Zinn & The Art Of Mountain Bike Maintenance - VeloPress

Zinn & The Art Of Mountain Bike Maintenance - VeloPress

Zinn & The Art Of Mountain Bike Maintenance - VeloPress

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

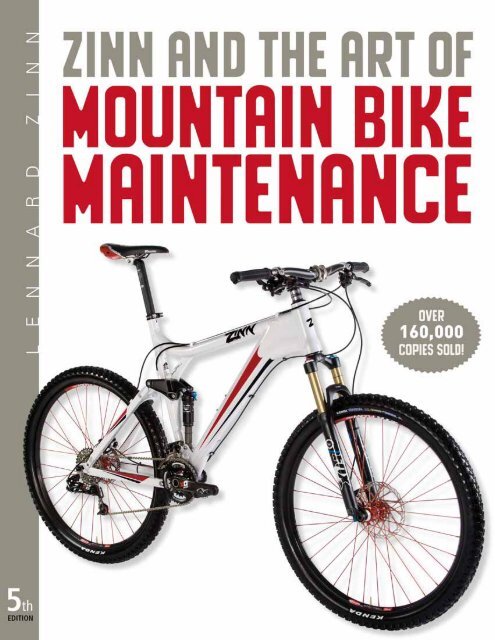

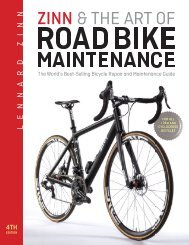

<strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th edition<br />

Text copyright © 2010 by Lennard <strong>Zinn</strong><br />

Illustrations copyright © 2010 by <strong>VeloPress</strong><br />

All rights reserved. Printed in the United States of America.<br />

No part of this book may be reproduced, stored in a retrieval system, or transmitted, in any form or by<br />

any means, electronic or photocopy or otherwise, without the prior written permission of the publisher<br />

except in the case of brief quotations within critical articles and reviews.<br />

1830 55th Street<br />

Boulder, Colorado 80301-2700 USA<br />

(303) 440-0601 · Fax (303) 444-6788 · E-mail velopress@competitorgroup.com<br />

Distributed in the United States and Canada by Ingram Publisher Services<br />

A Cataloging-in-Publication record for this book is available from the Library of Congress.<br />

ISBN: 978-1-934030-59-2<br />

For information on purchasing <strong>VeloPress</strong> books, please call (800) 811-4210 ext. 2169<br />

or visit www.velopress.com.<br />

This book is printed on 100 percent recovered/recycled fiber, 30 percent postconsumer waste,<br />

elemental chlorine free, using soy-based inks.<br />

Cover and interior design by Erin Johnson<br />

Composition by Erin Johnson and Jessica Xavier<br />

Cover photo by Brad Kaminski; bike built by Lennard <strong>Zinn</strong><br />

Custom paint job on cover bike by Spectrum Powder Works, Colorado Springs, CO<br />

Title font Sign Production JNL; body text Caecilia Roman<br />

10 11 12 / 11 10 9 8 7 6 5 4 3 2 1

CONTENTS<br />

A Tip of the Helmet to . . . ix<br />

Introduction xiii<br />

Chapters<br />

1 Tools 1<br />

2 Basic Stuff: Preride inspection, wheel removal,<br />

and general cleaning 15<br />

3 Emergency Repairs: How to get home when<br />

something big breaks or you get lost or hurt 33<br />

4 Chains 51<br />

5 Transmission: Front and rear derailleurs, cables,<br />

and shifters 71<br />

6 Wheels: Tires, rims and spokes, hubs, cassettes,<br />

and freewheels 111<br />

7 Brakes: Cables, levers, and calipers 147<br />

8 Cranksets 195<br />

9 Pedals 225<br />

10 Saddles and Seatposts 243<br />

11 Handlebars, Stems, and Headsets 257<br />

12 Wheelbuilding 291<br />

13 Forks 311<br />

14 Frames 347<br />

Appendixes<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

A Troubleshooting Index 371<br />

B Gear Development 377<br />

C <strong>Mountain</strong> <strong>Bike</strong> Fitting 383<br />

D Torque Table 393<br />

Glossary 409<br />

Bibliography 421<br />

Index 423<br />

Illustration Index 433<br />

About the Author and Illustrator 437

INTRODUCTION<br />

Peace of mind isn’t at all superficial, really. It’s the<br />

whole thing. That which produces it is good maintenance;<br />

that which disturbs it is poor maintenance.<br />

What we call workability of the machine is just an<br />

objectification of this peace of mind. <strong>The</strong> ultimate<br />

test’s always your own serenity. If you don’t have this<br />

when you start and maintain it while you’re working,<br />

you’re likely to build your personal problems right into<br />

the machine itself.<br />

—Robert M. Pirsig,<br />

Zen and the <strong>Art</strong> of Motorcycle <strong>Maintenance</strong><br />

ABOUT THIS BOOK<br />

This book is intended for people who have an<br />

interest in maintaining their own mountain<br />

bikes. I have written it for mountain bike owners<br />

who do not think they’re capable of maintain-<br />

ing their own bikes, as well as for those who do<br />

and who want the how-to details at their finger-<br />

tips. In Zen and the <strong>Art</strong> of Motorcycle <strong>Maintenance</strong>,<br />

Robert Pirsig explores the dichotomy between<br />

the purely classical and purely romantic views<br />

of the world, a dichotomy that also applies to<br />

mountain biking. Riding a mountain bike is<br />

generally a romantic experience of emotion,<br />

inspiration, and intuition, even when solving the<br />

complex physics of how to negotiate a technical<br />

section of trail without putting your foot down.<br />

<strong>Mountain</strong> bike mechanics, however, is a purely<br />

classical structure of underlying form dominated<br />

by reason and physical laws. <strong>The</strong> two practices—<br />

bike riding and bike maintenance—fit eloquently<br />

together. Each is designed to function in a par-<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

ticular way, and to have one without the other<br />

would be missing out on half the fun.<br />

<strong>The</strong> romantic can appreciate how success at<br />

bike mechanics requires that the procedures be<br />

done with love, without which the care you imag-<br />

ined putting into your mountain bike would be<br />

lost. And even the pure romantic can follow the<br />

simple step-by-step procedures and “exploded”<br />

diagrams in this book (of which Fig. I.1 is an<br />

extreme example and is the only one not intended<br />

to be simple and clear!) and discover a passion for<br />

spreading new grease on old parts.<br />

<strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong> is<br />

organized in such a way that you can pick main-<br />

tenance tasks appropriate for you. <strong>The</strong> repairs in<br />

these pages require no special skills to perform;<br />

anyone can do them. It takes only a willingness<br />

to learn.<br />

<strong>Mountain</strong> bikes are admirably resilient mach-<br />

ines. You can keep one running a long time just<br />

by changing the tires and occasionally lubricating xiii

xiv<br />

the chain. Chapter 2 is about the most minimal<br />

maintenance your bike requires. Even if that is<br />

the only part of this book you end up using, you’ll<br />

have gotten your money’s worth by avoiding some<br />

unpleasant experiences out on the trail.<br />

This book was originally intended for home<br />

enthusiasts, not shop mechanics. For that reason,<br />

I have not included the long and precise lists of<br />

parts specifications that a shop mechanic might<br />

need. Nonetheless, when combined with a speci-<br />

fication manual, this book can be a useful, easy-<br />

to-follow reference for shop mechanics, too.<br />

WHY DO IT YOURSELF?<br />

<strong>The</strong>re are a number of reasons why you would<br />

want to maintain your own mountain bike.<br />

Obviously, if done right, it is a lot cheaper to do<br />

yourself than to pay someone else to do it. This is<br />

certainly an important factor for those riders who<br />

live to ride and have no visible means of support.<br />

Self-maintenance is a necessity for that crew.<br />

As your income goes up and the time available<br />

to maintain your bike goes down, this becomes<br />

less and less true. If you’re a well-paid profes-<br />

sional with limited free time, it probably does<br />

not make as much economic sense to maintain<br />

your own bike. Yet you may find that you enjoy<br />

working on your bike for reasons other than<br />

just saving money. Unless you have a mechanic<br />

whom you trust and to whom you take your bike<br />

regularly, you are not likely to find anyone else<br />

who cares as much about your bicycle’s smooth<br />

operation and cleanliness as you do. You may also<br />

need your bike fixed faster than a local shop can<br />

do during its busy season. And you need to be<br />

able to fix mechanical breakdowns that occur on<br />

the trail.<br />

It is a given: Breakdowns will happen, even<br />

if you have the world’s best mechanic working<br />

on your bike. For this reason, it takes away from<br />

my enjoyment of a ride if I have something on<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

