Rapid Die Face Design: a step towards End-to-End ... - ESI Group

Rapid Die Face Design: a step towards End-to-End ... - ESI Group

Rapid Die Face Design: a step towards End-to-End ... - ESI Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

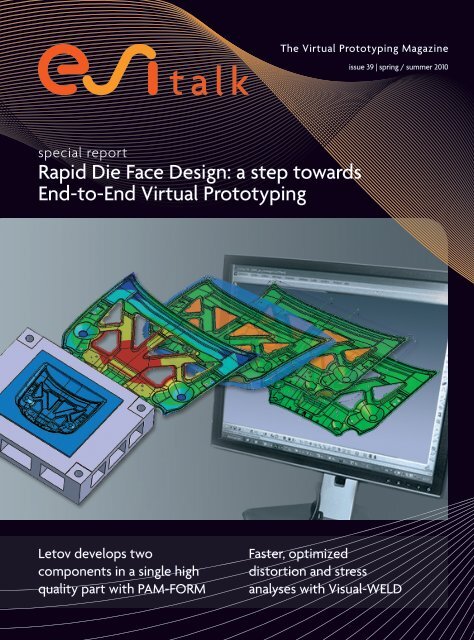

special report<br />

<strong>Rapid</strong> <strong>Die</strong> <strong>Face</strong> <strong>Design</strong>: a <strong>step</strong> <strong><strong>to</strong>wards</strong><br />

<strong>End</strong>-<strong>to</strong>-<strong>End</strong> Virtual Pro<strong>to</strong>typing<br />

Le<strong>to</strong>v develops two<br />

components in a single high<br />

quality part with PAM-FORM<br />

The Virtual Pro<strong>to</strong>typing Magazine<br />

issue 39 | spring / summer 2010<br />

Faster, optimized<br />

dis<strong>to</strong>rtion and stress<br />

analyses with Visual-WELD

contents<br />

esi talk is issued bi-annually by <strong>ESI</strong> <strong>Group</strong><br />

Executive Edi<strong>to</strong>r: Amy de Rouvray<br />

Edi<strong>to</strong>r-in-Chief: Elise Lavoue - elise.lavoue@esi-group.com<br />

<strong>ESI</strong> <strong>Group</strong> Marketing<br />

PARC D’AFFAIRES SILIC<br />

99 RUE DES SOLETS - BP 80112<br />

94513 Rungis Cedex - FRANCE<br />

Tel: +33 (0) 1 41 73 58 00 - Fax: +33 (0) 1 46 87 72 02<br />

www.esi-group.com - info@esi-group.com<br />

<strong>Design</strong>: Agence TETRAKTYS<br />

ISSN 1635 – 866X<br />

Print: RIVET PRESSE EDITION<br />

24, rue Claude-Henri-Gorceix - 87022 Limoges<br />

Dépôt légal: Mai 2010<br />

All PAM- and SYS- product names as well as other products belonging <strong>to</strong> <strong>ESI</strong>’s portfolio are tradenames or trademarks of <strong>ESI</strong><br />

<strong>Group</strong>, except specified proprietary mention. All other trademarks are the property of their respective owners.<br />

All text and images included in the articles are the copyright of the companies presenting their applications and simulation tasks.<br />

Pho<strong>to</strong> credits: Tower Au<strong>to</strong>motive, Seat, J. Walter Miller Company, Europea Microfusioni Aerospaziali, Renault, Dongfeng Mo<strong>to</strong>r<br />

Corporation, Ford, Tecnalia-Labein, Le<strong>to</strong>v, International Au<strong>to</strong>motive Components, Piaggio Aero Industries, University of West<br />

Bohemia.<br />

G/RO/10.58-A<br />

04 special report<br />

• <strong>Rapid</strong> <strong>Die</strong> <strong>Face</strong> <strong>Design</strong>: a <strong>step</strong> <strong><strong>to</strong>wards</strong> <strong>End</strong>-<strong>to</strong>-<strong>End</strong><br />

Virtual Pro<strong>to</strong>typing<br />

07 success s<strong>to</strong>ries<br />

• J. Walter Miller Company selects QuikCAST <strong>to</strong> support its<br />

technological transition <strong>to</strong> larger castings<br />

• Europea Microfusioni Aerospaziali optimizes nozzle guide vane<br />

blades with casting simulation<br />

• Renault Mégane III scores 5 stars at EuroNCAP thanks <strong>to</strong> Virtual<br />

Performance Solution<br />

• Dongfeng Mo<strong>to</strong>r Corporation draws on Virtual Performance<br />

Solution <strong>to</strong> validate the Fengshen S30<br />

• Ford uses PAM-CRASH for human modeling <strong>to</strong> advance<br />

au<strong>to</strong>motive safety research<br />

• Tecnalia-Labein uses PAM-STAMP 2G <strong>to</strong> design an industrial<br />

hotformed part<br />

• IAC streamlines its au<strong>to</strong>motive component simulation and<br />

reporting process with Visual-Process<br />

• Le<strong>to</strong>v develops two components in a single high quality part<br />

with PAM-FORM<br />

17 partner highlights<br />

• <strong>ESI</strong> is actively involved in the Research & Development of<br />

composite materials<br />

• <strong>ESI</strong> sponsors the Student Formula SAE Racing Team Pilsen<br />

19 product news<br />

• Virtual Performance Educational Package initiates students <strong>to</strong><br />

simulation<br />

• VA One v2009.0 includes advanced models of foam and fibers<br />

• Faster, optimized dis<strong>to</strong>rtion and stress analyses with Visual-<br />

WELD<br />

21 corporate<br />

• VisualDSS features in Oracle Partners Innovation 2009<br />

magazine<br />

• PROCESSWorks is recognized as ‘having educational value’<br />

• Upcoming Expert Seminars<br />

• Save the date!<br />

• Users’ Conferences Worldwide on <strong>End</strong>-<strong>to</strong>-<strong>End</strong> Virtual<br />

Pro<strong>to</strong>typing<br />

• Financial news<br />

edi<strong>to</strong>rial<br />

Harald Porzner and Martin Skrikerud<br />

Virtual Manufacturing Product Line, <strong>ESI</strong> <strong>Group</strong><br />

Virtual Manufacturing has become very powerful for the<br />

industry as it helps prevent and solve critical problems that<br />

can occur during production. Indeed, many of the existing<br />

Computer-Aided Engineering/<strong>Design</strong>/Manufacturing systems<br />

are dedicated <strong>to</strong> a specific manufacturing process or testing<br />

procedure, which makes them both essential and easy-<strong>to</strong>-use.<br />

These systems, however, are reaching their limits – for the<br />

same reasons that have made them strong. Because these<br />

are dedicated <strong>to</strong>ols, it is a challenge <strong>to</strong> move on <strong>to</strong> the next<br />

<strong>step</strong>: <strong>End</strong>-<strong>to</strong>-<strong>End</strong> Virtual Pro<strong>to</strong>typing, <strong>to</strong> integrate the entire<br />

manufacturing chain. The performance of manufactured parts<br />

and components depends on their manufacturing his<strong>to</strong>ry. A<br />

stamped part will have thickness variations, stresses and strains<br />

introduced and modified by the welding which will ultimately<br />

change the performance of the part. This is why the entire<br />

manufacturing chain must be taken in<strong>to</strong> account for accurate<br />

<strong>End</strong>-<strong>to</strong>-<strong>End</strong> Virtual Pro<strong>to</strong>typing. The key strength and differentiation<br />

of <strong>End</strong>-<strong>to</strong>-<strong>End</strong> Virtual Pro<strong>to</strong>typing is that it enables<br />

the concurrent engineering of all manufacturing effects, not<br />

only <strong>to</strong> evaluate manufacturability but also <strong>to</strong> improve the<br />

performance of the simulation models.<br />

When looking at Sheet Metal Forming, the trend is <strong>to</strong> integrate<br />

the simulation stage in<strong>to</strong> the Product Lifecycle Management<br />

and Computer-Aided <strong>Design</strong> systems. The prior process<br />

was <strong>to</strong> perform early feasibility studies based on rapid die<br />

face designs, which did not allow for connected engineering<br />

updates. Throughout the design phase of a new product,<br />

single parts typically undergo several design changes or adjustments,<br />

which then imply new feasibility tests. In support of<br />

this recent trend, <strong>ESI</strong> offers PAM-DIEMAKER for CATIA V5, a<br />

rapid and comprehensive die face design software directly<br />

integrated in the CATIA environment.<br />

Our Sheet Metal Forming cus<strong>to</strong>mers are now able <strong>to</strong> benefit<br />

from a solution allowing continuous data flow throughout all<br />

die engineering as well as maintenance of design iterations<br />

within the Product Lifecycle Management, while delivering<br />

rapid feasibility assessments through simulation.<br />

issue 39 | spring / summer 2010 3

s p e c i a l r e p o r t D I E F A C E D E S I G N<br />

<strong>Rapid</strong> <strong>Die</strong> <strong>Face</strong> <strong>Design</strong>:<br />

a <strong>step</strong> <strong><strong>to</strong>wards</strong> <strong>End</strong>-<strong>to</strong>-<strong>End</strong><br />

