third semester - Zakir Hussain College of Engineering & Technology ...

third semester - Zakir Hussain College of Engineering & Technology ...

third semester - Zakir Hussain College of Engineering & Technology ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

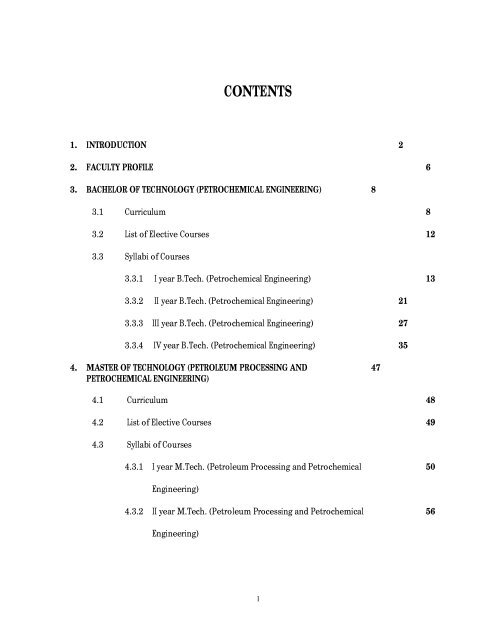

CONTENTS<br />

1. INTRODUCTION 2<br />

2. FACULTY PROFILE 6<br />

3. BACHELOR OF TECHNOLOGY (PETROCHEMICAL ENGINEERING) 8<br />

3.1 Curriculum 8<br />

3.2 List <strong>of</strong> Elective Courses 12<br />

3.3 Syllabi <strong>of</strong> Courses<br />

3.3.1 I year B.Tech. (Petrochemical <strong>Engineering</strong>) 13<br />

3.3.2 II year B.Tech. (Petrochemical <strong>Engineering</strong>) 21<br />

3.3.3 III year B.Tech. (Petrochemical <strong>Engineering</strong>) 27<br />

3.3.4 IV year B.Tech. (Petrochemical <strong>Engineering</strong>) 35<br />

4. MASTER OF TECHNOLOGY (PETROLEUM PROCESSING AND 47<br />

PETROCHEMICAL ENGINEERING)<br />

4.1 Curriculum 48<br />

4.2 List <strong>of</strong> Elective Courses 49<br />

4.3 Syllabi <strong>of</strong> Courses<br />

4.3.1 I year M.Tech. (Petroleum Processing and Petrochemical 50<br />

<strong>Engineering</strong>)<br />

4.3.2 II year M.Tech. (Petroleum Processing and Petrochemical 56<br />

<strong>Engineering</strong>)<br />

1

INTRODUCTION<br />

2

The idea <strong>of</strong> establishing an Institute <strong>of</strong> Petroleum <strong>Technology</strong> at Aligarh Muslim University was<br />

conceived following the visit <strong>of</strong> His Highness Sheikh Zaid Bin Sultan Al Nahyan, President <strong>of</strong> UAE who<br />

visited Aligarh Muslim University, Aligarh on Jan 01, 1975. A sum <strong>of</strong> US $ 2 lacs was also contributed<br />

by H.H. Sheikh Zaid for the Institute. In view <strong>of</strong> the above and realizing the importance <strong>of</strong> the job<br />

oriented courses and future demand <strong>of</strong> the country in the area <strong>of</strong> Petroleum Studies, the University<br />

submitted a proposal for the Establishment <strong>of</strong> the Petroleum Institute to the University Grants<br />

Commission, Govt. <strong>of</strong> India, New Delhi. The UGC sanctioned the Establishment <strong>of</strong> the Institute <strong>of</strong><br />

Petroleum Studies & Chemical <strong>Engineering</strong> in 1983 in phased manner, renamed as Department <strong>of</strong><br />

Petroleum Studies. A Grant <strong>of</strong> Rs. 111.45 lacs (N.R) for building, laboratory facilities, books etc and<br />

Rs. 3.52 Lacs (R) per annum for teaching and laboratory supporting staff was provided. The UGC also<br />

sanctioned a one year Post- graduate Diploma in Petroleum Processing for which teaching staff<br />

consisting <strong>of</strong> two posts <strong>of</strong> Pr<strong>of</strong>essor and two posts <strong>of</strong> Reader were also sanctioned for running the<br />

above course. Five Posts <strong>of</strong> Laboratory Supporting Staff were also sanctioned to maintain the proper<br />

laboratories facilities.<br />

The P.G. Diploma in Petroleum Processing course was started with an intake <strong>of</strong> 10 students from the<br />

session 1984-85. Various laboratories relating to testing and determining the characteristics and<br />

properties <strong>of</strong> refinery and petrochemicals products, petroleum and petrochemical processing and<br />

other facilities have also been established from the UGC grant.<br />

The P.G Diploma in Petroleum Processing course sanctioned by UGC was upgraded to full – fledged<br />

M.Sc. <strong>Engineering</strong> in Petroleum Processing from the session 1988-89 to enhance the job<br />

potentialities <strong>of</strong> the post graduate students and to initiate research work in the area <strong>of</strong> Petroleum<br />

Processing and Conversion. A Proposal to start another M.Sc. <strong>Engineering</strong> in Petrochemicals course<br />

was submitted to UGC in 1992. The UGC vide its letter No. F0 5-71 /92 (T-I) dated May 18, 1993<br />

agreed with the above proposal and sanctioned the integration <strong>of</strong> Petrochemicals course with<br />

existing Petroleum Processing course. The M.Sc. <strong>Engineering</strong> in Petrochemicals course was<br />

3

started in the Petroleum Institute from the session 1995-96 with an intake <strong>of</strong> 6 students.<br />

Presently, the following facilities have been created from the grants received from the University<br />

Grants Commission and Sheikh Zaid Donation Fund.<br />

� Crude Evaluation Laboratory<br />

� Petroleum Products Testing Laboratories<br />

� Computer Controlled Process Control laboratory<br />

� Reaction <strong>Engineering</strong> and High Pressure Laboratory<br />

� Polymer Processing Laboratory<br />

� Instrumental and FIA Analysis Laboratory<br />

� Computational Laboratory<br />

� Research Laboratory<br />

� Workshop, Store and Seminar facilities and<br />

� Some Unit operation experimental facilities in the Department <strong>of</strong> Chemical <strong>Engineering</strong><br />

The University Grants Commission also sanctioned two posts <strong>of</strong> lecturer in IX plan and six posts <strong>of</strong><br />

teaching staff (Pr<strong>of</strong>essor = 1, Reader = 2, Lecturer = 3) in X plan. Presently there are 10 sanctioned<br />

teaching posts.<br />

The research facilities in the area <strong>of</strong> Hydrodesulfurization, Heat Transfer Studies to Boiling<br />

Hydrocarbon Liquids and their Mixtures in Vertical tube Thermosiphon Reboiler, Nucleate Boiling <strong>of</strong><br />

Hydrocarbon Mixtures on Smooth and Enhanced Surfaces, Studies on Corrosion & its Control for<br />