my bike that I do not understand well enough to<br />

know whether it is likely to last the ride or how to<br />

fix it if it does not.<br />

<strong>The</strong>re is an aspect of bicycle mechanics<br />

that can be extremely enjoyable in and of itself,<br />

almost independent of riding the bike. Bicycles<br />

are the epitome of elegant simplicity. Bicycle<br />

parts, particularly high-end components, are<br />

meant to work well and last a long time. With the<br />

proper attention, they can shine both in appear-<br />

ance and in performance for years to come.<br />

<strong>The</strong>re is real satisfaction in dismantling a filthy<br />

part that is not functioning well, cleaning it up,<br />

lubricating it with fresh grease, and reassembling<br />

it so that it works like new again. Knowing that<br />

I made those parts work so smoothly—and that I<br />

can do it again when they get dirty or worn—is<br />

rewarding. I am eager to ride hard to see how<br />

they hold up rather than being reluctant to ride<br />

for fear of breaking something.<br />

Also, if you share my stubborn unwillingness<br />

to throw something out and buy a replacement<br />

simply because it has quit working—be it a leaky<br />

Waterpik; a torn tent; a duffle bag with a broken<br />

zipper; or an old car, dishwasher, clock, or chain-<br />

saw that is no longer running well—then this<br />

book is for you. It is satisfying to keep an old piece<br />

of equipment running long past its time, and it’s a<br />

great learning experience!<br />

<strong>The</strong>re is also something very liberating about<br />

going on a long ride and knowing that you can<br />

fix just about anything that might go wrong with<br />

your bike out on the trail. Armed with this knowl-<br />

edge (which begins with learning to identify the<br />

parts of a mountain bike, shown in Fig. I.2) and<br />

the tools to put it into action, you will have more<br />

confidence to explore new areas and to go farther<br />

than you might have otherwise.<br />

To illustrate, an experience from way back in<br />

1995 comes to mind, when I took a day to ride<br />

the entire 110-mile White Rim Trail loop in Utah’s

Canyonlands National Park. It is as desolate as<br />

you can imagine out there, and I was completely<br />

alone with the sky, the sun, and the rocks for long<br />

stretches. I had a good mileage base in my legs, so<br />

I knew I was physically capable of doing the ride<br />

during the limited daylight hours of late October.<br />

I had checked, replaced, or adjusted practically<br />

every part of my bike in the days before the ride.<br />

I had also tried out the bike on long rides close to<br />

town. Finally, I added to my saddlebag tool kit a<br />

few tools that I do not ordinarily carry.<br />

I knew that there was very little chance of<br />

anything going wrong with my bike, and with the<br />

tools I had, I could fix almost anything short of a<br />

broken frame on the trail. Armed with this knowl-<br />

edge and experience, I really enjoyed the ride! I<br />

stopped and gawked at almost every breathtak-<br />

ing vista, vertical box canyon, colorful balanced<br />

rock, or windblown arch. I took scenic detours.<br />

I knew that I had a good cushion of safety, so I<br />

could totally immerse myself in the pleasure of<br />

the ride. I had no nagging fear of something going<br />

wrong to dilute the experience.<br />

Confidence in your mechanical ability allows<br />

you to be more courageous about what you will try<br />

on trails. And armed with this confidence you’ll<br />

be more willing to share your love of the sport<br />

with less experienced riders. Bringing new people<br />

along on rides is a lot more fun if you know that<br />

you can fix their bikes and they won’t be stranded<br />

with an old junker that won’t roll.<br />

HOW TO USE THIS BOOK<br />

Skim through the entire book. Skip the detailed<br />

steps, but look at the exploded diagrams and get<br />

the general flavor of the book and what’s inside.<br />

When it is time to perform a particular task,<br />

you’ll know where to find it, and you’ll have a<br />

basic idea of how to approach it.<br />

Illustrator Todd Telander and I have done our<br />

best to make these pages as understandable as<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

possible. Exploded diagrams are purposefully<br />

used instead of photographs to show more clearly<br />

how each part goes together. <strong>The</strong> first time you<br />

go through a procedure, you may find it easier to<br />

have a friend read the instructions out loud as you<br />

perform the steps.<br />

Obviously, some maintenance tasks are more<br />

complicated than others. I am convinced that<br />

anyone with an opposable thumb can perform<br />

virtually any repair on a bike. Still, it pays to spend<br />

some time getting familiar with the really simple<br />

tasks, such as fixing a flat, before throwing your-<br />

self into complex jobs, such as building a wheel.<br />

e LEVEL 1<br />

eeLEVEL 2<br />

eeeLEVEL 3<br />

Tasks and tools required are divided into<br />

three levels indicating their complexity or your<br />

proficiency. Level 1 tasks need level 1 tools and<br />

require of you only an eagerness to learn. Level 2<br />

and level 3 tasks also have corresponding tool sets<br />

and are progressively more difficult. All repairs<br />

mentioned in this book are classified as level 1<br />

unless otherwise indicated. Tools are shown in<br />

Chapter 1. <strong>The</strong> section at the end of Chapter 2,<br />

“Performing Mechanical Work: A General Guide”<br />

(§ii-17), is a must-read; it states general policies<br />

and approaches that apply to all mechanical work.<br />

Each chapter starts with a list of required tools<br />

in the margin. If a section involves a higher level<br />

of work, there will be an icon designating the level<br />

and tools necessary to perform the tasks in that<br />

section. Tasks and illustrations are numbered for<br />

easy reference. Section references use the sym-<br />

bol “§.” For instance, “§iii-6” means “see Section<br />

iii-6 in Chapter 3.” Illustrations are referred to as<br />

“Figures,” for instance, “Fig. 3.3.”<br />

INTRODUCTION<br />

xv<br />

INTRODUCTION

xx<br />

and 650B (27.5-inch) tires and wheels are gaining<br />

favor, particularly for tall riders. Smaller 24-inch<br />

wheels and tires are found on small mountain bikes.<br />

Tire widths and shapes vary and include everything<br />

from studded snow tires to smooth street tires. This<br />

book also covers “hybrid” bikes (Fig. I.5), which are a<br />

cross between road bikes and mountain bikes.<br />

No matter how a mountain bike is configured,<br />

even those who see themselves as having no<br />

mechanical skills will be able to tackle problems<br />

as they arise if they study the steps necessary<br />

to properly maintain and repair their bike. With<br />

a little bit of practice and a willingness to learn,<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

your bike will transform itself from a mysterious<br />

contraption seemingly too complicated to tamper<br />

with to a simple, very understandable machine<br />

that can be a genuine delight to work on. Just<br />

allow yourself the opportunity and the dignity to<br />

follow along, rather than deciding in advance that<br />

you will never be able to do this. All you have to<br />

do is follow the instructions and trust yourself.<br />

So, set aside your self-image as someone who<br />

is “not mechanically oriented” (and any other fac-<br />

tors that may stand in the way of your making<br />

your mountain bike ride like a dream), and let’s<br />

start playing with your bike!

Behold, we lay a tool here and on the morrow it is gone.<br />

—<strong>The</strong> Book of Mormon<br />

You can’t do much work on a bike without<br />

tools. Still, it’s not always clear exactly which<br />

tools to buy. This chapter clarifies the tools you<br />

should consider owning on the basis of your level<br />

of mechanical experience and interest.<br />

As I mentioned in the Introduction, the main-<br />

tenance and repair procedures in this book are<br />

classified by their degree of difficulty. Nearly all the<br />

repairs in this book are classified as level 1, unless<br />

otherwise indicated. <strong>The</strong> tools for levels 1, 2, and 3<br />

are pictured and described in the following pages.<br />

Lists of the tools needed in each chapter are shown<br />

in the margin at the beginning of each chapter.<br />

For the uninitiated, there is no need to rush<br />

out and buy a large number of bike-specific tools.<br />

With only a few exceptions, the Level 1 Tool Kit<br />

(Fig. 1.1A) consists of standard metric tools. This<br />

kit is similar to the collection of tools I recom-<br />

mend later in this chapter to carry with you on<br />

rides, though in a more compact and lightweight<br />

form (Figs. 1.5–6). <strong>The</strong> Level 2 Tool Kit (Fig. 1.2)<br />

contains several bike-specific tools, allowing you<br />

to do more complex work on the bike. <strong>The</strong> tools<br />

in the Level 3 Tool Kit (Fig. 1.3) are extensive (and<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