Virtual Pro<strong>to</strong>typing<br />

PAM-DIEMAKER for CATIA V5 combines the convenience and speed<br />

of rapid die face design with the quality of the native CAD surfacing.<br />

Traditionally, the die face design job was a time consuming trial-anderror<br />

task with a high risk of production delays. With the introduction<br />

of numerical simulation in the last few decades, these risks were significantly<br />

reduced along with the pro<strong>to</strong>typing time. Nonetheless, the<br />

complexity of the job still meant that engineers were often creating a<br />

draft design of the <strong>to</strong>ol on which feasibility studies could be performed.<br />

Once a feasible design had been reached based on the draft dies, the<br />

die face design had <strong>to</strong> be repeated <strong>to</strong> obtain a better quality <strong>to</strong> validate<br />

the design with simulation. Once validated, the final CAD-based<br />

What is PAM-DIEMAKER for CATIA V5?<br />

PAM-DIEMAKER for CATIA V5 is a dedicated workbench inside the<br />

CATIA PLM context, providing a trade-oriented solution for rapid stamping<br />

<strong>to</strong>ol design directly within CATIA V5. Using this application, <strong>to</strong>ol<br />

4<br />

die face design could be produced. This process thus implied designing<br />

the same <strong>to</strong>ol three times with different accuracy levels along with the<br />

uncertainty that the dies used for simulation might differ from the ones<br />

actually used for milling. In the end, this meant that the pro<strong>to</strong>type could<br />

still offer some unpleasant surprises.<br />

PAM-DIEMAKER for CATIA V5 offers a new approach, allowing engineers<br />

<strong>to</strong> create their entire die face design inside the CATIA PLM environment.<br />

The risk of encountering difficulties during the pro<strong>to</strong>typing phase is thus<br />

considerably reduced thanks <strong>to</strong> a validation of the simulation based on<br />

the exact same <strong>to</strong>ols used for milling.<br />

The new improved workflow based on PAM- DIEMAKER for CATIA V5 (bot<strong>to</strong>m), clearly shows potential time savings.<br />

designers implement <strong>to</strong>ol design and process knowledge by following<br />

the natural <strong>to</strong>ol face design process, thereby gaining in efficiency. This<br />

dedicated solution also provides guidance and support for part preparation,<br />

binder development and die addendum.<br />

1<br />

2<br />

3 4<br />

Typical workflow using PAM-DIEMAKER for CATIA V5; from part (1) over blankholder design (2) <strong>to</strong> addendum surfaces (3) and finally solid model export (4)<br />

esi talk

3 questions for…<br />

Mark Vrolijk<br />

<strong>Die</strong> <strong>Face</strong> <strong>Design</strong> Product Manager<br />

What are the main market challenges?<br />

“As many other areas, the die face design market has felt the impact of<br />

the economic crisis; thus reinforcing the urge <strong>to</strong> save time and money,<br />

without compromising on quality. During a die face design process, the<br />

design is often modified several times; although we still observe an<br />

increasing lack of au<strong>to</strong>mation as we go forward in the process – meaning<br />

a lot of manual re-work.<br />

In fact, while the cost estimation and feasibility phases can largely be<br />

au<strong>to</strong>mated, the final die face design, where more details and higher surface<br />

accuracy need <strong>to</strong> be considered, cannot. The user is left with a<br />

generic CAD environment which does not contain dedicated functionalities<br />

and workflow for his/her job. In practice this means that die face<br />

designs are often created twice: once for pro<strong>to</strong>typing, often in a CAE<br />

environment, and once for production, in a CAD environment.<br />

Additionally, many CAE-based die face designs cannot be used for the<br />

final die milling, which implies a redesign in a CAD environment. When<br />

taking in<strong>to</strong> account all of these above limitations and challenges, saving<br />

time and money are therefore not an easy task.”<br />

What are the opportunities presented by<br />

PAM-DIEMAKER for CATIA V5?<br />

“PAM-DIEMAKER for CATIA V5 enables data transferability and consistency<br />

between the various stages of the die face design process by offering<br />

surface quality and functionality required for each <strong>step</strong>. By avoiding<br />

time-consuming duplication of geometries, considerable time-saving<br />

can be achieved. Moreover, due <strong>to</strong> the fact that all phases in the die<br />

face design process can be supported in a fast and efficient manner,<br />

there is no longer a need for a costly in-house die face design solution<br />

in a CAE environment.<br />

Most of the die face design solutions currently available work with<br />

parametric 2D profiles. This is a very fast and efficient way <strong>to</strong> create<br />

the addendum geometry. However, when working on more complicated<br />

geometries, it frequently fails <strong>to</strong> create the required geometry and<br />

either the user has <strong>to</strong> make a compromise, or he needs <strong>to</strong> model the die<br />

design (partially) in a CAD environment. PAM-DIEMAKER for CATIA V5<br />

is very flexible: it is based on the 2D profile approach, but when specific<br />

geometries are required, all available CATIA V5 (surface) functionality<br />

can be used <strong>to</strong> create the shape required.”<br />

What is the future and strategic importance of<br />

Virtual Manufacturing as a whole?<br />

“The world is full of changes, with some of them, such as climate change,<br />

straining the manufacturing industry. Consequently, the industry continually<br />

needs <strong>to</strong> come up with new ideas, manufacturing methods, and<br />

materials <strong>to</strong> meet the ever-changing requirements and expectations.<br />

‘New’ entails test and validation before implementation. Testing new<br />

ideas is thus a common and regular task.<br />

Virtual Manufacturing allows this ‘testing’ in a fast and efficient way –<br />

whilst saving resources. So before anything is built, Virtual Manufacturing<br />

is performed <strong>to</strong> select the right innovations.<br />

The fundamental idea <strong>to</strong> create an integrated and synthetic environment,<br />

<strong>to</strong> support Virtual Manufacturing, is now at an advanced stage<br />

with the offer of PAM-DIEMAKER for CATIA V5 for instance. The next<br />

<strong>step</strong>, already underway, is fully enabling <strong>End</strong>-<strong>to</strong>-<strong>End</strong> Virtual Pro<strong>to</strong>typing<br />

throughout the entire chain from manufacturing <strong>to</strong> performance testing<br />

and <strong>to</strong> delivering the product.”<br />

F r o m p a r t d a t a . . . . . . t o F i n a l t o o l .<br />

issue 39 | spring / summer 2010 5

s p e c i a l r e p o r t<br />

PAM-DIEMAKER for CATIA V5 has been widely tested and proves <strong>to</strong> be a highly valuable <strong>to</strong>ol for die face design.<br />

SEAT’s Pro<strong>to</strong>type Center of Development (CPD), situated in the manufacturing<br />

plant of the Spanish au<strong>to</strong>motive company in Mar<strong>to</strong>rell (Barcelona)<br />

is considered one of the most innovative in the Spanish industry and is<br />

emblematic within the Volkswagen <strong>Group</strong>. It gathers in a single location all<br />

activities linked <strong>to</strong> the development of pro<strong>to</strong>types for virtual and physical<br />

phases, from pre-serial vehicles <strong>to</strong> serial analyses.<br />

“For SEAT’s Pro<strong>to</strong>type Center of Development (CPD), the release of <strong>to</strong>ols<br />

integrated in<strong>to</strong> CATIA V5 such as PAM-DIEMAKER for CATIA V5, allows a<br />

rapid and accurate development of die face design. It is very valuable <strong>to</strong> be<br />

able <strong>to</strong> perform the appropriate geometrical changes and <strong>to</strong> have these<br />

evolutions simultaneously available for machining within CATIA.<br />

This represents a tremendous advantage in terms of productivity as well<br />

as for the final quality of our design, giving us the opportunity <strong>to</strong> perform<br />

our work in a common environment during all process phases.”<br />

Javier Diaz Martinez,<br />

Manager of the Pro<strong>to</strong>type Center of Development (CPD), SEAT S.A.<br />

