The Olefin Metathesis Reaction

The Olefin Metathesis Reaction

The Olefin Metathesis Reaction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Myers<br />

Reviews:<br />

Nicolaou, K. C.; Bulger, P. G.; Sarlah, D. Angew. Chem., Int. Ed. Engl. 2005, 44, 4490–4527.<br />

Grubbs, R. H. Tetrahedron 2004, 60, 7117–7140.<br />

Chatterjee, A. K.; Choi, T.-L.; Sanders, D. P.; Grubbs, R. H.<br />

J. Am. Chem. Soc. 2003, 125, 11360–11370.<br />

Connon, S. J.; Blechert, S. Angew. Chem., Int. Ed. Engl. 2003, 42, 1900–1923.<br />

Fürstner, A. Angew. Chem., Int. Ed. Engl. 2000, 39, 3013–3043.<br />

Grubbs, R. H.; Chang, S. Tetrahedron 1998, 54, 4413–4450.<br />

Armstrong, S. K. J. Chem. Soc., Perkin Trans. 1 1998, 371–388.<br />

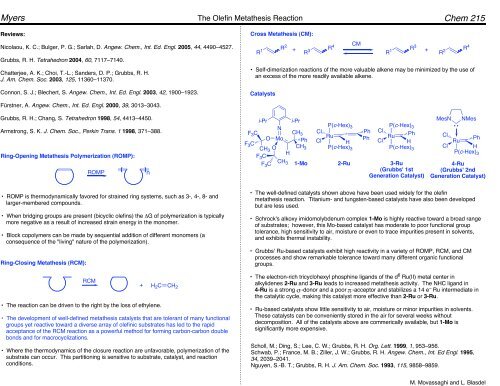

Ring-Opening <strong>Metathesis</strong> Polymerization (ROMP):<br />

ROMP<br />

• ROMP is thermodynamically favored for strained ring systems, such as 3-, 4-, 8- and<br />

larger-membered compounds.<br />

• When bridging groups are present (bicyclic olefins) the ΔG of polymerization is typically<br />

more negative as a result of increased strain energy in the monomer.<br />

• Block copolymers can be made by sequential addition of different monomers (a<br />

consequence of the "living" nature of the polymerization).<br />

Ring-Closing <strong>Metathesis</strong> (RCM):<br />

RCM<br />

• <strong>The</strong> reaction can be driven to the right by the loss of ethylene.<br />

n<br />

H 2C CH 2<br />

• <strong>The</strong> development of well-defined metathesis catalysts that are tolerant of many functional<br />

groups yet reactive toward a diverse array of olefinic substrates has led to the rapid<br />

acceptance of the RCM reaction as a powerful method for forming carbon-carbon double<br />

bonds and for macrocyclizations.<br />

• Where the thermodynamics of the closure reaction are unfavorable, polymerization of the<br />

substrate can occur. This partitioning is sensitive to substrate, catalyst, and reaction<br />

conditions.<br />

+<br />

<strong>The</strong> <strong>Olefin</strong> <strong>Metathesis</strong> <strong>Reaction</strong> Chem 215<br />

Cross <strong>Metathesis</strong> (CM):<br />

R 1<br />

R 2<br />

R3 R4 R1 R3 CM<br />

+ +<br />

• Self-dimerization reactions of the more valuable alkene may be minimized by the use of<br />

an excess of the more readily available alkene.<br />

Catalysts<br />

i-Pr i-Pr<br />

N<br />

F3C CH3 O Mo Ph<br />

F3C CH O CH3 3<br />

H<br />

F3C F<br />

CH3 3C 1-Mo<br />

Cl<br />

Cl<br />

P(c-Hex) 3<br />

Ru<br />

H<br />

P(c-Hex) 3<br />

2-Ru<br />

Cl<br />

Cl<br />

P(c-Hex) 3<br />

Ru<br />

Ph<br />

H<br />

P(c-Hex) 3<br />

3-Ru<br />

(Grubbs' 1st<br />

Generation Catalyst)<br />

• <strong>The</strong> well-defined catalysts shown above have been used widely for the olefin<br />

metathesis reaction. Titanium- and tungsten-based catalysts have also been developed<br />

but are less used.<br />

• Schrock's alkoxy imidomolybdenum complex 1-Mo is highly reactive toward a broad range<br />

of substrates; however, this Mo-based catalyst has moderate to poor functional group<br />

tolerance, high sensitivity to air, moisture or even to trace impurities present in solvents,<br />

and exhibits thermal instability.<br />

• Grubbs' Ru-based catalysts exhibit high reactivity in a variety of ROMP, RCM, and CM<br />

processes and show remarkable tolerance toward many different organic functional<br />

groups.<br />

Ph<br />

Ph<br />

• <strong>The</strong> electron-rich tricyclohexyl phosphine ligands of the d6 Ru(II) metal center in<br />

alkylidenes 2-Ru and 3-Ru leads to increased metathesis activity. <strong>The</strong> NHC ligand in<br />

4-Ru is a strong -donor and a poor -acceptor and stabilizes a 14 e – σ π<br />

Ru intermediate in<br />

the catalytic cycle, making this catalyst more effective than 2-Ru or 3-Ru.<br />

• Ru-based catalysts show little sensitivity to air, moisture or minor impurities in solvents.<br />

<strong>The</strong>se catalysts can be conveniently stored in the air for several weeks without<br />

decomposition. All of the catalysts above are commerically available, but 1-Mo is<br />

significantly more expensive.<br />

R 2<br />

MesN<br />

Cl<br />

Cl<br />

R 4<br />

NMes<br />

Ph<br />

Ru<br />

H<br />

P(c-Hex) 3<br />

4-Ru<br />

(Grubbs' 2nd<br />

Generation Catalyst)<br />

Scholl, M.; Ding, S.; Lee, C. W.; Grubbs, R. H. Org. Lett. 1999, 1, 953–956.<br />

Schwab, P.; France, M. B.; Ziller, J. W.; Grubbs, R. H. Angew. Chem., Int. Ed Engl. 1995,<br />

34, 2039–2041.<br />

Nguyen, S.-B. T.; Grubbs, R. H. J. Am. Chem. Soc. 1993, 115, 9858–9859.<br />

M. Movassaghi and L. Blasdel

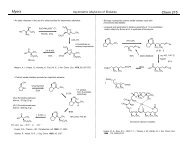

Mechanism:<br />

• <strong>The</strong> olefin metathesis reaction was reported as early as 1955 in a Ti(II)-catalyzed<br />

polymerization of norbornene: Anderson, A. W.; Merckling, M. G. Chem. Abstr. 1955,<br />

50, 3008i.<br />

• 15 years later, Chauvin first proposed that olefin metathesis proceeds via<br />

metallacyclobutanes: Herisson, P. J.-L.; Chauvin, Y. Makromol. Chem. 1970, 141,<br />

161–176.<br />

• It is now generally accepted that both cyclic and acyclic olefin metathesis reactions<br />

proceed via metallacyclobutane and metal-carbene intermediates: Grubbs, R. H.; Burk,<br />

P. L.; Carr, D. D. J. Am. Chem. Soc. 1975, 97, 3265–3266.<br />

EtO 2C<br />

CO 2Et<br />

Cl<br />

P(c-Hex) 3<br />

H<br />

Ru<br />

Cl H<br />

P(c-Hex) 3<br />

5 mol%<br />

CD 2Cl 2, 25 °C<br />

EtO 2C CO 2Et<br />

• A kinetic study of the RCM of diethyl diallylmalonate using a Ru-methylidene describes<br />

two possible mechanisms for olefin metathesis:<br />

• <strong>The</strong> "dissociative" mechanism assumes that upon binding of the olefin a phosphine is<br />

diplaced from the metal center to form a 16-electron olefin complex, which undergoes<br />

metathesis to form the cyclized product, regenerating the catalyst upon recoordination of<br />

the phosphine.<br />

• <strong>The</strong> "associative" mechanism assumes that an 18-electron olefin complex is formed<br />

which undergoes metathesis to form the cyclized product.<br />

• Addition of 1 equivalent of phosphine (with respect to catalyst) decreases the rate of the<br />

reaction by as much 20 times, supporting the dissociative mechanism.<br />

• It was concluded in this study that the "dissociative" pathway is the dominant reaction<br />

manifold (>95%).<br />

Dias, E. L.; Nguyen, S.-B. T.; Grubbs, R. H. J. Am. Chem. Soc. 1997, 119, 3887–3897.<br />