Petroleum Industries, Kinetics Studies <strong>of</strong> Hydrogenation and Oxidation Reactions, etc. are also<br />

available.<br />

The Expert Committee appointed by the UGC for the Petroleum Institute has also recommended the<br />

expansion with subsequent starting <strong>of</strong> the courses in Petroleum Refining / Petrochemical <strong>Engineering</strong><br />

and <strong>Technology</strong>, Polymer Science and <strong>Technology</strong>, Plastics and Gas Processing and creation <strong>of</strong><br />

4

esearch facilities in the Petroleum Processing and Conversion, Polymer Science and <strong>Technology</strong>,<br />

Polymer Chemistry, Plastics and Organic Synthetic Fertilizers and Hydrocarcking.<br />

Following the directives <strong>of</strong> the UGC and keeping in view the requirements to develop <strong>of</strong> our own<br />

technologies and become competitive and to meet the ever-increasing demand <strong>of</strong> manpower <strong>of</strong> our<br />

country in the field <strong>of</strong> Petroleum Refining / Petrochemicals / Gas Processing, a Four year Bachelor <strong>of</strong><br />

<strong>Technology</strong> in Petrochemical <strong>Engineering</strong> course was introduced in the Petroleum Institute from the<br />

session 1997-98 with an intake <strong>of</strong> 20 students. The Institute is renamed as Department <strong>of</strong> Petroleum<br />

Studies in Feb 2000. Presently following courses are running in the Department:<br />

� 4 year B.Tech. (Petrochemical <strong>Engineering</strong>) Course with an Intake <strong>of</strong> 25 plus 05 NRI students.<br />

� 2 year M.Tech. (Petroleum Processing & Petrochemical <strong>Engineering</strong>) Course with an Intake <strong>of</strong><br />

16 students<br />

The Department will serve the long felt need <strong>of</strong> deploying young engineers in Petrobased Industries<br />

and will bridge the gap between academic institutions and industrial requirements. Its courses and<br />

curriculum have been so designed as to enable its products to handle / execute the Industrial Jobs<br />

and Research without difficulty. Our Students are serving premier organizations namely, Reliance<br />

Industries limited, Technip KTI, Duncan Fertilizers, Punj Lloyd, Indian Oil Corporation Ltd, Oil and<br />

Natural Gas Corporation Ltd, Hindustan Petroleum Corporation Limited, M I Swaco, Oswal Chemicals<br />

and Fertilizers Limited, Council <strong>of</strong> Scientific & Industrial Research, etc.<br />