6<br />

Tower Au<strong>to</strong>motive do Brazil is part of Tower Au<strong>to</strong>motive, one of the larg-<br />

est independent global suppliers of au<strong>to</strong>motive metal structural compo-<br />

nents and assemblies. The company uses PAM-DIEMAKER for CATIA V5<br />

for speed and surface quality of the die face design performed in their<br />

Technical Center.<br />

“The software <strong>to</strong>ol PAM-DIEMAKER for CATIA V5 gave us the opportunity<br />

<strong>to</strong> perform all the <strong>step</strong>s of our work in a single environment during all<br />

phases of the development process. This brought us more speed for<br />

our cost estimation analysis, with precise blank sizing and formability<br />

simulations. We are finally more competitive when we present an offer<br />

<strong>to</strong> our clients, having strong arguments with a guaranteed quality.”<br />

Vladimir B. Ferreira Jr.<br />

Tech Center, Tower Au<strong>to</strong>motive, Brazil<br />

sheet metal forming<br />

Come meet the experts on <strong>Rapid</strong> <strong>Die</strong> <strong>Face</strong> <strong>Design</strong><br />

with PAM-DIEMAKER for CATIA V5<br />

FREE<br />

SEMINAR<br />

rapid die <strong>Face</strong> design roadshow 2010 locations & dates:<br />

Zamudio, Spain - May 27, 2010 Milan, Italy - June 10, 2010 Shanghai, China - July 2, 2010<br />

Rungis, France - June 9, 2010 Erfurt, Germany - June 24, 2010<br />

Beijing, China - June 30, 2010<br />

Seoul, Korea - July 6, 2010<br />

For registration & exact locations, please visit:<br />

www.esi-group.com/die-design-roadshow<br />

esi talk

casting<br />

J. Walter Miller Company selects<br />

QuikCAST <strong>to</strong> support its<br />

technological transition<br />

<strong>to</strong> larger castings<br />

s u c c e s s s t o r i e s<br />

With QuikCaSt, JWmC fully reconfigures its complex castings in 2 weeks instead of the 12 required<br />

by conventional trial and error, and at minimal cost.<br />

His<strong>to</strong>rically, J. Walter miller Company (JWmC)<br />

was specialized in small castings but has lately<br />

been growing in<strong>to</strong> larger sizes with the acquisition<br />

of the diSa match 130, a match plate<br />

molding machine. as a result, JWmC recently<br />

under<strong>to</strong>ok a profound technological evolution<br />

from manual green sand squeeze molding <strong>to</strong><br />

fully au<strong>to</strong>mated molding machines where each<br />

squeezer pattern needed <strong>to</strong> be converted <strong>to</strong><br />

run on the new equipment.<br />

For a foundry producing non-leaded pump<br />

components, impellers are a main challenge<br />

because of the heavy and thin sections of<br />

the casting. indeed, JWmC’s impeller castings<br />

exhibited shrink porosity and voids in the hub<br />

when machined at the cus<strong>to</strong>mer’s facility; thus,<br />

the riser at the hub area required redesign.<br />

the initial design, prior <strong>to</strong> the use of QuikCaSt<br />

software, led <strong>to</strong> the addition of a core in the<br />

hub, <strong>to</strong> reduce the amount of liquid metal<br />

required <strong>to</strong> feed the hub during solidification,<br />

showing no defect after boring. However, a<br />

new defect began <strong>to</strong> appear in the wear ring<br />

section of the casting.<br />

at this time, JWmC decided <strong>to</strong> explore the use<br />

of QuikCaSt solidification software <strong>to</strong> determine<br />

the cause of this frustrating new defect<br />

and was subsequently able <strong>to</strong> find a new design<br />

configuration, eliminating the shrink during<br />

machining. QuikCaSt thus enabled JWmC <strong>to</strong><br />

reduce the number of iterations required <strong>to</strong><br />

reconfigure patterns, reduce porosity in finished<br />

castings and explore opportunities for<br />

yield improvement. in addition, JWmC’s cus-<br />

<strong>to</strong>mer witnessed a dramatic reduction of scrap<br />

in the machining process, which contributed <strong>to</strong><br />

large cost savings for both the cus<strong>to</strong>mer and<br />

JWmC.<br />

Left: Closed riser and cored hub design –<br />

Shrink pocket shown in wear ring.<br />

Right: Open riser, solid hub design – No shrink<br />

pocket in wear ring.<br />

“this problem would have taken about 12 weeks<br />

and $6,000 in pattern changes plus countless<br />

hours of machine time <strong>to</strong> solve using conventional<br />

trial and error methods. With QuikCaSt,<br />

we can easily solve similar problems in 2 weeks<br />

and produce a good pattern the first time. We<br />

have used simulation on about 20 parts <strong>to</strong> date<br />

and the simulation results are similar <strong>to</strong> what<br />

we see in the shop,” said Dan Rudolph, Quality<br />

Engineer at J. Walter miller Company.<br />

Left: original Shrink defect found in<br />

the heavy hub section of the casting<br />

Right: Hub with no shrink cracks present<br />

“ We selected QuikCaSt<br />

b e ca u se i t h a s the<br />

most comprehensive<br />

capabilities for simulating<br />

brass and bronze alloys.<br />

QuikCaSt is a very<br />

powerful simulation<br />

<strong>to</strong>ol.”<br />

Dan Rudolph,<br />

Quality Engineer,<br />

J. Walter miller Company<br />

A B O U T J . WA LT E R M I L L E R<br />

C O M PA N y<br />

J. Walter Miller Company has been producing<br />

brass and bronze castings for the fire protection,<br />

pumping and valve industries since 1887.<br />

JWMC is a leader in casting no lead alloys and<br />

helps its cus<strong>to</strong>mers convert from leaded castings<br />

<strong>to</strong> no lead castings through a smooth transition<br />

thanks <strong>to</strong> its design services and pattern<br />

shop.<br />

www.jwaltermiller.com<br />

for more information:<br />

www.esi-group.com/casting/quikcast<br />

issue 39 | spring / summer 2010 7

s u c c e s s s t o r i e s<br />

Europea Microfusioni<br />

Aerospaziali optimizes<br />

nozzle guide vane blades<br />

with casting simulation<br />

Using ESi software during the early stage of their design process, Ema saves time and money while<br />

benefiting from yield improvement and better process control.<br />

thanks <strong>to</strong> the development of dedicated techniques<br />

over the last two decades, investment<br />

casting modeling with ESi software has become<br />

reliable and efficient <strong>to</strong> optimize safety components<br />

such as turbine blades for jet engines.<br />

the solution includes dedicated superalloy<br />

material databases and ceramics characterization<br />

allowing very accurate predictions.<br />

Europea microfusioni aerospaziali (Ema) study<br />

presented here refers <strong>to</strong> a sta<strong>to</strong>r type nozzle<br />

Guide Vane (nGV) with three airfoils including<br />

cores. ESi software was used <strong>to</strong> carry out a<br />

design of Experiments (doE) with several independent<br />

variables covering about 103 feasibility<br />

hypotheses.<br />

8<br />

Fig. 1: Solidification time<br />

ESi software can be used within an au<strong>to</strong>matic<br />

optimization loop. indeed, ESi’s simulation <strong>to</strong>ol<br />

allows <strong>to</strong> perform a doE au<strong>to</strong>matically after<br />

defining an objective such as minimizing porosity<br />

without going against defined constraints.<br />

With this module, one can also perform design<br />

robustness analysis in order <strong>to</strong> control the stability<br />

of the process.<br />

“ When you have the right<br />

<strong>to</strong>ol in your hands, you<br />

can easily get quick and<br />

optimal solutions arising<br />

from extremely complex<br />

problems in superalloy<br />

foundry. ESi software<br />

does have the potential<br />

<strong>to</strong> do this.”Ciro Caramiello PhD,<br />

process modeling,<br />

Ema rolls-royce<br />

these simulations led <strong>to</strong> the au<strong>to</strong>matic run of<br />

about thirty models, in batch mode (command<br />

line programming) (Fig. 2).<br />

Preheating phase<br />

the preheating phase includes preliminary<br />

heating of the shell before metal pouring. this<br />

stage is important as it affects significantly the<br />

final part integrity. preheating temperature<br />

and heat transfer losses are fundamental, and<br />

therefore undergo the doE parameter level.<br />

the former is the temperature reached by the<br />

shell at the end of the pre-heating cycle; the<br />

latter is the elapsed time from when the shell<br />

is taken out of the pre-heating furnace <strong>to</strong> the<br />

start of the pouring phase.<br />

Fig. 3 shows, in particular, the thermal field of<br />

the shell with a sliced view of the critical areas<br />

such as the leading Edge (lE), the trailing Edge<br />

(tE), and the core.<br />

Pouring phase<br />

casting<br />

the pouring phase is the next important <strong>step</strong><br />

in the investment casting process. the velocity<br />

profile, pouring angle and pouring time will<br />

influence the quality of the component (shrinkage<br />

porosity, local grain size, etc.).<br />

typically, in a modelled doE, it is important<br />

<strong>to</strong> take in<strong>to</strong> account the thermal and fluid<br />

