710 WBS 01-0710<br />

ZSG 15-3030<br />

ZKE 15-3030<br />

ZKF 15-3030<br />

� 898<br />

130<br />

35<br />

k1<br />

1350<br />

1143 1333<br />

1143<br />

505 801<br />

505<br />

317<br />

540<br />

450 450 450<br />

100<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

160<br />

180<br />

200<br />

225<br />

250<br />

317<br />

1341<br />

G<br />

1936<br />

1936<br />

2039<br />

2039<br />

2185<br />

RD 0 RD 90 RD 270<br />

Frequency Inverter Unit MM420<br />

for 3~ Line Choke for 3~ Frequency Inverter 6SE6430-<br />

647<br />

100<br />

1152<br />

1350<br />

317<br />

493<br />

100<br />

k1<br />

31<br />

31<br />

31<br />

31<br />

92<br />

k2<br />

–<br />

6<br />

44<br />

25<br />

39<br />

LG 0 LG 90 LG 270<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430-<br />

RZM 15-<br />

0710-6D-26 MM420 3AC 400V 7.50KW EMV B 6SE6400-3CC02-2CD3 - -<br />

0710-6D-28 MM420 3AC 400V 11.0KW EMV B 6SE6400-3CC02-5CD3 - -<br />

0710-6D-31 - 6SE6400-3CC04-4DD0 6SE6430-2AD31-8DA0 6SE6400-0BE00-0AA0<br />

0710-4D-31 - 6SE6400-3CC04-4DD0 6SE6430-2AD32-2DA0 6SE6400-0BE00-0AA0<br />

0710-4D-33 - 6SE6400-3CC05-2DD0 6SE6430-2AD33-0DA0 6SE6400-0BE00-0AA0<br />

0710-4D-36 - 6SE6400-3CC08-3ED0 6SE6430-2AD33-7EA0 6SE6400-0BE00-0AA0<br />

0710-4D-37 - 6SE6400-3CC08-3ED0 6SE6430-2AD34-5EA0 6SE6400-0BE00-0AA0<br />

RZM 18-<br />

0710-4D-39 - 6SE6400-3CC11-2FD0 6SE6430-2AD35-5FA0 6SE6400-0BE00-0AA0<br />

241

RZM ..-0800<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 808 mm<br />

Number of blades z 12<br />

Moment of Inertia J 6.850 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

3500<br />

� RZM 18 only<br />

� do not use in this area<br />

p F<br />

242<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

40<br />

Speed<br />

q V<br />

v 2<br />

2<br />

pd2 �945 1/min<br />

Speed<br />

>945 1/min<br />

2<br />

P a<br />

2<br />

1.0<br />

1.5<br />

8000<br />

2.0<br />

2.5<br />

3.0<br />

10000<br />

3<br />

4.0<br />

8.0<br />

7.0<br />

6.0<br />

5.0<br />

10<br />

1.0<br />

15<br />

f pd<br />

20<br />

1.05<br />

75<br />

1.1<br />

Impeller Data<br />

Impeller weight m 69 kg<br />

Density of media r 1 1.2 kg/m³<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

1.2<br />

78<br />

kW<br />

1.3<br />

A – 1.4<br />

69%<br />

81<br />

60<br />

75<br />

84<br />

70<br />

87<br />

80<br />

90<br />

L WA 4;7<br />

93<br />

96<br />

84<br />

99<br />

80<br />

102<br />

� a (N max )<br />

70<br />

105<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

50<br />

40<br />

108 dB<br />

3 4 5 6 7 8 9 10 15 20 30<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

15000 20000<br />

4 5 6 7<br />

30000<br />

8 9<br />

40000<br />

10 15<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

60000 80000 100000<br />

20<br />

30<br />

25<br />

A<br />

m³/h<br />

m³/s<br />

m/s<br />

Pa<br />

1/min m/s<br />

1890<br />

1600<br />

1400<br />

1200<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

550<br />

N<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.995<br />

0.99<br />

f�<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0800<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0800-6D-28 11.00 6 160L 400 3~ 50 D 24.00 965 965 50 524<br />