5<br />

Chairman<br />

Department <strong>of</strong> Petroleum Studies<br />

Aligarh Muslim University Aligarh

FACULTY PROFILE<br />

6

NAME DESIGNATION ACADEMIC QUALIFICATIONS FIELDS OF SPECIALIZATION / INTEREST<br />

7

Dr. Hamid Ali<br />

Dr. Mohd. Kamil<br />

Mrs. Najam Sardar<br />

Mr. Ashraf Mateen<br />

Ms. Seemi Rafique<br />

Mr. S. J. A. Rizvi<br />

Mr. M. Yusuf Ansari<br />

Pr<strong>of</strong>essor & Chairman<br />

D/o Petroleum Studies &<br />

Dean Faculty <strong>of</strong> Engg. &<br />

Tech.<br />

Pr<strong>of</strong>essor<br />

Associate Pr<strong>of</strong>essor<br />

Assistant Pr<strong>of</strong>essor<br />

Assistant Pr<strong>of</strong>essor<br />

Assistant Pr<strong>of</strong>essor<br />

Assistant Pr<strong>of</strong>essor<br />

�<br />

� B.Tech.(Chemical Engg)<br />

I.I.T. Roorkee, Roorkee<br />

� M.Tech.(Chemical Engg)<br />

� I.I.T. Roorkee, Roorkee<br />

� Ph.D.(Chemical Engg)<br />

� AMU, Aligarh<br />

� B. Tech. (Chemical<br />

Engg)<br />

� M.Tech. (Chemical<br />

Engg)<br />

� Ph.D. (Chemical Engg)<br />

� B. Tech. (Chemical<br />

Engg)<br />

� M. Tech.(Petrochemical<br />

Engg)<br />

� B. Tech. (Chemical Engg)<br />

� M. Tech(Petrochemical<br />

Engg)<br />

� B. Tech. (Chemical<br />

Engg)<br />

� M. Tech.(Petrochemical<br />

Engg)<br />

� B. Tech. (Chemical<br />

Tech)Specialization in<br />

Plastic <strong>Technology</strong><br />

� M. Tech (Polymer Tech)<br />

� B. Tech. (Petrochemical<br />

Engg)<br />

� M. Tech.(Petrochemical<br />

Engg)<br />

COURSE CURRICULUM FOR FIRST YEAR B.TECH. (PETROCHEMICAL ENGINEERING)<br />

8<br />

� Thermal Fluid Sciences and<br />

<strong>Engineering</strong><br />

� Studies on Corrosion Inhibitors in<br />

Petroleum Industry<br />

� Thermal Oxidation <strong>of</strong> Refinery<br />

Sludge<br />

� Thermal Fluid Sciences<br />

� Petroleum Processing<br />

� Modeling & Simulation<br />

� Synthesis and Characterization <strong>of</strong><br />

Shear thicken <strong>of</strong> Fluids.<br />

� Studies on Polymer Surfactant<br />

Interaction<br />

� Studies on Corrosion Inhibitors in<br />

Petroleum Industry<br />

� Modeling & Simulation <strong>of</strong> Refining<br />

Processes<br />

� Petroleum <strong>Engineering</strong><br />

� Heavy Oil Processing<br />

� Process <strong>Engineering</strong> & Design<br />

� Oil & Gas Processing<br />

� Plant Safety<br />

� Alternate Fuels<br />

� Polymer Processing and<br />

� Mould Design<br />

� CAD/CAM<br />

� Industrial Automation<br />

� Separation Processes<br />

� Petrochemical <strong>Technology</strong><br />

� Gas Conversion

Course<br />

Category<br />

Course<br />

No<br />

Course Title<br />

FIRST SEMESTER (Autumn)<br />

Period/Week<br />

L T P<br />

SECOND SEMESTER (Winter)<br />

9<br />

Credits<br />

(Cr)<br />

Course<br />

Work<br />

Marks<br />

Mid<br />

Sem.<br />

Exam<br />

Marks<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

BS APIII Applied Physics 3 1 - 4 15 25 60 100<br />

BS AMIII Applied Mathematics -I 3 1 - 4 15 25 60 100<br />

HM EN101 English 3 1 - 4 15 25 60 100<br />

ESA CEIII Environmental Studies 3 1 - 4 15 25 60 100<br />

ESA MEIII<br />

Mechanics & Strength <strong>of</strong><br />

Material<br />

Total<br />

3 1 - 4 15 25 60 100<br />

BS AP194 Applied Physics Lab 0 1 2 2 60 40 100<br />

ESA ME194 Manufacturing Process Lab<br />

Course<br />

Category<br />

Course<br />

No<br />

0 1 2 2 60 40 100<br />

Total 15 7 4 24 - - -<br />

Course Title<br />

Period/Week<br />

L T P<br />

Credits<br />

(Cr)<br />

Course<br />

Work<br />

Marks<br />

Mid<br />

Sem.<br />

Exam<br />

Marks<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

BS ACIII Applied Chemistry 3 1 - 4 15 25 60 100<br />

BS AM112 Applied Mathematics-II 3 1 - 4 15 25 60 100<br />

ESA ME101 Basic Thermal Sciences 3 1 - 4 15 25 60 100<br />

ESA EEIII<br />

Basic Electrical &<br />

Electronic Engg<br />

Total<br />

3 1 - 4 15 25 60 100<br />

BS AC194 Applied Chemistry Lab 0 1 2 2 60 40 100<br />

ESA CO191<br />

Computer Programming<br />

Lab<br />

0 1 2 2 60 40 100<br />

ESA ME193 <strong>Engineering</strong> Graphics Lab 1 0 2 2 60 40 100<br />

Total 13 06 06 22 - - -

Course<br />

Category<br />

Course<br />

No<br />

COURSE CURRICULUM FOR SECOND YEAR B.TECH. (PETROCHEMICAL ENGINEERING)<br />

Course Title<br />

THIRD SEMESTER (Autumn)<br />

Period/Week<br />

L T P<br />

10<br />

Credits<br />

(Cr)<br />

Course Work<br />

Marks<br />

Mid Sem. Exam<br />

Marks<br />

DC PK-211 Basic Principles <strong>of</strong> Chemical <strong>Engineering</strong> 3 1 - 4 15 25 60 100<br />

DC PK-231 Chemistry <strong>of</strong> Hydrocarbons 3 1 - 4 15 25 60 100<br />

DC PK-232 Fluid Mechanics 3 1 - 4 15 25 60 100<br />

DC PK-214 Reaction Kinetics and Reactor Design 3 1 - 4 15 25 60 100<br />

DC PK-233 Fluid -Particle Operations 3 1 - 4 15 25 60 100<br />

BS AM-241 Higher Mathematics 3 1 - 4 15 25 60 100<br />

ESA ME-294 Machine Drawing and Computer Graphics 1 2 2 60 - 40 100<br />

Total 18 07 02 26 - - -<br />

Course<br />

Category<br />

Course<br />

No<br />

Course Title<br />

FOURTH SEMESTER (Winter)<br />

Period/Week<br />

L T P<br />

Credits<br />

(Cr)<br />

Course Work<br />

Marks<br />

Mid Sem. Exam<br />

Marks<br />

DC PK-221N Chemical <strong>Engineering</strong> Thermodynamics 3 1 - 4 15 25 60 100<br />

DC PK-241<br />

Separation Processes in Hydrocarbon<br />

Industries<br />

3 1 - 4 15 25 60 100<br />

DC PK-242 Process Development and Equipment Design 3 1 - 4 15 25 60 100<br />

DE Departmental Elective-I 3 1 - 4 15 25 60 100<br />

BS AM-242 Applied Numerical Methods 3 1 - 4 15 25 60 100<br />

ESA CH-292 Unit Operations Laboratory-I<br />

- 1 2 2 60 - 40 100<br />

DC PK-293 Petroleum Testing Laboratory - 1 2 2 60 - 40 100<br />

HM EZ-291 Communication Skills Laboratory - 1 2 2 60 - 40 100<br />

Total 15 8 6 26 - - -<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

Total<br />

Total

Course<br />

Category<br />

Course<br />

No<br />

COURSE CURRICULUM FOR THIRD YEAR B. TECH. (PETROCHEMICAL ENGINEERING)<br />

Course Title<br />

FIFTH SEMESTER (Autumn)<br />

Period/Week<br />

L T P<br />

11<br />

Credits<br />

(Cr)<br />

Course Work<br />

Marks<br />

Mid Sem. Exam<br />

Marks<br />

DC PK-311N Petroleum Refining Processes 3 1 - 4 15 25 60 100<br />

DC PK-312N Heat Transfer Operations 3 1 - 4 15 25 60 100<br />

DC PK-313N Mass Transfer Operations 3 1 - 4 15 25 60 100<br />

DC PK-331 Refinery <strong>Engineering</strong> Calculations 3 1 4 15 25 60 100<br />

HM ME-340 Economics and Management 3 1 - 4 15 25 60 100<br />

ESA AC-311 <strong>Engineering</strong> Materials 3 1 4 15 25 60 100<br />

DC PK-393 Computer Applications Laboratory - 1 2 2 60 - 40 100<br />

Total 18 7 2 26 - - -<br />

Course<br />

Category<br />

Course<br />

No<br />

Course Title<br />

SIXTH SEMESTER (Winter)<br />

Period/Week<br />

L T P<br />

Credits<br />

(Cr)<br />

Course Work<br />

Marks<br />

Mid Sem.<br />

Exam Marks<br />

DE Departmental Elective – II<br />

3 1 - 4 15 25 60 100<br />

DC PK-342 Petrochemical <strong>Technology</strong> - I 3 1 - 4 15 25 60 100<br />

DC PK-323 Transport Phenomena 3 1 - 4 15 25 60 100<br />

DC PK-343<br />

Health, Safety and Environment in Hydrocarbon<br />

Industries<br />

3 1 - 4 15 25 60 100<br />

DC PK-315N Natural Gas Processing 3 1 - 4 15 25 60 100<br />

ESA CH-393 Unit Operation Laboratory-II - 1 2 2 60 - 40 100<br />

DC PK-394 Reaction Engg. Laboratory - 1 2 2 60 - 40 100<br />

DC PK-395 Process Equipment Design 1 2 2 60 - 40 100<br />

Total 15 8 6 26<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

Total<br />

Total

Course<br />

Category<br />

Course<br />

No<br />

COURSE CURRICULUM FOR FOURTH YEAR B.TECH. (PETROCHEMICAL ENGINEERING)<br />

SEVENTH SEMESTER (Autumn)<br />

Period/Week<br />

Course Title<br />

L T P<br />

13<br />

Credits<br />

(Cr)<br />

Course Work<br />

Marks<br />

Mid Sem. Exam<br />

Marks<br />

DC PK-411 Process Dynamics and Control 3 1 - 4 15 25 60 100<br />

DC PK-431 Plant Design & Economics 3 1 - 4 15 25 60 100<br />

DC PK-432 Petrochemical <strong>Technology</strong> – II 3 1 - 4 15 25 60 100<br />

DC PK-433 Polymer Science and <strong>Technology</strong> 3 1 - 4 15 25 60 100<br />

OE ---- Open Elective I 3 1 - 4 15 25 60 100<br />

DC PK-493 Project - 4 - 4 �<br />

30 - - 30<br />

DC PK-481 Seminar - 1 2 2 60 - 40 100<br />

Total 15 9 2 26<br />

�<br />

In complete grade (I) is to be awarded, which will be converted in to regular grades at VIII Semester Level<br />

