TMS Solution TMS Solution - LMR

TMS Solution TMS Solution - LMR

TMS Solution TMS Solution - LMR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TMS</strong> <strong>Solution</strong><br />

<strong>TMS</strong> <strong>Solution</strong><br />

Surveying for tunnelling professionals

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

Amberg <strong>TMS</strong> <strong>Solution</strong><br />

… the surveying solution for all<br />

underground projects<br />

The foundation for success<br />

� Close cooperation with<br />

customers<br />

� 30 years experience in tunnel<br />

surveying<br />

� Verification through own service<br />

department<br />

� Using latest technologies<br />

� Powerful technology partners<br />

2

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> – The universal measurement system<br />

� Conventional tunnelling<br />

� Tunnel refurbishment<br />

� Mining<br />

� Hydropower station construction<br />

3<br />

� Shaft construction<br />

� Bunker construction<br />

� Small diameter construction<br />

� Cavern construction

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

Amberg‘s history in tunnel market<br />

1976: A.MT. Profiler<br />

1 st automatic profile<br />

measuring instrument<br />

1981: Foundation<br />

Amberg Technologies<br />

1966 1970 1980 1990 1995<br />

2000<br />

Foundation<br />

Amberg Engineering<br />

4<br />

1999: <strong>TMS</strong> Profile<br />

3D profile control<br />

1995:<br />

Profiler 4000<br />

2002: <strong>TMS</strong> Setout<br />

Autom. tunnel stake out<br />

2002:<br />

GRP 3000<br />

2004:<br />

GRP<br />

System FX<br />

2006: <strong>TMS</strong> Tunnelscan<br />

Complete tunnel<br />

documentation<br />

2005<br />

2005:<br />

GRP 5000<br />

2006:<br />

XRide<br />

2006: TunnelMap<br />

Digital tunnel inspection<br />

2009<br />

2009:<br />

Amberg Rail

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

Amberg Technologies world wide projects<br />

5

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

Amberg OptiPlan<br />

Optimal readiness of application<br />

and optimal efficiency of Amberg<br />

measuring system<br />

Advantages for customers<br />

� Individual support, maintenance<br />

and servicing benefits<br />

� Training and optimization of<br />

system knowledge<br />

� Support by local Amberg service<br />

and support partner<br />

� Project optimization<br />

6

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Support<br />

� Support engineers with practical<br />

experience and background<br />

knowledge<br />

� Readily available & quick<br />

response times<br />

� Systems tested in real conditions<br />

� Strongly supported by partners<br />

such as Leica Geosystems and<br />

Zoller+Fröhlich<br />

� Partners are incorporated in the<br />

ongoing development of <strong>TMS</strong><br />

� Understand the needs of the<br />

building sites and of the<br />

customers<br />

7

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> <strong>Solution</strong><br />

Surveying for tunnelling professionals<br />

Product overview<br />

8

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

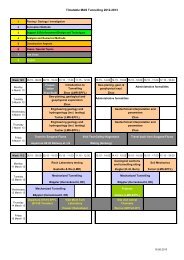

<strong>TMS</strong> – The solution for typical construction methods<br />

9<br />

Jetting<br />

Drill & Blast<br />

Road header<br />

TBM<br />

Heading<br />

Drill & Blast <strong>TMS</strong><br />

<strong>TMS</strong><br />

Visual guidance<br />

Guidance system *)<br />

Guidance System *)<br />

Not part of <strong>TMS</strong> *)<br />

Jetting<br />

Back up Inner lining<br />

<strong>TMS</strong><br />

<strong>TMS</strong><br />

Road header<br />

TBM

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> – Flexible application in all construction phases<br />