0800-6D-31 15.00 6 180L 400 3~ 50 D 29.50 965 1050 54 562<br />

0800-6D-33 18.50 6 200La 400 3~ 50 D 37.00 975 1130 58 681<br />

0800-6D-34 22.00 6 200Lb 400 3~ 50 D 44.00 975 1200 61 681<br />

0800-6D-37 30.00 6 225M 400 3~ 50 D 58.00 978 1330 68 751<br />

0800-6D-39 37.00 6 250M 400 3~ 50 D 71.00 980 1430 73 898<br />

Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 18- kW – V Hz A 1/min 1/min Hz kg<br />

0800-4D-37 45.00 4 225M 400 3~ 50 D 82.00 1475 1510 51 865<br />

0800-4D-39 55.00 4 250M 400 3~ 50 D 101.00 1480 1615 54 970<br />

Dimensions in mm, subject to change.<br />

RZM 15-0800<br />

RZM 18-0800<br />

� 8×112<br />

k2<br />

Accessories<br />

G<br />

Ø12<br />

G1<br />

� 1003<br />

� 1043<br />

� 1087<br />

1040<br />

1000<br />

ZSR 51-0800 ZSG 01-0800 WBS 01-0800<br />

ZSG 15-3232<br />

ZKE 15-3232<br />

ZKF 15-3232<br />

� 1007<br />

130<br />

35<br />

k1<br />

1520<br />

1280 1499<br />

1280<br />

563 903<br />

563<br />

359<br />

607<br />

P1 P1 P1<br />

G3<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

160<br />

180<br />

200<br />

225<br />

250<br />

359<br />

1510<br />

G<br />

2046<br />

2046<br />

2149<br />

2210<br />

2299<br />

G1<br />

665<br />

665<br />

665<br />

665<br />

670<br />

RD 0 RD 90 RD 270<br />

Frequency Inverter Unit MM420<br />

for 3~ Line Choke for 3~ Frequency Inverter 6SE6430-<br />

727<br />

G3<br />

G3<br />

100<br />

100<br />

100<br />

100<br />

120<br />

1290<br />

1520<br />

359<br />

554<br />

G3<br />

k1<br />

30<br />

30<br />

30<br />

91<br />

86<br />

k2<br />

–<br />

–<br />

–<br />

25<br />

39<br />

P1<br />

500<br />

500<br />

500<br />

500<br />

495<br />

LG 0 LG 90 LG 270<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430-<br />

RZM 15-<br />

0800-6D-28 MM420 3AC 400V 11.0KW EMV B 6SE6400-3CC02-5CD3 - -<br />

0800-6D-31 - 6SE6400-3CC04-4DD0 6SE6430-2AD31-8DA0 6SE6400-0BE00-0AA0<br />

0800-6D-33 - 6SE6400-3CC04-4DD0 6SE6430-2AD32-2DA0 6SE6400-0BE00-0AA0<br />

0800-6D-34 - 6SE6400-3CC05-2DD0 6SE6430-2AD33-0DA0 6SE6400-0BE00-0AA0<br />

0800-6D-37 - 6SE6400-3CC08-3ED0 6SE6430-2AD33-7EA0 6SE6400-0BE00-0AA0<br />

0800-6D-39 - 6SE6400-3CC08-3ED0 6SE6430-2AD33-7EA0 6SE6400-0BE00-0AA0<br />

RZM 18-<br />

0800-4D-37 - 6SE6400-3CC08-3ED0 6SE6430-2AD34-5EA0 6SE6400-0BE00-0AA0<br />

0800-4D-39 - 6SE6400-3CC11-2FD0 6SE6430-2AD35-5FA0 6SE6400-0BE00-0AA0<br />

243

RZM ..-0900<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 905 mm<br />

Number of blades z 12<br />

Moment of Inertia J 15.5 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

3500<br />

� RZM 18 only<br />

� do not use in this area<br />

p F<br />

244<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

P a<br />

1.0<br />

2.0<br />

40<br />

8000 10000<br />

Speed<br />

q V<br />

v 2<br />

2<br />

pd2 �844 1/min<br />

Speed<br />

>844 1/min<br />

2<br />

3<br />

2.5<br />

3.0<br />

4.0<br />

8.0<br />

7.0<br />

6.0<br />

5.0<br />

10<br />

15<br />

1.0<br />

f pd<br />

20<br />

45<br />

40<br />

35<br />

30<br />

50<br />

25<br />

1.05<br />

75<br />

1.1<br />

Impeller Data<br />

Impeller weight m 109 kg<br />

Density of media r 1 1.2 kg/m³<br />

60<br />

78<br />

1.2<br />

kW<br />

1.3<br />

81<br />

A – 1.4<br />

69%<br />

80<br />

70<br />

84<br />

75<br />

87<br />

90<br />

80<br />

L WA 4;7<br />

100<br />

93<br />

96<br />

84<br />

99<br />

80<br />

102<br />

� a (N max )<br />

3 4 5 6 7 8 9 10 15 20 30<br />

105<br />

70<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

108<br />

50<br />

40<br />

25<br />

A<br />

111 dB<br />

150000 m³/h<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 V · Duty point<br />