dynamics profiles, as well as the solid fraction<br />

and thermal flow during pouring. the filling<br />

phase is particularly important for equiaxed<br />

components (grain formation) compared with<br />

directional Solidified (dSX) ones. it is therefore<br />

always subject <strong>to</strong> a doE study, at least for a<br />

couple of the above-mentioned parameters.<br />

esi talk

Solidification phase<br />

the study of the solidification phase concludes<br />

the doE analysis. in general, the cooling rates,<br />

the local solidification times, and the shrink-<br />

age porosity prediction are analyzed. However,<br />

advanced metallurgical analyses such as grain<br />

structure or freckle prediction (SX) are also<br />

possible and will determine more directly the<br />

integrity and the specifications of the as-casted<br />

part.<br />

Fig. 2: Testing domain showing some parameters and their respective levels<br />

Fig. 3: Isotherms view just before<br />

the pouring starts<br />

Fig. 4: Filling pattern temperature field<br />

<strong>to</strong> conclude, the general aim of the doE analysis<br />

is <strong>to</strong> achieve a pare<strong>to</strong> optimality, i.e. a condition<br />

in which any change <strong>to</strong> a dependant<br />

variable, such as porosity, is impossible without<br />

adversely affecting the performance of another<br />

variable, such as grain structure for instance.<br />

<strong>to</strong> fulfill this, the two following conditions<br />

must be met:<br />

1) pare<strong>to</strong> optimal solutions must be identified<br />

(e.g. maximizing performance only as regards<br />

porosity),<br />

2) the process must be stable (design<br />

robustness).<br />

Fig. 5: Temperature con<strong>to</strong>urs and<br />

fraction of solid<br />

modeling casting processes is a very complex<br />

task in terms of testing domain: it may well<br />

be regulated by over a hundred variables. the<br />

advantage of using an optimization <strong>to</strong>ol is<br />

straightforward. the <strong>to</strong>ol helps find the optimal<br />

process parameters as well as evaluate the risk<br />

of possible casting rejections due <strong>to</strong> random<br />

fluctuations in the process.<br />

Fig. 6: Final shrinkage porosity prediction<br />

resulting in a sound part as critical porosity<br />

remains in the risering system<br />

A B O U T E U R O P E A M I C R O F U -<br />

S I O N I A E R O S PA z I A L I ( E M A )<br />

Located in Italy, EMA is a world class investment<br />

casting foundry for the production of<br />

components dedicated <strong>to</strong> civil and defense<br />

aerospace, marine and energy industries. The<br />

company is qualified <strong>to</strong> produce superalloys<br />

components, using the equiaxed, directional<br />

solidification and single crystal technologies.<br />

EMA is owned by Rolls-Royce and thus has<br />

inherited its know-how for developing and<br />

refining innovative and industrially advanced<br />

methods.<br />

www.emaht.com<br />

for more information:<br />

www.esi-group.com/casting<br />

issue 39 | spring / summer 2010 9

s u c c e s s s t o r i e s<br />

Renault Mégane III scores 5 stars<br />

at EuroNCAP thanks <strong>to</strong> Virtual<br />

Performance Solution<br />

the new renault mégane iii earned 5 stars, the highest possible rating with 37 points at EuronCap<br />

vehicle safety test.<br />

renault started using Virtual performance<br />

Solution with pam-CraSH in 2001 for structural<br />

crash simulation. over the past few years, several<br />

renault car models such as the laguna iii and the<br />

Scenic were validated by simulation with pam-<br />

CraSH and obtained excellent results, earning<br />

both of these five stars at EuronCap.<br />

the new renault mégane (also known as mégane<br />

iii), launched in november 2009 in Europe, with<br />

a new design and enhanced key features, has followed<br />

this trend for safety excellence. indeed, the<br />

mégane iii was awarded five stars at EuronCap<br />

crash test. the highest rating was granted for<br />

frontal crash testing, partly thanks <strong>to</strong> prior simulation<br />

results obtained with pam-CraSH.<br />

this high score for mégane iii is a turning point<br />

for renault as they are the only au<strong>to</strong>maker <strong>to</strong><br />

have ever earned eleven times five stars at the<br />

EuronCap.<br />

renault relied on virtual pro<strong>to</strong>typing <strong>to</strong> validate<br />

the design of the mégane iii car model,<br />

10<br />

“ pam-CraSH is a tailored<br />

solution fully adapted<br />

<strong>to</strong> renault’s problematic,<br />

especially during the<br />

development of the<br />

mégane iii.”<br />

Eric Duguet,<br />

CaE Body-in-White manager,<br />

renault <strong>Group</strong><br />

before testing any physical pro<strong>to</strong>types. Virtual<br />

performance tests with pam-CraSH spanned<br />

Body-in-White modeling, structural crash<br />

analysis, as well as spotweld modeling. these<br />

also included safety simulation with ESi’s occupant<br />

safety analysis application within Virtual<br />

performance Solution, such as airbags release,<br />

belt pretentioners and occupant behavior under<br />

load cases.<br />

one important challenge renault addressed<br />

during the development phase of mégane iii<br />

was the decrease of Co emissions. in order <strong>to</strong><br />

2<br />

achieve this, they optimized the steel parts of<br />

the Body-in-White <strong>to</strong> reduce the weight of the<br />

car, thus decreasing the overall Co expense and<br />

2<br />

keeping the same standard of vehicle robustness.<br />

another target was <strong>to</strong> reduce the number of<br />

physical pro<strong>to</strong>types relative <strong>to</strong> the mégane ii,<br />

thereby saving in development costs.<br />

Mégane III front crash simulation and EuroNCAP test<br />

“Simulation is key <strong>to</strong> our project development<br />

process,” said Eric Duguet, CaE Body-in-White<br />

manager, renault <strong>Group</strong>. “pam-CraSH allows<br />

us <strong>to</strong> identify not only the behavior of standard<br />

vehicle definition but also the probability <strong>to</strong><br />

improve our crash performance and <strong>to</strong> build virtually<br />

every element that has an impact on our<br />

decision-making.”<br />

A B O U T R E N A U LT<br />

Renault S.A. (Euronext: RNO) is a French au<strong>to</strong>maker<br />

producing cars, vans, buses, trac<strong>to</strong>rs,<br />

and trucks. The strategic alliance with the<br />

Japanese au<strong>to</strong>maker Nissan in 1999, makes<br />

Renault the world’s fourth largest au<strong>to</strong>maker.<br />

Established in 1898 by the Renault brothers, the<br />

company is well-known for numerous revolutionary<br />

designs, security technologies and<br />

mo<strong>to</strong>r racing. Renault also owns the Romanian<br />

au<strong>to</strong>maker Au<strong>to</strong>mobile Dacia and the Korean<br />

au<strong>to</strong>maker Renault Samsung Mo<strong>to</strong>rs.<br />

www.renault.com<br />

crash, impact & safety<br />

for more information:<br />

www.esi-group.com/virtual-performancesolution<br />

esi talk

crash, impact & safety<br />

Dongfeng Mo<strong>to</strong>r Corporation<br />

draws on Virtual Performance<br />

Solution <strong>to</strong> validate the Fengshen S30<br />

Virtual performance Solution allows the entire development process and validation of the Fengshen<br />