Dissociative:<br />

Cl<br />

Cl<br />

R<br />

Cl<br />

R<br />

Cl<br />

Cl<br />

Cl<br />

P<br />

Ru<br />

P<br />

P<br />

Cl H<br />

Ru<br />

H<br />

P<br />

P<br />

Ru<br />

P<br />

H<br />

H<br />

P<br />

Cl H<br />

Ru<br />

H<br />

P<br />

EtO 2C CO 2Et<br />

Associative:<br />

H<br />

H<br />

Cl<br />

R<br />

R<br />

c-C 5H 6(CO 2Et) 2<br />

R<br />

P<br />

Cl H<br />

Ru<br />

H<br />

P<br />

EtO 2C CO 2Et<br />

–P<br />

+P<br />

Cl<br />

c-C 5H 6(CO 2Et) 2<br />

Cl<br />

P<br />

Cl H<br />

Ru<br />

H<br />

Cl<br />

P<br />

Cl H<br />

Ru<br />

H<br />

P<br />

P<br />

Cl H<br />

Ru<br />

H<br />

EtO 2C CO 2Et<br />

Cl<br />

P = P(c-Hex) 3<br />

EtO2C R<br />

Cl<br />

H<br />

R<br />

Cl<br />

H<br />

R<br />

P<br />

Cl H<br />

Ru<br />

H<br />

P<br />

EtO 2C CO 2Et<br />

Cl<br />

=<br />

P<br />

Cl H<br />

Ru<br />

H<br />

P<br />

Cl H<br />

Ru<br />

H<br />

EtO 2C CO 2Et<br />

P<br />

Cl H<br />

Ru<br />

H<br />

P<br />

Cl<br />

CO 2Et<br />

Cl<br />

H<br />

Cl<br />

R<br />

Cl<br />

H<br />

R<br />

P<br />

Cl<br />

Ru<br />

P<br />

Cl<br />

Ru<br />

EtO 2C CO 2Et<br />

P<br />

Cl<br />

Ru<br />

P<br />

EtO 2C CO 2Et<br />

P<br />

Cl<br />

Ru<br />

P<br />

– C 2H 4<br />

– C 2H 4<br />

M. Movassaghi

Catalytic RCM of Dienes:<br />

substrate product time (h)<br />

O<br />

N X<br />

O Ph<br />

O Ph<br />

O<br />

O<br />

O<br />

R<br />

Ph<br />

Ph<br />

X = CF 3<br />

X = Ot-Bu<br />

R = CO 2H<br />

CH 2OH<br />

CHO<br />

a 2-4 mol% 2-Ru, C6H 6, 20 °C.<br />

O<br />

O Ph<br />

O<br />

O<br />

O<br />

N X<br />

O<br />

Ph<br />

Ph<br />

PhCH2 H<br />

N Cl –<br />

+ 4 mol% 2-Ru<br />

R<br />

Ph<br />

20 °C, 36 h<br />

CH 2Cl 2; NaOH<br />

79%<br />

1<br />

1<br />

CH2Ph N<br />

yield (%) a<br />

93<br />

91<br />

2 84<br />

5 86<br />

8 72<br />

1 87<br />

• Five-, six-, and seven-membered oxygen and nitrogen heterocycles and cycloalkanes are<br />

formed efficiently.<br />

• Catalyst 2-Ru can be used in the air, in reagent-grade solvents (C 6H 6, CH 2Cl 2, THF,<br />

t-BuOH).<br />

• In contrast to the molybdenum catalyst 1-Mo, which is known to react with acids, alcohols,<br />

and aldehydes, the ruthenium catalyst 2-Ru is stable to these functional groups.<br />

• Free amines are not tolerated by the ruthenium catalyst; the corresponding hydrochloride<br />

salts undergo efficient RCM with catalyst 2-Ru.<br />

Fu, G. C.; Nguyen, S.-B. T.; Grubbs, R. H. J. Am. Chem. Soc. 1993, 115, 9856–9857.<br />

1<br />

1<br />

1<br />

87<br />

88<br />

82<br />

Synthesis of Tri- and Tetrasubstituted Cyclic <strong>Olefin</strong>s via RCM<br />

substrate a<br />

E E R<br />

E E<br />

E E<br />

E E<br />

CH 3<br />

E E CH 3<br />

CH 3<br />

CH3E E<br />

E E<br />

R = CH<br />

E E<br />

3<br />

93<br />

CH 3<br />

CH 3<br />

i-Pr<br />

CH 3<br />

t-Bu<br />

Ph<br />

Br<br />

CH 2OH<br />

H 3C<br />

product<br />

H 3C<br />

E<br />

R<br />

E E<br />

CH3 E E<br />

E E<br />

E E<br />

E<br />

CH 3<br />

CH 3<br />

CH 3<br />

yield<br />

with 3-Ru (%) b<br />

98<br />

NR<br />

25<br />

NR<br />

98<br />

No RCM d<br />

NR<br />

NR<br />

yield<br />

with 1-Mo (%) c<br />

100<br />

100<br />

96<br />

97<br />

NR<br />

decomp<br />

97 100<br />

96 100<br />

No RCM d<br />

a E = CO2Et. b 0.01 M, CH 2Cl 2, 5 mol%. c 0.1 M, C 6H 6, 5 mol%. d Only<br />

recovered starting material and an acyclic dimer were observed. e <strong>The</strong><br />

isomeric cyclopentene product is not observed.<br />

93<br />

61<br />

96 e 100 e<br />

• Functional group compatibility permitting, the Mo-alkylidene catalyst is typically more<br />

effective for RCM of substituted olefins.<br />

Kirkland, T. A.; Grubbs, R. H. J. Org. Chem. 1997, 62, 7310–7318.<br />

–<br />

M. Movassaghi

Geminal Substitution<br />

H3C CH3 Si<br />

n<br />

O<br />

R<br />

O<br />

R R<br />

R R<br />

RCM in Methanol and Water<br />

Ph<br />

Cl<br />

Cl<br />

P(c-Hex) 3<br />

Ph<br />

Ru<br />

H<br />

P(c-Hex) 3<br />

3-Ru<br />

RuL n<br />

R<br />

Cl<br />

Cl<br />

R<br />

P<br />

Ru<br />

P<br />

6-Ru<br />

L nRu<br />

N(CH 3) 3 + Cl –<br />

Ph<br />

H<br />

N(CH +<br />

3) 3 Cl –<br />

R<br />

Cl –<br />

H3C CH3 N<br />

+<br />

Cl<br />

Cl<br />

H 3C<br />

P<br />

Ru<br />

P<br />

N Cl –<br />

+<br />

7-Ru<br />

• Alkylidenes 6-Ru and 7-Ru are well-defined, water-soluble Ru-based metathesis catalysts<br />

that are stable for days in methanol or water at 45 °C.<br />

• Although benzylidene 3-Ru is highly active in RCM of dienes in organic solvents, it has no<br />

catalytic acitivity in protic media.<br />

L nRu<br />

Ph<br />

H<br />

EtO 2C<br />

CO 2Et<br />

Ph<br />

solvent:<br />

5 mol% 3-Ru<br />

23 °C<br />

CH 2Cl 2<br />

CH 3OH<br />

EtO 2C<br />

100%<br />

95<br />

methanol<br />

methanol<br />

methanol<br />

water<br />

water<br />

6-Ru<br />

7-Ru<br />

6-Ru<br />

7-Ru<br />

7-Ru<br />

7-Ru<br />

7-Ru<br />

a E = CO2Et. b 5 mol% catalyst (6- or 7-Ru), 0.37 M substrate, 45 °C. c Conversions were<br />

determined by 1 H NMR. d Substrate conc. = 0.1 M. e 30 h. f 2 h. g 10 mol% 7-Ru used.<br />

• Alkylidene 7-Ru is a significantly more active catalyst than alkylidene 6-Ru in these<br />

cyclizations; this higher reactivity is attributed to the more electron-rich phosphines in 7-Ru.<br />

• Cis-olefins are more reactive in RCM than the corresponding trans-olefins.<br />

• Phenyl substitution within the starting material can also greatly increase the yield of RCM in<br />

organic solvents.<br />

5 mol% 3-Ru<br />

CH 2Cl 2<br />

R = H<br />

R = Ph<br />

H H<br />

N +<br />

60%<br />

100%<br />

Kirkland, T. A.; Lynn, D. M.; Grubbs, R. H. J. Org. Chem. 1998, 63, 9904–9909.<br />

M. Movassaghi<br />

Cl –<br />

conversion c<br />

80<br />

95<br />

40<br />

90 e<br />

30<br />

>95 f<br />

90<br />

60<br />

90 g

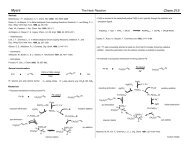

NHC Ruthenium Catalysts:<br />

Mes N N Mes Mes N N Mes<br />

Cl<br />

Cl<br />

Ru<br />

Ph<br />

H<br />

P(c-Hex) 3<br />

Cl<br />

Cl<br />

Ru<br />

Ph<br />

H<br />

P(c-Hex) 3<br />

Mes N N Mes<br />

Cl<br />

Cl<br />

Ru<br />

8-Ru 4-Ru 9-Ru<br />

substrate a<br />

E E t-Bu<br />

E E CH 3<br />

CH 3<br />

CH3E E<br />

H OH<br />

CH 3<br />

H 3C<br />

H 3C<br />

product<br />

E E<br />

E E<br />

E E<br />

H OH<br />

t-Bu<br />

CH 3<br />

CH 3<br />

time<br />

(h)<br />

1 37<br />

Ph<br />

H<br />

P(c-Hex) 3<br />

a E = CO2Et. b 5 mol% of catalyst, CD 2Cl 2, reflux. c 1.5 h.<br />

yield of product (%) using catalyst: b<br />

1-Mo 3-Ru 8-Ru 4-Ru 9-Ru<br />

0 100 100 100<br />

24 93 0 40 31 55<br />

c<br />

1.5 52 0 95 90 87<br />

0.2 0 0 NA 100 100<br />

• Alkylidenes 4- and 9-Ru are the most reactive Ru-based catalysts.<br />

• In the case of 4- and 9-Ru as little as 0.05 mol% is sufficient for efficient RCM.<br />

Scholl, M.; Ding, S.; Lee, C.-W.; Grubbs, R. H. Org. Lett. 1999,1, 953-956.<br />

Scholl, M.; Trnka, T. M.; Morgan, J. P.; Grubbs, R. H. Tetrahedron Lett. 1999, 40, 2247–2250.<br />

For the first Ru-based metathesis catalyst employing the Arduengo carbene ligand, see:<br />