1 2 4 6 8 10<br />

1. Automatic tunnel setting out<br />

1.1 drill pattern, 1.2 drill rig positioning,<br />

1.3 profile contour, 1.4 steel arch positioning<br />

2. Real-time profile control<br />

Excavation, steel arch<br />

3. Excavation documentation &<br />

analysis Excavation, shotcrete layer<br />

4. Backup set out<br />

4.1 Rock support , 4.2 cross passages, niches<br />

5. Quality control outer lining<br />

Shotcrete profile & surface undulation<br />

10<br />

3 5 7 9 11<br />

6. Reworks quality profile checks<br />

Critical spots<br />

7. Final tunnel surface quality<br />

control<br />

Profile & surface undulation<br />

8. Inner lining set out<br />

Construction joints, reference heights<br />

9. Formwork acceptance control<br />

Profile<br />

10. Set out for installation works<br />

Banquettes, installations<br />

11. Tunnel quality control<br />

Profile, assets

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> – The universal tunnel measurement system<br />

<strong>TMS</strong> Office<br />

Administration of project data<br />

Evaluation of measurements<br />

<strong>TMS</strong> Setout<br />

For automatic tunnel setting out<br />

<strong>TMS</strong> Profile<br />

For real-time 3D profile control<br />

<strong>TMS</strong> Tunnelscan<br />

For complete tunnel as-built<br />

analysis<br />

11

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Office<br />

Before the survey<br />

� Project definition<br />

� Definition of setout jobs<br />

� Laser offset list<br />

After the survey<br />

� Profiles evaluation<br />

� Volume computation<br />

� Layer thickness<br />

� Conformity check of undulation<br />

� Complete infrastructure<br />

documentation<br />

Based on a single software<br />

platform!<br />

12

<strong>TMS</strong> <strong>Solution</strong> - - Surveying for for tunnelling professionals<br />

<strong>TMS</strong> Setout – Automatic tunnel setting out<br />

13

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout – Features<br />

� A single software tool for all set<br />

out works in tunnelling<br />

� All project data onboard<br />

� Real-time computation of<br />

measurement vs. design data<br />

� Efficient operation<br />

� Automatic set out for one-person<br />

operation mode<br />

14

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout Plus – For automatic tunnel setting out<br />

� 24 hours motorized laser<br />

functionality for setting out of<br />

� Grout umbrellas (jetting)<br />

� Excavation profiles and blast<br />

pattern<br />

� Shotcrete layer thickness<br />

� Steel arches positioning and<br />

profile check<br />

� Formwork carriage<br />

� Drilling machine<br />

� Intuitive user interface for:<br />

� Surveyors<br />

� Foremen<br />

15

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout Plus – Tunnel-like operating concept<br />

The 24 hours tunnel surveyor<br />

� An ingenious operating concept<br />

� Two separate operating modes<br />

DESIGN MODE (surveyor)<br />

� Preparation of surveying tasks<br />

and operation parameters<br />

� Setup of total station in tunnel<br />

PRODUCTION MODE (tunnel<br />

crew)<br />

� Independent, around the clock<br />

surveying by the tunnelling crew<br />

16

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout Plus – “Active Mode” for precise tunnelling<br />

The intelligent Active Mode:<br />

Your insurance for high precision<br />

tunnel excavation<br />

� Automatic setting out with<br />

reflectorless distance<br />

measurement<br />

� Automatic correction of stationing<br />

inaccuracies<br />

� Errors in the setting out are<br />

excluded - even with<br />

unfavourable conditions in curves<br />

or tunnel faces not perpendicular<br />

to the centerline<br />

17<br />

2<br />

1

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout – Advantages for the contractor<br />

� Cost and time savings through<br />

precise setting out<br />

� Excavation<br />

� Shotcrete and Concrete<br />

� Optimise the construction<br />

workflow:<br />

� Reduced waiting/down time<br />

� Short-term set out available<br />

� Automatic set out routines<br />

� Fast reaction of changes from<br />

the owner<br />

� Direct control of all set out tasks<br />

in the field<br />

18

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout – Advantages for the surveyor<br />

From an obstacle to a friend<br />

� Flexible - All project data onboard<br />

� Precise - Direct and exact stake<br />

out without any pre-calculation in<br />

the office<br />

� Effective - One-person operation<br />

(without any paper docs)<br />

� Economical - More project with<br />

less personnel (7 days and 24<br />

hours)<br />

� Healthy – Less time spent in the<br />

tunnel<br />

19

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout – Advantages for the foreman<br />

