The future of CO2 cooling in particle physics - Www Group Slac ...

The future of CO2 cooling in particle physics - Www Group Slac ...

The future of CO2 cooling in particle physics - Www Group Slac ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

verlaat@nikhef.nl<br />

bverlaat@nikhef.nl<br />

bverlaat@nikhef.nl<br />

Evaporative CO 2 <strong>cool<strong>in</strong>g</strong> for thermal<br />

control <strong>of</strong> scientific equipments<br />

SLAC Advanced Instrumentation Sem<strong>in</strong>ars<br />

March 28, 2012, 1:30 PM, Kavli 3rd floor<br />

Bart Verlaat<br />

(Nikhef/CERN)<br />

1

verlaat@nikhef.nl<br />

CO 2 Cool<strong>in</strong>g Sem<strong>in</strong>ar<br />

• Introduction to 2phase <strong>cool<strong>in</strong>g</strong> and fluid<br />

trade-<strong>of</strong>f<br />

• CO 2 <strong>cool<strong>in</strong>g</strong> model<strong>in</strong>g<br />

• Introduction to the 2PACL CO 2 circulation<br />

method.<br />

• CO 2 <strong>cool<strong>in</strong>g</strong> <strong>in</strong> the AMS-Experiment.<br />

• CO 2 <strong>cool<strong>in</strong>g</strong> <strong>in</strong> the LHCb Velo Detector<br />

• Ongo<strong>in</strong>g projects.<br />

• Conclusions<br />

2

verlaat@nikhef.nl<br />

Temperature (°C)<br />

Pressure (Bar)<br />

90<br />

60<br />

30<br />

0<br />

-30<br />

What happens <strong>in</strong>side a <strong>cool<strong>in</strong>g</strong> tube?<br />

Heat<strong>in</strong>g a flow from liquid to gas<br />

Liquid<br />

Liquid<br />

Superheat<strong>in</strong>g<br />

Enthalpy (J/kg)<br />

Low ΔT<br />

2-phase<br />

Target flow condition<br />

Isotherm<br />

Sub cooled liquid 2-phase liquid / vapor<br />

Dry-out zone<br />

Gas<br />

Increas<strong>in</strong>g ΔT<br />

(Dry-out)<br />

3<br />

Super heated vapor

verlaat@nikhef.nl<br />

Cool<strong>in</strong>g efficiently scientific<br />

equipment.<br />

• What do we expect <strong>in</strong> general from a 2phase flow<br />

<strong>in</strong> scientific equipment?<br />

– Inside the equipment (Evaporator):<br />

• Small additional <strong>cool<strong>in</strong>g</strong> hardware (small diameter tub<strong>in</strong>g)<br />

• Large heat removal capacity<br />

• Low temperature gradients<br />

– Low gradient from tube wall to fluid<br />

– Low gradient over tube length (Isothermal)<br />

– Outside the equipment (Circulation system)<br />

• Stable temperature<br />

• Control over fluid condition <strong>in</strong> side evaporator<br />

• Which fluid is most suitable?<br />

4

Temperature<br />

bverlaat@nikhef.nl<br />

Temperature pr<strong>of</strong>iles<br />

• To compare different fluids it must be understood which mechanism<br />

contributes to the thermal performance.<br />

ΔT(ΔP)<br />

(Reduced<br />

diameter)<br />

ΔT(ΔP)<br />

Tube length<br />

ΔT(HTC)<br />

(Reduced<br />

diameter)<br />

ΔT(HTC)<br />

ΔT(ΔP+HTC)<br />

(Reduced<br />

diameter)<br />

ΔT(ΔP+HTC)<br />

• For efficient heat transfer: ΔT(ΔP+HTC) as small as possible<br />

• For isothermal heat transfer: ΔT(ΔP) as small as possible<br />

• As <strong>in</strong> general small <strong>cool<strong>in</strong>g</strong> tubes are preferred, so lets <strong>in</strong>troduce a new<br />

property to dist<strong>in</strong>guish the heat transfer relative to the needed volume<br />

Overall Volumetric Heat<br />

Q<br />

V tube*ΔT(ΔP+HTC))<br />

Isothermal Volumetric Heat<br />

Transfer Conduction (W/m3K): Transfer Conduction (W/m 3 K): V tube*ΔT(ΔP))<br />

Q<br />

5

verlaat@nikhef.nl Fluid<br />

• Fluid trade-<strong>of</strong>f regard<strong>in</strong>g<br />

temperature gradients, for<br />

simplicity:<br />

– Pressure drop: Friedel<br />

correlation<br />

– Heat transfer gradients:<br />

Kandlikar correlation.<br />

Temperature<br />

ΔT(ΔP)<br />

(Reduced<br />

diameter)<br />

ΔT(ΔP)<br />

Tube length<br />

Trade-<strong>of</strong>f (1)<br />

CO 2<br />

Heat Transfer<br />

dT(HTC)<br />

(Dashed l<strong>in</strong>es)<br />

ΔT(HTC)<br />

(Reduced<br />

diameter)<br />

Heat transfer gradients (°C)<br />

ΔT(HTC)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Heat transfer temperature gradients<br />

L=1 m, Q=100 W, T=-20 °C, VQ=0.5<br />

Total dT(dP+HTC)<br />

(Thick l<strong>in</strong>es)<br />

Pressure drop<br />

dT(dP)<br />

<strong>CO2</strong> (19.7 bar)<br />

Ethane (14.2 bar)<br />

R116 (10.5 bar)<br />

Propane (2.4 bar)<br />

R218 (2 bar)<br />

Ammonia (1.9 bar)<br />

R134a (1.3 bar)<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Tube diameter (mm)<br />