Course<br />

Category<br />

Course<br />

No<br />

Course Title<br />

EIGHTH SEMSETER (Winter)<br />

Period/Week Credits<br />

L T P (Cr)<br />

DE Departmental Elective III 3<br />

DC PK-422N Process Utilities and Energy Management 3<br />

Course Work<br />

Marks<br />

Mid Sem. Exam<br />

Marks<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

End<br />

Sem.<br />

Univ.<br />

Exam<br />

Marks<br />

Total<br />

Total<br />

1 - 4 15 25 60 100<br />

1 - 4 15 25 60 100<br />

DE Departmental Elective IV 3 1 - 4 15 25 60 100<br />

OE ------ Open Elective II 3 1 - 4 15 25 60 100<br />

DC PK-493 Project - 4 4 40 - 30 70<br />

DC PK-494 Instrumentation and Process Control Laboratory - 1 2 2 60 - 40 100<br />

DC PK-495 Polymer Laboratory - 1 2 2 60 - 40 100<br />

Total 12 10 4 24 100<br />

`<br />

Category Credits Recommended Actual Category Credits Recommended Actual<br />

BS 20-36 28 DC 60-116 106<br />

ESA 20-40 32 DE 16-32 16<br />

HM 10-18 10 OE 8-16 8<br />

NOTE: In order to wind up the old curriculum quickly, there will be a need for alternative courses, filler courses and many other measures. The Dean is authorized to approve alternative<br />

courses, approve filler courses and take such other measures, in consultation with the respective Chairmen, as may be suitable to wind up the old curriculum quickly.

LIST OF ELECTIVES COURSES<br />

DEPARTMENTAL ELECTIVES<br />

Alternate Fuels and Energy Resources<br />

Renewable Energy<br />

Energy Resources and Environment Management<br />

Synthetic Fuels<br />

Heterogeneous Reaction <strong>Engineering</strong><br />

Catalysis<br />

Chemical Reactor Design<br />

Process Instrumentation<br />

Piping and Instrumentation<br />

Instrumentation <strong>Engineering</strong><br />

Fertilizer <strong>Technology</strong><br />

Coal and Gas Conversion <strong>Technology</strong><br />

Selected Topics in Refining and Petrochemicals<br />

OPEN ELECTIVES<br />

Petroleum Refining <strong>Technology</strong><br />

Equilibrium Stage Processes<br />

Plant Safety<br />

Petrochemical <strong>Technology</strong><br />

Bioprocess <strong>Engineering</strong><br />

Modeling and Simulation<br />

Polymer <strong>Technology</strong><br />

Fundamentals <strong>of</strong> Petroleum <strong>Engineering</strong><br />

Introduction to Hydrocarbon <strong>Technology</strong><br />

Polymer Structure Property Relationship<br />

Natural Gas <strong>Technology</strong><br />

Industrial Instrumentation<br />

Waste Management <strong>Technology</strong><br />

Pollution Control Equipment Design<br />

Process Equipment and Piping Design<br />

14

Process Design & Integration<br />

Refinery Equipment Design<br />

Fundamentals <strong>of</strong> Petroleum Prospecting<br />

Oil Recovery Techniques<br />

FIRST YEAR B.TECH. (PETROCHEMICAL ENGINEERING)<br />

15

FIRST & SECOND SEMESTER<br />

AC111 APPLIED CHEMISTRY<br />

UNIT-1: METHODS OF CHEMICAL ANANLYSIS<br />

Qualitative and quantitative analysis, Principle <strong>of</strong> gravimetry and steps involved in gravimetric<br />

analysis, digestion and its importance, favourable conditions for precipitation.<br />

Titration, titrant, analyte, primary and secondary standards. Basic requirements <strong>of</strong> a titrimetric<br />

method, classification <strong>of</strong> titrations (acid-base, oxidation-reduction, precipitation and<br />

chelometric titrations with examples).<br />

Absorption Spectrophotometry : Beer and Lambert’s law (definition and units <strong>of</strong> terms involved.<br />

deviaton from Beer’s Law) Block diagram <strong>of</strong> single bean UV-Visible Spectrophotometer.<br />

Definition <strong>of</strong> chromatography and chromatographic system (stationary and mobile phase),<br />

classification <strong>of</strong> chromatography on the basis <strong>of</strong> physical mode (planar and column<br />

chromatorgrahy) and mechanism (sorption, partition and ion exchange chromatorgrahy).<br />

Calculation <strong>of</strong> RF Value, separation factor, resolution and capacity factor from chromatorgram.<br />

UNIT-II: WATER TRATMENT<br />

Hardness <strong>of</strong> water (units <strong>of</strong> hardness, calculation on hardness, determination by soap and EDTA<br />

methods). Sludge, scale priming and foaming. Boiler corrosion and caustic embrittlement<br />

(causes, defects and prevention). Lime-soda, zeolite and ion exchange processes. Calculations<br />

based on Lim-soda and zeolite proesses. Sedimentation, coagulation and filtration. Disinfection,<br />

requirements <strong>of</strong> a good disinfecting agent and types <strong>of</strong> disinfecting agents, (bleaching powder,<br />

liquid chlorine, ozone, UV radiation and chloramines). Break point chlorination:<br />

UNIT-III FUELS<br />

Classification <strong>of</strong> fuels and characteristics <strong>of</strong> a good fuel, calorific value and its determination by<br />

Boom Calorimeter and Dulong’s formula (Numerical problems). Analysis <strong>of</strong> coal (Proximate<br />

Ultimate analysis) Composition and classification <strong>of</strong> petroleum. Important factions <strong>of</strong> petroleum<br />

and their uses. Synthetic petrol ( Polymerizations and cracking, Fisher Tropsch and Bergius<br />

processes). Advantages and disadvantages <strong>of</strong> gaseous fuels, composition and uses <strong>of</strong> natural<br />

gas, CNG, LPG, Combustion calculations on solid and gaseous fuels.<br />

UNIT-IV LUBRICANTS<br />

Definition and classification <strong>of</strong> lubricants Mechanisms <strong>of</strong> lubrication. Mineral oils, fatty oils,<br />

compounded oils and silicone fluids. Testing <strong>of</strong> liquid lubricants, Viscosity, and index Flash and<br />

Fire points. Cloud, pour and setting Point, Saponification value, Aniline point, Types <strong>of</strong> greases<br />

and conditions for their use. Consistency test, and Drop Point <strong>of</strong> Greases.<br />

UNIT-V CORROSION AND ITS PREVENTION<br />

Definition, significance and classification <strong>of</strong> corrosion. Mechanism <strong>of</strong> oxidation metals, Pilling-<br />

Bedworth rule. Nernst equation, electrochemical and galvanic series. Cathodic and anodic<br />

reactions. Factors affecting corrosion. Corrosion control (design and selection <strong>of</strong> materials,<br />

cathodic protection, metallic coatings, galvanizing and tinning anodized coating). Paints<br />

definition, compositions and the function <strong>of</strong> each component).<br />