Simpler than a mobile phone<br />

� Independent operation by the<br />

working crew<br />

� Simple selection of pre-defined<br />

tasks<br />

� Indicate with laser point and<br />

deviation to the design point<br />

� Log files and profile controls to<br />

check quality<br />

� Exact working without laser<br />

offset list<br />

� Employment of tunnel-suited<br />

hardware components<br />

20

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout – Advantages through cost reduction<br />

Assumptions<br />

� Tunnel length 1000m<br />

� 200m grout umbrellas (jetting)<br />

heading with steel arches<br />

positioning<br />

� 800m conventional outbreak<br />

Potential costs savings<br />

� Reduction up to 2/3<br />

� No downtime and impact on<br />

tunnelling works<br />

21<br />

90'000<br />

80'000<br />

70'000<br />

60'000<br />

50'000<br />

40'000<br />

30'000<br />

20'000<br />

10'000<br />

0<br />

Heading costs with <strong>TMS</strong> SetOut<br />

70000<br />

24000

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Setout<br />

Reference list extract<br />

Beton & Monierbau (Jagdbergtunnel), Marti AG<br />

(Bibratunnel), Glückauf Vermessung<br />

(Höllbergtunnel), Geodat (Hengstbergtunnel)<br />

22<br />

Germany<br />

Veidekke SA (Oslo), MIKA Norway<br />

Kiewit Construction Company (Devil's Slide),<br />

J.F. Shea (No.7 Line Extension, New York)<br />

Larsen & Toubron Limited (ECC Divison)<br />

Chennai<br />

TAT Konsortium Gotthard Basistunnel,<br />

Implenia, Grunder, SWR<br />

Yunnan machinery import & export co<br />

(Kunming)<br />

Bombela (Gautrain), CMC Di Ravenna /<br />

Impregilo (Ingula Pumped Storage), DeBeers<br />

(Cullinan Diamond Mine)<br />

USA<br />

India<br />

Switzerland<br />

China<br />

South Africa

<strong>TMS</strong> <strong>Solution</strong> - - Surveying for for tunnelling professionals<br />

<strong>TMS</strong> Profile – 3D profile control for tunnelling<br />

23

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Module<br />

<strong>TMS</strong> Office<br />

Administration of project data<br />

Evaluation of measurements<br />

<strong>TMS</strong> Profile<br />

For real-time 3D profile control<br />

<strong>TMS</strong> ProScan<br />

Tunnel application<br />

<strong>TMS</strong> ProFit<br />

Office application<br />

24

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Features<br />

� The standard software package<br />

for automatic reflectorless data<br />

acquisition of tunnel profiles with<br />

motorized Leica total station<br />

� 6 different measurement modes,<br />

incl. shaft survey<br />

� Plus functionality: Measurement<br />

� automatically perpendicular to<br />

the tunnel design axis<br />

� of vertical or sloped profiles at<br />

selected exact stationing<br />

25

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Real time 3D profile control<br />

� Automatic 3D profile control<br />

� Flexible single profile<br />

measurement during tunnelling<br />

work<br />

� Results available in real-time<br />

� Visualisation of under and over<br />

break directly in the field<br />

26

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Extensive evaluation<br />

<strong>TMS</strong> ProFit –– for fast evaluation<br />

of profile measurements<br />

� Comprehensive graphic-numeric<br />

data analysis<br />

� Comprehensive import interface<br />

for absolute coordinates<br />

� Direct calculation of profile<br />

distances, volumes, geological<br />

overbreak, sealing foil lengths, …<br />

� Flexible report according to<br />

customer requirements<br />

� DXF data interface<br />

� Export possibilities for 3Dvisualisation<br />

27

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Advantages for the project owner<br />