opt<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

15000 20000<br />

4 5 6 7<br />

30000<br />

8 9<br />

40000<br />

10 15<br />

60000 80000 100000<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />

-3 0 -1 -3 -6 -8 -14 -21 dB<br />

-5 -3 -3 -3 -6 -7 -13 -21 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

-2 -1 -3 -1 -6 -10 -15 -21 dB<br />

-7 -4 -5 -1 -6 -9 -14 -21 dB<br />

-10 -7 -8 -1 -5 -8 -13 -21 dB<br />

-10 -8 -8 -2 -6 -8 -11 -18 dB<br />

20<br />

30<br />

40<br />

m³/s<br />

m/s<br />

Pa<br />

1/min m/s<br />

1690<br />

1400<br />

1200<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

550<br />

N<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

u<br />

1.0<br />

0.995<br />

f�<br />

Measured in installation B<br />

according to ISO 5801:<br />

Relative sound power level for discharge side L Wrel4 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

13 7 4 -3 -8 -14 -17 -25 dB<br />

10 5 3 -2 -7 -13 -17 -25 dB<br />

7 2 2 -2 -6 -12 -18 -27 dB<br />

5 1 1 -2 -6 -10 -17 -27 dB<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

11 4 2 0 -7 -12 -17 -24 dB<br />

7 1 -2 -3 -6 -10 -15 -23 dB<br />

3 -2 -4 -3 -5 -9 -14 -23 dB<br />

2 -3 -5 -3 -5 -9 -12 -21 dB

RZM ..-0900<br />

Technical Data<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 15- kW – V Hz A 1/min 1/min Hz kg<br />