ΔT(ΔP+HTC)<br />

(Reduced<br />

diameter)<br />

ΔT(ΔP+HTC)<br />

6

Volumetric heat transfer conduction (W/mm 3 K)<br />

0.035<br />

0.03<br />

0.025<br />

0.02<br />

0.015<br />

0.01<br />

0.005<br />

bverlaat@nikhef.nl<br />

Overall volumetric heat transfer conduction<br />

L=1 m, Q=500 W, T=-20 °C, VQ=0.5<br />

CO 2<br />

Overall<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Tube diameter (mm)<br />

Fluid Trade-<strong>of</strong>f (2)<br />

<strong>CO2</strong> (19.7 bar)<br />

Ethane (14.2 bar)<br />

R116 (10.5 bar)<br />

Propane (2.4 bar)<br />

R218 (2 bar)<br />

Ammonia (1.9 bar)<br />

R134a (1.3 bar)<br />

Volumetric heat transfer conduction (W/mm 3 K)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Isothermal volumetric heat transfer conduction<br />

L=1 m, Q=500 W, T=-20 °C, VQ=0.5<br />

Isothermal<br />

CO 2<br />

<strong>CO2</strong> (19.7 bar)<br />

Ethane (14.2 bar)<br />

R116 (10.5 bar)<br />

Propane (2.4 bar)<br />

R218 (2 bar)<br />

Ammonia (1.9 bar)<br />

R134a (1.3 bar)<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Tube diameter (mm)<br />

• Translat<strong>in</strong>g the temperature gradients to the volumetric heat transfer<br />

conductance<br />

– Clearly visible: CO 2 is a w<strong>in</strong>ner <strong>in</strong> both overall and isothermal.<br />

– Another <strong>in</strong>terest<strong>in</strong>g phenomena: <strong>The</strong> higher the pressure the more<br />

efficient. Is this maybe the simple answer to the perfect fluid?<br />

7

verlaat@nikhef.nl<br />

Is high pressure the answer to<br />

an efficient <strong>cool<strong>in</strong>g</strong> fluid?<br />

• In fact it is, the higher the pressure:<br />

– <strong>The</strong> more the vapor stays compressed<br />

– <strong>The</strong> smaller the needed volume<br />

– But as well: lower gas speeds mean lower pressure<br />

drop.<br />

• Other properties are also important:<br />

– High latent heat (=less flow)<br />

– Low viscosity (=low pressure drop)<br />

– CO 2 is favorable for both properties.<br />

• And on top <strong>of</strong> that pressure drop is less significant<br />

at high pressures as it doesn’t effect the boil<strong>in</strong>g<br />

pressure as it would do at low pressure fluids.<br />

8

verlaat@nikhef.nl<br />

CO 2 a perfect <strong>cool<strong>in</strong>g</strong> fluid<br />

for scientific use<br />

• As shown, CO 2 is a really good candidate <strong>cool<strong>in</strong>g</strong> fluid<br />

if the follow<strong>in</strong>g properties are required (In general for<br />

scientific and high-tech equipment):<br />

– Low mass and low volume <strong>cool<strong>in</strong>g</strong> pipes<br />

– Isothermal behavior<br />

– High heat removal capacity<br />

• <strong>The</strong> stability <strong>in</strong> time is a merit <strong>of</strong> the attached <strong>cool<strong>in</strong>g</strong><br />

plant, here fore the 2PACL pr<strong>in</strong>ciple was <strong>in</strong>vented for<br />

<strong>particle</strong> detector <strong>cool<strong>in</strong>g</strong>.<br />

– However high pressure fluids are less sensitive to<br />

pressure changes, so <strong>in</strong> fact they are as well beneficial for<br />

stable temperature systems.<br />

9

verlaat@nikhef.nl CO<br />

2 heat transfer and<br />

pressure drop model<strong>in</strong>g<br />

• Nowadays good prediction models <strong>of</strong> CO 2 are<br />

available. Especially the models <strong>of</strong> J. Thome from<br />

EPFL Lausanne (Switzerland)<br />

– See SLAC’s Advanced Instrumentation Sem<strong>in</strong>ar talk by<br />

J.Thome @ 9 feb 2011<br />

• Models are flow pattern based and are reasonably well<br />

predict<strong>in</strong>g the flow conditions and the related heat<br />

transfer and pressure drop.<br />

• <strong>The</strong> Thome models are successfully used to predict<br />

the complex thermal behavior <strong>of</strong> <strong>particle</strong> detector<br />

<strong>cool<strong>in</strong>g</strong> circuits.<br />

• A simulation program called CoBra is developed to<br />

analyze full detector <strong>cool<strong>in</strong>g</strong> branches.<br />

10

verlaat@nikhef.nl<br />

Experimental heat transfer<br />

data (measured at SLAC)<br />

Interest<strong>in</strong>g research on<br />

heat transfer is done at<br />

SLAC <strong>in</strong> a jo<strong>in</strong>t effort<br />

with Nikhef.<br />

M. Oriunno (SLAC) &<br />

G. Hemm<strong>in</strong>k (Nikhef)<br />

11

verlaat@nikhef.nl<br />

P x,H x<br />

CoBra Calculator<br />

(<strong>CO2</strong> BRAnch Calculator)<br />

Q x = Q applied + Q environment +Q exchanged<br />

dP x= f(D,Q 1,MF,VQ,P,T) or f(Cv)<br />

dH x= Q tot/MF or pump work<br />

dP pump=∑dP all<br />

dH condenser = ∑dH all<br />

P x+1 = P x - dP x<br />

H x+1 = H x + dH x<br />

T x,VQ xand properties<br />

derived from Refprop<br />

• Iterative method chopp<strong>in</strong>g a long l<strong>in</strong>e <strong>in</strong> small elements (~1mm).<br />