� Exact economy figures for<br />

reliable project accounting and<br />

cost management<br />

� Quality control through:<br />

� Exact profile compliance<br />

� As-built documentation<br />

� Layer thickness analysis<br />

(Concrete, Shotcrete)<br />

� Shorter time required in the<br />

hazardous zone of the tunnel<br />

28

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Advantages for the contractor<br />

� Exact economy figures for<br />

authentic project accounting<br />

� Cost savings for excavation:<br />

� Min. re-excavation<br />

� Min. over-excavation<br />

� Reduced shutdown time for<br />

heading process:<br />

� Immediate analysis<br />

� Assembly check of steel<br />

arches<br />

� Operation in construction mode<br />

after a short training of the<br />

foremen<br />

29

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Advantages for the surveyor<br />

� One multi-functional total station<br />

for profile measurement and<br />

other survey jobs<br />

� Real-time data available<br />

(Stationing value, offset to the<br />

axis, deviation, derolement, …)<br />

� Perfect profile compliance<br />

� Direct and exact profile<br />

measurements<br />

� High efficiency through<br />

automatic data acquisition<br />

� Eliminates manual computations<br />

thus reducing chance of error<br />

30

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile – Advantages through cost reduction<br />

Assumptions<br />

� Tunnel diameter of 10m<br />

� Tunnel length 1000m<br />

� 125 USD / m3 Over-excavation<br />

� 200 USD / m3 Concrete<br />

� 350 USD / m3 Shotcrete<br />

Cost savings due to minimisation of<br />

overbreak areas:<br />

� USD 525’000 by 5cm<br />

� USD 1’050’000 by 10cm<br />

� USD 1’530’000 by 15cm<br />

31<br />

1'600'000<br />

1'400'000<br />

1'200'000<br />

1'000'000<br />

800'000<br />

600'000<br />

400'000<br />

200'000<br />

0<br />

Costs of over brak areas<br />

1.530.000<br />

1.050.000<br />

525.000

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Profile<br />

Reference list extract<br />

Skanska Stockholm Sweden<br />

MTR (Mass Transit Railway Cooperation<br />

Hongkong)<br />

Hong Kong<br />

Subterra, Metrostav, Doprastav Czech Republic<br />

Astaldi, SARGIN Construction Co. Turkey<br />

Aktor (E65) Greece<br />

JV Karahnjukar Project Iceland<br />

Anglo Platinum (Twickenham Mine)<br />

Marti Tunnelbau AG, TRIGONET, Swissphoto,<br />

Strabag, Frutiger<br />

32<br />

South Africa<br />

Switzerland

<strong>TMS</strong> <strong>Solution</strong> - - Surveying for for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Complete tunnel information at a glance<br />

33

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan - For complete tunnel as-built analysis<br />