S30 car model, the first passenger car designed and developed by dongfeng mo<strong>to</strong>r Corporation.<br />

as a new comer in the car construction market,<br />

dongfeng mo<strong>to</strong>r Corporation (dFm) had <strong>to</strong><br />

quickly gain experience and at the same time<br />

competitive advantage <strong>to</strong> penetrate successfully<br />

one of <strong>to</strong>day’s most competitive markets.<br />

they chose <strong>to</strong> implement Virtual pro<strong>to</strong>typing<br />

in order <strong>to</strong> reduce their time <strong>to</strong> market and<br />

optimize their product development Cycle by<br />

decreasing the <strong>to</strong>tal number of physical tests;<br />

thus strongly cutting development costs.<br />

<strong>to</strong> enable Virtual pro<strong>to</strong>typing during the development<br />

of the Fengshen S30, dFm validated<br />

its virtual car model with Virtual performance<br />

Solution before building a real physical pro<strong>to</strong>type<br />

<strong>to</strong> pass the high safety requirements<br />

demanded by China’s national forced regulations.<br />

pam-CraSH, crash simulation <strong>to</strong>ol featured<br />

in Virtual performance Solution, was<br />

widely used by engineers <strong>to</strong> analyze the component<br />

structure strength as well as the entire<br />

car strength and stiffness.<br />

the occupant restraint system integration was<br />

also tested virtually for safety using Virtual<br />

performance Solution.<br />

“ our analysis engineers love<br />

pam-CraSH. it is becoming<br />

the reference analysis <strong>to</strong>ol<br />

of the crash simulation<br />

platform.”<br />

Dr. Chen Gan,<br />

deputy Chief Engineer,<br />

dongfeng mo<strong>to</strong>r Corporation<br />

dFm benefited from a single simulation model<br />

<strong>to</strong> run all performance tests, thus avoiding<br />

repeating work. While the side crash engineers<br />

set up seat, airbag and dummy for side crash<br />

testing and performed the side crash, another<br />

team of engineers from a different speciality are<br />

able <strong>to</strong> divide the basic model, load seat belt<br />

anchors and improve the local model. through<br />

strict job analysis, the Fengshen S30 solved<br />

the defects early in the product development<br />

Cycle, passed successfully and even surpassed<br />

national forced regulations, and ensured the<br />

development tasks were done favorably.<br />

“We used Virtual performance Solution for a<br />

number of crash and safety simulation analyses<br />

with pam-CraSH <strong>to</strong> develop the dongfeng<br />

Fengshen S30. We found and solved many<br />

problems. pam-CraSH is a good crash and<br />

safety simulation <strong>to</strong>ol, which guarantees finishing<br />

the design work in time. We are planning <strong>to</strong><br />

use it widely in new product developments,”<br />

said Dr. Chen Gan, deputy Chief Engineer at<br />

dongfeng mo<strong>to</strong>r Corporation.<br />

A B O U T D O N G F E N G M O T O R<br />

C O R P O R AT I O N<br />

Dongfeng Mo<strong>to</strong>r Corporation is one of the<br />

three giant au<strong>to</strong> makers in China; including passenger<br />

vehicles, commercial vehicles, engine,<br />

au<strong>to</strong> parts & components, and equipment as<br />

main businesses. With about a 14% share of<br />

China’s au<strong>to</strong>motive market in 2008, Dongfeng<br />

Mo<strong>to</strong>r Corporation ranks respectively twentieth<br />

in the Top 500 domestic enterprises and<br />

fifth in the Top 500 domestic manufacturers<br />

in China.<br />

www.dfmc.com.cn<br />

s u c c e s s s t o r i e s<br />

Body-In-White simulation<br />

Frontal crash simulation<br />

for more information:<br />

www.esi-group.com/virtual-performancesolution<br />

issue 39 | spring / summer 2010 11

s u c c e s s s t o r i e s<br />

A long-standing relationship<br />

Ford mo<strong>to</strong>r Company and ESi have had a longstanding<br />

relationship since the early nineties. it<br />

is then that Ford mo<strong>to</strong>r Company started using<br />

pam-CraSH for advanced biomechanics simulation<br />

in research and development, and they<br />

still do <strong>to</strong>day. pam-CraSH is ESi’s structural<br />

crash analysis application software, included in<br />

Virtual performance Solution.<br />

the project started with human head injury<br />

modeling in pam-CraSH and continued <strong>to</strong><br />

12<br />

building the whole human body model. Ford<br />

is one of the few carmakers developing human<br />

body modeling techniques <strong>to</strong>day. thanks <strong>to</strong><br />

these technologies, virtual human crash tests<br />

can be realized. the virtual human models<br />

are savvy alternatives <strong>to</strong> study the dynamic<br />

responses of real humans during blunt impacts,<br />

since using actual human subjects for physical<br />

testing is undesirable, if not impossible.<br />

Defining impact injury<br />

criteria<br />

Ford mo<strong>to</strong>r Company uses pam-CraSH mostly<br />

<strong>to</strong> perform impact biomechanics research.<br />

Engineers set up model and related parameters<br />

<strong>to</strong> measure the impact responses of the vehicle<br />

and different parts of the occupant – including<br />

brain, chest, thorax, abdomen and low extremity<br />

– during vehicle crashes.<br />

the starting point of the project is brain injury<br />

modeling, which is of high importance and<br />

complexity in vehicle safety. then the rest of<br />

the body is modeled.<br />

it is essential that the model be as close as<br />

possible <strong>to</strong> the real human, and that including<br />

accurate model geometry and human-like<br />

material properties.<br />

biomechanics<br />

Ford uses PAM-CRASH for human<br />

modeling <strong>to</strong> advance au<strong>to</strong>motive<br />

safety research<br />

“ pam-CraSH is a tailored<br />

s i m u l a t i o n t o o l fo r<br />

a d v a n c i n g r e s e a r c h<br />

i n b i o m e c h a n i c s i n<br />

replacement of impact<br />

tests with human body<br />

models.”<br />

Dr. Jesse Ruan,<br />

technical Specialist, Biomechanics and<br />

Human Body modeling,<br />

Ford mo<strong>to</strong>r Company<br />

Crash Simulation with Dummy Model Crash Simulation with Human Body Model<br />

Stress-strain analyses are performed on the<br />

deformable model, as stresses/strains are the<br />

physical parameters related <strong>to</strong> injury, recovery,<br />

and growth of biological tissues.<br />

injury criteria are then defined once the mechanisms<br />

of injury are known through the impact<br />

simulations with the human body model.<br />

Human Head Injury Finite Element Model<br />

A B O U T F O R D M O T O R<br />

C O M PA N y<br />

Ford Mo<strong>to</strong>r Company, a global au<strong>to</strong>motive<br />

industry leader based in Dearborn (MI, USA),<br />

manufactures or distributes au<strong>to</strong>mobiles<br />

across six continents. With about 200,000<br />

employees and about 90 plants worldwide,<br />

the company’s au<strong>to</strong>motive brands include<br />

Ford, Lincoln and Mercury. The company provides<br />

financial services through Ford Mo<strong>to</strong>r<br />

Credit Company.<br />

www.ford.com<br />

crash, impact & safety<br />

for more information:<br />

www.esi-group.com/biomechanics<br />

esi talk

sheet metal forming<br />

Tecnalia-Labein uses<br />

PAM-STAMP 2G<br />

<strong>to</strong> design an industrial<br />

hotformed part<br />

s u c c e s s s t o r i e s<br />

Hotforming simulation enables tecnalia-labein <strong>to</strong> notably reduce quenching times and direct cost,<br />

better understand the process and obtain a robust design.<br />

Hotforming involves the stamping and press hardening<br />

of high temperature heated blanks with<br />

active cooled <strong>to</strong>ols, a complex process in which a<br />

high number of physical phenomena occur simultaneously.<br />

is it possible <strong>to</strong> use a fully coupled simulation<br />

handling all these parameters? or is uncoupled<br />

simulation still the best way for optimum process<br />

design?<br />

<strong>to</strong> find out, tecnalia-labein chose pam-Stamp<br />

2G <strong>to</strong> simulate the hotforming of the central part<br />

of an au<strong>to</strong>motive B-pillar, geometry courtesy of<br />

renault, where physical tests with a pro<strong>to</strong>type<br />

<strong>to</strong>oling manufactured by diede were used <strong>to</strong><br />

validate the methodology and results.<br />

Hotformed au<strong>to</strong>motive B-Pillar<br />

Simulation was first performed in terms of drawin<br />

shape and value, thinning, thickness, radius<br />

runover, wrinkling, thermal distribution within the<br />

blank, press force, and hardness. the results were<br />

then confronted <strong>to</strong> experimental results, correlating<br />

accurately.<br />

the next <strong>step</strong> was <strong>to</strong> determine the die behavior<br />

and identify potential cooling improvements that<br />

could be applied on the final <strong>to</strong>ol design, by using<br />

another general purpose Finite Element method<br />

(FEm), in an uncoupled way. the optimization of<br />

fac<strong>to</strong>rs affecting heat transfer from the hot blank<br />

<strong>to</strong> the cooling fluid within the <strong>to</strong>oling is essential<br />