• Model can read simple configuration files giv<strong>in</strong>g simple tube<br />

geometry<br />

• Heat leak and <strong>in</strong>ternal heat exchange between elements can be<br />

taken <strong>in</strong>to account.<br />

• CoBra is a very helpful tool for predict<strong>in</strong>g the complex behavior <strong>of</strong> 2phase<br />

flow.<br />

12<br />

Q x+1<br />

dP x+1<br />

dH x+1<br />

P x+2,H x+2

verlaat@nikhef.nl<br />

CoBra example calculation<br />

2mmID x 5m tube temperature and pressure pr<strong>of</strong>ile. MF=0.3g/s, Tsp=-30ºC, Q=90, x end =0.99<br />

Delta T (`C) & Delta P(Bar)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Liquid<br />

5mx1.5mmID tube (4m heated), Mass flow=0.3g/s, Q=90Watt , T=-30ºC<br />

Slug<br />

Annular<br />

dT Tube wall (ºC)<br />

dT Fluid (ºC)<br />

dP Fluid (Bar)<br />

Dry-out<br />

1<br />

-1<br />

0<br />

2<br />

0.5 1 1.5 2 2.5 3 3.5 4<br />

3<br />

4.5<br />

4<br />

5<br />

Branch length (m)<br />

0<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

• CoBra is able to analyze complex thermal<br />

behavior <strong>of</strong> CO 2 <strong>in</strong> long tubes<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

Bubbly<br />

Slug<br />

Stratified<br />

Annular<br />

Process path<br />

Stratified Wavy<br />

Dry-<br />

out<br />

Mist<br />

13

Delta T (`C) & Delta P(Bar)<br />

bverlaat@nikhef.nl<br />

Internal heat exchange and<br />

IBL temperature and pressure pr<strong>of</strong>ile. MF=0.8g/s, Tsp=-40ºC, Q=101.8, x end =0.5<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Stave TFoM: 13ºC*cm 2 /W<br />

Pixel maximum temperature:<br />

-24.2ºC<br />

Capillary<br />

Boil<strong>in</strong>g starts<br />

0<br />

1 2 3 4 56 78 9 10 11 12<br />

-2<br />

0 5 10 15 20 25<br />

Branch length (m)<br />

ambient heat<strong>in</strong>g<br />

dT Tube wall (ºC)<br />

dT Fluid (ºC)<br />

dP Fluid (Bar)<br />

dT Pixel Chip (ºC)<br />

IBL temperature and pressure pr<strong>of</strong>ile. MF=0.8g/s, Tsp=-40ºC, Q=101.8, x end =0.41<br />

0<br />

1 2 3 4 56 78 9 10 11 12<br />

-2<br />

0 5 10 15 20 25<br />

Figure 7: CoBra calculation example <strong>of</strong> the IBL <strong>cool<strong>in</strong>g</strong> tube. <strong>The</strong> branch has a 1mm <strong>in</strong>let (1-4), a 1.5 mm <strong>cool<strong>in</strong>g</strong> tube (4-<br />

8), a 2mm outlet (8-9) followed by a 3mm outlet (9-12). <strong>The</strong> dashed temperature pr<strong>of</strong>ile is the actual sensor temperature<br />

tak<strong>in</strong>g <strong>in</strong>to account the conductance <strong>of</strong> the support structure. <strong>The</strong> graph on the left has no <strong>in</strong>ternal heat exchange, the<br />

right graph takes <strong>in</strong>ternal heat exchange <strong>of</strong> the <strong>in</strong> and outlet tube <strong>in</strong>to account.<br />

Delta T (`C) & Delta P(Bar)<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Stave TFoM: 13ºC*cm 2 /W<br />

Pixel maximum temperature:<br />

-24.4ºC<br />

No Boil<strong>in</strong>g<br />

Branch length (m)<br />

Boil<strong>in</strong>g starts<br />

Figures from: DESIGN CONSIDERATIONS OF LONG LENGTH EVAPORATIVE <strong>CO2</strong> COOLING LINES<br />

Bart Verlaat and Joao Noite, GL-209, 10th IIF/IIR Gustav Lorentzen Conference on Natural Work<strong>in</strong>g Fluids, Delft, <strong>The</strong> Netherlands 2012<br />

dT Tube wall (ºC)<br />

dT Fluid (ºC)<br />

dP Fluid (Bar)<br />

dT Pixel Chip (ºC)<br />

14

verlaat@nikhef.nl<br />

Comparison to test results<br />

m = 1.48g/s | Q total = 256.87W | P <strong>in</strong> = 26.40Bar | T <strong>in</strong> = -17.40°C | dP = 6.33Bar | dT = 10.86°C<br />

Temperature [°C]<br />

-6<br />

-8<br />

-10<br />

-12<br />

-14<br />

-16<br />

-18<br />

Electronics (1.8mm)<br />

CMS-B-PIX<br />

Inlet tube (1.8mm)<br />

CMS detector<br />

(1.4mm)<br />

Exp. Wall Temperature<br />

<strong>The</strong>ory Wall Temperature<br />

<strong>The</strong>ory CO 2 Temperature<br />

<strong>The</strong>ory CO 2 Pressure<br />

-20<br />

0 5 10 15<br />

Loop Length [m]<br />

20<br />

Outlet tube (1.8mm)<br />

27<br />

26<br />

25<br />

24<br />

23<br />

22<br />

21<br />

IBL temperature and pressure pr<strong>of</strong>ile. MF=1.1g/s, Tsp=-26.71ºC, Q=73.5, x end =0.36<br />