expensive), and they ensure that your riding bud-<br />

dies will show up not only to ask your sage advice,<br />

but also to borrow your tools.<br />

And if you really want to go all out and be set<br />

up like a pro (and even have mechanics wanting<br />

to borrow your tools), you can splurge on the set<br />

shown in Figure 1.4. If you loan tools, you might<br />

consider marking your collection to help recover<br />

those items that might otherwise take a long<br />

time finding their way back to your workshop.<br />

It wouldn’t hurt writing down the details about<br />

which tool you lent to whom and on what date.<br />

You would be surprised how easy it is to forget<br />

who has one of your seldom-used tools such as<br />

snapring pliers or a metric tap.<br />

LEVEL 1 TOOL KIT<br />

e LEVEL 1<br />

i-1<br />

Level 1 repairs are the simplest and do not<br />

require a workshop, although it is nice to have a<br />

good space to work. You will need the following<br />

tools (Fig. 1.1A):<br />

TOOLS<br />

1<br />

1

2<br />

• Tire pump with a gauge and a valve head<br />

to match your bike’s tubes (either Presta or<br />

Schrader valves—see Fig. 1.1B; most good pumps<br />

will fit both). A spare rubber valve-seal insert for<br />

the head is a good idea; these wear out.<br />

• Standard screwdrivers: small, medium, and<br />

large (one of each).<br />

• Phillips-head screwdrivers: one small and one<br />

medium.<br />

• Set of three plastic tire levers (Figs. 6.5–6).<br />

• At least two spare tubes of the same size and<br />

valve type as those on your bike.<br />

• Container of regular talcum powder. It works<br />

well for coating tubes and the inner casings<br />

of tires. Do not inhale this stuff; it’s bad for<br />

the lungs.<br />

• Patch kit. Choose one that comes with sand-<br />

paper instead of a metal scratcher and patches<br />

with soft orange rubber backing to the black<br />

rubber (Fig. 6.11). At least every year and a half,<br />

check that the glue has not dried up, regard-<br />

less of whether the tube has been opened or<br />

not. On rides, you might as well take a little<br />

packet of glueless patches; they don’t work as<br />

well as standard patches, but if the glue has<br />

dried up, you’ll be glad you have them.<br />

• One 6-inch adjustable wrench (aka “Crescent<br />

wrench”).<br />

• Pliers: regular and needle-nose.<br />

• Set of metric hex keys (aka “Allen wrenches”<br />

or “hex wrenches”) that includes 2.5mm, 3mm,<br />

4mm, 5mm, 6mm, 8mm, and 10mm sizes.<br />

Folding sets are available and work nicely to<br />

keep your wrenches organized but are not<br />

strong enough or long enough in the big sizes<br />

(6mm and up); big bolts require more leverage.<br />

I also recommend buying extras of the 4mm,<br />

5mm, 6mm, and 8mm sizes.<br />

• Set of metric open-end/box-end wrenches<br />

that includes 7mm, 8mm, 9mm, 10mm, 13mm,<br />

14mm, 15mm, and 17mm sizes.<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

1.1A Level 1 Tool Kit<br />

spare tube<br />

patch kit<br />

15mm pedal wrench<br />

modern shock pump<br />

tire levers<br />

grease<br />

• 15mm pedal wrench. This is thinner and lon-<br />

ger than a standard 15mm wrench and thicker<br />

than a cone wrench (Fig. 9.3). Your bike’s ped-<br />

als may accept only a 6mm or 8mm hex key<br />

(Fig. 9.4), so you may not need this tool.<br />

plenty of rags<br />

• Chain tool for disconnecting and reconnecting<br />

chain tool<br />

chain lube

spoke wrench<br />

talcum<br />

powder<br />

talc<br />

chain-elongation gauge<br />

noggin<br />

rubbing<br />

alcohol<br />

rubbing alcohol<br />

Schrader valve adapter<br />

for old Marzocchi and<br />

RockShox forks<br />

chains (Figs. 4.10–11). Older chain tools may<br />

be too wide for the narrow chains on newer<br />

bikes; read the Pro Tip in Chapter 4 before<br />

buying one.<br />

• Chain-elongation gauge to monitor the condi-<br />

tion of the chain (Figs. 4.5–6).<br />

needle-nose<br />

pliers<br />

tire<br />

pump<br />

with<br />

gauge<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

metric hex<br />

keys<br />

pliers<br />

folding metric<br />

hex keys<br />

standard and Phillipshead<br />

screwdrivers<br />

1.1B Valve types<br />

Presta<br />

6" adjustable wrench<br />

metric open-end/box-end wrenches<br />

Schrader<br />

CHAPTER 1<br />

3<br />

TOOLS

4<br />

• Spoke wrench to match the size of nipples<br />

used on your bike’s wheels.<br />

• Tube or jar of grease. I recommend using<br />

grease designed specifically for bicycles; how-<br />

ever, standard automotive grease is okay,<br />

except in suspension forks and twist shifters.<br />

• Drip bottle or can of chain lubricant (Fig. 4.1).<br />

Please choose a nonaerosol; it is easier to<br />

control, uses less packaging, and wastes less<br />

in overspray.<br />

• Rubbing alcohol for cleaning disc-brake pads,<br />

rotors, shocks, and internal parts and for<br />

removing and installing handlebar grips.<br />

• A lot of rags!<br />

Other useful items:<br />

• If you have an air-sprung suspension fork or<br />

rear shock, you need a shock pump. Get one<br />

with a no-leak head if the front or rear shock<br />

has standard Schrader valves (Fig. 13.10),<br />

and get the adapter you need if your bike’s<br />

fork requires either a ball needle or a spe-<br />

cial adapter to insert down inside a sunken<br />

Schrader valve.<br />

LEVEL 2 TOOL KIT<br />

eeLEVEL 2<br />

i-2<br />

Level 2 repairs are a bit more complex, and I<br />

recommend that you create a well-organized<br />

workspace with a shop bench. Keeping your work-<br />

space organized is probably the best way to make<br />

maintenance and repair easy and quick. You will<br />

need the entire Level 1 Tool Kit (Fig. 1.1A) plus the<br />

following tools (Fig. 1.2):<br />

�� Portable bike stand. Be sure that the stand is<br />

sturdy enough to remain stable when you’re<br />

really cranking on the wrenches. If for some<br />

reason you can’t clamp your bike’s seatpost,<br />

you will need a bike stand that holds the bike<br />

by the bottom bracket and the front or rear end<br />

with one wheel out; see the one in Figure 1.4.<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

1.2 Level2ToolKit<br />

Channel-lock<br />

pliers<br />

snapring<br />

pliers<br />

duct tape<br />

tire pressure<br />

gauge<br />

sound system<br />

portable bike<br />

stand<br />

rubber gloves<br />

ball-peen hammer<br />

splined pedalspindle<br />

removal<br />

tool

A chain is only as strong as its weakest link.<br />

—Anonymous<br />

A sausage is only as good as its last link.<br />

bike chain is a simple series of links connected<br />

A by rivets. Rollers surround each rivet between<br />

the link plates and engage the teeth of the cogs<br />

and chainrings. It is an extremely efficient method<br />

of transmitting mechanical energy from the ped-<br />

als to the rear wheel. In terms of weight, cost, and<br />

efficiency, the bicycle chain has no equal, and—<br />

believe me—people have tried without success to<br />

improve on it for years.<br />

To keep your bike running smoothly, you have<br />

to take care of the chain. It needs to be kept clean<br />

and well lubricated in order to transmit your<br />

energy efficiently and shift smoothly. Chains need<br />

to be replaced frequently to prolong the working<br />

life of other, more expensive, drivetrain compo-<br />

nents because a chain gets longer as its internal<br />

parts wear, thus contacting the gear teeth differ-<br />

ently than intended.<br />

CHAIN SERVICE AND ASSEMBLY<br />

iv-1<br />

LUBRICATING THE CHAIN<br />

When lubricating the chain, use a lubricant<br />

intended for bicycle chains. If you want to get<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

—Bluto<br />

fancy about it, you can assess the type of condi-<br />

tions in which you ride and choose a lubricant<br />

intended for those conditions. Some lubricants<br />

are dry and pick up less dirt in dry conditions.<br />

Some are sticky and therefore less likely to<br />

wash off in wet conditions. Still others claim to<br />

be “metal conditioners” that actually penetrate<br />

and alter the surface of the metal. One of these,<br />

ProGold’s ProLink, gives me longer chain life in all<br />

riding conditions, with daily use, than anything<br />

else I have tried, so that’s what I use. I’m not say-<br />

ing that there aren’t other equally good products,<br />

but by recommending one that I know is good,<br />

I can cut down on the e-mails asking me what<br />

chain lube I suggest.<br />

Chain lubes generally come in spray cans and<br />

in squeeze bottles. Sprays should be avoided for<br />

regular maintenance chores because they tend<br />

to spew too much oil over everything, includ-<br />

ing in the air where you can inhale the lube. <strong>The</strong><br />

chain needs oil only between contacting parts.<br />

On the outside, a thin film is sufficient to keep<br />

corrosion at bay; more than that will only attract<br />

dirt and gunk without improving the function of<br />

the chain.<br />

CHAINS<br />

TOOLS<br />

4<br />

chain lubricant<br />

12-inch ruler<br />

chain tool<br />

lots of rags<br />

rubber gloves<br />

OPTIONAL<br />

chain-elongation<br />

indicator<br />

master link pliers<br />

solvent (citrus<br />

based)<br />

self-contained chain<br />

cleaner<br />

old water bottle<br />

caliper<br />

pliers<br />

solvent tank<br />

Rohloff cog-wear<br />

indicator<br />

51

52<br />

4.1 Lubing the chain<br />

1. Drip a small amount of lubricant across each<br />

roller (Fig. 4.1). Periodically move the chain so<br />

that you can easily access the links you are<br />

working on. To speed the process, turn the<br />

crank slowly while dripping lubricant onto<br />

the chain as it goes by. Yes, this method will<br />

cause you to apply excess lubricant, which<br />

will pick up more dirt. But overlubricating is<br />

far preferable to not lubricating, and if you<br />

wipe and lube the chain after each ride or<br />

two, it won’t build up excessive grime.<br />

4.2 Wiping the chain with a rag<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

2. Wipe the chain off lightly with a rag. In wet<br />

conditions, expect to use more lubricant (after<br />

every ride or even during a long, rainy ride).<br />

iv-2<br />

CLEANING THE CHAIN BY FREQUENT<br />

WIPING AND LUBRICATION<br />

Cleaning the chain can be accomplished in<br />

a number of ways. <strong>The</strong> simplest method to<br />

maintain a chain is to wipe it down frequently,<br />

lubricate it, and then wipe off the excess lube. If<br />

you do this procedure before every ride, you will<br />

never need to clean the chain with a solvent.<br />

<strong>The</strong> lubricant softens the old sludge buildup,<br />

which is driven out of the chain when you<br />

ride. <strong>Of</strong> course, the lubricant also picks up new<br />

dirt and grime, but if you wipe them off before<br />

they’re driven deep into the chain and relubri-<br />

cate the chain frequently, it will stay clean and<br />

supple. Chain cleaning can be performed as fol-<br />

lows with the bike standing on the ground or in<br />

a bike stand:

4.3 Wiping the jockey wheels with a rag 4.4 Using a solvent-bath chain cleaner<br />

1. Grab the chain with a rag. Grasp the lower<br />

length of the chain (between the bottom of<br />

the chainring and the rear-derailleur lower<br />

jockey wheel).<br />

2. Turn the crank backward a number of revo-<br />

lutions. Pull the chain through the rag (Fig.<br />

4.2). Periodically rotate the rag to present a<br />

cleaner section of it to the chain.<br />

3. Lubricate the chain as in §iv-1.<br />

To encourage regular care, leave a pair of rub-<br />

ber gloves, a rag, and some chain lube next to your<br />

bike. <strong>The</strong>n, whenever you return from a ride, put on<br />

the gloves, wipe and lube the chain, and put your<br />

bike away. It takes maybe a minute, your hands<br />

stay clean, and your bike is ready for the next ride.<br />

If you can find time to take a shower after you ride,<br />

you can find time for this. Wipe the chainrings,<br />

cogs, front derailleur, and jockey wheels (Fig. 4.3)<br />

while you’re at it, and the entire drivetrain will<br />

always work ideally.<br />

iv-3<br />

USING CHAIN-CLEANING UNITS<br />

Several companies make chain-cleaning units<br />

that scrub the chain with a solvent while it is<br />

on the bike. <strong>The</strong>se chain cleaners are generally<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

made of clear plastic and have two or three<br />

rotating brushes that scrub the chain as it moves<br />

through the solvent bath (Fig. 4.4). <strong>The</strong> units offer<br />

the advantage of letting you clean the chain<br />

without removing it from the bike. Regularly<br />

removing the chain shortens any chain’s life;<br />

moreover, with 9- or 10-speed chains unless you<br />

use a master link, you may find that the chain<br />

breaks under high load, thereby driving your foot,<br />

and perhaps your entire body, into the ground.<br />

Most chain-cleaning units come with a non-<br />

toxic, citrus-based solvent. For your safety, and<br />

other environmental reasons, I strongly recom-<br />

mend that you purchase nontoxic citrus solvents<br />

for the chain-cleaning unit, even if it already<br />

comes with a petroleum-based solvent. If you<br />

recycle used diesel fuel, then go ahead and use it.<br />

In any case, wear gloves and glasses when using<br />

any solvent.<br />

Citrus chain solvents often contain some<br />

lubricants, so they won’t dry the chain out. <strong>The</strong><br />

combination of lubricant and solvent is why diesel<br />

fuel has had such a following as a chain cleaner.<br />

A really strong solvent without lubricant (acetone,<br />

for example) will displace the oil from inside the<br />

rollers. <strong>The</strong> solvent will later evaporate, leaving a<br />

CHAPTER 4<br />

53<br />

CHAINS

54<br />

dry, squeaking chain that is hard to rehabilitate.<br />

<strong>The</strong> same can happen with a citrus-based solvent<br />

that does not include a lubricant if no lubricant is<br />

separately applied, especially if the chain is not<br />

allowed to dry long enough. <strong>The</strong> procedure for<br />

using a chain-cleaning unit is straightforward:<br />

1. Remove the top and pour in the solvent up<br />

to the fill line.<br />

2. Place the chain-cleaning unit up against the<br />

bottom of the chain. Reinstall the top so that<br />

the chain runs through it (Fig. 4.4).<br />

3. Turn the bike’s crank backward. Run the<br />

chain through the unit’s brushes until it is<br />

clean.<br />

4. Remove the unit from the chain.<br />

5. Lubricate the chain as in §iv-1.<br />

6. Let the solvent settle, decant the clear por-<br />

tion, and discard the sludge.<br />

iv-4<br />

REMOVING AND CLEANING THE CHAIN<br />

e LEVEL 1<br />

You can also clean the chain by removing it from<br />

the bicycle and cleaning it in a solvent. I do not<br />

recommend this procedure unless the chain has<br />

a master link, because repeatedly disassembling<br />

the chain by pushing rivets in and out weakens it.<br />

<strong>Mountain</strong> bike chains are prone to break-<br />

age because of the conditions in which they are<br />

used, but chain breakage is even more of an issue<br />

because of the narrow width of 9- and 10-speed<br />

chains. A chain that breaks during riding gener-<br />

ally does so when you shift the front derailleur<br />

while pedaling hard. This technique can pry a<br />

link plate open so that the head of a rivet pops<br />

out of the plate, tearing the chain apart. Chain<br />

disassembly and reassembly expand the size of<br />

the rivet hole where you put the chain together,<br />

allowing the rivet to pop out more easily. Shimano<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

supplies special “subpins” for reassembly of its<br />

chains that are meant to prevent this problem,<br />

but the chain is still not as strong there as if you<br />

had left the original pin in place.<br />

A hand-opened master link can avoid the<br />

problem of repeatedly opening and reassembling<br />

the chain. Master links are standard on SRAM,<br />

Wippermann, Taya, and KMC chains. An after-<br />

market master link, like Lickton’s SuperLink, can<br />

also be installed into any chain so long as you<br />

make sure that the master link is the right width.<br />

If you do disassemble the chain (see §iv-7<br />

or §iv-11 for instructions), you can clean it well,<br />

even without a solvent tank. Just drop the chain<br />

into an old jar or water bottle half filled with sol-<br />

vent. Using an old water bottle or jar allows you<br />

to clean the chain without touching or breathing<br />

the solvent—something to be avoided even when<br />

you are using citrus solvents.<br />

<strong>The</strong> procedure for cleaning the chain without<br />

using a chain-cleaning unit could not be simpler:<br />

1. Remove the chain from the bike (§iv-7 or<br />

§iv-11).<br />

2. Drop it in a water bottle or jar.<br />

3. Pour in enough solvent to cover the chain.<br />

4. Shake the bottle vigorously. Keep it low to<br />

the ground in case the top pops off or the jar<br />

breaks.<br />

5. Hang the chain to air-dry.<br />

6. Reassemble it on the bike (see §iv-8 to<br />

§iv-11).<br />

7. Lubricate it as in §iv-1.<br />

Whatever you do, don’t leave the chain to<br />

soak for extended periods in citrus-based sol-<br />

vents, because these are water based and will<br />

cause the chain to oxidize (rust), making it move<br />

with more friction and be more prone to break-<br />

age. (Some people believe in having two chains<br />

they rotate on and off the bike, leaving one soak-<br />

ing in solvent while the other one is on the bike.