Weskamp, T.; Schattenmann, W. C.; Spiegler, M.; Herrmann, W. A. Angew. Chem., Int. Ed.<br />

Engl. 1998, 37, 2490–2493.<br />

Mes<br />

Cl<br />

Cl<br />

N N Mes<br />

Ru<br />

P(c-Hex) 3<br />

10-Ru<br />

H<br />

CH 3<br />

CH 3<br />

RCM of functionalized dienes<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

diene product yield (%)<br />

O<br />

O<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH 3<br />

a <strong>Reaction</strong>s conducted with 5 mol% 10-Ru.<br />

O<br />

O<br />

O<br />

• Substrates containing both allyl and vinyl ethers provide RCM products while no RCM<br />

• α,β-Unsaturated lactones and enones of various ring sizes are produced in good to<br />

Chatterjee, A. K.; Morgan, J. P.; Scholl, M.; Grubbs, R. H. J. Am. Chem. Soc. 2000, 122,<br />

3783–3784.<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

CH 3<br />

products are observed if vinyl ethers alone are present.<br />

excellent yields.<br />

49<br />

0<br />

97<br />

86<br />

93<br />

M. Movassaghi

O<br />

Bn<br />

BnO<br />

RCM Applications in Synthesis:<br />

N<br />

O<br />

O<br />

BnO<br />

H<br />

BnO CO2CH3 O<br />

N<br />

1. n-Bu 2BOTf, Et 3N<br />

CH 2Cl 2, 0 °C<br />

2. CH 2=CHCHO<br />

–78 → 0 °C<br />

82%, >99% de<br />

5 mol% 2-Ru<br />

110 °C, 48 h<br />

70%<br />

BnO<br />

H<br />

BnO<br />

BnO<br />

O<br />

O<br />

Bn<br />

N<br />

Bn<br />

O<br />

O<br />

N<br />

O<br />

O OH<br />

Crimmins, M. T.; King, B. W. J. Org. Chem. 1996, 61, 4192–4193.<br />

Overkleeft, H. S.; Pandit, U. K. Tetrahedron Lett. 1996, 37, 547–550.<br />

O<br />

N<br />

OH<br />

HO<br />

HO<br />

1 mol% 3-Ru<br />

CH 2Cl 2<br />

97%<br />

HO<br />

H OH<br />

N<br />

Castanospermine<br />

• Particularly difficult cyclizations (due to steric congestion or electronic deactivation) can be<br />

achieved by relay ring closing metathesis, which initiates catalysis at an isolated terminal<br />

olefin. <strong>The</strong> reaction is driven by release of cyclopentene.<br />

Hoye, T. R.; Jeffrey, C. S.; Tennakoon, M. A.; Wang, J.; Zhao, H. J. Am. Chem. Soc.<br />

2004, 126, 10210–10211.<br />

TBSO<br />

O<br />

H 3C<br />

O<br />

OPMB<br />

O<br />

3<br />

10 mol% 5-Ru<br />

CH 2Cl 2, 40 °C<br />

TBSO<br />

O<br />

H 3C<br />

O<br />

OPMB<br />

O<br />

RuL n<br />

TBSO<br />

O<br />

O<br />

OPMB<br />

Wang, X.; Bowman, E. J.; Bowman, B. J.; Porco, J. A., Jr. Angew. Chem. Int. Ed. 2004, 43,<br />

3601–3605.<br />

71%<br />

O<br />

trans epoxide<br />

MOMO<br />

MOMO<br />

MOMO<br />

cis epoxide<br />

MOMO<br />

O<br />

O<br />

O CH 3<br />

O<br />

O<br />

H<br />

O CH3 H<br />

O<br />

H<br />

O<br />

HO<br />

H<br />

OH<br />

Cl<br />

O<br />

O CH 3<br />

O<br />

HO<br />

Pochonin C<br />

5 mol% 4-Ru<br />

toluene, 120 °C<br />

10 min<br />

87%<br />

5 mol% 4-Ru<br />

toluene, 120 °C<br />

10 min<br />

21%<br />

Cl<br />

MOMO<br />

MOMO<br />

MOMO<br />

MOMO<br />

O<br />

O CH 3<br />

O<br />

O<br />

H<br />

O CH3 H<br />

O<br />

O<br />

H<br />

• Pre-organization of the substrate can have a dramatic effect upon the reaction efficiency.<br />

• Both epoxide substrates produce macrocycles with good regioselectivity (i.e., the<br />

14-membered ring rather than the 12-membered ring) and E/Z selectivity. However, the<br />

trans epoxide macrocycle is formed in a much higher yield.<br />

Barluenga, S.; Lopez, P.; Moulin, E.; Winssinger, N. Angew. Chem. Int. Ed. 2004, 43,<br />

2367–2370.<br />

O<br />

H<br />

L. Blasdel and M. Movassaghi

Ph<br />

N<br />

O<br />

N<br />

O<br />

CO<br />

H<br />

2CH3 H<br />

N<br />

H CH 2OTDS<br />

N O<br />

O<br />

D<br />

O<br />

N<br />

O<br />

N<br />

H<br />

N<br />

N<br />

H<br />

OH<br />

100 mol% 2-Ru<br />

23 °C, 5 d<br />

C 6D 6<br />

30%<br />

Ph<br />

N<br />

O<br />

N<br />

O<br />

H CH 2OTDS<br />

N O<br />

Borer, B. C.; Deerenberg, S.; Bieraugel, H.; Pandit, U. K. Tetrahedron Lett. 1994, 35,<br />

3191–3194.<br />

5 mol% 1-Mo<br />

50 °C, 4 h<br />

C 6H 6<br />

63%<br />

CO<br />

H<br />

2CH3 N<br />

H<br />

Martin, S. F.; Liao, Y.; Wong, Y.; Rein, T. Tetrahedron Lett. 1994, 35, 691–694.<br />

E<br />

Manzamine A<br />

• <strong>The</strong> use of RCM in construction of both the D and the E rings of Manzamine A<br />

has been reported:<br />

O<br />

O<br />

H 3C<br />

CH3 CH3 20 mol% 1-Mo<br />

OAc<br />

O<br />

H<br />

O<br />

22 °C, 10 h<br />

NHCOCF3 C6H6 H<br />

O<br />

OAc<br />

H3C 91%<br />

N CH3 H<br />

N<br />

H<br />

CH 3<br />

O<br />

H<br />

O<br />

CH 3<br />

CH3 OAc<br />

O<br />

NHCOCF3 H<br />

OAc<br />

• Before the advent of NHC ligands, 1-Mo was used more frequently than the Ru catalysts<br />

for macrocyclization of trisubstituted olefins. <strong>The</strong> latter catalysts are typically less reactive<br />

with sterically hindered substrates.<br />

Zhongmin, X.; Johannes, C. W.; Houri, A. F.; La, D. S.; Cogan, D. A.; Hofilena, G. E.;<br />

Hoveyda, A. H. J. Am. Chem. Soc. 1997, 119, 10302–10316.<br />

Slight changes in substrate structure can control whether the E- or Z-olefin is formed:<br />

H 3C<br />

O<br />

OCH 3 O<br />

O<br />

OP<br />

H 3C<br />

CH 3<br />

CH 2<br />

CH 3<br />

CH 3<br />

H 3C<br />

O<br />

O<br />

O<br />

OCH3 OP<br />

H 3C<br />

CH 3<br />

CH 2<br />

86% 10 mol% 4-Ru<br />

80%<br />

E-olefin only CH2Cl2, 40 °C<br />

Z-olefin only<br />

O<br />

O<br />

PO CH 3O O<br />

O<br />

O<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

P = p-BrBz<br />

O<br />

CH 3<br />

O<br />

PO O OCH3<br />

OHC O<br />

HO<br />

OHC O<br />

HO<br />

Coleophomone B Coleophomone C<br />

Nicolaou, K. C.; Montagnon, T.; Vassilikogiannakis, G.; Mathison, C. J. N. J. Am. Chem. Soc.<br />

2005, 127, 8872–8888.<br />

O<br />

CH 3<br />

O<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

M. Movassaghi and L. Blasdel

Synthesis of Epothilone C:<br />

• Small changes can drastically affect reaction outcome. In the example below, TBS<br />

protective groups changes the E/Z selectivity.<br />

R1O CH3 H3C CH3 H 3C<br />

O<br />

OR 2<br />

O<br />

CH 3<br />

H<br />

O<br />

S<br />

N<br />

CH 3<br />

R1O CH3 H3C CH3 H 3C<br />

O<br />

OR 2<br />

O<br />

CH 3<br />

H<br />

O<br />

R 1 R 2 Catalyst Conditions Yield E/Z<br />

H<br />

H<br />

TBS<br />

TBS<br />

H<br />

TBS<br />

TBS<br />

TBS<br />

1-Mo<br />

3-Ru<br />

3-Ru<br />

1-Mo<br />

50 mol%, PhH, 55 °C<br />

10 mol%, CH 2Cl 2, 25 °C<br />

6 mol%, CH 2Cl 2, 25 °C<br />

50 mol%, PhH, 55 °C<br />

65 %<br />

85%<br />

94%<br />

86%<br />

Nicolaou, K. C.; He, Y.; Vourloumis, D.; Vallberg, H.; Roschangar, F.; Sarabia, F.;<br />

Ninkovic, S.; Yang, Z.; Trujillo, J. I. J. Am. Chem. Soc. 1997, 119, 7960–7973.<br />

Meng, D.; Bertinato, P.; Balog, A.; Su, D.-S.; Kamenecka, T.; Sorensen, E. J.;<br />