UNIT-VI POLYMER<br />

Definition and classification <strong>of</strong> Polymers. Polymerization (addition and condensation),<br />

mechanism <strong>of</strong> free radical addition polymerization.<br />

16

Definition, preparation, properties and uses <strong>of</strong> thermoplastic (PMMA Teflon), and thermosetting<br />

plastics (Bakelite, Polyesters) synthetic fibres (Nylon 66, or lon). Natural rubber and<br />

vulcanization.<br />

BOOKS RECOMMENDED FOR APPLIED CHEMISTRY COURSES (AC-III)<br />

1. Analytical Chemistry by G.D. Christian, John Wiley and Sons, New York.<br />

2. Quantitative Analysis by R.A. Day and A.L. Underwood.<br />

3. A Text Book <strong>of</strong> <strong>Engineering</strong> Chemistry by S.S. Dara. S. Chand & Co., New Delhi (India)<br />

4. <strong>Engineering</strong> Chemistry by B.K. Sharma, Krishna Prakashan Media (P) Ltd., Meerut (India).<br />

5. <strong>Engineering</strong> Chemistry by P.C. Jain, Dhanpat Rai Publishing Company, New Delhi.<br />

AP111 APPLIED PHYSIC<br />

UNIT 1.<br />

Semiconductors Elemental and compound semiconductors, Energy bands, Direct and<br />

indirect semiconductors, Electrons and holes, Effective mass, Intrinsic material, Extrinsic<br />

material, Fermi level Electron and hole concentration at equilibrium, temperature<br />

dependence <strong>of</strong> carrier concentrations, compensation and space charge neutrality,<br />

conductivity and mobility, hall effect in semiconductors<br />

Superconductivity Zero resistivity, Meissner effect, Type I and Type II Superconductors, High<br />

Temperature Superconductors, BCS theory (Qualitative), Josephson effect, SQUIDS.<br />

UNIT II.<br />

Masers and lasers, Basic principle, Einstein coefficients for induced absorption, Spontaneous<br />

Emission and induced emission, Ammonia maser and its applications, Ruby and He-Ne<br />

Lasers, Semiconductor laser, spatial and temporal coherence, characteristics <strong>of</strong> lasers and its<br />

applications based on these characteristics (such as in Industry, Science, Medicine,<br />

Communications, Surveying, Holography, Fusion reactors, Isotope separations etc).<br />

Fibre Optic, Basic principle, Fibre construction and dimensions light Propagation in fibres,<br />

Numerical aperture <strong>of</strong> the fibre, Step index and graded index fibres signal distortion in<br />

optical fibres, Transmission losses, light wave communication in optical fibres, Fibre Optics<br />

in medicine and industry.<br />

UNIT III.<br />

Particles and waves, Mechanism <strong>of</strong> X-ray production (continuous and characteristic X-rays,<br />

Duane-Hunt limit Compton effect, Pair production, Phase and group velocities, Uncertainty<br />

principle.<br />

Quantum Mechanic, Introduction to quantum mechanics wave function, conditions<br />

necessary for physically acceptable wavefunction, Probability density and probability,<br />

Schrodinger equation (Time dependent form and steady state or time independent form),<br />

Eigen values and eigen functions, Expectations values Particle in a box (Infinite potential<br />

well), Tunnel effect.<br />

UNIT IV<br />

Statistical Mechanics, Statistical distributions, Maxell- Boltzman statistics, Molecular<br />

energies in an ideal gas, Quantum statistics, specific heats <strong>of</strong> solids, free electron in a metal<br />

Electron-energy distribution.<br />

Nuclear Physic, Q value and threshold energy <strong>of</strong> nuclear reactions, Cross section <strong>of</strong> nuclear<br />

reaction and reaction rate, Breeder reactors, Fusion reactors, Nuclear detectors (names and<br />

general working principle), gas filled detectors, Scintillation detectors.<br />

Text Books<br />

17

1. Ben G. Streetman, “Solid State Electronic Devices” 5 th edition(2000), Prentice-Hall <strong>of</strong><br />

India Private Limited New Delhi<br />

2. Arthur Beiser, “ Concepts <strong>of</strong> Modern Physics 6 th edition (2003), Mc. Graw Hill Inc.<br />

International Edition.<br />

3. M.R. Wehr, J.A. Richards. Jr. and TW AdairIII, Physics <strong>of</strong> the Atom 4 th editions (1984),<br />

Addison Wesley / Narosa.<br />

4. M.R. Srinivasan, Physics <strong>of</strong> Engineers 1 st Edition (1996), New age International (P)<br />

Limited Publishers.<br />

AM111 MATHEMATIC<br />

UNIT 1.<br />

Rank <strong>of</strong> a matrix with applications to consistency <strong>of</strong> system <strong>of</strong> linera equations, Eigenvalues<br />

and Eigen vectors <strong>of</strong> a matrix, Cayley-Hamilton Theorem.<br />

UNIT 2.<br />

Asymptotes and simple curve tracing. Successive Differentiation, Leibnitz’s Theorem,<br />

Taylor and Maclaurin series with remainder terms.<br />

UNIT 3.<br />

Applications <strong>of</strong> integration to lengths <strong>of</strong> curves, surfaces and volumes <strong>of</strong> solids <strong>of</strong><br />

revolution.<br />

UNIT 4.<br />

Solutin <strong>of</strong> exact differential equations, Linear differential equations <strong>of</strong> second and<br />

higher order with constant coefficients. Homogeneous differential equations.<br />

Simultaneous linear differential equations, Applications to physical problems.<br />

AM112 MATHEMATIC<br />

UNIT 1.<br />

Partial differentiation, Euler’s Theorem, Total differential, small errors, change <strong>of</strong><br />

variables, Jacobians.<br />

UNIT 2.<br />

Taylor series for functions <strong>of</strong> two variables approximate calculations Maxima and<br />

minima <strong>of</strong> functions <strong>of</strong> two variables, lagrange’s multipliers.<br />

UNIT 3.<br />

Double and triple integrals, change <strong>of</strong> variables, change <strong>of</strong> order <strong>of</strong> integration,<br />

Applications <strong>of</strong> areas and volume.<br />

UNIT 4.<br />

General equations <strong>of</strong> second degree, Tracing <strong>of</strong> conics introduction to polar form <strong>of</strong><br />

conics.<br />

UNIT I.<br />

CE111 ENVIRONMENT STUDIES<br />

18

Concepts <strong>of</strong> Ecology, Ecosystem, Energy and nutrient flow in ecosystem, food chain,<br />

Environmental segments. Atmospheric structure, classification <strong>of</strong> Air pollutants, sources<br />

<strong>of</strong> air pollution and their effects on human heath and property. Atmospheric chemistry,<br />

Photochemical Smong, Ozone depletion<br />

UNIT II.<br />

Air Quality and standards, Meteorological phenomena and their influence on Air<br />

Quality, Lapse rates Dispersion <strong>of</strong> Pollutants.<br />

Air Pollution Control Introduction to Particulate and Gaseous pollutant control<br />

UNIT III.<br />

Water Quality Physical, Chemical and Biological parameters water quality standards,<br />