0900-8D-31 11.00 8 180L 400 3~ 50 D 25.00 725 790 54 706<br />

0900-8D-33 15.00 8 200La 400 3~ 50 D 32.50 725 870 60 847<br />

0900-6D-34 22.00 6 200Lb 400 3~ 50 D 44.00 975 985 50 847<br />

0900-6D-37 30.00 6 225M 400 3~ 50 D 58.00 978 1100 56 981<br />

0900-6D-39 37.00 6 250M 400 3~ 50 D 71.00 980 1180 60 1028<br />

0900-6D-41 45.00 6 280S 400 3~ 50 D 84.00 985 1260 64 1265<br />

0900-6D-42 55.00 6 280M 400 3~ 50 D 100.00 985 1350 68 1265<br />

Technical Data<br />

Nominal<br />

motor<br />

current<br />

Max.<br />

operating<br />

frequency Weight<br />

Nominal<br />

Motor<br />

Nominal fre-<br />

Nominal Max. fan<br />

motor power Poles Motor size voltage Phases quency Connection<br />

motor speed speed<br />

RZM 18- kW – V Hz A 1/min 1/min Hz kg<br />

0900-4D-41 75.00 4 280S 400 3~ 50 D 137.00 1485 1485 50 1354<br />

Dimensions in mm, subject to change.<br />

RZM 15-0900<br />

RZM 18-0900<br />

� 8×125<br />

k2<br />

G<br />

Ø12<br />

734<br />

� 1126<br />

� 1174<br />

� 1220<br />

1180<br />

1130<br />

ZSR 51-0900 ZSG 01-0900 WBS 01-0900<br />

ZSG 15-3434<br />

ZKE 15-3434<br />

ZKF 15-3434<br />

� 1130<br />

130<br />

40<br />

k1<br />

1707<br />

1432 1687<br />

1432<br />

628 1016<br />

406<br />

628<br />

681<br />

565 565 565<br />

120<br />

RD 90 RD 0<br />

RD 270<br />

Motor<br />

180<br />

200<br />

225<br />

250<br />

280<br />

406<br />

1697<br />

G<br />

2246<br />

2246<br />

2292<br />

2376<br />

2508<br />

RD 0 RD 90 RD 270<br />

Accessories<br />

Frequency Inverter 6SE6430-<br />

Control Panel for Frequency Inverter<br />

6SE6420- and 6SE6430- Line Choke for 3~<br />

RZM 15-<br />

0900-8D-31 6SE6430-2AD31-5CA0 6SE6400-0BE00-0AA0 6SE6400-3CC03-5CD3<br />

0900-8D-33 6SE6430-2AD31-8DA0 6SE6400-0BE00-0AA0 6SE6400-3CC04-4DD0<br />

0900-6D-34 6SE6430-2AD33-0DA0 6SE6400-0BE00-0AA0 6SE6400-3CC05-2DD0<br />

0900-6D-37 6SE6430-2AD33-7EA0 6SE6400-0BE00-0AA0 6SE6400-3CC08-3ED0<br />

0900-6D-39 6SE6430-2AD33-7EA0 6SE6400-0BE00-0AA0 6SE6400-3CC08-3ED0<br />

0900-6D-41 6SE6430-2AD34-5EA0 6SE6400-0BE00-0AA0 6SE6400-3CC08-3ED0<br />

0900-6D-42<br />

RZM 18-<br />

6SE6430-2AD35-5FA0 6SE6400-0BE00-0AA0 6SE6400-3CC11-2FD0<br />

0900-4D-41 6SE6430-2AD37-5FA0 6SE6400-0BE00-0AA0 6SE6400-3CC11-2FD0<br />

816<br />

120<br />

1444<br />

1707<br />

406<br />

620<br />

120<br />

k1<br />

35<br />

35<br />

35<br />

35<br />

95<br />

k2<br />

–<br />

2<br />

25<br />

39<br />

40<br />

LG 0 LG 90 LG 270<br />

245

RZM ..-1000<br />

Technical Data<br />

Impeller Data<br />

Impeller diameter D r 1000 mm<br />

Number of blades z 12<br />

Moment of Inertia J 22 kgm²<br />

Technical Data<br />

Pa<br />

Please note coloured area!<br />

� all types suitable<br />

4000<br />

3500<br />

� RZM 18 only<br />

� do not use in this area<br />

p F<br />

246<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

800<br />

600<br />

500<br />

400<br />

300<br />

200<br />

150<br />

100<br />

80<br />

60<br />

40<br />

10000<br />

Speed<br />

3<br />

qV v 2<br />

2<br />

pd2 �764 1/min<br />

Speed<br />

>764 1/min<br />

P a<br />

1.0<br />

2<br />

2.5<br />

3.0<br />

4.0<br />

8.0<br />

7.0<br />

6.0<br />

5.0<br />

10<br />

15000 20000<br />

15<br />

1.0<br />

20<br />

f pd<br />

45<br />

40<br />

35<br />

30<br />

50<br />

25<br />

1.05<br />

75<br />

1.1<br />

Impeller Data<br />

Impeller weight m 133 kg<br />

Density of media r 1 1.2 kg/m³<br />

80<br />

70<br />

60<br />

78<br />

1.2<br />

kW<br />

81<br />

1.3<br />

A – 1.4<br />

69%<br />

100<br />

84<br />

75<br />

87<br />

90<br />

80<br />

93<br />

L WA 4;7<br />

96<br />

84<br />

99<br />

102<br />

80<br />

105<br />

� a (N max )<br />

70<br />

108<br />

Direct <strong>driven</strong> centrifugal fans / RZM / Technical Data<br />

60<br />

50<br />

40<br />

A<br />

25<br />

111 dB<br />

3 4 5 6 7 8 9 10 15 20 30<br />

3 4 5 6 8 10 20 30 40 50 60 80 100 200 300 400 600 800 Pa<br />

Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Duty point<br />

�0.8 qVopt >0.8–1.2 qVopt >1.2–1.6 qVopt >1.6 qVopt Normal<br />

operation area<br />

4 5 6 7<br />

30000<br />

8 9<br />

40000<br />

10 15<br />

60000 80000 100000<br />

Relative sound power level for inlet side L Wrel7 at octave centre<br />

frequencies f m<br />

63 125 250 500 1000 2000 4000 8000 Hz<br />

0 2 0 -3 -6 -9 -12 -19 dB<br />

-2 1 -2 -3 -6 -8 -14 -20 dB<br />