� Complete profile control<br />

� Determination of all areas of<br />

under and overbreak<br />

� Layer thickness determination<br />

� Detailed calculation of quantities<br />

� Conformity check of undulation<br />

of the tunnel surface layer<br />

� Scaled image documentation<br />

� Detailed quality check<br />

34

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Fields of application<br />

Complete tunnel as-built<br />

1. Excavation records<br />

(e.g. profile, volume)<br />

2. Complete quality control<br />

(e.g. profile, shotcrete layer<br />

thickness, undulation, volume)<br />

3. Acceptance checks<br />

(e.g. profile, undulation,<br />

concrete volume)<br />

4. Final as-built documentation<br />

(e.g. profile, concrete layer<br />

thickness, asset documentation)<br />

5. Tunnel surface deformation<br />

35<br />

1 2<br />

3 4<br />

5

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Features<br />

� The complete software package<br />

for high-performance scanning<br />

� Supported Scanner:<br />

� Amberg Profiler 5003<br />

� Z+F IMAGER5003/6(i)<br />

� Leica HDS4500/6000/6100<br />

� High production rates with<br />

Amberg Positioning Method<br />

APM<br />

� Complete data structure<br />

(geometry and high res. scan)<br />

� Profile, area and undulation<br />

check<br />

36

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Workflow: Measurement<br />

APM<br />

Amberg Positioning Method<br />

� Scanner positioning by use of<br />

total station<br />

� <strong>TMS</strong> Scan target (sphere) within<br />

scan range<br />

Advantages<br />

� Flexible scanner set up<br />

� Fast scan without impact<br />

on tunnelling works<br />

� 12.5 Million Points < 2 Min.<br />

(= typical resolution 10 x 10 mm)<br />

APM TM is optimised for fast deduction scanning and measurement of<br />

long tunnel stretches in short time without impact on tunnelling works<br />

37

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Workflow<br />

38<br />

<strong>TMS</strong> ScanControl<br />

Geo-referencing<br />

<strong>TMS</strong> ScanRex<br />

Direct<br />

evaluation<br />

Profile evaluation<br />

<strong>TMS</strong> ProFit<br />

<strong>TMS</strong> Scan Cloud<br />

Complete tunnel analyses

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Workflow: Data Analysis / Reporting<br />

High performance reports<br />

� Scaled greyscale-image<br />

documentation<br />

� Complete area results:<br />

� Profile analysis<br />

� Conformity check of<br />

undulation<br />

� Layer thickness reports<br />

� Accurate volume computation<br />

� Individual color code in<br />

coordination with the project<br />

requirements<br />

39

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Workflow: Profiles export<br />

Full automation for profile<br />

analysis<br />

� Direct import into <strong>TMS</strong> ProFit<br />

module for analysis<br />

� Profile extraction with user<br />

defined definition of:<br />

� Number of point per profile<br />

� Interval between the profiles<br />

� Automatic announcement of<br />

the critical points<br />

� Reports: Area and volume<br />

computation, point lists, LSQ,<br />

geological overbreak, ...<br />

� Export Formats: ASCII, DXF,<br />

40 PDF, …

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Advantages for the project owner<br />

� Exact economy figures for<br />

reliable project accounting<br />

� Undulation control which can<br />

cause damages in sealing liner<br />

� Quality control of different layers<br />

� Preservation of evidence to the<br />

building contractor/construction<br />

company<br />

� Optimization of tunnel axis<br />

(formwork carriage)<br />

� Increase tunnel safety by high<br />

quality of construction<br />

41

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Advantages for the contractor<br />

� Exact economy figures<br />

� Minimization of concrete amount<br />

� Optimization of axis<br />

� Results which everybody can<br />

interpret<br />

� Preservation of evidence to<br />

owners and subcontractors<br />

� Conformity check of undulation<br />

before applying sealing liner<br />

� Layer thickness of sprayed<br />

concrete � quality check<br />

42

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan – Advantages for the surveyor<br />

� Quality – complete record of the<br />

constructed tunnel<br />

� Efficiency – 200m tunnel<br />

scanning/hour<br />

� Flexibility – No additional<br />

supporting infrastructure required<br />

(e.g. external power supply, no<br />

lights, …)<br />

� Highest performance with oneperson-operation<br />

without impact<br />

on construction<br />

43

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan - optimisation inner lining<br />

Assumptions<br />

� Tunnel length 1000m<br />

� TBM heading<br />

� Block length 12m ca. 83 Blocks<br />

� 200USD/m3 Concrete backfilling<br />

� Setup of formwork carriage<br />

respecting the required concrete<br />

layer thickness<br />

Potential costs savings<br />

� Reduction of the concrete<br />

volume for the inner lining<br />

building: 15m3 per Block (3000<br />

USD) with 5cm radius variation of<br />

formwork carriage<br />

44<br />

1'200'000<br />

1'000'000<br />

800'000<br />

600'000<br />

400'000<br />

200'000<br />

0<br />

Costs of formwork carriage<br />

996.000<br />

747.000<br />

498.000<br />

249.000

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan - Assumptions for sealing foil<br />