Biochemical (BOD) and Chemical Oxygen Demand (COD). BOD/ COD Calculations.<br />

Environmental Analyses, pH, Alkalinity, Conductivity, Ammmonia, Fluorids, Sulphate,<br />

Chloride. Analysis and measeurement <strong>of</strong> gaseous pollutants.<br />

UNIT IV.<br />

Water purification processes in natural systems, Dissolved Oxygen (DO), Impact <strong>of</strong><br />

wastewater discharge <strong>of</strong> streams, Oxygen Sag curve.<br />

Introduction to Water treatment Technologies, Sedimentation, Coagulation and<br />

Flocculation, Hardness Reduction Filtration and Disinfection.<br />

UNIT V.<br />

Waste water Characteristics, Introduction to wastewater treatment technologies,<br />

Primary Treatment, Screening, Grit Removal, Flow measurement, Flow equalization.<br />

Secondary Treatment. Microbial growth curve, Suspended and attached growth<br />

systems.<br />

UNIT V1.<br />

Solid Waste, Classification, Sources and Characteristics.<br />

Waste Management, Solid Waste Generation, Collection, Processing and Disposal<br />

Methods. Resource Recovery in Waste Management, Biological and Thermal Conversion<br />

Processes.<br />

Note: Unites I and III shall be taught by the Department <strong>of</strong> Applied Chemistry<br />

Units II and VI shall be taught by the Department <strong>of</strong> Chemical <strong>Engineering</strong><br />

Units IV and V shall be taught by the Department <strong>of</strong> Civil <strong>Engineering</strong><br />

Reference Book:<br />

1. Venugopala Rao, P., 2006 Principles <strong>of</strong> Environmental Science and <strong>Engineering</strong>,<br />

Prentice- Hall <strong>of</strong> India Private Limited, New Delhi.<br />

2. Masters, G.M., 1991, Introduction <strong>of</strong> Environmental <strong>Engineering</strong> and Science,<br />

Prentice- Hall International, Inc., Englewood Cliffs, NJ.<br />

3. Peavy, H.S., D.R. Rowe and G. Tchobanglous, 1985 Environmental <strong>Engineering</strong>,<br />

McGraw-Hill Book Company, New York.<br />

4. Henry, J.G. and G.W. Heinke, 1989, Environmental Science and <strong>Engineering</strong>,<br />

Prentice-Hall International, Inc., Englewood Cliffs, NJ.<br />

5. Sawyer, C.N. and P.L. McCarty, 1978, Chemistry for Environmental <strong>Engineering</strong>, 3 rd<br />

Edition, McGraw-Hill Book Company, New York.<br />

19

6. Tchobanoglous, G., H. Theisen and S.Vigil, 1993, Integrated Solid Waste<br />

Management, McGraw-Hill Inc, Singapore.<br />

EN101 ENGLISH<br />

UNIT I<br />

Text. Comprehension Questions, Summary Type as well as short answer type and<br />

questions on Vocabulary for 10 passages <strong>of</strong> the Basic Scientific English by Ewer and<br />

Latorre (Longman). Units are 1,3,4,5,8 & 11 from main book and passages 4,11,13,17<br />

from the supplement.<br />

UNIT II<br />

Comprehension questions, summary or short answer type from the following<br />

supplementary readers:<br />

1. Animal Farm by George Orwell<br />

2. The time machine by HG Wells retold by Margery Gree Macmillan)<br />

UNIT III<br />

Note taking, note making exercises, report and process writings.<br />

UNIT IV<br />

Precis writing<br />

UNIT V<br />

Composition and spoken English.<br />

EE111 BASIC ELECTRICAL AND ELECTRONIC ENGINEERING<br />

PAPT-A<br />

UNIT-I: Circuits and Transformers<br />

Review <strong>of</strong> de circuits and theorems, I-Phase as circuits, superposition theorem,<br />

Thevenin’s norton’s theorem for ac circuits, RLC series & Parallel circuits, 3 phase<br />

balanced ac circuits<br />

Magnetic circuits, magnetization curve, hysteresis & eddy current losses.<br />

Transformer construction, equivalent circuit, calculation <strong>of</strong> losses and efficiency.<br />

UNIT II: Instruction to Electrical <strong>Technology</strong><br />

Fundamentals <strong>of</strong> 3-phase alternators, 3-phase induction motors and 1-phase induction<br />

motors.<br />

Basic elements <strong>of</strong> an instrument, MC & MI instruments, dynamometer wattmeter<br />

energymeter.<br />

Elements <strong>of</strong> power system, layout <strong>of</strong> thermal and hydro plants.<br />

Introduction to renewable energy sources and recent trends in generation.<br />

PART-B<br />

UNIT III: Diode and BJT; Characteristics & Applications<br />

Terminal characteristics <strong>of</strong> diodes, Diode models; Ideal constant voltage and piecewise<br />

linear, load line concept, Diode applications; Rectifiers, logic gates, Zener diode,<br />

operation, characteristics, voltage regulation, Bipolar Junction Transistor; construction,<br />

20

operation configurations, Characteristics <strong>of</strong> common emitter configuration, DC load line<br />

analysis.<br />

UNIT IV : MOSFET and OpAmp; Characteristics & Applications<br />

Introduction to MOSFET; Depletion MOSFET construction & operation, Enhancement<br />

MOSFET construction & operation, Operational Amplifier; equivalent; circuit, ideal<br />

behavior, open loop and closed loop concept concept <strong>of</strong> virtual short, simple OpAmp<br />

applications; Unity gain amplifier, inverting, non-inverting, integrator, differentiator,<br />

subtractor, summer.<br />

TEXT Books<br />

1. Ashfaq Husain, “ Fundamentals <strong>of</strong> Electrical <strong>Engineering</strong> 3 rd edition Dhanpat Rai &<br />

Sons.<br />

2. R. Boylestad & L. Nashelsky, Electronics Devices and Circuits, Prentice Hall, 1995.<br />

Reference Books<br />

1. Hughes, Electrical <strong>Technology</strong> 7 th edition, Addison Wesley<br />

2. A.K. Sawhney, A Course in electrical & Electronic Meas. & Inst. Dhanpat Rai & Sons<br />

3. B.R. Gupta. Generation <strong>of</strong> Electrical Energy, S. Chand.<br />

4. Mathur, Chadda and Kulshrestha, Electronics Devices, Applications and Integrated<br />

Circuits, Umesh Publications.<br />

ME101 BASIC THERMAL SCIENCE<br />

UNIT I<br />

Dimensions and units system boundary types <strong>of</strong> systems and boundaries property cycle<br />

thermodynamic equilibrium and quasi-static process.<br />

Pressure and its measurement, zero’th law <strong>of</strong> thermodynamics, temperature and its<br />

measurement, numerical problems.<br />

UNIT II<br />

Thermodynamic and mechanics definition <strong>of</strong> work. Displacement work and its<br />

expressions engine indicator and indicated work, introduction to 2-stroke and 4stroke<br />

engines, heat, work and heat as energy interactions, Joule’s experiment & mechanical<br />

equivalent <strong>of</strong> heat, firs law <strong>of</strong> thermodynamics for cycle and non cyclic processes.<br />