Danishefsky, S. J. J. Am. Chem. Soc. 1997, 119, 11073–11092.<br />

Schinzer, D.; Bauer, A.; Bohm, O. M.; Limberg, A.; Cordes, M. Chem. Eur. J. 1999, 5,<br />

2483–2491.<br />

S<br />

N<br />

2 : 1<br />

1 : 1.2<br />

1 : 1.7<br />

1 : 1.7<br />

CH 3<br />

Solid-Phase Synthesis of Epothilone A:<br />

HO<br />

CH3 CH3 H3C O<br />

H3C O<br />

H3C TBSO<br />

O<br />

HO CH3 H3C CH3 H 3C<br />

= Merrifield resin<br />

O<br />

O<br />

OTBS<br />

O<br />

H 3C<br />

CH 3<br />

O<br />

HO CH3 H3C CH3 S<br />

N<br />

S<br />

N<br />

O<br />

CH 3<br />

O<br />

OTBS<br />

CH 3<br />

O<br />

CH 3<br />

S<br />

N<br />

3-Ru (0.75 equiv)<br />

25 °C, 48 h<br />

CH 2Cl 2<br />

CH 3<br />

HO<br />

CH3 CH3 H3C O<br />

H3C O<br />

H3C TBSO<br />

O<br />

15.6% 15.6%<br />

5.2%<br />

HO CH3 H3C CH3 H 3C<br />

O<br />

O<br />

OTBS<br />

15.6%<br />

• <strong>The</strong> amount of alkylidene 3-Ru (75%) used was greater than the total yield of product (52%),<br />

perhaps reflecting the generation of a resin-bound Ru intermediate.<br />

• Addition of n-octene or ethylene has been documented to provide a catalytic cycle; see:<br />

Maarseveen, J. H.; Hartog, J. A. J.; Engelen, V.; Finner, E.; Visser, G.; Kruse, C. G.<br />

Tetrahedron Lett. 1996, 37, 8249.<br />

Nicolaou, K. C.; Winssinger, N.; Pastor, J.; Ninkovic, S.; Sarabia, F.; He, Y.; Vourloumis, D.;<br />

Yang, Z.; Li, T.; Giannakakou, P.; Hamel, E. Nature 1997, 387, 268–272.<br />

O<br />

CH 3<br />

S<br />

N<br />

S<br />

N<br />

CH 3<br />

CH 3<br />

M. Movassaghi and L. Blasdel

Catalytic RCM of <strong>Olefin</strong>ic Enol Ethers:<br />

Ph<br />

CH 3<br />

O<br />

O<br />

O<br />

O Ph<br />

CH 3CHBr 2, TiCl 4<br />

Zn, TMEDA,<br />

cat. PbCl 2,<br />

20 °C, 11 h<br />

THF<br />

55%<br />

CH 3CHBr 2, TiCl 4<br />

Zn, TMEDA,<br />

cat. PbCl 2,<br />

20 °C, 5 h<br />

THF<br />

79%<br />

Tandem <strong>Olefin</strong>ation-<strong>Metathesis</strong><br />

H<br />

BnO<br />

H<br />

O<br />

O<br />

H<br />

O<br />

O<br />

R<br />

CH3 CH 3<br />

Ph<br />

CH 3<br />

CH 3<br />

O<br />

Tebbe reagent<br />

(4.0 equiv)<br />

THF, 25 °C, 0.5 h;<br />

reflux, 4h<br />

O Ph<br />

• Only catalyst 1-Mo is effective for RCM of these substrates.<br />

Fujimura, O.; Fu, G. C.; Grubbs, R. H. J. Org. Chem. 1994, 59, 4029–4031.<br />

Ti CH 2<br />

Cl<br />

H<br />

BnO<br />

H<br />

O<br />

O<br />

H<br />

O<br />

R<br />

R = H<br />

50%<br />

CH3 54%<br />

• Here, a Ti-alkylidene is used in RCM.<br />

12 mol% 1-Mo<br />

20 °C, 3.5 h<br />

n-pentane<br />

Ph<br />

O<br />

O<br />

Al CH 3<br />

CH 3<br />

Nicolaou, K. C.; Postema, M. H. D.; Yue, E. W.; Nadin, A. J. Am. Chem. Soc. 1996, 118,<br />

10335-10336.<br />

88%<br />

12 mol% 1-Mo<br />

20 °C, 7 h<br />

n-pentane<br />

87%<br />

Tebbe reagent<br />

Ph<br />

Tandem Ring Opening-Ring Closing <strong>Metathesis</strong> of Cyclic <strong>Olefin</strong>s<br />

substrate product<br />

H H<br />

O O<br />

H H<br />

O<br />

O<br />

H H<br />

O O<br />

H H<br />

O O<br />

O O<br />

H H O H H O<br />

O<br />

O<br />

H<br />

O<br />

O<br />

H<br />

O<br />

H H<br />

H H<br />

H H<br />

O O<br />

R O O R 6 mol% 3-Ru<br />

H<br />

O<br />

H H<br />

C6H6, 45 °C<br />

6 h<br />

R = H<br />

H<br />

CH3 O<br />

• Without sufficient ring strain in the starting cyclic olefin, competing oligomerization (via CM)<br />

can occur.<br />

• Higher dilution favors intramolecular reaction:<br />

yield<br />

(%)<br />

82<br />

90<br />

70<br />

68<br />

92<br />

0.12 M<br />

0.008 M<br />

0.2 M<br />

catalyst 3-Ru<br />

(mol %)<br />

16%<br />

73%<br />

42%<br />

O<br />

H<br />

• <strong>The</strong> relative rate of intramolecular metathesis versus CM may be further increased<br />

by substitution of the acyclic olefin.<br />

3<br />

5<br />

3<br />

6<br />

5<br />

conc.<br />

(M)<br />

0.1<br />

0.1<br />

0.07<br />

0.04<br />

0.04<br />

time<br />

(h)<br />

1.5<br />

2<br />

6<br />

2<br />

3<br />

temp.<br />

(°C)<br />

45<br />

60<br />

45<br />

45<br />

60<br />

M. Movassaghi

Proposed Mechanism for Ring Opening-Ring Closing <strong>Metathesis</strong>:<br />

H H<br />

O O<br />

H H<br />

O O<br />

H 2C CH 2<br />

L nRu CH 2<br />

L nRu<br />

L nRu CHPh<br />

Ph<br />

H H<br />

O O<br />

H H<br />

O O<br />

RuL n<br />

H H<br />

O O<br />

O<br />

H<br />

RuL n<br />

H<br />

O<br />

• Initial metathesis of the acyclic olefin is supported by the fact that substitution of this olefin<br />

decreases the rate of metathesis and by the beneficial effects of dilution upon the<br />

intramolecular manifold.<br />

• Subtle conformational preferences within the substrate are key to the success of these<br />

transformations; as shown, trans-1,4-dihydronaphthalene diamide undergoes efficient<br />

ring opening-ring closing metathesis while the corresponding diester and diether<br />

derivatives do not.<br />

CH3 CH3 O N<br />

O N<br />

unreactive substrates:<br />

O N<br />

CH3 O O<br />

O O<br />

10 mol% 3-Ru<br />

0.1 M, C 6D 6<br />

40 °C, 8 h<br />

95%<br />

O<br />

O<br />

O<br />

N<br />

CH3 Zuercher, W. J.; Hashimoto, M.; Grubbs, R. H. J. Am. Chem. Soc. 1996, 118, 6634–6640.<br />

H 3C<br />

Examples in Complex Synthesis:<br />

O<br />

CH 3<br />

CH3 2 mol% 3-Ru<br />

H 3C<br />

ethylene<br />

O<br />

98%<br />

H 3C H<br />

HO HO<br />

HO<br />

Ingenol<br />

CH 3<br />

OH<br />

CH 3<br />

H 3C<br />

O<br />

O<br />

O<br />

CH 3<br />

H 3C<br />

CH 3<br />

H<br />

O<br />

O<br />

O<br />

CH 3<br />

H<br />

H 3C<br />

CH 3<br />

OPMB<br />

O<br />

CH 3<br />

CH 3<br />

OPMB<br />

25 mol% 5-Ru<br />

toluene, Δ<br />

Nickel, A.; Maruyama, T.; Tang, H.; Murphy, P. D.; Greene, B.; Yusuff, N.; Wood, J. L. J. Am.<br />

Chem. Soc. 2004, 126, 16300–16301.<br />

O<br />

H 3C<br />

CH 3<br />

O<br />

20 mol% 4-Ru<br />

ethylene, toluene<br />

43% (3 steps)<br />

O<br />

H H<br />

H 3C CH 3<br />

H 3C<br />

O<br />

H3C CH3 H H<br />

CH 3<br />

Cyanthiwigin U<br />

Pfeiffer, M. W. B.; Phillips, A. J. J. Am. Chem. Soc. 2005, 127, 5334–5335.<br />