12<br />

-1<br />

0 5<br />

3 4<br />

10<br />

56 78 9<br />

15<br />

10<br />

20<br />

1112<br />

25<br />

Branch length (m)<br />

Figure 8: Temperature and pressure test results <strong>of</strong> the CMS pixel upgrade <strong>cool<strong>in</strong>g</strong> branch (left) and the Atlas IBL<br />

<strong>cool<strong>in</strong>g</strong> branch (right). Comparison with the CoBra calculator showed that the calculator is a promis<strong>in</strong>g tool for<br />

predict<strong>in</strong>g the temperature and pressure gradients over long length <strong>cool<strong>in</strong>g</strong> branches.<br />

Pressure [Bar]<br />

Delta T (`C) & Delta P(Bar)<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Inlet tube<br />

(1mm)<br />

Atlas-IBL<br />

Detector<br />

(1.5mm)<br />

Outlet tube (2mm)<br />

dT Tube wall (ºC)<br />

dT Fluid (ºC)<br />

dP Fluid (Bar)<br />

Outlet tube<br />

(3mm)<br />

Figures from: DESIGN CONSIDERATIONS OF LONG LENGTH EVAPORATIVE <strong>CO2</strong> COOLING LINES<br />

Bart Verlaat and Joao Noite, GL-209, 10th IIF/IIR Gustav Lorentzen Conference on Natural Work<strong>in</strong>g Fluids, Delft, <strong>The</strong> Netherlands 2012<br />

15

Temperature (°C)<br />

Pressure (Bar)<br />

Pressure<br />

90<br />

60<br />

30<br />

0<br />

-30<br />

bverlaat@nikhef.nl What<br />

Liquid Vapor<br />

2-phase<br />

Enthalpy<br />

What happens <strong>in</strong>side a <strong>cool<strong>in</strong>g</strong> tube?<br />

Heat<strong>in</strong>g a flow from liquid to gas<br />

Liquid<br />

Liquid<br />

Superheat<strong>in</strong>g<br />

Enthalpy (J/kg)<br />

Low ΔT<br />

2-phase<br />

Target flow condition<br />

Sub cooled liquid 2-phase liquid / vapor<br />

circulation method can we use?<br />

Isotherm<br />

Dry-out zone<br />

Gas<br />

Increas<strong>in</strong>g ΔT<br />

(Dry-out)<br />

3<br />

Super heated vapor<br />

Refrigeration method:<br />

(Atlas)<br />

Compressor<br />

Cool<strong>in</strong>g plant<br />

BP. Regulator<br />

Vapor compression system<br />

Warm transfer<br />

Heater<br />

Detector<br />

If we remember slide 3, we see that proper<br />

<strong>cool<strong>in</strong>g</strong> takes place on the liquid side, while<br />

compressors need gas as <strong>in</strong>put. It is better to<br />

<strong>in</strong>vent a cycle stay<strong>in</strong>g on the liquid side.<br />

=> externally cooled pump cycle.

Pressure<br />

bverlaat@nikhef.nl New cycle for <strong>particle</strong> detectors: 2PACL<br />

(<strong>The</strong> 2-Phase Accumulator Controlled Loop )<br />

Liquid Vapor<br />

2-phase<br />

Enthalpy<br />

2PACL method:<br />

(LHCb)<br />

Compressor<br />

Chiller Liquid circulation<br />

Pumped liquid system,<br />

cooled externally<br />

Cold transfer<br />

• <strong>The</strong> 2PACL has the follow<strong>in</strong>g advantages:<br />

– Cycle stays on the liquid side, no heat required (experiment can be cooled unpowered<br />

and no control heaters required)<br />

– Evaporator pressure=(temperature) controlled with a 2-phase vessel away from the<br />

experiment. No local control nor sens<strong>in</strong>g needed!<br />

– All control hardware <strong>in</strong> a distant accessible <strong>cool<strong>in</strong>g</strong> plant<br />

– Primary <strong>cool<strong>in</strong>g</strong> can be anyth<strong>in</strong>g, no accurate temperature control needed as long as it<br />

is colder than the 2PACL 2-phase temperature.<br />

– Inlet fluid state def<strong>in</strong>ed by <strong>physics</strong> => saturated liquid.<br />

– Large temperature range (typical from room temperature down to -40°C)<br />

17<br />

Pump<br />

Cool<strong>in</strong>g plant Detector

verlaat@nikhef.nl<br />

Cool<strong>in</strong>g plant (controls &<br />

actuators) <strong>in</strong> a safe and<br />

accessible area<br />

HFC Chiller<br />

P 7<br />

1<br />

Condenser<br />

2PACL application <strong>in</strong> a<br />

2-Phase<br />

Accumulator<br />

Heat <strong>in</strong><br />

Pump<br />

<strong>particle</strong> detector<br />

Shield<strong>in</strong>g wall<br />

Long distance<br />

(50-100m)<br />

6<br />

2 3<br />

Transfer l<strong>in</strong>e<br />

(Heat exchanger)<br />

5<br />

Only passive pip<strong>in</strong>g <strong>in</strong><br />

detector area. Manifolds<br />

<strong>in</strong> accessible locations.<br />

Capillaries (3-4)<br />

for flow distribution<br />

Evaporator <strong>in</strong>side<br />

detector (4-5)<br />

4<br />

P 4-5<br />

18

verlaat@nikhef.nl<br />

Pressure control<br />

with accumulator.<br />

Change set-po<strong>in</strong>t.<br />

1<br />

7<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Red dot (detector)<br />

on saturation l<strong>in</strong>e.<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Enthalpy<br />