Definition <strong>of</strong> energy as a property, internal energy, enthalpy, specific heats, first law for<br />

a control volume, steady flow energy Equation (SFEE) and it’s applications, numerical<br />

problems.<br />

UNIT III<br />

Pure substance, different phases <strong>of</strong> pure substance, tow property rule property<br />

diagrams, tables and charts equation <strong>of</strong> state <strong>of</strong> an ideal gas t��, t�p, p�v, and t�v<br />

diagrams, phase boundaries, S-L-V region, CP and TP, dryness fraction and its<br />

measurement using throttling calorimeter, limitations <strong>of</strong> throttling calorimeter,<br />

separating & throttling calorimeter, numerical problems.<br />

UNIT IV<br />

Limitations <strong>of</strong> first law , heat engine heat pump refrigerator, second law <strong>of</strong><br />

thermodynamics-kelvin planck’s and Clausius statements and their equivalence<br />

efficiency <strong>of</strong> heat engine and coefficient <strong>of</strong> performance <strong>of</strong> heat pump and refrigerator,<br />

21

eversible and irreversible processes. Carnot cycle and its efficiency corollaries <strong>of</strong> second<br />

law, the thermodynamic scale. Inequality <strong>of</strong> Clausius, entropy, principle <strong>of</strong> increase <strong>of</strong><br />

entropy, isentropic process, t�s and h�s diagrams (Mollier chart), second law<br />

applications, air standard otto, diesel, dual simple Brayton and steam power cycles<br />

(Rankine cycle) numerical problems.<br />

UNIT V<br />

Modes <strong>of</strong> heat transfer, Fourier’s law <strong>of</strong> steady state heat conduction (one dimensional<br />

conduction), thermal conductivity and its unit, conduction through slab or plane wall,<br />

conduction through composite walls and hollow cylinders, convective heat transfer,<br />

Newton’s law <strong>of</strong> cooling, combine heat transfer, electrical analogy and overall heat<br />

transfer coefficient radiation, black body emissive power emissivity, Kirch<strong>of</strong>f’s law<br />

Stefan Boltzmann’s law. Numerical problems.<br />

Book<br />

1. Thermodynamics, An <strong>Engineering</strong> Approach by yunus A. Cengel and Michael A Boles<br />

2. <strong>Engineering</strong> Thermodynamics by D. B. Spalding and E.H.Cole.<br />

3. <strong>Engineering</strong> Thermodynamics by R. Joel<br />

4. <strong>Engineering</strong> Thermodynamics by P.K.Nag.<br />

5. <strong>Engineering</strong> Heat Transfer by C.P. Gupta and R. Prakash.<br />

ME111 APPLIED MECHANIC<br />

UNIT 1<br />

Fundamental concepts and principles <strong>of</strong> Mechanic, Reduction <strong>of</strong> a system <strong>of</strong> forces to a<br />

force couple system, free body diagrams, equilibrium <strong>of</strong> rigid bodies in 3 Dimensions,<br />

Reactions, loading indeterminacy and solvability. Friction forces and laws <strong>of</strong> dry friction<br />

principle and application <strong>of</strong> virtual work.<br />

UNIT 2<br />

Analysis <strong>of</strong> Multiple particle system application <strong>of</strong> Newton;s laws, linear and angular<br />

momentum, kinetic energy and work energy principle, principle <strong>of</strong> impulse and<br />

momentum to a system <strong>of</strong> particles.<br />

UNIT 3<br />

Translation and rotation about a fixed axis, general plane motion absolute and relative<br />

velocity in plane motion angular momentum <strong>of</strong> rigid body in plane motion. Problems <strong>of</strong><br />

motion <strong>of</strong> rigid bodies and system <strong>of</strong> rigid bodies principle <strong>of</strong> work and energy,<br />

conservation <strong>of</strong> energy for rigid body and a system <strong>of</strong> rigid bodies.<br />

UNIT 4<br />

Analysis <strong>of</strong> stress and strain Mechanical properties analysis <strong>of</strong> simple state <strong>of</strong> stress and<br />

strains, elastic constant, example <strong>of</strong> state <strong>of</strong> tension compression and shear<br />

UNIT 5<br />

22

Bending shear and torsion: Concept <strong>of</strong> bending and shear forces in shear forces in simple<br />

beams, relationship between load, bending moment and shear force. Bending and shear<br />

stresses in simples beams, concept <strong>of</strong> torsion in circular shafts.<br />

Text Books<br />

1. Beer Ferdinand P. and Johnston Jr. E Russel, Vector Mechanics for <strong>Engineering</strong> Statics<br />

and Dynamic Metric edition, Mc Graw Hill, New Delhi.<br />

2. Popov E., <strong>Engineering</strong> Mechanics <strong>of</strong> Solids, PHI, Delhi.<br />

Reference Books<br />

1. Merium, JL, <strong>Engineering</strong> Mechanics (Volume I and II), 3 rd edition, (SI version) John<br />

Wiley and sons, Inc, NT<br />

THIRD SEMESTER<br />

AM- : APPLIED MATHEMATICS III<br />

UNIT I: Vector differentiation, scalar field, gradient <strong>of</strong> a scalar field, vector field, divergence &<br />

curves <strong>of</strong> vector fields, solenoidal angle and irrotational field. Determination <strong>of</strong> potential<br />

function.<br />

UNIT II: Vector integration, line integral, conservation fields, Gauss divergence theorems,<br />

Greens theorem and Stokes theorem.<br />

UNIT III: Laplace’s transformation, shifting theorems, transforms <strong>of</strong> derivatives and integrals.<br />

Differentiation and Integration <strong>of</strong> transforms. Inverse transforms, Application with single and<br />

system <strong>of</strong> linear differential equations.<br />

UNIT IV: Boundary Value Problems, solution <strong>of</strong> 2D laplace equation in Cartesian and polar coordinates,<br />

solution <strong>of</strong> one dimensional diffusion and wave equation by method <strong>of</strong> separation <strong>of</strong><br />

variables.<br />

BOOKS:<br />

1. Prasad, C., “Mathematics for Engineers”, Prasad Mudranalaya, New Delhi, 1985.<br />

PK-214: REACTION KINETICS AND REACTOR DESIGN<br />

23

UNIT I: Rate <strong>of</strong> Reaction , elementary and non-elementary reactions molecularity and order <strong>of</strong><br />

reaction, thermodynamics formulations <strong>of</strong> rates, mechanism <strong>of</strong> reaction, Temperature<br />

dependency from thermodynamics, arrhenius, collision and activated complex theories,<br />