O<br />

OH<br />

CH3 76%<br />

M. Movassaghi and L. Blasdel

Kinetic Resolution via Asymmetric RCM<br />

Et 3SiO<br />

F3C F3C CH 3<br />

Ar = 2,6-(i-Pr) 2C 6H 3<br />

i-Pr i-Pr<br />

F3C F3C N<br />

Ph<br />

O Mo CH3 O CH3 H<br />

CF3 CF3 CH 3<br />

N<br />

H3C O Mo<br />

O<br />

Ar<br />

CF 3<br />

CF 3<br />

11-Mo<br />

H<br />

DISFAVORED<br />

2 mol% 11-Mo<br />

–20 °C, 660 min<br />

toluene<br />

CH 3<br />

OSiEt 3<br />

H<br />

Et 3SiO<br />

CH 3<br />

F3C F3C CH 3<br />

Proposed Transition State Models for the Observed Selectivity<br />

N<br />

H3C O Mo<br />

O<br />

Ar<br />

+<br />

CF 3<br />

CF 3<br />

H<br />

FAVORED<br />

Fujimura, O.; Grubbs, R. H. J. Org. Chem. 1998, 63, 824–832.<br />

Fujimura, O.; Grubbs, R. H. J. Am. Chem. Soc. 1996, 118, 2499–2500.<br />

Et 3SiO<br />

38%, 48% ee 62%<br />

• <strong>The</strong> first catalytic, asymmetric kinetic resolution via RCM was achieved, with low selectivity,<br />

using the chiral alkylidene 11-Mo.<br />

H 3C<br />

t-Bu<br />

CH3 H3C R 1<br />

O<br />

O<br />

CH 3<br />

CH 3<br />

R 1<br />

N<br />

Mo<br />

H<br />

CH3 R2 CH3 t-Bu<br />

12-Mo: R 1 = i-Pr<br />

13-Mo: R 1 = CH 3<br />

14-Mo: R 1 = Cl<br />

15-Mo: R 1 = Cl<br />

H<br />

R 2 = Ph<br />

R 2 = Ph<br />

R 2 = Ph<br />

R 2 = CH 3<br />

CH 3<br />

OSiEt 3<br />

Catalytic, Enantioselective RCM<br />

CH 3<br />

CH 3<br />

CH 3<br />

H OSiEt 3<br />

H<br />

CH3 OSiEt3 5 mol% 12-Mo<br />

22 °C, 10 min<br />

C 6H 6<br />

5 mol% 12-Mo<br />

22 °C, 2 h<br />

C 6H 6<br />

CH 3<br />

CH 3<br />

CH 3<br />

H OSiEt 3<br />

19%, >99% ee<br />

H<br />

CH3 OSiEt3 50%,

• <strong>The</strong> alkylidene catalysts 12-Mo and 13-Mo are very effective in catalytic, enantioselective<br />

desymmetrization processes, especially in the case of secondary allylic ethers.<br />

H 3C<br />

O<br />

R R<br />

R = H<br />

R = CH 3<br />

O<br />

O<br />

CH 1-2 mol% 13-Mo<br />

3<br />

22 °C, 5 min<br />

neat<br />

H<br />

H 3C<br />

R<br />

H 3C<br />

O<br />

85%, 93% ee<br />

93%, 99% ee<br />

• Remarkably, this catalytic, asymmetric RCM can be carried out in the absence of solvent,<br />

with 20:1 de<br />

Kiely, A. F.; Jernelius, J. A.; Schrock, R. R.; Hoveyda, A. H. J. Am. Chem. Soc. 2002, 124,<br />

2868.<br />

CH 3<br />

catalyst<br />

CH 3<br />

H3C N<br />

Ph<br />

n<br />

PhH, 22 °C<br />

%mol<br />

H3C N<br />

Ph<br />

n<br />

n catalyst catalyst time yield ee<br />

1<br />

2<br />

3<br />

H 3C<br />

O O<br />

CH 3<br />

12-Mo<br />

12-Mo<br />

15-Mo<br />

5 mol% 14-Mo<br />

PhH, 22 °C, 12 h<br />

5<br />

2<br />

5<br />

20 min<br />

7 h<br />

20 min<br />

CH 3<br />

41%, >98% conv.<br />

83% ee O O<br />

• Only 29% ee was observed using 12-Mo. 14-Mo is the catalyst of choice for synthesizing<br />

non-racemic acetals.<br />

Weatherhead, G. S.; Houser, J. H.; Ford, J. G.; Jamieson, J. Y.; Schrock, R. R.;<br />

Hoveyda, A. H. Tetrahedron Lett. 2000, 41, 9553-9559.<br />

78%<br />

90%<br />

93%<br />

98%<br />

95%<br />

>98%<br />

Dolman, S. J.; Sattely, E. S.; Hoveyda, A. H.; Schrock, R. R. J Am. Chem. Soc. 2002, 124,<br />

6991–6997.<br />

M. Movassaghi and L. Blasdel

Catalytic RCM of Dienynes: Construction of Fused Bicyclic Rings<br />

n m n m n m<br />

L n[M]<br />

R R<br />

OSiEt 3<br />

CH 3<br />

OSiEt 3<br />

R<br />

R<br />

H<br />

CH 3<br />

i-Pr<br />

t-Bu<br />

Ph<br />

CO 2CH 3<br />

Si(CH 3) 3<br />

Sn(n-Bu) 3<br />

Cl, Br, I<br />

OSiEt 3<br />

CH3 dienyne<br />

RCM<br />

95%<br />

[M]L n<br />

R R<br />

• Fused [5.6.0], [5.7.0], [6.6.0], and [6.7.0] bicyclic rings have been successfully constructed<br />

by RCM of dienynes.<br />

3 mol% 2-Ru<br />

25 °C, 8 h<br />

0.06 M<br />

CH 2Cl 2<br />

• <strong>The</strong> dienyne RCM is largely favored over the competing diene RCM.<br />

3-5 mol% 2-Ru<br />

0.05-0.1 M<br />

C 6D 6<br />

yield (%) conditions<br />

>98<br />

95<br />

78<br />

NR<br />

96<br />

82<br />

NR<br />

NR<br />

NR<br />

+<br />

23 °C, 15 min<br />

23 °C, 8 h<br />

60 °C, 4 h<br />

60 °C, 3 h<br />

60 °C, 4 h<br />

H 3C<br />

OSiEt 3<br />

R<br />

diene<br />

RCM<br />

Enyne <strong>Metathesis</strong> <strong>Reaction</strong>s Catalyzed by PtCl 2<br />

PhO 2S<br />

H<br />

O<br />

substrate product yield<br />

Ts H<br />

N<br />

H<br />

O<br />

O OCH 3<br />

SO 2Ph<br />

CH 3O<br />

O O H<br />

H<br />

TsN<br />

PhO 2S<br />

H<br />

O<br />

SO 2Ph<br />

70%<br />

54%<br />

80%<br />

a <strong>Reaction</strong>s conducted in toluene at 80 °C using 4-10 mol% of PtCl2<br />

• In most cases commercial PtCl 2 was used as received.<br />

• A cationic reaction pathway, involving the complexation of cationic Pt(II) with the<br />

alkyne, has been proposed.<br />

• Remote alkenes are unaffected.<br />

Fürstner, A.; Szillat, H.; Stelzer, F. J. Am. Chem. Soc. 2000, 122, 6785–6786.<br />

96%<br />

Enyne <strong>Metathesis</strong> in Synthesis<br />

TBSO<br />

H 3C<br />

TBSO<br />

H 3CO<br />

OTBS<br />

TBSO<br />

OCH 3<br />

40 mol% 3-Ru<br />

ethylene, toluene, 45 °C<br />

TBSO<br />

H 3C<br />

CH 3<br />

31%<br />

OTBS<br />

H<br />

O<br />

H<br />

O<br />

H OHC<br />

O<br />

TBSO<br />

CH 3<br />

TBSO<br />

OTBS<br />

CH 3 OTBS<br />

CH 3<br />

O<br />

CH 3<br />

OCH 3<br />

1. 50 mol% 3-Ru<br />

ethylene, CH 2Cl 2, 40 °C<br />

2. TBAF, THF, 0 → 23 °C<br />

42% (two steps)<br />

CH 3<br />

OCH 3<br />

(–)-Longithorone A<br />

Layton, M. E.; Morales, C. A.; Shair, M. D. J. Am. Chem. Soc. 2002, 124, 773–775.<br />

H 3C<br />

CH 3<br />

CH 3<br />

H 3C<br />

CO 2CH 3<br />

CH 3<br />

CH 3<br />

12 mol% 4-Ru<br />

H 3CO 2C<br />

CH2Cl2, reflux, 3 h<br />

CH3 82% H3C CH3 O<br />

OHC<br />

OH<br />

AcO<br />

H3C CH3 CH3 CH3 Guanacastepene A<br />

Boyer, F.-D.; Hanna, I.; Ricard, L. Org. Lett. 2004, 6, 1817–1820.<br />

CH 3<br />

L. Blasdel and M. Movassaghi

Cross <strong>Metathesis</strong><br />

<strong>Olefin</strong> categorization and rules for selectivity<br />

Selective Cross-<strong>Metathesis</strong> <strong>Reaction</strong>s as a Function of Catalyst Structure:<br />

<strong>Olefin</strong> type<br />

Type I<br />

(fast homodimerization)<br />

Type II<br />

(slow homodimerization)<br />

Type III<br />

(no homodimerization)<br />

Type IV<br />

(spectators to CM)<br />

Type I – Rapid homodimerization, homodimers consumable<br />

Type II – Slow homodimerization, homodimers sparingly consumable<br />

Type III – No homodimerization<br />

Type IV – <strong>Olefin</strong>s inert to CM, but do not deactivate catalyst (spectator)<br />