Although this would work with diesel fuel as the<br />

solvent, it won’t work with water-based solvents.<br />

In any case, you gain nothing by soaking the chain<br />

for extended periods, so just don’t do it.)<br />

After removing the chain, allow the solvent<br />

in the bottle or jar to settle for a few days so that<br />

you can decant the clear stuff and use it again. I’ll<br />

say this throughout the book: Use a citrus-based<br />

solvent. It is not only safer for the environment;<br />

it is also gentler on your skin and less harmful<br />

to breathe. Wear rubber gloves when working<br />

with any solvent, and use a respirator meant for<br />

volatile organic compounds if you are not using<br />

a citrus-based solvent. <strong>The</strong>re is no sense in fixing<br />

your bike to go faster if you end up becoming a<br />

slow, sickly bike rider.<br />

iv-5<br />

REPLACING THE CHAIN<br />

e LEVEL 1<br />

As the rollers, pins, and plates wear out, the<br />

chain lengthens. That, in turn, hastens the wear<br />

and tear on other drivetrain parts. An elongated<br />

chain concentrates the load on each individual<br />

gear tooth, rather than distributing it over all of<br />

the teeth that the chain is wrapped around, and<br />

as a result the gear teeth become hook-shaped<br />

and the tooth valleys become wider. If such wear<br />

has already occurred, a new chain will not solve<br />

the problem. A new chain will not mesh prop-<br />

erly with deformed teeth, and it is likely to skip<br />

whenever you pedal hard. So before all of that<br />

extra wear and tear hits your pocketbook, get in<br />

the habit of checking the chain on a regular basis<br />

(§iv-6) and replacing it as needed.<br />

How long it takes for the chain to wear out<br />

will vary, depending on chain type, maintenance,<br />

riding conditions, and strength and weight of the<br />

rider. Figure on replacing the chain every 500 to<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

1,000 miles, especially for bikes ridden in dirty<br />

conditions by a large rider. Lighter riders riding<br />

mostly on paved roads can often extend replace-<br />

ment time to more than 2,000 miles.<br />

iv-6<br />

CHECKING FOR CHAIN ELONGATION<br />

e LEVEL 1<br />

a. Chain-elongation gauges<br />

<strong>The</strong> simplest accurate method for checking chain<br />

elongation is to use a gauge. Make sure you check a<br />

number of spots on the chain; you’ll find variation.<br />

<strong>The</strong> Rohloff gauge (Fig. 4.5) is simple, quick,<br />

and reliable. It’s a go/no-go gauge. Brace the hook<br />

end against a chain roller, and if the opposing<br />

curved tooth falls completely into the chain so<br />

that the length of the tool’s body contacts it, the<br />

chain is shot. If the chain is still in good shape, the<br />

curved tooth will not go all of the way in. <strong>The</strong> tooth<br />

marked “S” is for checking a chain running strictly<br />

on steel rear cogs, and the tooth marked “A” is for<br />

checking aluminum and titanium cogs, but I use<br />

just the A side. I find that if the A edge comes down<br />

to the chain and I replace it right then, I get almost<br />

infinite life out of my chainrings and cogs, even<br />

titanium ones. That’s worth it to me.<br />

<strong>The</strong> ProGold chain gauge (Fig. 4.6) is also quick<br />

and accurate. Brace the hooked end against a<br />

chain roller, and let the long tooth drop into the<br />

4.5 Checking chain wear with the Rohloff gauge.<br />

If the curved tooth with the S (steel cogs)<br />

falls completely into the chain, replace the<br />

chain (A is for aluminum cogs).<br />

CHAPTER 4<br />

55<br />

CHAINS

198<br />

“Square taper,” “Octalink,” and “ISIS” are three<br />

different bottom-bracket and crankarm interface<br />

standards. Square-taper bottom-bracket spindles are<br />

square on the end (Figs. 8.1, 8.18, 8.21–23) and fit into<br />

a square hole in the crankarm. <strong>The</strong> spindle ends are<br />

tapered (at a 2-degree angle) to tighten into the crank<br />

as the arm is pushed into the spindle. ISIS (Fig. 8.19)<br />

and Shimano Octalink (Fig. 8.20) are both oversized<br />

hollow spindles (aka “pipe spindles”) with longitudinal<br />

splines on the ends.<br />

3. Unscrew the crank puller’s (Fig. 8.6) center<br />

push bolt so that its tip is flush with the<br />

face of the tool. Make sure the flat end of<br />

the push bolt is the right size for the bottom<br />

bracket; the push bolt end is much smaller<br />

for a square-taper spindle than for an ISIS or<br />

a Shimano Octalink splined spindle.<br />

4. Thread the crank puller into the hole in the<br />

crankarm. Be sure that you thread it in (by<br />

hand) as far as it can go; otherwise, you will<br />

not engage sufficient crank threads when you<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

tighten the push bolt, and you will damage<br />

the threads. Future crank removal depends<br />

on those threads being in good condition.<br />

5. Tighten the push bolt clockwise (Fig. 8.6)<br />

until the crankarm pulls off the spindle. Use<br />

a socket wrench or the included handle.<br />

6. Unscrew the puller from the crankarm.<br />

Installation<br />

a. Integrated-spindle cranks with two pinch<br />

bolts on the left arm<br />

e LEVEL 1<br />

1. Grease the spindle tip and the bore of each<br />

bearing.<br />

2. Push the spindle (which is attached to the<br />

right crankarm) in through the bearings from<br />

the drive side.<br />

3. Slide the left arm onto the end of the spindle.<br />

Check that the crank is at 180 degrees from<br />

the right arm.<br />

8.5 Removing and installing a Shimano 2007–2010 XTR FC-M970 crankset<br />

spindle<br />

right<br />

crankarm<br />

right<br />

bearing<br />

cup<br />

TL-FC35<br />

crankarm<br />

removal<br />

tool<br />

spacer<br />

TL-FC17<br />

adjusting<br />

nut tool<br />

spindle cover<br />

with O-rings<br />

bolt<br />

spacer<br />

washer adjusting nut<br />

left bearing cup<br />

left crankarm<br />

(Attention: left-hand thread!)<br />

washer<br />

retainer<br />

bolt

INDEX<br />

Adjustable cups, 207, 215, 216, 221,<br />

409<br />

Air compressors, 11, 122, 154<br />

Air pressure, 318, 320, 326–327<br />

Air-sleeves, servicing, 353, 354, 355<br />

Alignment tool, 10<br />

Antiseize compound, 28, 200<br />

Antitwist tool, 9<br />

Automatic transmission fluid (ATF),<br />

336, 337<br />

Axle-clamp tool, 10<br />

Axle nuts, 15, 20<br />

Axles, 30, 212, 299, 409<br />

checking, 19<br />

cleaning, 130<br />

removing, 129<br />

replacing, 235<br />

securing, 23–24<br />

through-, 20–22, 23, 128<br />

Ball bearings, 142, 174, 203, 204,<br />

207, 218, 231, 234, 358, 359,<br />

360, 361, 409<br />

angular-contact, 272, 277, 278,<br />

279, 281<br />

ceramic, 136, 217, 219<br />

cleaning, 130–131, 133, 221, 237,<br />

277, 280<br />

loose, 278, 279<br />

lubricating, 131, 132, 281, 286<br />

orienting, 218–219, 278<br />

overtightening, 272<br />

press-in, 211, 279<br />

replacing, 130, 131, 217–220, 277,<br />

280, 282, 359–360<br />

sealed, 416<br />

standard, 280<br />

steel, 136, 217<br />

See also Cartridge bearings<br />

Bar ends, 153, 154, 287, 409<br />

installing, 95–96, 255, 257<br />

position of, 390–391<br />

replacing, 95–96, 257, 258<br />

Barrel adjusters, 77, 78, 88, 89, 90,<br />

92, 93, 149, 151, 152, 153, 154,<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