19

verlaat@nikhef.nl<br />

Lower<strong>in</strong>g saturation<br />

pressure<br />

7<br />

Cool<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red dot (detector)<br />

follows saturation l<strong>in</strong>e.<br />

Enthalpy<br />

20

verlaat@nikhef.nl<br />

Lower<strong>in</strong>g saturation<br />

pressure<br />

7<br />

Cool<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red dot (detector)<br />

follows saturation l<strong>in</strong>e.<br />

Enthalpy<br />

21

verlaat@nikhef.nl<br />

Lower<strong>in</strong>g saturation<br />

pressure<br />

7<br />

Cool<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red dot (detector)<br />

follows saturation l<strong>in</strong>e.<br />

Enthalpy<br />

22

verlaat@nikhef.nl<br />

Set po<strong>in</strong>t reached<br />

1<br />

7<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Enthalpy<br />

23

verlaat@nikhef.nl<br />

Increas<strong>in</strong>g saturation<br />

pressure<br />

7<br />

Heat<strong>in</strong>g<br />

1<br />

7<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red dot (detector)<br />

follows saturation l<strong>in</strong>e.<br />

Enthalpy<br />

24

verlaat@nikhef.nl<br />

Increas<strong>in</strong>g saturation<br />

pressure 7<br />

Heat<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red dot (detector)<br />

follows saturation l<strong>in</strong>e.<br />

Enthalpy<br />

25

verlaat@nikhef.nl<br />

Increas<strong>in</strong>g saturation<br />

pressure<br />

7<br />

Heat<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red dot (detector)<br />

follows saturation l<strong>in</strong>e.<br />

Enthalpy<br />

26

verlaat@nikhef.nl<br />

Set po<strong>in</strong>t reached<br />

1<br />

7<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Enthalpy<br />

27

verlaat@nikhef.nl<br />

Switch<strong>in</strong>g on detector<br />

1<br />

7<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Red dot (detector)<br />

evaporation starts.<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Enthalpy<br />

Heat<br />

28

verlaat@nikhef.nl<br />

Power<strong>in</strong>g detector<br />

Cool<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4 5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red l<strong>in</strong>e (detector)<br />

<strong>in</strong> evaporation.<br />

Enthalpy<br />

Heat<br />

29

verlaat@nikhef.nl<br />

Power<strong>in</strong>g detector<br />

Cool<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

3<br />

2-phase<br />

(Evaporation)<br />

4 5<br />

6<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red l<strong>in</strong>e (detector)<br />

<strong>in</strong> evaporation.<br />

Enthalpy<br />

Heat<br />

30

verlaat@nikhef.nl<br />

Detector is on<br />

1<br />

7<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

3<br />

2-phase<br />

(Evaporation)<br />

4 5<br />

6<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red l<strong>in</strong>e (detector)<br />

<strong>in</strong> evaporation.<br />

Enthalpy<br />

Heat<br />

31

verlaat@nikhef.nl<br />

Unpower<strong>in</strong>g detector<br />

Heat<strong>in</strong>g 7<br />

1<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4 5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Red l<strong>in</strong>e (detector)<br />

Evaporates.<br />

Enthalpy<br />

32

verlaat@nikhef.nl<br />

Detector power is <strong>of</strong>f<br />

1<br />

7<br />

2-Phase Accumulator Controlled Loop<br />

(2PACL)<br />

7<br />

Pump<br />

Pressure<br />

6<br />

2<br />

1<br />

Liquid<br />

2<br />

6<br />

3<br />

4&5<br />

2-phase<br />

(Evaporation)<br />

Isothermal l<strong>in</strong>e<br />

3<br />

5<br />

4<br />

Gas<br />

Enthalpy<br />

33

verlaat@nikhef.nl<br />

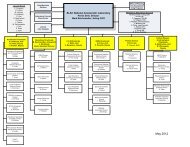

CO 2 <strong>cool<strong>in</strong>g</strong> projects <strong>in</strong><br />

<strong>particle</strong> <strong>physics</strong><br />

• 2 CO 2 <strong>cool<strong>in</strong>g</strong> systems have successfully been built for<br />

<strong>particle</strong> detectors<br />

– AMS-Tracker experiment on the International Space Station<br />

– LHCb-Velo experiment for the Large Hadron Collider at CERN<br />

• Many <strong>future</strong> CO 2 <strong>cool<strong>in</strong>g</strong> systems are under design:<br />

– Atlas Inner B-layer @ CERN<br />

– CMS upgrade pixel @ CERN<br />

– Belle-2 @ KEKb (Japan)<br />

• Some are foreseen for the far <strong>future</strong>:<br />

– CMS upgrade tracker @ CERN<br />

– Atlas upgrade pixel and tracker @ CERN<br />

– LC-TPC for the <strong>future</strong> L<strong>in</strong>ear Collider<br />

34

verlaat@nikhef.nl<br />

<strong>The</strong> 1 st CO 2 <strong>cool<strong>in</strong>g</strong> system <strong>in</strong> Space!<br />

A CO 2 <strong>cool<strong>in</strong>g</strong> system for Alpha Magnetic Spectrometer (AMS)<br />