MesN<br />

Cl<br />

Cl<br />

NMes<br />

Ph<br />

Ru<br />

H<br />

P(c-Hex) 3<br />

Cl<br />

Cl<br />

P(c-Hex) 3<br />

Ru<br />

Ph<br />

H<br />

P(c-Hex) 3<br />

4-Ru 3-Ru<br />

terminal olefins, 1° allylic alcohols, esters, allyl<br />

boronate esters, allyl halides, styrenes (no large<br />

ortho substit.), allyl phosphonates, allyl silanes,<br />

allyl phosphine oxides, allyl sulfides, protected<br />

allyl amines<br />

styrenes (large ortho substit.), acrylates,<br />

acrylamides, acrylic acid, acrolein, vinyl keones,<br />

unprotected 3° allylic alcohols, vinyl epoxides, 2°<br />

allylic alcohols, perfluoalkyl substituted olefins<br />

1,1-disubstituted olefins, non-bulky trisub. olefins,<br />

vinyl phosphonates, phenyl vinyl sulfone, 4° allylic<br />

carbons (all alkyl substituents), 3° allylic alcohols<br />

(protected)<br />

vinyl nitro olefins, trisubstituted allyl alcohols<br />

(protected)<br />

terminal olefins, allyl silanes, 1° allylic alcohols,<br />

ethers, esters, allyl boronate esters, allyl halides<br />

styrene, 2° allylic alcohols, vinyl dioxolanes,<br />

vinyl boronates<br />

vinyl siloxanes<br />

<strong>Reaction</strong> between two olefins of Type I................................... Statistical CM<br />

<strong>Reaction</strong> between two olefins of same type (non-Type I)........ Non-selective CM<br />

<strong>Reaction</strong> beween olefins of two different types....................... Selective CM<br />

1,1-disubstituted olefins, disub a,b-unsaturated<br />

carbonyls, 4° allylic carbon-containing olefins,<br />

perfluorinated alkane olefins, 3° allyl amines<br />

(protected)<br />

i-Pr i-Pr<br />

F3C O<br />

F3C CH3 N<br />

Mo<br />

O<br />

CH3 Ph<br />

CH3 H<br />

F3C F3C CH3 1-Mo<br />

terminal olefins, allyl silanes<br />

styrene, allyl stannanes<br />

3° allyl amines, acrylonitrile<br />

1,1-disubstituted olefins<br />

Chatterjee, A. K.; Choi, T.-L.; Sanders, D. P.; Grubbs, R. H. J. Am. Chem. Soc. 2003, 125, 11360–11370. L. Blasdel

Non-selective Cross <strong>Metathesis</strong>: Two Type I <strong>Olefin</strong>s<br />

3<br />

+<br />

AcO<br />

2 equiv<br />

OAc<br />

3 mol% catalyst<br />

CH 2Cl 2, 40 °C, 12 h<br />

80%<br />

catalyst<br />

3-Ru<br />

4-Ru<br />

• <strong>The</strong> difference in E/Z ratios reflects the enhanced activity of 4-Ru relative to 3-Ru.<br />

Because it is more active, 4-Ru can catalyze secondary metathesis of the product,<br />

allowing equilibration of the olefin to the more thermodynamically stable trans isomer.<br />

Chatterjee, A. K.; Choi, T.-L.; Sanders, D. P.; Grubbs, R. H. J. Am. Chem. Soc. 2003,<br />

125, 11360–11370.<br />

E/Z<br />

3.2 : 1<br />

• Selectivity for the trans olefin can also be enhanced using sterically hindered substrates:<br />

PhO<br />

7 : 1<br />

+ SiR3 2 mol% 1-Mo<br />

PhO SiR3 3 DME, 23 °C, 4 h<br />

3<br />

R Yield E/Z<br />

CH 3<br />

Ph<br />

72%<br />

77%<br />

Crowe, W. E.; Goldberg, D. R.; Zhang, Z. J. Tetrahedron Lett. 1996, 37, 2117–2120.<br />

• In addition, steric bulk can assist in favoring the cross metathesis reaction over<br />

homodimerization pathways.<br />

• <strong>The</strong> lower yield obtained with the unprotected alcohol is a result of homodimerization of<br />

the tertiary allylic alcohol. Subjecting this dimer to the reaction conditions results in no<br />

CM product, indicating that the dimer cannot undergo a secondary metathesis reaction.<br />

AcO<br />

+<br />

CH3 OR<br />

CH3 6 mol% 4-Ru<br />

CH 2Cl 2, 40 °C, 12 h<br />

80%<br />

AcO<br />

3<br />

2.6 : 1<br />

7.6 : 1<br />

OAc<br />

CH3 OR<br />

CH3 R = H 58% yield<br />

R = TBS 97% yield<br />

Chatterjee, A. K.; Choi, T.-L.; Sanders, D. P.; Grubbs, R. H. J. Am. Chem. Soc. 2003,<br />

125, 11360–11370.<br />

<strong>Olefin</strong> 1 <strong>Olefin</strong> 2 product a,b<br />

Secondary allylic alcohols (Type I with Type II)<br />

BzO<br />

HO<br />

TBDPSO<br />

CH 3<br />

CH 3<br />

3<br />

3<br />

OAc<br />

OAc<br />

Quaternary allylic olefins (Type I with Type III)<br />

H 3C<br />

HO<br />

CH 3<br />

2.0 equiv<br />

O<br />

H 3C<br />

CH 3<br />

O<br />

1.0 equiv<br />

3<br />

3<br />

3<br />

OAc<br />

OAc<br />

OAc<br />

1,1-Disubstituted olefins (Type I with Type III)<br />

BzO<br />

H 2N<br />

HO<br />

H<br />

O<br />

O<br />

O<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

2.0 equiv<br />

1.0 equiv<br />

2.0 equiv<br />

7<br />

3<br />

8<br />

OAc<br />

2.0 equiv<br />

OTBS<br />

1.2 equiv<br />

CH 3<br />

1.1 equiv<br />

BzO<br />

HO<br />

TBDPSO<br />

CH 3<br />

CH 3<br />

CH 3<br />

H 3C CH 3<br />

HO<br />

O<br />

H 3C<br />

BzO<br />

H 2N<br />

HO<br />

O<br />

O<br />

O<br />

CH 3<br />

CH 3<br />

CH 3<br />

OAc<br />

Isolated<br />

Yield (%) E/Z<br />

82 10 : 1<br />

50 c (62) d 14 : 1<br />

53 6.7 : 1<br />

93 >20 : 1<br />

91 >20 : 1<br />

80 4 : 1<br />

71 > 20 : 1<br />

23 4 : 1<br />

O<br />

H3C OAc<br />

3 H<br />

(OAc) 97 > 20 : 1<br />

CH 3<br />

3<br />

CH3 1.0 equiv<br />

7<br />

3<br />

3<br />

3<br />

3<br />

8<br />

3<br />

OAc<br />

3<br />

OAc<br />

OAc<br />

OAc<br />

OAc<br />

OTBS<br />

CH 3<br />

a 3–5 mol% 4-Ru, CH2Cl 2, 40 °C. b See last reference on left half of this page.<br />

c With 2 equiv <strong>Olefin</strong> 2, the yield was 92%. d <strong>Reaction</strong> was performed at 23 °C.<br />

L. Blasdel

<strong>Olefin</strong> 1 <strong>Olefin</strong> 2 product a<br />

Type II and Type III<br />

HO<br />

t-BuO<br />

HO<br />

EtO<br />

H 3C<br />

H 3C<br />

F<br />

O<br />

O<br />

O<br />

O<br />

F<br />

F<br />

CH 3<br />

R<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

C(CH3) 3 HO<br />

neat<br />

C(CH3) 3 HO<br />

neat<br />

3<br />

4.0 equiv<br />

3<br />

4.0 equiv<br />

CH 3<br />

CH 3<br />

HO<br />

HO<br />

O<br />

O<br />

O<br />

O<br />

AcO OAc F<br />

2.0 equiv<br />

AcO OAc<br />

2.0 equiv<br />

O<br />

OCH3 1.5–2.0 equiv<br />

O<br />

OEt<br />

1.5–2.0 equiv<br />

O<br />

OEt<br />

1.5–2.0 equiv<br />

a 1–5 mol% 4-Ru, CH2Cl 2, 40 °C.<br />

H 3C<br />

F<br />

C(CH 3) 3<br />

C(CH 3) 3<br />

C(CH 3) 3<br />

C(CH 3) 3<br />

OAc<br />

OAc<br />

CO 2CH 3<br />

CH 3<br />

CO 2Et<br />

CO 2Et<br />

Isolated<br />

Yield (%) E/Z<br />

73<br />

73<br />

83<br />

55 R = H<br />

83 R = CH 3<br />

Chatterjee, A. K.; Choi, T.-L.; Sanders, D. P.; Grubbs, R. H. J. Am. Chem. Soc. 2003,<br />