<strong>to</strong> ensure completely quenched parts whilst<br />

reducing cycle time, thermal stresses and <strong>to</strong>ol<br />

wear.<br />

Using thermal simulations with the general purpose<br />

FEm code, the final <strong>to</strong>ol’s cooling channels<br />

were redesigned <strong>to</strong> eliminate hot spots while<br />

achieving a low and uniform temperature distribution,<br />

ensuring proper quenching of the part,<br />

following diede and renault specifications.<br />

Thickness correlation<br />

“ pam-Stamp 2G has<br />

enabled a fast design of<br />

the hotforming <strong>to</strong>oling,<br />

and due <strong>to</strong> the high<br />

level of accuracy of the<br />

results, it has allowed the<br />

validation of the <strong>to</strong>oling<br />

and simulation results<br />

with the experimental<br />

tests.”<br />

Iñigo Aranguren /Marian Gutiérrez<br />

(au<strong>to</strong>motive Unit, tecnalia-labein)<br />

A B O U T T E C N A L I A - L A B E I N<br />

Originally founded in 1955, Tecnalia-Labein is<br />

the biggest technology center in Spain working<br />

mainly with businesses, which seeks <strong>to</strong> be<br />

a natural ally of firms in the marketplace and<br />

help them develop their innovation capabilities<br />

using technology <strong>to</strong> provide a competitive<br />

edge.<br />

www.labein.es<br />

for more information:<br />

www.esi-group.com/sheet-metal-forming<br />

issue 39 | spring / summer 2010 13

s u c c e s s s t o r i e s<br />

IAC streamlines its au<strong>to</strong>motive<br />

component simulation and<br />

reporting process with<br />

Visual-Process<br />

by dE Edi<strong>to</strong>rs | published February 24, 2010<br />

as part of its operations, international<br />

au<strong>to</strong>motive Components (iaC) receives geometric<br />

studio design surfaces for interior components<br />

from au<strong>to</strong>motive original equipment<br />

manufacturers (oEms) in the form of a computer-aided<br />

design (Cad) files. the company’s<br />

engineers use this information <strong>to</strong> design parts<br />

and meet federal crash test requirements. the<br />

oEms are responsible for testing the systems <strong>to</strong><br />

ensure they comply with Federal mo<strong>to</strong>r Vehicle<br />

Safety Standards (FmVSS) for instrument panels<br />

(ips) and upper interior components.<br />

Federal Safety Standards<br />

FmVSS 201 states that when an area of the<br />

instrument panel is hit by a 6.8 Kg, 165 mm<br />

diameter head at 19 Km/hr, the deceleration<br />

of the head should not exceed 80 g continuously<br />

for more than 3 ms. FmVSS 201U provides<br />

a similar requirement for upper interior<br />

components, such as the pillar trim, headliner,<br />

and grab handle, but it is expressed in terms of<br />

Head injury Criteria (HiC(d)) of less than 1000.<br />

European ECE-21 and EEC 74/60 regulations are<br />

similar, except they specify an impact speed of<br />

24 Km/hr.<br />

the oEm or supplier is responsible for identifying<br />

the zone in which the passenger’s head may<br />

contact the ip and upper interior components<br />

(Fig. 1). FmVSS 201 defines the head-impact area<br />

as the nonglazed surfaces of the interior that<br />

are statically contactable by a 6.5-inch diameter<br />

spherical head form, having a pivot point<br />

<strong>to</strong> <strong>to</strong>p-of-head adjustment ranging from 7.36<br />

14<br />

<strong>to</strong> 7.40 m. this process is normally undertaken<br />

<strong>to</strong> cover the range of dummies (5th%, 50th%,<br />

and 95th %).<br />

the regulations state that all points in the<br />

impact zone must meet the 80 g deceleration<br />

requirements. the oEm or supplier must select<br />

the number of representative points for simulation<br />

that fall in the calculated head-impact<br />

zone. For each impact point, the oEm or supplier<br />

must determine the impact angle of the<br />

head with that point. the regulations state the<br />

angle should be determined by positioning a<br />

line vertically at the seating reference point,<br />

the rearmost normal position where the hip<br />

contacts the seat and rotated down <strong>to</strong>ward<br />

the instrument panel until contact occurs. the<br />

intersection of the perpendicular with the<br />

panel assembly surface is the location of the<br />

point of impact, and the direction of impact is<br />

taken along the perpendicular.<br />

The Manual Process<br />

in the past, <strong>to</strong> assess the performance of interior<br />

systems, iaC analysts had <strong>to</strong> perform a<br />

lengthy manual process in a Cad system <strong>to</strong> calculate<br />

the potential head-impact zone, define<br />

impact points and approach angles, create<br />

input data for crash simulation, and generate<br />

a report from the simulation results. as part of<br />

this process, they selected a series of points<br />

in the impact zone and computed the impact<br />

angle for each point. the analysts positioned<br />

the head form at the impact point, assigned it<br />

an initial velocity, created contacts between<br />

the head form and ip, created input-output<br />

simulation systems integration<br />

the au<strong>to</strong>mated workflow substantially reduces design and crash testing analysis time, increases<br />

accuracy, and cuts engineering costs.<br />

control cards, exported lS-dYna input data,<br />

read the lS-dYna result files, and created an<br />

electronic report of the analysis results.<br />

iaC’s engineers were dissatisfied with this process<br />

because it tied up highly skilled analysts for<br />

a considerable amount of time. in addition, it<br />

often was a bottleneck in the delivery schedule.<br />

Finding a Better Way<br />

Fig. 1<br />

the analysts evaluated several possible solutions<br />

for au<strong>to</strong>mating the manual process.<br />

a number of vendors offered the ability <strong>to</strong><br />

develop au<strong>to</strong>mated workflow around different<br />

Cad and simulation solutions. iaC’s engineers<br />

decided that ESi offered a flexible solution that<br />

enabled them <strong>to</strong> develop a script that au<strong>to</strong>matically<br />

determines the impact zones, selects<br />

impact points, and calculates impact angles at<br />

a studio released Cad level very early in the<br />

product development cycle.<br />

“ESi’s Visual-process solution made it possible<br />

<strong>to</strong> au<strong>to</strong>mate the entire simulation setup and<br />

reporting process,” said Arun Chickmenahalli,<br />

Computer aided Engineering manager for<br />

iaC. “this substantially increased the time-<br />

esi talk

savings that we were able <strong>to</strong> achieve in this<br />

application.”<br />

Developing an<br />

Au<strong>to</strong>mated System<br />

iaC worked with ESi <strong>to</strong> develop an au<strong>to</strong>mated<br />

system for this process. the solution is based<br />

on ESi’s VisualdSS (decision Support System),<br />

which is designed <strong>to</strong> build and manage simulation<br />

models for multiple domains, au<strong>to</strong>mate<br />

processes and workflows, manage simulation<br />

content and data, and support knowledgebased<br />

decisions and au<strong>to</strong>mated reporting. the<br />

environment captures and au<strong>to</strong>matically executes<br />

simulation processes, using wrappers for<br />

popular simulation and Cad <strong>to</strong>ols. templates<br />

are defined, using the python scripting language,<br />

and the task-execution sequences can<br />

be described through a visual interface. the<br />

templates library can be searched, using filters<br />

and defined criteria for re-use in new projects.<br />

another key component in the application<br />

is ESi’s Visual-Crash dyna, which provides an<br />

environment that enables both au<strong>to</strong>mated and<br />

manual creation of lS-dYna models. Visual-<br />

Crash dyna enables graphical creation of an<br />

lS-dYna input deck, modification and deletion<br />

of contacts, materials, constraints, control<br />

cards, and crash entities. Visual-Crash dyna<br />

modification <strong>to</strong>ols help correct errors before<br />

the model is submitted <strong>to</strong> the solver. Visual-<br />

Crash dyna is incorporated in the au<strong>to</strong>mated<br />

process, and analysts also use it <strong>to</strong> check and<br />

tweak the input deck.<br />

Script Operation<br />

iaC analysts defined the inputs and outputs<br />

required <strong>to</strong> execute the sequence of codes <strong>to</strong><br />

