Jenei István

Jenei István

Jenei István

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>István</strong> <strong>Jenei</strong>: Lean transformation of hospital processes – Structuring foreign and Hungarian experiences,<br />

PhD Dissertation, Corvinus University of Budapest, Doctoral School in Business Administration<br />

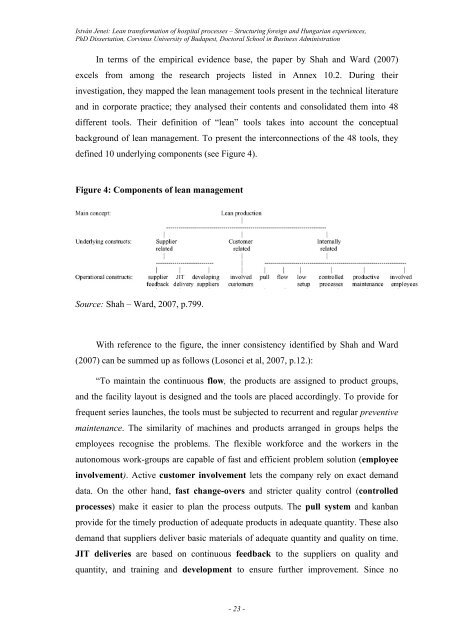

In terms of the empirical evidence base, the paper by Shah and Ward (2007)<br />

excels from among the research projects listed in Annex 10.2. During their<br />

investigation, they mapped the lean management tools present in the technical literature<br />

and in corporate practice; they analysed their contents and consolidated them into 48<br />

different tools. Their definition of “lean” tools takes into account the conceptual<br />

background of lean management. To present the interconnections of the 48 tools, they<br />

defined 10 underlying components (see Figure 4).<br />

Figure 4: Components of lean management<br />

Source: Shah – Ward, 2007, p.799.<br />

With reference to the figure, the inner consistency identified by Shah and Ward<br />

(2007) can be summed up as follows (Losonci et al, 2007, p.12.):<br />

“To maintain the continuous flow, the products are assigned to product groups,<br />

and the facility layout is designed and the tools are placed accordingly. To provide for<br />

frequent series launches, the tools must be subjected to recurrent and regular preventive<br />

maintenance. The similarity of machines and products arranged in groups helps the<br />

employees recognise the problems. The flexible workforce and the workers in the<br />

autonomous work-groups are capable of fast and efficient problem solution (employee<br />

involvement). Active customer involvement lets the company rely on exact demand<br />

data. On the other hand, fast change-overs and stricter quality control (controlled<br />

processes) make it easier to plan the process outputs. The pull system and kanban<br />

provide for the timely production of adequate products in adequate quantity. These also<br />

demand that suppliers deliver basic materials of adequate quantity and quality on time.<br />

JIT deliveries are based on continuous feedback to the suppliers on quality and<br />

quantity, and training and development to ensure further improvement. Since no<br />

- 23 -