Tracker Detector on the International Space station (ISS)<br />

CO 2 <strong>cool<strong>in</strong>g</strong><br />

radiator<br />

AMS <strong>in</strong> the Shuttle<br />

(STS-134, May 2011)<br />

AMS on the ISS<br />

35

verlaat@nikhef.nl<br />

MAGNETE<br />

AMS-Tracker <strong>The</strong>rmal Control System<br />

(AMS-TTCS)<br />

144 WATT<br />

TRD<br />

TOF<br />

TRACKER<br />

TOF<br />

RICH<br />

ECAL<br />

RADIATORE<br />

150 Watt detector with<br />

evaporator r<strong>in</strong>gs<br />

condensatori<br />

Primary <strong>cool<strong>in</strong>g</strong> not<br />

needed <strong>in</strong> space as<br />

environment is cold.<br />

Direct radiation to space<br />

Cool<strong>in</strong>g system<br />

component boxes<br />

(1 redundant)<br />

36

verlaat@nikhef.nl<br />

Tracker connections<br />

Inner plane silicon<br />

ladders<br />

AMS-Tracker with<br />

CO 2 <strong>cool<strong>in</strong>g</strong> r<strong>in</strong>gs.<br />

Inner plane thermal<br />

bars and hybrids<br />

Inner plane<br />

evaporator r<strong>in</strong>gs<br />

37

verlaat@nikhef.nl<br />

Temperature (°C)<br />

10<br />

5<br />

0<br />

-5<br />

-10<br />

-15<br />

-20<br />

-25<br />

AMS TTCS Cool<strong>in</strong>g<br />

performance <strong>in</strong> space (1)<br />

Evaporator partly s<strong>in</strong>gle<br />

phase (gradients)<br />

Heat<br />

exchanger<br />

heat<strong>in</strong>g<br />

1 orbit (~1.5hour)<br />

Accumulator<br />

set po<strong>in</strong>t<br />

change<br />

Evaporator<br />

fully 2-phase<br />

13:00 15:00 17:00 19:00 21:00 23:00 01:00<br />

Pump <strong>in</strong>let (PT02_P)<br />

Accumulator (PT01_P)<br />

Evaporator <strong>in</strong>let (DS13-P)<br />

Evap 1 (SensE)<br />

Evap 2 (SensG)<br />

Evap 3 (SensF)<br />

Vary<strong>in</strong>g CO 2 liquid<br />

due to orbital<br />

fluctuations<br />

Time(HH:MM)<br />

38

verlaat@nikhef.nl<br />

Temperature (°C)<br />

20<br />

15<br />

10<br />

5<br />

0<br />

-5<br />

-10<br />

-15<br />

-20<br />

-25<br />

-30<br />

08/06/11<br />

Soyuz<br />

dock<strong>in</strong>g<br />

AMS TTCS Cool<strong>in</strong>g<br />

performance <strong>in</strong> space (2)<br />

10/06/11<br />

12/06/11<br />

14/06/11<br />

Detector<br />

switched-<strong>of</strong>f<br />

Solar Panel<br />

orientation<br />

change<br />

16/06/11<br />

18/06/11<br />

20/06/11<br />

Pump <strong>in</strong>let (PT02_P)<br />

Accumulator (PT01_P)<br />

Evaporator <strong>in</strong>let (DS13-P)<br />

Evap 1 (SensE)<br />

Evap 2 (SensG)<br />

Evap 3 (SensF)<br />

Magnet Average<br />

Date (DD/MM/YY)<br />

39

verlaat@nikhef.nl<br />

AMS TTCS Cool<strong>in</strong>g<br />

performance <strong>in</strong> space (3)<br />

6 month stable at 0⁰C despite cold low beta periods<br />

40

verlaat@nikhef.nl<br />

VELO detector: 1.5 kW@-30°C<br />

(Runn<strong>in</strong>g successfully s<strong>in</strong>ce 2007)<br />

CO 2 <strong>cool<strong>in</strong>g</strong> projects <strong>in</strong> LHC<br />

27 km<br />

CMS pixel: 15 kW@-20°C<br />

(Operational 2014)<br />

LHC<br />

Atlas IBL: 1.5 kW@-40°C<br />

(Operational 2013)<br />

Ca. 100m<br />

41

verlaat@nikhef.nl<br />

LHCb-Velo <strong>The</strong>rmal Control System<br />

(LHCb-VTCS)<br />

Transfer tube<br />

Concentric assembly<br />

Evaporator<br />

Passive tub<strong>in</strong>g only Cool<strong>in</strong>g Plant<br />

All active hardware<br />

Cool<strong>in</strong>g capacity: 1.5 kW@-30°C<br />

42

verlaat@nikhef.nl VTCS<br />

Evaporator<br />

43

gas<br />

2-phase<br />

R507a<br />

chiller<br />

gas<br />

2-phase<br />

bverlaat@nikhef.nl<br />

Start–up <strong>of</strong> the VTCS dur<strong>in</strong>g October<br />

80<br />

2009 commission<strong>in</strong>g:<br />

8:40 - Start-up with set-po<strong>in</strong>t -5°C<br />

11:10 - Detector switched on<br />

60<br />

12:50 – Set po<strong>in</strong>t to -15°C<br />

15:30 - Set po<strong>in</strong>t to -25°C<br />

50<br />

17:10 - Set po<strong>in</strong>t to -30°C<br />

18:20 - Set po<strong>in</strong>t to -35°C (System Limit)<br />

19:10 - Set po<strong>in</strong>t to -34°C 40<br />

19:30 - Set po<strong>in</strong>t to -25°C<br />

20:00 - Detector Switched <strong>of</strong>f<br />

Condenser<br />

10<br />

Accumulator<br />

Transfer l<strong>in</strong>es<br />

Cool<strong>in</strong>g plant area (Ca. 10 50m) VELO area<br />

9<br />

Pump<br />

1 2<br />

8<br />

Accumulator Set-po<strong>in</strong>t temperature Silicon temperature (°C) (°C) Pump liquid Accumulator temperature Set-po<strong>in</strong>t (°C) temperature Evaporator (°C) saturation Pump liquid temperature (°C)<br />