au<strong>to</strong>mate the entire crash simulation set-up<br />

and reporting process. ESi developed the application’s<br />

core by using iaC’s expertise and best<br />

practices. the actual process begins when the<br />

user inputs data, such as the seating reference<br />

point and the center of gravity of the head, and<br />

reads the Cad data from dassault Systèmes<br />

Catia, Siemens plm nX Cad software, or any<br />

other suitable Cad format. the script au<strong>to</strong>matically<br />

scans the Cad file by moving the<br />

head model as specified in FmVSS regulations<br />

<strong>to</strong> identify the impact zones. the script selects<br />

impact points based on criteria provided by the<br />

analyst/oEms (Fig. 2). For example, one oEm<br />

Fig. 2. The crash-test analysis calculates<br />

the head-impact zone.<br />

Fig. 3. The au<strong>to</strong>mated analysis also calculates<br />

target points and approach angles<br />

for head impacts.<br />

might specify that impact points be selected<br />

every 100 mm, starting with the center of the<br />

impact zone. the script computes the impact<br />

angle for each point and positions the head<br />

form at the impact point (Fig. 3). the initial<br />

velocity is assigned <strong>to</strong> the head form as defined<br />

in the regulation. the script then creates<br />

lS-dYna contacts between the head form<br />

and the instrument panel interior and among<br />

the instrument panel interior components.<br />

afterward, the script creates the lS-dYna<br />

input-output control cards. an experienced<br />

analyst reviews the input data and sometimes<br />

makes changes, using the Visual-Crash dyna<br />

environment.<br />

For example, an analyst may move an impact<br />

point, perhaps <strong>to</strong> a location on the ip, opposite<br />

a bracket, which may be particularly sensitive<br />

in terms of causing injury. the analyst directs<br />

the script <strong>to</strong> export the lS-dYna input data<br />

and submits it <strong>to</strong> the solver. When the solver<br />

has completed its run, the script captures the<br />

results. the analyst then runs the report-generation<br />

command. the script captures the results<br />

and formats them as defined by a template created<br />

by the analyst. the software can produce<br />

reports in Html, pdF, and ppt formats.<br />

The Benefits<br />

“the Visual-process script has substantially<br />

improved our process <strong>to</strong> comply with FmVSS<br />

201 regulations. Unlike other solutions that we<br />

looked at, Visual-process was able <strong>to</strong> au<strong>to</strong>mate<br />

the complete end-<strong>to</strong>-end head-impact simulation<br />

process,” said Arun Chickmenahalli.<br />

“ as a result, we have<br />

been able <strong>to</strong> reduce by<br />

four weeks the time<br />

needed <strong>to</strong> complete<br />

the simulation process<br />

required <strong>to</strong> comply<br />

with regulations, while<br />

increasing the accuracy<br />

of the simulation.”<br />

Arun Chickmenahalli,<br />

Computer aided Engineering manager,<br />

iaC<br />

the time savings help iaC bring products <strong>to</strong><br />

market faster, reduce its engineering costs, and<br />

enable its analysts <strong>to</strong> complete more projects.<br />

the improvements in accuracy are impossible<br />

<strong>to</strong> quantify at this time but are also substantial.<br />

the definition of impact zones, selection<br />

of impact points, calculation of impact angles,<br />

and other aspects of the process are now performed<br />

by an auditable process so the company<br />

has eliminated the risk of manual errors.<br />

A B O U T I N T E R N AT I O N A L<br />

A U T O M O T I V E C O M P O N E N T S<br />

( I A C )<br />

IAC is a leading global supplier of instrument<br />

and door panels, headliners, carpet and acoustic<br />

systems, cockpits, and fascias. Originally the<br />

former interiors divisions of Lear and Collins &<br />

Aikman, IAC has nearly a century of expertise,<br />

dating back <strong>to</strong> the Ford Model T. The company<br />

has more than 80 manufacturing sites<br />

and more than 90 <strong>to</strong>tal locations in 17 countries.<br />

IAC has more than 23,000 employees and<br />

approximately $3.2 billion in sales worldwide.<br />

www.iacna.com<br />

for more information:<br />

www.esi-group.com/simulation-systems-integration<br />

issue 39 | spring / summer 2010 15

s u c c e s s s t o r i e s<br />

LETOV develops two<br />

components in a single high<br />

quality part with PAM-FORM<br />

By enabling the forming of an integrated shape in one shot, pam-Form helps lE<strong>to</strong>V<br />

reduce the weight of the part as well as the cost of production without impairing<br />

its mechanical characteristics.<br />

nowadays, the use of composite materials<br />

has expanded in various areas of science and<br />

technology due <strong>to</strong> their special properties.<br />

thus, developers and manufacturers of composite<br />

parts in order <strong>to</strong> remain competitive, are<br />

urged <strong>to</strong> leverage their engineering expertise<br />

<strong>to</strong> address the challenges of high performance<br />

composites and increase the process and material<br />

understanding for future applications.<br />

one of lE<strong>to</strong>V’s recent projects has been the<br />

production of clips for a major aircraft construc<strong>to</strong>r.<br />

Clips are small joining parts in the fuselage<br />

structure of an airplane made of two components.<br />

they have chosen this project <strong>to</strong> try<br />

out the development of an integrated part in<br />

a single shot without impacting the mechanical<br />

properties of the clip, using virtual pro<strong>to</strong>typing<br />

in order <strong>to</strong> lower production costs and weight.<br />

<strong>to</strong> do so, lE<strong>to</strong>V engineers used ESi composites<br />

forming simulation software pam-Form<br />

<strong>to</strong> evaluate multiple strategies and determine<br />

the right <strong>to</strong>oling and process parameters of the<br />

integrated composites clip. as the clip’s shape is<br />

quite complex, this would have required many<br />

trials and considerable development time without<br />

the use of a dedicated software <strong>to</strong>ol.<br />

pam-Form was also used for <strong>to</strong>ol design optimization<br />

where lE<strong>to</strong>V engineers measured<br />

the high temperature material property values<br />

characterizing the forming behavior of the composites<br />

part. the simulation displayed the fiber<br />

orientation changes resulting from the shaping,<br />

especially in the corners. the fiber orientation<br />

induced by the forming process is critical for the<br />

mechanical behavior of the final part.<br />

16<br />

Simulation with pam-Form allowed lE<strong>to</strong>V<br />

engineers <strong>to</strong> design a theoretical virtual model<br />

with the forming <strong>to</strong>ol and blank shape they<br />

determined <strong>to</strong> be best. the use of pam-Form<br />

for the virtual pro<strong>to</strong>typing of clips proved <strong>to</strong><br />

be a success and confirmed that the combination<br />

of experienced engineers and pam-Form<br />

simulation <strong>to</strong>ol can be very effective for problem<br />

solving in high performance composite<br />

applications.<br />

“ pam-Form helped us<br />

achieve our project<br />

goals: lower weight and<br />

cost of production while<br />

preserving the mechanical<br />

properties of the part.<br />

additionally, it provided<br />

us with more information<br />

o n o p t i m i z i n g o u r<br />

p ro d u c t i o n p ro ce ss<br />

which can be reapplied<br />

<strong>to</strong> similar projects.”<br />

Josef K ena,<br />

development manager<br />

lE<strong>to</strong>V lEtECKa VYroBa ltd.,<br />

GroUpE latECoErE<br />

composites & plastics<br />

A B O U T L E T O V L E T E C K A<br />

V y R O B A LT D<br />

The company was established in 1918 as the<br />

first facility for aircraft manufacturing in the<br />

Czech Republic, developing and manufacturing<br />

parts and subassemblies for civil and<br />

military aircraft. Since 2000, LETOV LETECKA<br />

VyROBA Ltd. is a subsidiary of the French company,<br />

GROUPE LATECOERE. The Composite<br />

Production Center was created for manufacturing<br />

and also development of composite<br />

parts for civil aircrafts.<br />

www.le<strong>to</strong>v.cz<br />

Axial Strain on Fibers after forming<br />

for more information:<br />

www.esi-group.com/composites<br />

Pro<strong>to</strong>type built based on<br />

PAM-FORM computations<br />

esi talk

composites & plastics<br />

<strong>ESI</strong> is actively involved in<br />

the Research & Development<br />

of composite materials<br />

<strong>ESI</strong> GmbH successfully coordinates the PreCarBi project<br />

<strong>to</strong>day, advanced composites in the aerospace<br />

industry mostly use either prepreg tape<br />

laying, or resin infusion of dry textiles (liquid<br />

Composite molding or lCm). Generally, prepreg<br />

composites have superior stiffness, strength<br />

and fatigue resistance due <strong>to</strong> <strong>to</strong>ughened resins<br />

and high fiber content. However, this type of<br />

materials suffers from high costs, limited shapeability,<br />

complex, expensive and time-consuming<br />

manufacturing, and limited shelf life.<br />

While lCm technologies can overcome these<br />

drawbacks, lCm relies on low viscosity resins for<br />

infusion and suffers from fiber misalignments<br />

due <strong>to</strong> textile patterns, both leading <strong>to</strong> poorer<br />

mechanical performance in<strong>to</strong>lerable for many<br />

structural aircraft applications.<br />

this is why and where ESi initiated the European<br />

Commission (EC) funded project – preCarBi -<br />

three years ago <strong>to</strong> improve composite materials<br />

accelerating its contribution <strong>to</strong> the research<br />

& development of composite materials, ESi<br />

GmbH coordinates the recently initiated 4-year<br />

inFUComp European research Consortium.<br />

the Consortium involves fourteen partners<br />

and aims at providing an <strong>End</strong>-<strong>to</strong>-<strong>End</strong> Virtual<br />

pro<strong>to</strong>typing solution from pre-form design <strong>to</strong><br />