166, 409<br />

BBT-39 tool, 200, 212<br />

Bearing cups, 207, 211, 212, 409<br />

Bearing pullers, 211, 219–220<br />

Bearing removers, 11<br />

Belt drives, 64–66, 101<br />

<strong>Bike</strong> dimensions, 385<br />

<strong>Bike</strong> fitting, 383–391, 385–393<br />

<strong>Bike</strong> stands, 4, 9<br />

Blankets, 14, 48<br />

Body measurements, 385–388<br />

Bosses, 176, 180, 181, 183, 186, 188,<br />

191, 194, 309<br />

brake, 148, 150, 345, 348, 410<br />

cantilever, 148, 311, 312, 313, 348,<br />

350, 351, 411<br />

disc-brake, 312, 313, 350, 351<br />

Bottom-bracket cups, 30, 83, 213,<br />

217, 223, 350<br />

Bottom-bracket shells, 11, 58, 66, 81,<br />

83, 207, 208, 209, 210, 212, 213,<br />

214, 215, 216, 220, 222, 223,<br />

252, 352, 387, 410<br />

cleaning, 211, 212<br />

full-carbon, 204<br />

tapping, 350<br />

unthreaded, 203<br />

Bottom-bracket tools, 6<br />

Bottom brackets, 65, 102, 108, 109,<br />

110, 191, 195, 198, 203–216, 231,<br />

345, 388, 409<br />

adjusting, 201, 222, 223<br />

BB30: 220<br />

BB86: 204, 205, 206<br />

BB90: 204, 206<br />

BB92: 204–206, 210–211, 220<br />

BB95: 204–206, 210–211, 219<br />

cartridge, 212–213, 216, 220–221,<br />

223–225<br />

cup-and-cone, 213–216, 221, 222,<br />

223<br />

eccentric, 58, 66<br />

external-bearing, 203, 205, 206,<br />

209–210<br />

height, 384, 386, 410<br />

installing, 83, 208–216, 221<br />

integrated-spindle, 216, 217<br />

ISIS, 198, 213<br />

ISO, 206<br />

noise in, 221–224<br />

overhauling, 109, 216–221, 223<br />

PF24: 205, 210–211, 220<br />

PF30: 204, 220<br />

Shimano, 207, 209, 213, 215<br />

square-taper, 198, 203, 208<br />

threaded, 206–207, 217–220, 350<br />

threadless, 204, 210–212, 219<br />

Box-cutter knife, 6<br />

Brake boosters, 189, 194, 410<br />

Brake hoses, 46, 164, 166, 173<br />

installing, 189<br />

Brake levers, 96, 152–155, 177, 184,<br />

255<br />

positioning, 152–154<br />

removing, 96, 152–154, 258<br />

shift cables and, 88<br />

squeezing, 15, 163<br />

Brake pads, 23, 42, 126, 164, 174,<br />

299, 410<br />

adjusting, 151, 177, 180, 181,<br />

188–189, 193<br />

checking, 15, 156<br />

cleaning, 156<br />

cottered, 155, 156, 157<br />

disc, 155–157<br />

offset of, 177–178, 182<br />

removing, 166, 171<br />

replacing, 166, 179–180, 181, 191,<br />

192, 193<br />

rims and, 40–41<br />

spacing, 149, 158, 166<br />

toeing in, 183, 191, 193–194<br />

worn, 148, 150, 193<br />

Brake reach, adjusting, 154–155<br />

Brakes, 23, 24, 152, 154, 170–171,<br />

173, 183, 185, 186, 410<br />

bleeding, 168–170<br />

checking, 15, 16, 22<br />

curved-face, 183<br />

cylindrical-arm, 183<br />

423

424<br />

cylindrical-clamp, 182<br />

disconnecting, 328, 331<br />

feel of, 184<br />

Hayes, 157, 159, 168–170, 173<br />

hub, 414<br />

linkage, 148, 190, 194<br />

mounting, 162-163<br />

opening, 40–41<br />

options for, 147–148<br />

releasing, 16–17, 23, 148, 150<br />

rim, 16, 149, 150, 301<br />

rubbing, 370<br />

Shimano, 88–89, 95, 167, 185<br />

troubleshooting with, 192–194<br />

See also Cantilever brakes; Disc<br />

brakes; Hydraulic brakes;<br />

Roller-cam brakes; U-brakes;<br />

V-brakes<br />

Braking, 291, 322<br />

chattering/vibration when, 183,<br />

369, 372, 374, 375<br />

problems with, 369–370<br />

Brushes, 24, 26<br />

Buckets, 24<br />

Bushings, 180, 181, 211, 231, 234,<br />

330, 334, 335, 353, 354, 355,<br />

356, 358, 361, 410<br />

replacing, 359–360<br />

Cable cutters, 6, 86<br />

Cable stops, 348, 410<br />

Cable tension, 72, 76–78, 107<br />

adjusting, 71, 74, 85, 148–149, 151,<br />

152, 186, 230–231, 396<br />

Cables, 76, 97, 148–154, 178, 185,<br />

190, 251, 311, 410<br />

broken, 45–46<br />

clamping, 40–41<br />

Gore-Tex, 86, 94, 95, 178<br />

installing, 22, 74, 92–93, 94, 150<br />

loose, 40–41, 85<br />

lubricating, 30, 94–95, 107, 149,<br />

150<br />

maintaining, 103, 149, 152, 192<br />

replacing, 30, 85, 87–92, 149, 150,<br />

152<br />

shift, 80, 85, 88, 89–90<br />

Shimano, 89–90<br />

sticky, 68, 107<br />

tying, 43<br />

worn, 151, 193<br />

Calipers, 11, 41, 150, 156, 163, 170,<br />

313, 410<br />

cleaning, 171–173<br />

disc-brake, 31, 161, 162, 173–174<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