Assumptions<br />

� Subsequent refurbishment of wet<br />

places because of destroyed<br />

sealing foil<br />

� Elaborate method for<br />

refurbishment of wet areas (thin<br />

shotcrete layer with drainages)<br />

Potential costs savings<br />

� Price for each m2 refurbishment<br />

ca. 300USD<br />

� Clear documentation of the<br />

conformity check of undulation<br />

� Quality assurance<br />

45<br />

250'000<br />

200'000<br />

150'000<br />

100'000<br />

50'000<br />

0<br />

Refurbishment costs of wet zones

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Tunnelscan<br />

Reference list extract<br />

Sweco (Törnskog Tunnel, Stockholm), Skanska,<br />

Oden, LKAB (Kiruna), NCC<br />

DMT, BeMo (Jagdbergtunnel), Geodat<br />

(Blessbergtunnel), Glückauf Vermessung<br />

(Tragbergtunnel), Marti (Katzenbergtunnel)<br />

Geomonitoring Inc. Korea, Yatap Leaders<br />

Building<br />

J.F. Shea (No.7 Line Extension, New York)<br />

Durazzani (Firenze), GEOGRA<br />

RAZEL, Bouyges construction<br />

Geotunel (Barcelona)<br />

46<br />

Sweden<br />

Germany<br />

South Korea<br />

USA<br />

Italy<br />

France<br />

Spain

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> <strong>Solution</strong><br />

Surveying for tunnelling professionals<br />

Case Studies<br />

47

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies<br />

Uetlibergtunnel - Switzerland<br />

48

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Uetlibergtunnel Switzerland<br />

The Project<br />

� The Uetlibergtunnel is the<br />

longest tunnel of the new Westbypass<br />

of Zürich<br />

� Consists two parallel tubes, each<br />

about 4.4 km long<br />

� Variable cross slope<br />

� 1.6% longitudinal slope<br />

� 1 shaft<br />

� Cross cuts every 300 meter<br />

49

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Uetlibergtunnel Switzerland<br />

The challenge<br />

� 24 hours working site<br />

� 2 TBM<br />

� 6 soft ground headings<br />

� 1 shaft heading<br />

� Geotechnical measurements<br />

� Interior works<br />

� Complete project should be<br />

conducted by only 2 surveyors<br />

The solution<br />

� <strong>TMS</strong> Setout<br />

� <strong>TMS</strong> Profile<br />

50

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Uetlibergtunnel Switzerland<br />

Lasers for stake of the tunnel<br />

worked 24 hours with the foremen<br />

as operator<br />

� Automatic set out of drill pattern<br />

� Steel arch positioning<br />

� Visualisation of profile contour<br />

for excavation by e.g.<br />

roadheader<br />

� Drilling point setout and boom<br />

orientation for jetting and pipe<br />

umbrella advance<br />

� Set out for systematic anchoring<br />

(rock support)<br />

51

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Uetlibergtunnel Switzerland<br />

Shaft and ventilation gallery<br />

� Heading with motorized laser for<br />

excavation<br />

� Blast pattern<br />

� Arch positioning<br />

� Shotcrete control<br />

� Profile control in the shaft<br />

heading with <strong>TMS</strong> ProScan<br />

52

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case studies – Uetlibergtunnel Switzerland<br />

Control measurements and stake<br />

out for the interior works from the<br />

surveyor<br />

� Control point network<br />

measurements<br />

� Control of profiles<br />

� Stakeout of interior work and<br />

infrastructure<br />

� Administration of tunnel-laser<br />

� Stand-alone setting out<br />

53

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Uetlibergtunnel Switzerland<br />