Temperature(°C), Level(%)<br />

70<br />

30<br />

20<br />

0<br />

-10<br />

-20<br />

Concentric tube<br />

7<br />

3<br />

Restriction<br />

VTCS Commission<strong>in</strong>g results:<br />

Start-up and operation<br />

ator Set-po<strong>in</strong>t temperature (°C) Pump liquid temperature (°C) Evaporator saturation temperature (°C) Accumulator liquid level (%) Detector heat load (W)<br />

Temperature(°C), Level(%)<br />

4<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

-10<br />

-20<br />

-30<br />

-40<br />

-50<br />

-60<br />

09:00 12:00 15:00 18:00 21:00<br />

01-Oct-2009<br />

-25<br />

Time (hh:mm)<br />

5<br />

Silicon temperature (°C) Accumulator Set-po<strong>in</strong>t temperature (°C) Pump liquid temperature (°C) Evaporator saturation temperature (°C) Accumulator liquid<br />

Evaporator / Modules<br />

6<br />

10-Accu liquid level<br />

10-Accumulator set-po<strong>in</strong>t<br />

A<br />

Temperature(°C), Level(%)<br />

-26.4286<br />

-27.8571<br />

-29.2857<br />

-30.7143<br />

-32.1429<br />

-33.5714<br />

-35<br />

-36.4286<br />

-37.8571<br />

-39.2857<br />

-40.7143<br />

-42.1429<br />

Detector power<br />

A-Silicon temperature<br />

9-Pumped liquid<br />

-30°C SP<br />

-35°C SP<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

-34°C SP<br />

44<br />

Heatload (W)

Pressure (Bar)<br />

SP=21°C<br />

(Start-up)<br />

SP=-5°C<br />

bverlaat@nikhef.nl<br />

Freez<strong>in</strong>g<br />

(Solid/Liquid)<br />

SP=-15°C<br />

SP=-25°C<br />

SP=-30°C<br />

SP=-35°C<br />

VTCS Commission<strong>in</strong>g results:<br />

Start-up and operation <strong>in</strong> the PH-diagram<br />

T=-40°C<br />

9-Pump <strong>in</strong>let<br />

Liquid<br />

Enthalpy (kJ/kg)<br />

2-Phase<br />

(Liquid/Vapor)<br />

T=-40°C<br />

T=20°C<br />

T=0°C<br />

T=-20°C<br />

Start-up sequence<br />

1. Increase pressure to<br />

make liquid.<br />

2. Pump at high pressure<br />

and cool down <strong>in</strong> liquid<br />

mode<br />

3. Lower pressure to<br />

desired set-po<strong>in</strong>t<br />

4. Power-up detector<br />

Switch-<strong>of</strong>f detector<br />

Lowest possible set-po<strong>in</strong>t<br />

(liquid approaches<br />

saturation l<strong>in</strong>e)<br />

45

verlaat@nikhef.nl<br />

IBL detector:<br />

• Ø80mm x 800mm<br />

• 1.5 kW @ -40°C<br />

• 14 staves with 1 <strong>cool<strong>in</strong>g</strong> pipe<br />

New detector with smaller beam<br />

pipe <strong>in</strong> space <strong>of</strong> current beam pipe<br />

Atlas IBL-<strong>cool<strong>in</strong>g</strong> system (1)<br />

Carbon foam structure<br />

1.5mm ID titanium <strong>cool<strong>in</strong>g</strong> pipe<br />

Pixel detector<br />

chips<br />

(70watt/stave)<br />

46

verlaat@nikhef.nl<br />

CMS upgrade pixel <strong>cool<strong>in</strong>g</strong><br />

system<br />

• Replacement and<br />

upgrade <strong>of</strong> current<br />

pixel detector<br />

• 15kW @ -20ºC<br />

• Very long serial l<strong>in</strong>es<br />

with relative high heat<br />

flux<br />

F-PIX<br />

(Forward)<br />

47

verlaat@nikhef.nl<br />

KEK Belle-2 SVD and PXD<br />

Belle-2 PXD and SVD, 1.5 kW@-30ºC<br />

Common CO 2 <strong>cool<strong>in</strong>g</strong> plant<br />

development with Atlas IBL<br />

Belle-II SVD<br />

detector<br />

Belle-II pixel detector<br />

(Rapid Prototyp<strong>in</strong>g heat s<strong>in</strong>k)<br />

48

verlaat@nikhef.nl CO<br />

2 <strong>cool<strong>in</strong>g</strong> support<br />

Traci Cora Marco<br />

• To support the CO 2 <strong>cool<strong>in</strong>g</strong> projects <strong>in</strong> <strong>particle</strong> <strong>physics</strong> several test systems are under<br />

development:<br />

• Cora (CO 2 Research Apparatus)<br />

– Fixed test plant for CERN based research (0-2kW, +20 to -35ºC)<br />

• Marco (Multipurpose Apparatus for Research on CO 2<br />

– Fully automatic (User friendly) CO 2 test system for general use (0-2kW, +20 to -45ºC)<br />