125, 11360–11370.<br />

H 3C<br />

F<br />

CH 3<br />

CH 3<br />

98<br />

50<br />

92<br />

87<br />

5<br />

2 : 1<br />

2 : 1<br />

2 : 1<br />

>20 : 1<br />

>20 : 1<br />

>20 : 1<br />

>20 : 1<br />

>20 : 1<br />

Selective Cross-<strong>Metathesis</strong> <strong>Reaction</strong>s:<br />

Type I<br />

Type I<br />

O<br />

O N H<br />

+<br />

Si(CH 3) 3<br />

1.5 equiv<br />

O<br />

Cl 3C N H<br />

+<br />

OTr<br />

Si(CH 3) 3<br />

1.5 equiv<br />

OTr<br />

Type IV<br />

Type III<br />

10 mol% 4-Ru<br />

CH 2Cl 2, 40 °C, 4 h<br />

10 mol% 1-Mo<br />

CH 2Cl 2, 40 °C, 16 h<br />

(H 3C) 3Si<br />

Brümmer, O; Rückert, A.; Blechert, S. Chem. Eur. J. 1997, 3, 441–446.<br />

H<br />

CbzHN CO 2CH 3<br />

97% ee<br />

+<br />

+<br />

NC R<br />

R<br />

CH 2Si(CH 3) 3<br />

(CH 2) 3OBn<br />

(CH 2) 2CO 2Bn<br />

O<br />

OTr<br />

O<br />

O N H<br />

50% isolated yield<br />

1.5 : 1 E/Z<br />

OTr<br />

Si(CH<br />

Cl3C N<br />

3) 3<br />

H<br />

98% isolated yield<br />

>20 : 1 E/Z<br />

(H 3C) 3Si<br />

H<br />

10 mol% 1-Mo<br />

Si(CH3) 3 CbzHN CO2CH3 CH2Cl2, 8 h<br />

reflux<br />

95%, 92% ee<br />

Brümmer, O; Rückert, A.; Blechert, S. Chem. Eur. J. 1997, 3, 441–446.<br />

5 mol% 1-Mo<br />

23 °C, 3h<br />

CH 2Cl 2<br />

yield (%) E:Z<br />

76<br />

60<br />

44<br />

1:3<br />

1:7.6<br />

1:5.6<br />

• <strong>The</strong> basis for the high cis-selectivity with acrylonitrile as substrate is not known.<br />

Crowe, W. E.; Goldberg, D. R. J. Am. Chem. Soc. 1995, 117, 5162–5163.<br />

NC<br />

R<br />

L. Blasdel and M. Movassaghi

Reagent preparation<br />

A Horner–Wadsworth–Emmons reagent:<br />

O<br />

P<br />

EtO EtO<br />

A Suzuki reagent:<br />

+<br />

O<br />

OEt<br />

H 3C CH3<br />

AcO<br />

3<br />

+<br />

O<br />

B<br />

O<br />

CH3 CH3 CH3 One-pot CM and allylboration reactions:<br />

CH3 H3C H3C O<br />

B<br />

H3C O<br />

2.0 equiv<br />

+<br />

2.0 equiv<br />

4 mol% 4-Ru<br />

CH 2Cl 2 40 °C, 12 h<br />

87%<br />

> 20 : 1 E/Z<br />

5 mol% 4-Ru<br />

CH 2Cl 2 40 °C, 12 h<br />

58%,<br />

>20 : 1 E/Z<br />

1. 3 mol% 3-Ru<br />

CH 2Cl 2 40 °C, 24 h<br />

O<br />

P<br />

EtO EtO<br />

Toste, F. D.; Chatterjee, A. K.; Grubbs, R. H. Pure Appl. Chem. 2002, 74, 7–10.<br />

AcO 3<br />

Morrill, C.; Funk, T. W.; Grubbs, R. H. Tetrahedron Lett. 2004, 45, 7733–7736.<br />

2. PhCHO (2 equiv), 23 °C<br />

Yamamoto, Y.; Takahashi, M.; Miyaura, N. Synlett 2002, 128–130.<br />

O<br />

CH 3<br />

OEt<br />

H 3C CH3<br />

O CH3 B<br />

O CH3 Ph<br />

OH<br />

Ph<br />

88 %<br />

91 : 9 anti/syn<br />

Examples in synthesis<br />

• En route to the ABS ring fragment of thyrsiferol:<br />

H 3C<br />

H 3C<br />

Br<br />

O<br />

H 3C<br />

H 3C<br />

Br<br />

OAc<br />

CH3 O<br />

+<br />

CH3 CH3 O<br />

O<br />

OAc<br />

starting material homodimer<br />

O<br />

O<br />

OBn<br />

OBn<br />

OBn<br />

2<br />

O<br />

3.0 equiv<br />

OTBS<br />

McDonald, F. E.; Wei, X. Org. Lett. 2002, 4, 593–595.<br />

H<br />

O<br />

5 mol% 3-Ru<br />

H 3C<br />

H 3C<br />

Br<br />

CH 2Cl 2, 23 °C, 30 min<br />

OBn<br />

O OBn<br />

H<br />

OBn<br />

95%<br />

10 mol% 4-Ru<br />

CH 2Cl 2, 45 °C<br />

CH3 O<br />

OAc<br />

CH3 O<br />

44% E-isomer<br />

64% after recycling the homodimer<br />

AcO<br />

AcO<br />

H<br />

OAc<br />

5.0 equiv<br />

OAc<br />

H<br />

O<br />

O<br />

OBn<br />

O OBn<br />

H<br />

OBn<br />

H<br />

H<br />

O<br />

OTBS<br />

• CM can be difficult in the presence of strained olefins, as was found in the preparation of the<br />

AB ring fragment of ciguatoxin:<br />

AcO<br />

compound A<br />

OAc<br />

H<br />

19%<br />

via ring opening to compound A<br />

+<br />

40 mol% 3-Ru<br />

CH 2Cl 2, 40 °C<br />

33 h<br />

OBn<br />

O OBn<br />

H<br />

OBn<br />

8%<br />

AB ring fragment of ciguatoxin<br />

Oguri, H.; Sasaki, S.; Oishi, T.; Hirama, M. Tetrahedron Lett. 1999, 40, 5405–5408.<br />

L. Blasdel

Ring Opening Cross-<strong>Metathesis</strong>:<br />

CH 3O 2C<br />

O<br />

O<br />

substrate product alkene a<br />

O<br />

O<br />

CO 2CH 3<br />

NBoc<br />

O<br />

O<br />

CH 3OCH 2<br />

O<br />

Et<br />

Et<br />

CH 3OCH 2<br />

O<br />

CH 3O 2C<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

CO 2CH 3<br />

O<br />

NBoc<br />

CH 2OCH 3<br />

Et<br />

Et<br />

CH 2OCH 3<br />

A<br />

B<br />

C<br />

A 2 89 15 NA<br />

a 25 °C; 1.5 Equivalents of alkene used: A = trans-1,4-dimethoxybut-2-ene;<br />

B = trans-hex-3-ene; C = cis-hex-3-ene. Solvent: C 6H 6 (entries 1 and 2) or<br />

CH 2Cl 2 (entries 3 and 4). b Cat. = 2-Ru. c Cat. = 3-Ru.<br />

O<br />

mol %<br />

cat. b time yield E,E:E,Z<br />

6 96 94 2:1<br />

2 14 85 2:1<br />

8 c<br />

3 73 1.5:1<br />

• In these cases a preference for the E-olefin geometry is observed in ring opening<br />

metathesis.<br />

• Higher yields were achieved by the slow addition of the cyclic alkene to a solution of<br />

the 1,2-disubstituted alkene.<br />

• Faster and more efficient ring opening cross metathesis was observed using<br />

cis-hex-3-ene vs. trans-hex-3-ene.<br />

Schneider, M. F.; Blechert, S. Angew. Chem., Int. Ed. Engl. 1996, 35, 411-412.<br />

Enantioselective ROM–CM reactions have been described: La, D. S.; Ford, J. F.; Sattely,<br />

E. S.; Bonitatebus, P. J.; Schrock, R. R.; Hoveyda, A. H. J. Am. Chem. Soc. 1999, 121,<br />

11603–11604.<br />

Enyne Cross-<strong>Metathesis</strong><br />

• 4-Ru outperforms 3-Ru in both rate and overall conversion in the cross-metathesis of<br />

ethylene and alkynes.<br />

AcO<br />

CH 3<br />

substrate product time (h) yield (%)<br />

BnO<br />

OAc<br />

OR<br />

Ph<br />

CH 3<br />

OAc<br />

NTs<br />

OH<br />

AcO<br />

CH 3<br />

BnO<br />

CH 3<br />

OR<br />

OAc<br />

OAc<br />

NTs<br />

a <strong>Reaction</strong>s conducted in CH2Cl 2 at 23 °C using 5 mol% of 4-Ru at 60 psi of<br />

ethylene pressure.<br />

Smulik, J. A.; Diver, S. T. Org. Lett. 2000, 2, 2271–2274.<br />

R = H<br />

R = Ac<br />

R = TBS<br />

Ph<br />

2.0<br />

2.0<br />

8.5<br />

16 77<br />

4.0 69<br />

4.0 91<br />

OH<br />

73<br />

92<br />

91<br />

6.0 72<br />

• <strong>Reaction</strong>s conducted at 1 atm of ethylene pressure typically gave low conversions even<br />

after extended reaction times.<br />

• <strong>The</strong> more reactive imidazolylidene 4-Ru can tolerate free hydroxyl groups and<br />

coordinatingfunctionality at the propargylic and homopropargylic positions.<br />

• Chiral propargylic alcohols afford chiral diene products without loss of optical purity:<br />

4-Ru (5 mol%)<br />

ethylene (60 psi)<br />

CH 2Cl 2, 23 °C<br />

99% ee 99% ee<br />

M. Movassaghi

<strong>Metathesis</strong> of Alkynes and Diynes<br />

• Inspired by the activation of the triple bond of molecular nitrogen with molybdenum<br />

complexes of the general type Mo[N(t-Bu)Ar] 3 (see: Laplaza, C. E.; Cummins, C. C.<br />