manufacturing (lri) specific <strong>to</strong> the manufacture<br />

of large aerospace composite parts. Simulation<br />

will minimize expensive and time-consuming<br />

‘trial and error’ testing methods and help manufacture<br />

high quality parts, faster and at lower<br />

cost.<br />

the inFUComp project will positively contribute<br />

<strong>to</strong> further the use of textile composites in<br />

the aeronautic sec<strong>to</strong>r, lowering cost, improving<br />

performance, increasing payloads and reducing<br />

fuel emissions. although the planned research<br />

for lCm. involving eleven partners from 9 coun-<br />

tries, the consortium had for main objective <strong>to</strong><br />

develop a new generation of bindered composite<br />

materials and associated simulation <strong>to</strong>ols.<br />

the preCarBi project <strong>to</strong>ok in<strong>to</strong> account three<br />

principal materials: new composite materials<br />

for bindered carbon yarns, compatible resins,<br />

and converted new binder yarn composites<br />

in<strong>to</strong> industrial preforms (Woven or non-crimp<br />

Fabric).<br />

ESi’s major contribution <strong>to</strong> the project has been<br />

forming, infusion and mechanical analysis of<br />

industrial aerospace applications manufacturing<br />

with the liquid resin infusion (lri) technology,<br />

using pam-QUiKForm and pam-rtm, simulation<br />

solutions for thermoforming and manufacturing<br />

of plastics and composites.<br />

this resulting research is considered an important<br />

contribution for advanced liquid resin<br />

<strong>ESI</strong> initiates the 4-year INFUCOMP consortium<br />

focuses on aerospace applications, it is expected<br />

the results will be very relevant <strong>to</strong> other<br />

industries.<br />

“the inFUComp project is an essential part<br />

of an integrated composites solution package<br />

and will provide a unique opportunity <strong>to</strong> move<br />

forward with composites simulation and <strong>to</strong><br />

develop new <strong>to</strong>ols in collaboration with leading<br />

research and industrial aerospace partners,”<br />

said Dr. Anthony Pickett, Scientific direc<strong>to</strong>r at<br />

ESi GmbH.<br />

Coordina<strong>to</strong>r: ESi GmbH<br />

mergenthalerallee 15-21<br />

65760 Eschborn - GErmanY<br />

Phone: +49 (0)6196 9583 0<br />

Fax: +49 (0) 6196 9583 111<br />

E-mail: anthony.pickett@esi-group.com<br />

p a r t n e r h i g h l i g h t s<br />

infusion (lri) technologies <strong>to</strong> compete with<br />

expensive and complex prepreg composite<br />

technologies.<br />

The Research Consortium team included<br />

Airbus, Eurocopter, FACC, Toho Tenax Europe,<br />

Sigmatex, Huntsman Advanced Materials (Switzerland)<br />

GmbH, <strong>ESI</strong> <strong>Group</strong>, Cranfield University,<br />

IPM Latvia, University of Patras and SICOMP.<br />

P180 Aircraft<br />

Courtesy : Piaggio Aero Industries<br />

for more information:<br />

www.esi-group.com/composites<br />

issue 39 | spring / summer 2010 17

p a r t n e r h i g h l i g h t s<br />

<strong>ESI</strong> sponsors<br />

the Student Formula<br />

SAE Racing Team Pilsen<br />

the University of West Bohemia succeeds in designing the front deformable part of a Formulastyle<br />

race car thanks <strong>to</strong> pam-CraSH and Visual-Environment.<br />

the University of West Bohemia (UWB) in pilsen,<br />

Czech republic, joined the student design competition<br />

- Formula SaE® - organized by SaE<br />

international (Society of au<strong>to</strong>motive Engineers).<br />

the concept behind the competition is the<br />

development of a small Formula-style race car<br />

for a fictional manufacturing company. Each student<br />

team designs, builds and tests a pro<strong>to</strong>type<br />

based on a series of rules, which is <strong>to</strong> be evaluated<br />

for its potential as a production item.<br />

the UWB team is the first team in Czech<br />

republic <strong>to</strong> successfully complete the project<br />

by creating a pro<strong>to</strong>type which meets the set<br />

criteria. the UWB team obtained the support<br />

of mECaS ESi for the Formula’s deformable elements‘<br />

design, where simulation was needed.<br />

18<br />

Formula UWB Racing Team Pilsen<br />

Simulation of the front deformable element with PAM-CRASH<br />

crash, impact & safety<br />

simulation systems integration<br />

3 questions for Jiri Koldinský, UWB team leader:<br />

What are the main achievements of the team?<br />

We consider the fabrication of the entire<br />

Formula-style race car from the very beginning in<br />

only 6 months as our major success. indeed, we<br />

achieved this within a relatively small team, with<br />

limited material support and minimum skills. our<br />

goal was <strong>to</strong> participate in the Formula SaE italy<br />

where students had the opportunity <strong>to</strong> show<br />

their pro<strong>to</strong>type; an objective that we reached.<br />

How well did MECAS <strong>ESI</strong> support this project?<br />

mECaS ESi provided the pam-CraSH and<br />

Visual-Environment licenses free of charge <strong>to</strong><br />

the team, enabling us <strong>to</strong> efficiently design the<br />

frontal deformable element. indeed, the front<br />

part meets the safety requirements set in the<br />

series of rules. this would have been difficult <strong>to</strong><br />

accomplish without mECaS ESi’s help. the company<br />

gave us also valuable advices throughout<br />

the project in regards <strong>to</strong> virtual pro<strong>to</strong>typing.<br />

Do you wish <strong>to</strong> further cooperate with<br />

MECAS <strong>ESI</strong>?<br />

definitely! next year, we will have <strong>to</strong> design a<br />

lighter deformable part, project in which we will<br />

appreciate mECaS ESi’s help and cooperation.<br />

A B O U T F O R M U L A S A E ®<br />

Formula SAE® promotes careers and excellence<br />

in engineering as it encompasses all aspects of<br />

the au<strong>to</strong>motive industry including research,<br />

design, manufacturing, testing, developing,<br />

marketing, management and finances. Formula<br />

SAE takes students out of the classroom and<br />

allows them <strong>to</strong> apply textbook theories <strong>to</strong> real<br />

work experiences.<br />

www.students.sae.org<br />

for more information:<br />

www.esi-group.com/virtual-performancesolutionwww.esi-group/simulation-systems-integration<br />

www.uwbformula.cz<br />

esi talk

crash, impact & safety<br />

Virtual Performance Educational<br />

Package initiates students <strong>to</strong> simulation<br />

ESi is present in the academic community<br />

through active collaborations on research<br />

and development projects, and more recently<br />

through educational programs. indeed, with the<br />

release of a Virtual performance Educational<br />

package, ESi makes its Virtual performance<br />

Solution accessible <strong>to</strong> undergraduate and<br />

masters students in a special version for Finite<br />

Element simulation.<br />

offering an easy-learning introduction <strong>to</strong> simulation<br />

basics, the package enables static and<br />

modal analyses (implicit solver) as well as crash/<br />

impact simulation (pam-CraSH explicit solver)<br />

through self-learning tu<strong>to</strong>rials based on au<strong>to</strong>motive<br />

and aerospace case studies.<br />

“tu<strong>to</strong>rials using pam-CraSH explicit finite element<br />

code are an integral part of the Finite<br />

vibro-acoustics<br />

Elements and materials modeling module<br />

of the advanced materials mSc course at<br />

Cranfield University. the students use the soft-<br />

ware <strong>to</strong> reinforce their learning on explicit finite<br />

element technologies, whilst investigating real<br />

life impact problems. the tu<strong>to</strong>rials provided<br />

by ESi allow a very efficient introduction <strong>to</strong><br />

the pre- and post- processing <strong>to</strong>ols”, declared<br />

Dr. Alex Skordos, academic fellow at Cranfield<br />

University in the UK. “the Virtual performance<br />

Educational package is an extremely useful<br />

teaching <strong>to</strong>ol which ties very well with our<br />

research activities”.<br />

the Virtual performance Educational package<br />

is free for students and teachers during the<br />

first 6 months and is available for download at<br />

www.esi-educational.com.<br />

VA One v2009.0 includes advanced<br />

models of foam and fibers<br />

poroelastic materials such as foams and fibers<br />

are an important part of the design of quiet<br />

products with superior noise and vibration performance.<br />

the Va one 2009.0 release includes<br />

improved functionality for modeling foams and<br />

fibers at low frequencies using foam finite elements;<br />

and also at mid and high frequencies<br />

including au<strong>to</strong>matic calculation of treatment<br />

coverage from Cad or FE data.<br />