– Base design for <strong>future</strong> on detector <strong>cool<strong>in</strong>g</strong> plants (Atlas IBL, Belle-2)<br />

• Traci (Transportable Refrigeration Apparatus for CO 2 Investigation)<br />

– Small test system for laboratory use<br />

– New simplified 2PACL concept to reduce cost and complexity (0-350W, +20 to -40ºC)<br />

49

Experiment<br />

connection<br />

4<br />

5<br />

Experiment<br />

vent<strong>in</strong>g<br />

bverlaat@nikhef.nl TRACI<br />

Local experiment box<br />

condenser<br />

Flow regulation<br />

compressor<br />

Transportable Refrigeration Apparatus for Co 2 Investigation<br />

Concentric hose<br />

P T<br />

5<br />

Heater<br />

TEV<br />

R404a Chiller<br />

T<br />

6<br />

R404a evaporator/<br />

CO 2 condenser<br />

T<br />

1<br />

TRACI layout<br />

CO 2 pump<br />

P,T<br />

3<br />

P 10<br />

T<br />

CO 2 loop<br />

Accumulator<br />

-50<br />

9:00 10:30 12:00 13:30 15:00 16:30<br />

Time (hh:mm)<br />

• TRACI: A simplified new concept for provid<strong>in</strong>g a conditioned CO 2 flow for<br />

<strong>cool<strong>in</strong>g</strong> research.<br />

• 2PACL pr<strong>in</strong>ciple simplified (few functions have been <strong>in</strong>tegrated)<br />

– Integrated 2PACL (I-2PACL )<br />

– Patent <strong>of</strong> I-2PACL concept filed<br />

• Goal: An easy to (mass) produce user friendly system<br />

– Operational from +25⁰C to -40 ⁰C<br />

– Initial <strong>cool<strong>in</strong>g</strong> power up to 350 Watt (depend<strong>in</strong>g on m<strong>in</strong>imum temperature)<br />

Temperature (°C)<br />

30<br />

20<br />

10<br />

0<br />

-10<br />

-20<br />

-30<br />

-40<br />

<strong>CO2</strong> Chart liquid temperature Title (at pump)<br />

<strong>CO2</strong> temperature<br />

Accumulator saturation temperature<br />

150 W on Power <strong>of</strong>f<br />

150 W on<br />

50

verlaat@nikhef.nl<br />

<strong>The</strong> TRACI factory<br />

• Prototypes are already “mass produced”<br />

– 2 have been build (Atlas & LHCb)<br />

– 3 under construction (Atlas, CMS & Nikhef/AIDA for<br />

development)<br />

– Investigat<strong>in</strong>g a start-up company for real production<br />

51

verlaat@nikhef.nl<br />

Commercial chiller<br />

TRACI a modular design<br />

CO 2 pip<strong>in</strong>g <strong>in</strong> a 2Dfoambox<br />

User <strong>in</strong>terface:<br />

• On/<strong>of</strong>f and reset buttons<br />

• Error <strong>in</strong>dication<br />

• Pressure controller<br />

Control: Simple<br />

conditioner and relay<br />

logic<br />

52

verlaat@nikhef.nl MARCO<br />

Multipurpose Apparatus for Research on CO 2<br />

• MARCO is prototype CO 2 2PACL<br />

system for multipurpose use.<br />

• User friendly<br />

– Automatic experiment connection<br />

– Automatic fill<strong>in</strong>g<br />

• Designed accord<strong>in</strong>g to CERN<br />

experiment standards.<br />

– Basel<strong>in</strong>e concept for the detectors IBL<br />

(CERN) and Belle-2 (KEK), common<br />

development with MPI-Munich.<br />

– PVSS-Unicos control <strong>in</strong>terface<br />

• Low temperature design<br />

– 2kW@-45ºC<br />

– Frequency controlled 2-stage chiller<br />

53

verlaat@nikhef.nl MARCO<br />

A CO 2 2PACL build <strong>in</strong> MPI<br />

production<br />

Controls build<br />

at CERN-DT<br />

2-stage chiller for IBL<br />

temperatures from<br />

ECR-Nederland<br />

54

verlaat@nikhef.nl<br />

Conclusions<br />

• CO 2 is a very good candidate fluid for applications were limited <strong>cool<strong>in</strong>g</strong><br />

space is available or limited additional mass is allowed.<br />

• CO 2 <strong>cool<strong>in</strong>g</strong> is a good candidate if high power densities are present and an<br />

isothermal heat s<strong>in</strong>k is required<br />

• CO 2 <strong>cool<strong>in</strong>g</strong> is widely accepted <strong>in</strong> Particle Physics community as the <strong>future</strong><br />

<strong>cool<strong>in</strong>g</strong> method for the <strong>in</strong>ner silicon detectors.<br />

• <strong>The</strong> 2PACL concept has proven to be a good method for controll<strong>in</strong>g<br />

evaporation conditions <strong>in</strong> distant set-ups<br />

• 2 CO 2 systems are operational <strong>in</strong> <strong>particle</strong> <strong>physics</strong> and perform well.<br />

• Several new systems are under development <strong>in</strong>clud<strong>in</strong>g systems for test<strong>in</strong>g<br />

55

verlaat@nikhef.nl<br />

It’s cold here, can you<br />

turn the <strong>cool<strong>in</strong>g</strong> <strong>of</strong>f?<br />

Questions?<br />

56