Facts<br />

� 6 Headings soft ground<br />

� 2 TBM headings<br />

� 1 shaft with ventilation gallery<br />

� Interior work<br />

� Installation<br />

� Geotechnical measurements<br />

24h 7days – construction<br />

coverage through surveying<br />

team<br />

54<br />

<strong>TMS</strong> is the system to<br />

� Save time<br />

� 2 surveyors for this project<br />

� Work accurate<br />

� Control big projects with minimal<br />

personnel costs

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies<br />

Kiruna Mine - Sweden<br />

55

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Kiruna mine (Sweden)<br />

The project<br />

� The largest iron/ore mine of the<br />

world<br />

� Operating since 100 years<br />

� Since that extracts more than<br />

950Mt iron<br />

� 4km long, 80m thick<br />

and 2km deep ore body<br />

56

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Kiruna mine (Sweden)<br />

� 400 km tunnel divide on 10 floors<br />

� Deepest point at 1045 m below<br />

the surface<br />

� Ventilation shaft<br />

� Drill and blast heading<br />

� Trains for excavation material<br />

57

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Kiruna mine (Sweden)<br />

The challenge<br />

� Volume computation for statistic<br />

(iron per m3 )<br />

� Over/underbreak calculation<br />

� Installation and clearance<br />

analysis<br />

� Design blast pattern<br />

� Layer thickness determination<br />

� Horizontal cuts<br />

� Resolution: 2cm<br />

The solution<br />

� Acquisition with <strong>TMS</strong> Tunnelscan<br />

58

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Kiruna mine (Sweden)<br />

Results<br />

Over-underbreak report Profile report<br />

59

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Kiruna mine (Sweden)<br />

Results<br />

Horizontal cuts Profiles<br />

60

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Kiruna mine (Sweden)<br />

Why <strong>TMS</strong> Tunnelscan?<br />

� This system is estimate to save<br />

30% of time<br />

� Each year 20km tunnels are<br />

measured<br />

� Happy with service and support<br />

� Good functionalities for their<br />

needs<br />

61

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies<br />

Gotthard Base Tunnel - Switzerland<br />

62

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Gotthard Base Tunnel (CH)<br />

The Project<br />

� With its 57km, at the end of 2017,<br />

it will be the longest tunnel of the<br />

world<br />

� Multifunctional cavern in Faido<br />

� Five different points of attack<br />

� Bypass each 300m<br />

� Two parallel tunnels<br />

� 800m deep shaft in Sedrun<br />

� 3km long inclined shaft<br />

63

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Gotthard Base Tunnel (CH)<br />

Point of attack Faido<br />

� Building of a multifunctional<br />

cavern through a 3km long<br />

inclined shaft<br />

� Up to 6 drill and blast headings<br />

at the same time in North/South<br />

direction<br />

� Spray concrete and<br />

placement of arches<br />

Equipment<br />

� <strong>TMS</strong> Application SetOut Plus<br />

and ProScan plus<br />

� Leica TPS1100<br />

� Leica TCA2003<br />

64

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Gotthard Base Tunnel (CH)<br />

Point of attack Bodio<br />

� Two parallel tubes<br />

� Heading with TMB<br />

� Conformity check of undulation<br />

� Profile for optimizing the inner<br />

lining<br />

� State acceptance before<br />

applying the sealing foil<br />

� Profile analysis<br />

Equipment<br />

� <strong>TMS</strong> Tunnelscan<br />

� Amberg Profiler 5003<br />

� Leica TPS1200<br />

65

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Gotthard Base Tunnel (CH)<br />

Survey<br />

� The measurement is done<br />

stationary and is accomplished<br />

during tunnelling works, whereby<br />

a track is close<br />

� Measuring and geo-referencing<br />

based on the existent fix points<br />

network<br />

� Production rates:<br />

roughly 200m/hour<br />

66

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Gotthard Base Tunnel (CH)<br />

Results<br />

� Reflectivity information for a gray<br />

scale representation of the tunnel<br />

� Conformity check of undulation<br />

of the tunnel surface layer<br />

� Profiles evaluation<br />

� Circumference length for<br />

sealing foil<br />

� Geometry control<br />

� As-built analysis<br />

67

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies<br />

Törnskog Tunnel - Sweden<br />

68

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Törnskog Tunnel (Sweden)<br />