hydraulic, 156, 171–173<br />

measuring, 415<br />

mounting, 161–162<br />

overhauling, 173–174<br />

postmount, 163<br />

Cantilever brakes, 16, 22, 31, 41,<br />

147–148, 149, 150, 151, 175–180,<br />

411<br />

curved-face, 183<br />

overhauling, 180–187<br />

sidepull, 417<br />

Cantilevers, 147, 148, 150, 151, 152,<br />

194, 417<br />

Carbon-grip compound, 9<br />

Cartridge bearings, 103, 133–136,<br />

208, 219, 231, 276, 279, 280,<br />

286, 358, 359, 411<br />

angular-contact, 277, 278, 281<br />

cleaning, 133–134<br />

lubricating, 31<br />

See also Ball bearings<br />

Cartridge-removal tool, 340<br />

Cartridges, 208, 352<br />

air inflation, 35<br />

Centering, 126, 178–179, 301–303<br />

Chain cleaners, 26, 53–54<br />

Chain elongation, checking for,<br />

55–56, 67, 69<br />

Chain-elongation gauges, 3, 55–56,<br />

69<br />

Chain gap, 78–79<br />

Chain keepers, 7<br />

Chain length, determining, 57–59, 73<br />

Chain links, 411<br />

loosening, 67<br />

replacing, 38, 56, 60<br />

spacing between, 66<br />

spare, 13<br />

tight/stiff, 66, 67<br />

twisted, 36–38<br />

Chain retention devices, 100–101<br />

Chain stops, 110<br />

Chain suck, 66–67, 107, 201, 370, 411<br />

Chain tensioner, 101<br />

Chain tools, 2–3, 12, 33, 38, 42, 56,<br />

59, 61, 62<br />

Chain whips, 6, 7, 138, 139, 140, 141,<br />

142, 411<br />

Chainlines, 85, 107–108, 224, 411<br />

measuring, 108–110<br />

Chainring bolts, 195, 201, 202, 222<br />

Chainring-cassette removal tools, 6<br />

Chainring-nut tools, 6, 202, 411<br />

Chainrings, 27, 37, 42–45, 51, 53, 55,<br />

57, 58, 60, 64, 65, 195, 197–202,<br />

216, 411<br />

bent, 201<br />

chainstays and, 223–225<br />

cleaning, 26, 66, 200<br />

inner, 109, 223<br />

inspecting, 66, 200–201<br />

installing, 66, 202<br />

jammed chains and, 36<br />

loose, 221<br />

maintaining, 200<br />

middle, 10<br />

spindles and, 209<br />

worn, 200<br />

Chains, 411<br />

assembling, 51–52<br />

broken, 38, 54, 56, 57, 59<br />

cleaning, 26–27, 52–55, 66<br />

connecting, 57, 59–61<br />

dropping, 110, 370<br />

jammed, 15, 36–38, 370<br />

lubricating, 4, 13, 25–26, 27, 30,<br />

51–54, 66, 67, 74, 105, 254<br />

maintaining, 152<br />

measuring, 140<br />

removing, 27, 44, 45, 54–57, 63<br />

replacing, 55, 62, 67, 68, 74, 150<br />

Shimano, 26, 56, 59, 60–61, 62<br />

skipping, 67, 107, 370<br />

slapping, 370, 372<br />

squeaking, 67<br />

SRAM, 54, 56, 61, 62<br />

troubleshooting, 66–69<br />

with twisted link, 37–38<br />

wiping, 25, 26, 27, 30, 52–53, 67<br />

Wippermann, 37, 54, 56, 62, 67, 69<br />

Chainstays, 23, 40, 43, 65, 66, 74,<br />

81, 102, 103, 109, 159, 213, 349,<br />

361, 367, 411<br />

chain suck and, 67<br />

chainrings and, 223–225<br />

jammed chains and, 36<br />

Circlips, 208, 211, 212, 220, 313, 327,<br />

336<br />

Clamps, 58, 81, 82, 83, 254, 255, 276<br />

cylindrical, 182<br />

saddle, 245, 246<br />

seatpost, 31, 46, 253, 254<br />

split, 153<br />

See also Stem clamps<br />

Cleats, 226, 230<br />

adjusting, 227–229, 240<br />

installing, 227–229<br />

loose, 239–240<br />

Clunking noises, problems with,<br />

222–223, 372

Cog-wear indicator gauge, 11<br />

Cogs, 51, 55, 58, 64, 73, 74, 75, 77,<br />

78, 79, 108, 111, 127, 137–146,<br />

209, 411<br />

cassette, 138–141<br />

checking, 67–68<br />

cleaning, 26, 53, 138, 139, 140<br />

removing, 68, 102, 138, 139, 140,<br />

145–146<br />

replacing, 68, 139, 140, 141<br />

worn, 67, 139, 140<br />

Compression, 316, 357, 358, 361<br />

Compression damping, 321–322,<br />

362, 365, 366, 411<br />

adjusting, 316, 323, 325, 364<br />

Compression rings, 273, 276, 278<br />

Concentric-pivot systems, 43, 65,<br />

102<br />

Cones, 6, 127, 128–133, 213–216,<br />

221, 222, 223, 236, 237, 409, 411<br />

Crank bolts, 195, 197, 199, 200, 222,<br />

411<br />

Crank extraction tools, 197<br />

Crank pullers, 6, 195, 198<br />

Crankarms, 84, 195, 197–202, 210,<br />

211, 216, 217, 221, 225, 226, 227,<br />

244, 363, 385, 411<br />

length/determining, 388<br />

loose, 222–223<br />

removing/installing, 202, 212,<br />

215, 218<br />

Cranks<br />

custom, 388<br />

hard-to-turn, 223<br />

integrated-spindle, 195, 197,<br />

198–199, 203, 204, 205<br />

length, 390, 411<br />

removing/installing, 195, 197–200<br />

Shimano, 197, 199, 202, 207<br />

square taper, 197, 199<br />

troubleshooting, 221–224<br />

Cranksets, 195, 210, 412<br />

BB30: 204, 219<br />

external-bearing, 207<br />

lubricating, 31<br />

three-piece, 197, 199, 203, 204,<br />

207–209<br />

Truvativ, 209, 210, 218, 219<br />

two-piece, 203, 207<br />

Creaking noises, 372<br />

bottom bracket, 221–222<br />

crank, 221–222<br />

handlebar, 287<br />

pedaling, 207, 239–240<br />

seatpost, 254<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

Crowfoot sockets, 11, 412<br />

Crown-race punches, 285<br />

Crown-race removers, 11, 283, 284<br />

Cup removal tools, 7<br />

Cups, 412<br />

adjustable, 207, 215, 216, 221, 409<br />

bearing, 207, 211, 212, 409<br />

bottom bracket, 30, 83, 213, 217,<br />

223, 350<br />

fixed, 214, 413<br />

Damping, 318, 357, 412<br />

adjusting, 325–326, 327, 334<br />

changing oil and, 336–338,<br />

355–356<br />

compression, 316, 321–322, 323,<br />

325, 362, 364, 365, 366, 411<br />

hydraulic, 262, 309–310, 314<br />

preload, 363–364<br />

pressurizing, 358<br />

rebound, 318, 320–321, 323, 325,<br />

361, 362, 364, 365, 366, 416<br />

Damping adjusters, 326, 327, 334,<br />

365<br />

Damping systems, 325, 336–338<br />

Derailleur cages, 42, 68, 84, 107<br />

Derailleur-hanger alignment tools,<br />

11, 68, 349<br />

Derailleurs, 23, 27, 47, 57, 71–80,<br />

80–85, 209, 412<br />

adjusting, 68, 71, 74–80, 83–85,<br />

200<br />

bent, 43, 68, 107<br />

bottom-pull/top-pull, 82<br />

broken, 71, 103<br />

bypassing, 44<br />

cables and, 82, 85, 92–94<br />

chain length and, 57<br />

disassembling, 88, 106<br />

down-swing, 81<br />

E-type, 81, 82–83, 209, 213, 223<br />

installing, 73–74, 82–83<br />

lubricating, 30, 105<br />

maintaining, 26, 53, 103–106<br />

positioning, 83, 84, 107<br />

repairing, 42–44<br />

replacing, 69, 79, 105, 106<br />

Shimano, 45, 46, 71, 73, 74–75,<br />

76, 77, 79, 82–83, 84, 87, 88, 92,<br />

106, 107, 213<br />

spokes and, 370, 372<br />

SRAM, 78, 82, 87, 106, 107<br />

top-swing, 81, 224<br />

troubleshooting, 107–110<br />

worn, 67, 107<br />

Disc-brake pads, checking/replacing,<br />

155–157<br />

Disc brakes, 17, 22, 31, 147, 148, 152,<br />

155–164, 166–175, 192, 412<br />

adjusting, 158–164, 166<br />

cable-actuated, 155<br />

installing, 158–164, 166<br />

overhauling, 171–174<br />

Dishing, 301–303, 349, 367, 412<br />

Dishing tools, 7, 301, 302, 412<br />

Drills, 11<br />

Drivetrains, 60, 65, 74, 101, 107, 292,<br />

412<br />

cleaning, 24–26<br />

wear/tear on, 55<br />

Dropout-alignment tools, 11, 341–<br />

343, 342, 344, 367–368<br />

Dropout Saver, 351<br />

Dropouts, 18, 20, 23, 24, 65, 66, 71,<br />

73, 78, 102, 109, 128, 309, 311,<br />

349, 412<br />

aligning, 68, 342–343, 344, 366<br />

aluminum/titanium, 368<br />

bent, 80, 312, 344<br />

bolt-on, 367<br />

inspecting, 348<br />

sliding, 58<br />

spacing, 341, 342<br />

thickness of, 351<br />

Duct tape, 14<br />

Dust caps, 144, 199, 200, 236, 237,<br />

239, 412<br />

Dust covers, 143, 237<br />

Easy-outs, 354, 412<br />

Elastomers, 249, 262, 309, 311, 314,<br />

315, 318, 319, 324–326, 327,<br />

331, 361, 412<br />

End caps, 86, 152, 410, 412<br />

Fasteners, torque for, 396–407<br />

(table)<br />

Feeler gauges, 11<br />

Files, 6<br />

Firmly tightened, 29, 395<br />

Foot pounds (ft-lbs), Newtonmeters<br />

and, 397<br />

Fork braces, 311, 315<br />

Fork-crown race punch, 7<br />

Fork-crown race remover, 283<br />

Fork-crown races, 281, 282–284,<br />

285–286<br />

Fork crowns, 309, 310, 311, 312, 313,<br />

315, 413<br />

clamping, 268<br />

INDEX<br />

425

426<br />

fork legs and, 316, 327–328<br />

Fork legs, 40, 309, 311, 315, 325<br />

damaged, 313<br />

fork crowns and, 316<br />

removing, 327–328<br />

telescoping, 310<br />

Fork rake, 309, 413<br />

Fork travel, 319<br />

changing, 323, 338-339<br />

measuring, 315–317<br />

Forks, 16, 18, 115, 289, 310, 317, 413<br />

air-sprung, 312, 326–327<br />

alignment of, 312, 313, 314, 318,<br />

341–344<br />

aluminum, 314, 343<br />

carbon-fiber, 314, 343<br />

coil-spring, 311, 319, 324–326, 327<br />

double-crown, 327, 328, 330<br />

failure of, 311, 312<br />

headset installation and, 284–285<br />

high-end, 321, 331<br />

inspecting, 311–313, 313–314<br />

linkage, 312, 314<br />

lubricating, 31, 314<br />

maintaining, 313–314, 314–315<br />

Manitou, 34, 159, 331<br />

movement of, 321, 322<br />

overhauling, 314, 330–331,<br />

334–336<br />

rebound damping and, 321<br />

removing, 277, 280, 282, 330–331,<br />

341<br />

rigid, 309, 313–314, 344<br />

RockShox, 326, 327, 328, 337,<br />

338–339, 340, 357<br />

SID, 326, 327, 337<br />

single-crown, 327, 328<br />

steel, 341, 344<br />

stuck stems in, 287<br />

suspension, 20, 31, 46, 128, 189,<br />

263, 282, 284, 309, 310, 313,<br />

314, 314–315, 317–324, 330,<br />

384, 386<br />

telescoping, 310, 312, 314<br />

threaded, 265–266, 267, 312<br />

titanium, 314, 343<br />

triple-clamp, 327–328, 330<br />

tuning, 314, 315, 317–327<br />

upside-down, 419<br />

Frame size<br />

body measurements and,<br />

385–388<br />

correct, 384–385<br />

finding, 383, 386–387<br />

Frames, 31, 208, 212, 289, 413<br />

ZINN & THE ART OF MOUNTAIN BIKE MAINTENANCE<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