Science, 1995, 268, 861), the reactivity of this class of molybdenum catalysts toward<br />

alkynes was explored.<br />

RO<br />

CH 3<br />

t-Bu<br />

N<br />

CH3 CH3 t-Bu<br />

Mo N<br />

t-Bu<br />

N<br />

16-Mo<br />

CH 3<br />

CH 3<br />

R CH 3<br />

CH 3<br />

CH 3<br />

RX<br />

CH 3<br />

t-Bu<br />

RO<br />

N<br />

CH3 CH3 Cl<br />

t-Bu<br />

Mo<br />

N<br />

N<br />

t-Bu<br />

CH 3<br />

CH 3<br />

X = Cl<br />

X = Br<br />

• Oxidation of the Mo(III)-precatalyst 16-Mo occurs in situ upon addition of ~25 equivalents of<br />

additives such as CH 2Cl 2, CH 2Br 2, CH 2I 2, and BnCl.<br />

• Alkyne metathesis may be achieved with equal efficiency either by in situ oxidation of<br />

precatalyst 16-Mo or by use of pure Mo(IV)-catalysts 17-Mo and 18-Mo.<br />

16-Mo (10 mol%)<br />

CH 2Cl 2, Toluene<br />

17-Mo (10 mol%)<br />

CH 2Cl 2, Toluene<br />

17-Mo,<br />

18-Mo,<br />

CH 3<br />

R R<br />

• Catalyst 17-Mo is sensitive to acidic protons such as those of secondary amides.<br />

• Terminal alkynes are incompatible with the catalysts.<br />

R = H,<br />

R = CN,<br />

R = CH 3,<br />

R = THP,<br />

60%<br />

58%<br />

59%<br />

55%<br />

• Use of CH 2Cl 2 as the reaction solvent or the addition of ~25 equivalents of CH 2Cl 2<br />

per mol of 16-Mo in toluene are equally effective.<br />

• Catalysts 17-Mo and 18-Mo tolerate functional groups such as esters, amides,<br />

thioethers, basic nitrogen atoms, and polyether chains, many of which are<br />

incompatible with the tungsten alkylidyne catalysts previously used.<br />

OR<br />

CH 3<br />

RCM of Diynes<br />

• Efficient synthesis of ≥12-membered rings containing internal alkynes can be<br />

achieved with 17-Mo.<br />

O<br />

Ph<br />

Ph<br />

Si<br />

CH 3<br />

N<br />

O<br />

substrate<br />

O<br />

O<br />

O<br />

O<br />

O(CH 2) 10<br />

O(CH 2) 10<br />

O(CH 2) 10<br />

O(CH 2) 10<br />

O O<br />

O O<br />

O(CH 2) 10<br />

O<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

CH 3<br />

Ph<br />

Ph<br />

CH 3<br />

O<br />

Si<br />

O<br />

O<br />

O O<br />

O O<br />

O<br />

O<br />

O<br />

product a<br />

Fürstner, A.; Mathes, C.; Lehmann, C. W. J. Am. Chem. Soc. 1999, 121, 9453–9454.<br />

N<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

yield (%)<br />

a <strong>Reaction</strong>s conducted in toluene at 80 °C for 20-48h; 17-Mo was generated in situ<br />

from 16-Mo and CH 2Cl 2 (~25 equiv).<br />

88<br />

82<br />

74<br />

83<br />

91<br />

M. Movassaghi

Synthesis of Cyclic β-Turn Analogs by RCM<br />

H 3C<br />

H<br />

N<br />

Boc<br />

H3C H<br />

H<br />

N<br />

Boc<br />

H<br />

O H3C CH3 N O<br />

N H<br />

O H N O<br />

20 mol% 2-Ru<br />

H<br />

H<br />

O H3C CH3 N O<br />

N H<br />

O H N O<br />

N<br />

H<br />

CH2Cl2, 40 °C N<br />

Bn<br />

Boc<br />

60%<br />

N<br />

H<br />

Bn<br />

• <strong>The</strong> presence of the Pro-Aib sequence in the tetrapeptide induces a β-turn conformation<br />

which was covalently captured by RCM, yielding a 14-membered macrocycle.<br />

Miller, S. J.; Kim, S. H.; Chen, Z. R.; Grubbs, R. H. J. Am. Chem. Soc. 1995, 117, 2108–2109.<br />

Miller, S. J.; Grubbs, R. H. J. Am. Chem. Soc. 1995, 117, 5855-5856.<br />

N<br />

O<br />

CH 3<br />

CH 3<br />

N O<br />

H<br />

O H N O<br />

OBn<br />

30 mol% 3-Ru<br />

0.004 M, 21 h<br />

CH 2Cl 2, 40 °C<br />

60%<br />

H 3C<br />

H3C H<br />

H<br />

N<br />

Boc<br />

N<br />

O<br />

CH 3<br />

CH 3<br />

N O<br />

H<br />

O H N O<br />

• Although interactions that increase the rigidity of the substrate and reduce the entropic<br />

cost of cyclization can be beneficial in RCM, it is not a strict requirement for<br />

macrocyclization byRCM.<br />

Miller, S. J.; Blackwell, H. E.; Grubbs, R. H. J. Am. Chem. Soc. 1996, 118, 9606–9614.<br />

OBn<br />

Template-Directed RCM<br />

O<br />

O O<br />

O<br />

O<br />

O<br />

n<br />

n = 1, 2<br />

O<br />

O<br />

5 mol% 3-Ru<br />

"template"<br />

CH 2Cl 2, THF<br />

45 °C, 1 h<br />

0.02 M<br />

substrate (n) "template" (equiv) yield (%) cis:trans<br />

1<br />

1<br />

1<br />

2<br />

2<br />

none<br />

LiClO 4 (5)<br />

NaClO 4 (5)<br />

none<br />

LiClO 4 (5)<br />

39<br />

>95<br />

42<br />

57<br />

89<br />

O<br />

38:62<br />

100:0<br />

62:38<br />

26:74<br />

61:39<br />

O<br />

O<br />

O O<br />

O<br />

n = 1, 2<br />

• Preorganization of the linear polyether about a complementary metal ion can enhance RCM.<br />

• In general, ions that function best as templates also favor the formation of the cis isomer.<br />

5 mol% 3-Ru<br />

CH 2Cl 2<br />

1.2 M, 23 °C<br />

>95%<br />

5 mol% 3-Ru<br />

LiClO 4<br />

CH 2Cl 2, THF<br />

0.02 M, 50 °C<br />

>95% (cis)<br />

O<br />

M n = 65900<br />

n<br />

cis : trans, 1 : 3.7<br />

• Polymer degradation in the absence of a Li + template produced the corresponding<br />

crown ether as a mixture of cis- and trans-olefins (20% combined yield) along with<br />

other low molecular weight polymers.<br />

Marsella, M. J.; Maynard, H. D.; Grubbs, R. H. Angew. Chem., Int. Ed. Engl. 1997, 36, 1101–<br />

1103.<br />

O<br />

m<br />

M. Movassaghi

RCM-Mediated Covalent Capture<br />

• <strong>The</strong> eight-residue cyclic peptide cyclo[-(L-Phe-D- Me N-Ala-L-HomoallylGly-D- Me N-Ala) 2 - ]<br />

self-assembles to form two slow-exchanging antiparallel β-sheet-like hydrogen bonded<br />

cylinders (K a(CDCl 3) = 99 M –1 , only the reactive isomer is shown).<br />

Ph<br />

O O<br />

O<br />

N<br />

N<br />

O<br />

N<br />

N<br />

N<br />

H<br />

N<br />

N<br />

N<br />

O H O<br />

O H O H<br />

Ph<br />

O H O H<br />

H O H O<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

O<br />

O<br />

O O<br />

Ph Ph<br />

20-25 mol% 2-Ru<br />

CDCl 3, 23 °C, 48 h<br />

65%<br />

Ph<br />

O O<br />

O<br />

N<br />

N<br />

O<br />

N<br />

N<br />

N<br />

H<br />

N<br />

N<br />

N<br />

O H O<br />

O H O H<br />

Ph<br />

O H O H<br />

H O H O<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

O<br />

O<br />

O O<br />

Ph Ph<br />

• <strong>The</strong> hydrogen-bonded ensemble positions the terminal olefins of the four<br />

L-homoallylglycine residues in sufficiently close proximity that each pair undergoes RCM<br />

in the presence of alkylidene 2-Ru to give a tricyclic cylindrical product containing a 38membered<br />

ring as a mixture of three (cis-cis, cis-trans, trans-trans) olefin isomers.<br />

• This covalent capture strategy may be useful in stabilizing kinetically labile α-helical and<br />

β-sheet peptide secondary structures.<br />

Clark, T. D.; Ghadiri, M. R. J. Am. Chem. Soc. 1995, 117, 12364–12365.<br />

Synthesis of Catenanes<br />

2<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

N<br />

N<br />

O O<br />

O<br />

N<br />

N<br />

N<br />

N<br />

O<br />

O O<br />

O<br />

O<br />

32-membered catenane<br />

O<br />

O<br />

O<br />

O<br />

Cu(CH 3CN) 4PF 6<br />

CH 2Cl 2, CH 3CN<br />

100%<br />

KCN, H 2O<br />

CH 3CN<br />

~100%<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

= Cu +<br />

O<br />

O<br />

O<br />

O<br />

O<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

N<br />

O<br />

O<br />

O<br />

O O<br />

trans:cis, 98:2<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

5 mol% 3-Ru<br />

23 °C, 6 h<br />

0.01 M, CH 2Cl 2<br />

92%<br />

• <strong>The</strong> remarkable efficiency of this RCM is proposed to be due to preorganization of the<br />

substrate.<br />

O<br />

O<br />

+ –<br />

PF6 + PF –<br />

6<br />

Mohr, B.; Weck, M.; Sauvage, J.-P.; Grubbs, R. H. Angew. Chem., Int. Ed. Engl. 1997, 36,<br />

1308–1310.<br />

M. Movassaghi