Project<br />

� 30km North of Stockholm city<br />

centre<br />

� 2 parallel tunnels (each 2.1km<br />

length)<br />

� Client: Svenska Vägverkert<br />

� Surveying: Sweco VBB<br />

Stockholm<br />

� Drill and blast method<br />

� Geology: hard stone<br />

� Equipment<br />

� <strong>TMS</strong> Tunnelscan<br />

� Z+F IMAGER5003<br />

69<br />

Törnskog tunnel

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Törnskog Tunnel (Sweden)<br />

Requirements<br />

� Excavation control directly after<br />

the blast<br />

� Minimal distance to the inner<br />

lining available after one day<br />

(based on the scan)<br />

� Detect shotcrete and rock<br />

anchors<br />

� Generate 2D profiles<br />

� Point resolution 30mm<br />

The requirement from the<br />

contractor was: Excavation<br />

control available in less than 24h<br />

70

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Törnskog Tunnel (Sweden)<br />

Advantages<br />

� Cost savings for excavation<br />

delays through the use of<br />

modern technologies<br />

� Surveyor is no more a big<br />

obstacle on the construction site<br />

� Surveying time 20min (few<br />

Scans per blast)<br />

� 2min/scan<br />

� 40m Scanning in all 4 heading in<br />

less than 6h (incl. Acceleration<br />

distance)<br />

71

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – Törnskog Tunnel (Sweden)<br />

Advantages<br />

� Production cycle with traditional<br />

methods would take min. 3times<br />

more efforts of resources<br />

� Re-excavation has been done<br />

before the shotcrete is indicated<br />

� 3D-Visualisation of scan and<br />

profile data e.g. used for<br />

feasibility studies<br />

72

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies<br />

New York No. 7 Line Extension - USA<br />

73

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – New York No.7 Line (USA)<br />

The project<br />

� Shafts<br />

� Tunnels<br />

� Caverns<br />

Conclusions from Darrell Bartley<br />

(the survey manager)<br />

� “Until very recently, the methods<br />

used underground were a little<br />

primitive.”<br />

� We had no easy way to check<br />

quantities, locating overbreak<br />

was hard… It was all very<br />

challenging."<br />

74

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – New York No.7 Line (USA)<br />

The Performance<br />

� All <strong>TMS</strong> <strong>Solution</strong> module are<br />

used in this project<br />

� Measurements in 2 hours = 400<br />

meter with the APMTM-Method � Final maps of under and over<br />

break inclusive volume<br />

calculations within 4 hours<br />

� Scanner is used for<br />

� Visualisations<br />

� Find under and overbreak<br />

� Monitor shotcrete<br />

� Calculate volumes<br />

75<br />

“The Amberg <strong>TMS</strong> system has<br />

increased our productivity by at<br />

least 10 times…I can't imagine<br />

building a tunnel any other way,”<br />

Rob White<br />

Tunnel Survey Manager<br />

J.F. Shea Construction, Inc.

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – New York No.7 Line (USA)<br />

Benefits for the surveyor<br />

� High efficiency, accuracy<br />

� Open communication to Amberg<br />

� Surveyor with no tunnel<br />

background can work with the<br />

system<br />

“This is our first project with the<br />

equipment…we will save enough<br />

time and productivity to pay for it<br />

all.”<br />

Darrell Bartley, The Tunnel Survey Manager<br />

J.F. Shea Construction, Inc.<br />

76

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

<strong>TMS</strong> Case Studies – New York No.7 Line (USA)<br />

Benefits for contractor<br />

� Projects are completed in time<br />

� Interruptions to surrounding operations are minimised<br />

� Accordance to ever demanding specifications<br />

� Safer method for tunnel surveying<br />

� Weekly scans helped to order shotcrete more accurately<br />

„Amberg Technologies is open for wishes for ongoing developments.“<br />

(Darrell Bartley)<br />

77

<strong>TMS</strong> <strong>Solution</strong> - Surveying for tunnelling professionals<br />

78<br />

Tunnel and Rail – That‘s our business<br />

Thanks for your attention! Questions?<br />

Further information about the <strong>TMS</strong> <strong>Solution</strong> from Amberg<br />

Technologies are available from your local distributor or by<br />

e-mail: tunnel@amberg.ch