alignment of, 366–368<br />

carbon, 347, 348<br />

cleaning, 348<br />

designing, 345, 347<br />

diamond, 345, 412<br />

headset installation and, 284–285<br />

suspension, 101–102, 347, 358–<br />

361, 368, 386, 389, 390<br />

types of, 249, 347<br />

Freehubs, 78, 134, 137–146, 413<br />

disassembling, 144<br />

lubricating, 142–146<br />

overhauling, 111<br />

removing, 144, 146<br />

seized, 47<br />

solvents and, 142, 144<br />

Freewheel removers, 7, 141<br />

Freewheels, 127, 137–146, 413<br />

lubricating, 30, 146<br />

maintaining, 111<br />

replacing, 68, 111, 141<br />

seized, 47<br />

Front triangles, 345, 347, 349, 413<br />

Gauges, 56, 57, 68<br />

Gear development, 375–381<br />

for 26-inch wheels, 376–378<br />

(table)<br />

for 29-inch wheels, 381–383<br />

(table)<br />

Gloves, 13, 55<br />

Grease, 4, 13, 137, 201<br />

molybdenum disulfide, 94<br />

nonlithium, 6, 92, 97, 335<br />

silicone-based, 6<br />

Slick Honey, 251, 335, 355, 357,<br />

359<br />

Teflon, 92, 97<br />

Grease guns, 6, 136, 142<br />

Grip Shifts, 29, 78, 94, 95, 107, 258,<br />

413<br />

long/short, 97, 98<br />

overhauling, 91–92<br />

replacing, 96–97<br />

Grips, 111, 255, 266<br />

installing, 95–96, 257–258<br />

removing, 95–96, 153, 257, 258<br />

trimming, 258<br />

Hacksaw, 6<br />

Hammers<br />

ball-peen, 6, 7<br />

soft, 7<br />

Handlebar height, 385, 388, 389–390<br />

adjusting, 266, 392<br />

Handlebar position, 242, 244, 263,<br />

266, 388–391<br />

Handlebar reach, 384–385, 388, 390<br />

Handlebar slips, 286–287<br />

Handlebars, 251, 255, 257, 258–260,<br />

273, 315, 325, 413<br />

broken, 47, 260, 287<br />

carbon, 154, 260, 393<br />

drop, 384–385<br />

installing, 258–259<br />

knees and, 383, 384<br />

maintaining, 16, 259–260<br />

overtightened, 259, 393<br />

replacing, 258, 259–260, 266<br />

riser, 255, 391<br />

saddles and, 390<br />

troubleshooting, 286–287<br />

twisting, 259, 266, 267<br />

types of, 260, 266<br />

undertightened, 393<br />

Hangers, 13, 43, 69, 78, 80, 366, 410,<br />

412<br />

alignment of, 349–350<br />

bent, 68, 107, 349–350<br />

brake-cable, 271, 281<br />

derailleur, 348, 349–350, 351<br />

straddle-cable, 184<br />

Head angles, 309, 413<br />

Head tubes, 277, 278, 282, 284, 286,<br />

367, 388, 413<br />

measuring, 268, 270<br />

Headlights, 14<br />

Headset cups, 286<br />

removing, 276, 282<br />

Headset presses, 7, 11, 285–286<br />

Headset rockets, 282<br />

Headsets, 255, 263, 270–286, 312,<br />

313, 413<br />

adjusting, 265, 268, 272–276, 279,<br />

282, 286, 287<br />

cartridge-bearing, 272<br />

cupless, 268, 277, 278, 282<br />

installing, 284–286<br />

integrated, 270, 271, 274, 278,<br />

284, 414<br />

loose-ball, 278, 281<br />

loosening, 274–275<br />

overhauling, 276–282<br />

overtightening, 275<br />

pitted, 275, 287<br />

press-in internal with lipped<br />

cups, 268<br />

replacing, 281, 282–284, 287<br />

semi-integrated, 270<br />

threaded, 273–276, 279–282, 418

threadless, 269, 270–272, 276–<br />

279, 285, 387, 390<br />

tight, 272–273, 274–275, 287<br />

traditional, 168, 270<br />

troubleshooting, 286–287<br />

Hex keys, 12, 29, 47, 414<br />

metric, 2, 7, 20, 40, 41, 42<br />

HG-IG check tool, 68, 139<br />

Hose cutters, 11<br />

Housing, 76, 77, 82, 89, 90, 92, 148–<br />

152, 185, 193, 273, 410<br />

cutting, 11, 86, 153<br />

friction and, 150<br />

index-shift, 86<br />

installing, 74, 87<br />

lower-knuckle, 79<br />

lubricating, 30, 85, 94–95, 151, 152<br />

replacing, 30, 152<br />

sticky, 68<br />

Teflon-lined, 150, 151<br />

Hubs, 102, 103, 127–137, 231, 306,<br />

414<br />

assembling, 131–132<br />

cartridge-bearing, 127, 128,<br />

132–136<br />

cup-and-cone, 127, 128–133<br />

DT Swiss, 28, 125, 133, 134, 142,<br />

145<br />

front, 127, 292<br />

Grease Guard, 136–137<br />

high-end, 128, 136<br />

internal-gear, 101–103<br />

lubricating, 131–132<br />

overhauling, 111, 127–136<br />

replacing/flipping, 141–142<br />

sealed-bearing, 127, 128<br />

wheelbuilding and, 289, 291, 292,<br />

299<br />

Hydraulic brakes, 42, 99, 107, 148,<br />

150, 158, 166–173, 187–190,<br />

192, 193, 194, 414<br />

bleeding, 31, 166, 168, 170, 171,<br />

189–190<br />

disconnecting, 328<br />

replacing pads on, 189<br />

Hydraulic fluid, 158, 166, 167, 169,<br />

170, 171, 172, 173, 194<br />

Hydraulic oil, 325<br />

Inertial valves, 322, 325, 327, 365,<br />

414<br />

adjusting, 323, 364<br />

Inner legs, 310, 314, 327, 334, 335,<br />

336, 337, 339, 414<br />

installing, 328, 330<br />

Sample from <strong>Zinn</strong> & the <strong>Art</strong> of <strong>Mountain</strong> <strong>Bike</strong> <strong>Maintenance</strong>, 5th Ed.<br />

Copyright 2010 <strong>VeloPress</strong> All rights reserved<br />

Inner tubes, 114, 122, 123, 251<br />

finding leaks in, 115–116<br />

inflating, 35, 36<br />

installing, 36, 118–120<br />

patching, 36, 116<br />

removing, 111–112<br />

spare, 2, 12–13, 34–35<br />

tying knots in, 35<br />

International Organization for<br />

Standardization (ISO), 117, 159<br />

Interrupted-seat-tube configurations,<br />

387, 388<br />

Jockey wheels, 27, 43, 58, 59, 68, 73,<br />

74, 78, 80, 414<br />

bolts, 106<br />

cartridge-bearing, 104–105<br />

lost, 44–45<br />

maintaining, 68, 103–105<br />

wiping, 26, 53<br />

Knee clearance, 384<br />

Lacing, 289, 294, 296, 297–299, 306<br />

checking, 299, 307<br />

radial, 304–305<br />

three-cross, 304–305<br />

Leaks<br />

finding, 115–116<br />

sealing, 122, 123, 124<br />

Leverage, 154–155, 166, 176, 177, 414<br />

Levers, 89, 90, 150, 170, 173<br />

lockout, 362, 364<br />

Shimano, 87–88, 99–100, 107, 155<br />

split-clamp, 153<br />

SRAM, 87, 95, 97, 155<br />

See also Brake levers; Quickrelease<br />

levers; Tire levers<br />

Lickton’s SuperLink, 61<br />

Limit screws, 73, 107<br />

adjusting, 46, 71, 74, 75–76, 78,<br />

84, 85<br />

Locknuts, 58, 133, 145, 146, 149, 152,<br />

237, 271, 273, 275, 281, 414<br />

loosening, 128–129, 132, 151, 274<br />

removing, 236, 280<br />

tightening, 132<br />

Lockouts, 316, 362, 364, 414<br />

Lockring tools, 6, 160<br />

Lockrings, 78, 140, 160, 207, 213,<br />

224, 414<br />

adjustable-cup, 223<br />

removing, 139, 221<br />

tightening, 215–216<br />

Loctite, 28, 68, 77, 136, 212, 222,<br />

231, 313<br />

Lubrication, 30–31, 128, 330<br />

ball bearing, 31, 131, 132, 281, 286<br />

cable, 30, 94–95, 107, 149, 150<br />

chain, 4, 13, 25–26, 27, 30, 51–54,<br />

66, 67, 74, 105, 254<br />

crankset, 31<br />

derailleur, 30, 105<br />

fork, 31, 314<br />

freehub, 142–146<br />

freewheel, 30, 146<br />

housing, 30, 85, 94–95, 151, 152<br />

hub, 131–132<br />

pedal, 31, 239–240<br />

piston, 173, 190<br />

quill, 281<br />

saddle, 31<br />

seatpost, 31, 254, 266, 348<br />

shifters, 30<br />

wheel, 30<br />

Magnet, 7<br />

Master cylinders, 173, 415<br />

Master links, 13, 33, 42, 54, 57,<br />

59–60, 61, 63–64, 67, 69, 415<br />

Matches, 14, 48<br />

Money, 14<br />

patching sidewalls with, 36<br />

Morningstar Drumstix tool, 175<br />

Morningstar Freehub Buddy, 7, 142,<br />

143, 144<br />

Morningstar Freehub Soup, 142,<br />

143, 144<br />

Morningstar Rotors on Center (ROC)<br />

dial-indicator tool, 10, 174–175<br />

Mounting bolts, 69, 105, 192, 415<br />

Mounts<br />

broken, 348<br />

disc-brake, 309, 351<br />

IS, 159, 313<br />

ISCG, 101<br />

Multitools, 12, 38<br />

Needle bearings, 279, 280, 415<br />

Newton-meters (N-m), foot-pounds<br />

and, 397<br />

Nipples, 124, 127, 290, 292, 293, 294,<br />

307–308, 415<br />

tightening/loosening, 125, 299,<br />

300, 301, 302, 303<br />

types of, 126, 291, 308<br />

O-rings, 144, 158, 164, 172, 337, 354,<br />

355, 357, 362–363<br />

<strong>Of</strong>f-center rims (OCR), 292, 293, 308<br />

INDEX<br />

427

428<br />

Outer legs, 310, 312, 315, 323, 328,<br />

330, 334, 415<br />

Oversteering, 319, 322, 324<br />

Overtightening, 259, 272, 275, 393<br />

Pad spacers, 12, 190<br />

Pad swing, 182<br />

Pad-to-rim adjustment, 176–178,<br />

187, 189, 192<br />

Pad twist, 182<br />

Parts washer, 7<br />

Patch glue, 116<br />

Patch kits, 2, 12, 34–35, 36, 116<br />

Patches, 35, 36<br />

applying, 116–118<br />

Pedal overlap, 385, 415<br />