Introduction <strong>of</strong> industrial reactors.<br />

UNIT II: Integral and differential methods for analyzing kinetics data, interpretation <strong>of</strong> constant<br />

volume batch reactor data for zero, first second and <strong>third</strong> order reactions, half life period,<br />

irreversible reactions in parallel and series, auto catalytic reaction, shifting order reactions<br />

enzyme catalyzed and surface catalyzed reactions. Interpretation <strong>of</strong> variable volume batch<br />

reactor data for zero, first and second order reactions.<br />

UNIT III: Design equations for batch, plug flow, back mix, flow and semi batch reactors for<br />

isothermal, adiabatic reactions holding time and space time for flow system Design <strong>of</strong> batch plug<br />

flow and mixed flow reactors for first and second order single reactions. Optimum reactor size<br />

plug flow reactors in series / parallel Equal and different size <strong>of</strong> mixed reactors in series and<br />

finding the best system for a given conversion recycle reactor<br />

UNIT IV: Multiple reactions, independent, parallel and series reactions; mixed reactions,<br />

instantaneous and over all fractional yield, choice <strong>of</strong> reactors for simple and complex reactions<br />

and multiple reactor system; Introduction to thermal stability <strong>of</strong> reactors; temperature and<br />

pressure effects and optimal temperature progression for first order reactions. Introduction to<br />

Residence time Distribution <strong>of</strong> fluid in Vessel.<br />

BOOKS:<br />

1. Levenspiel, O., Chemical Reaction <strong>Engineering</strong>, John Wiley and Sons, New York, 3/e, 1998<br />

2. Fogler, H. S., Elements <strong>of</strong> Chemical Reaction <strong>Engineering</strong>, Prentice Hall, USA 4/e, 2005<br />

3. Smith, J. M., Chemical <strong>Engineering</strong> Kinetics, McGraw Hill Publications, New York, 1981<br />

PK-211: BASIC PRINCIPLES OF CHEMICAL ENGINEERING<br />

UNIT I: Introduction to Chemical <strong>Engineering</strong> and role <strong>of</strong> Chemical Engineer, Units and<br />

dimensions, stoichiometric and composition relationship, application <strong>of</strong><br />

thermodynamics and chemical principles in estimation <strong>of</strong> physical properties, ideal and<br />

real gas laws, critical properties, properties <strong>of</strong> mixtures and solutions, phase equilibria,<br />

vapor pressure<br />

UNIT II: Material balance without and with chemical reactions<br />

UNIT III: Energy balance without and with chemical reactions<br />

UNIT IV: Combined material and energy balance: Psychrometery, unsteady state<br />

material and energy balance, industrial applications.<br />

BOOKS :<br />

1. Felder, R.M. and Rousseau, R.W., “Elementary Principles <strong>of</strong> Chemical Processes”,<br />

Wiley International, New York, 3/e,2004.<br />

2. Himmelblau, D.M., “Basic Principles and Calculations in Chemical <strong>Engineering</strong>”,<br />

Prentice Hall, 7/e, 2004<br />

3. Hougen, O.A., Watson, K.M., and Regatz, R.A., “Chemical Process Principles, Vol.1”,<br />

Wiley International, New York,<br />

24

PK-213: FLUID MECHANICS<br />

Unit-I: Introduction to fluid mechanics, fluid static’s, Pascal’s and Hydrostatic law, manometers.<br />

velocity field, velocity gradient and rate <strong>of</strong> shear. Types <strong>of</strong> fluids, boundary layer concept,<br />

laminar and turbulent flow, boundary layer separation.<br />

Unit-II: Fluid dynamics; continuity equation, Euler equation, bernoullies equation, friction losses<br />

in pipe flow, valves and fittings, k-values, sudden expansion and contraction, pipe flow problems<br />

Unit-III: Transportation <strong>of</strong> fluids; types <strong>of</strong> pumps, centrifugal and positive displacement pumps<br />

compressors, fans, blowers, types <strong>of</strong> valves, pipes and tubes.<br />

Unit-IV: Metering <strong>of</strong> fluids; orifice meter, venturimeter, pitot tube, rotameter, notches, gas flow<br />

meters, coefficient <strong>of</strong> discharge<br />

BOOKS<br />

1. McCabe, W.L., Smith, Julian C. & Harriett, Peter, “Unit Operations <strong>of</strong> Chemical <strong>Engineering</strong>”,<br />

McGraw Hill, New Delhi, 7/e,2005.<br />

2. Kumar, K.L., <strong>Engineering</strong> Fluid Mechanics, Eurasia Publishing House (P) Ltd, New Delhi, 17/e,<br />

2008<br />

3. Bansal, R.K, “A Textbook <strong>of</strong> Fluid Mechanics”, Laxmi Publications(p) LTD, New Delhi, 2008<br />

PK-215: FLUID -PARTICLE OPERATIONS<br />

Unit-I: Particle technology; Particle size and shape , size distribution, equivalent particle<br />

diameter, volume surface mean diameter, determination <strong>of</strong> particle size ,screening, cumulative<br />

and differential plots, efficiency capacity and effectiveness <strong>of</strong> Industrial screens.<br />

Unit-II: Size reduction: crushing and grinding, energy requirement, rittengers law, kicks law,<br />

working <strong>of</strong> different crushers and grinders, power requirement. Close and open grinding.<br />

Storage <strong>of</strong> Solids: characteristics <strong>of</strong> solid masses, bins, silos, hoppers, Janssen’s equation.<br />

Unit-III: Particle dynamics: Drag From immersed body, effect <strong>of</strong> particle shape, wall and<br />

hindered settling, calculation <strong>of</strong> terminal settling velocity in stokes, Transition and Newton<br />

ranges. Particle Separation: sedimentation, elutriation, centrifuges and cyclone separation,<br />

Venturi scrubber, Electro-static precipitator<br />

Unit-IV: Flow Through Packed Beds: Types <strong>of</strong> packing, Characteristic <strong>of</strong> packing, pressure drop in<br />

packed beds, Kozeny-Carman equation, flooding and loading. Fluidization: aggregate and<br />

particulate fluidization, incipient fluidization velocity. Filtration; filter aids, plate and frame filter<br />

press, rotary drum filter.<br />

BOOKS:<br />

1. McCabe, W.L., Smith, Julian C. & Harriett, Peter, “Unit Operations <strong>of</strong> Chemical <strong>Engineering</strong>”,<br />

McGraw Hill, New Delhi, 7/e,2005.<br />

2. Narayanan, C.M., Bhattacharya, B.C., “Mechanical Operations for Chemical Engineers”,<br />

Khanna Publishers, Delhi., 3/e, 2005.<br />

3. Brown G.G., “Unit Operations”, John Wiley and Sons, New York, 1950.<br />

PK-212: CHEMISTRY OF HYDROCARBONS<br />

25

Unit I: origin and formation <strong>of</strong> Petroleum, Reserves and deposits, Indian Petroleum Industry, Composition<br />

<strong>of</strong> crude Oils, ultimate and chemical composition , non-hydrocarbons in petroleum, Asphltenes and<br />

Resins, classification <strong>of</strong> petroleum, evaluation <strong>of</strong> crude oil, Bench mark crudes.<br />

Unit II: characterization <strong>of</strong> crude oils : TBP and ASTM distillation, Classification by chemical composition,<br />

Correlation Index, Density, API gravity, Viscosity, UOP characterization factor, etc. Physical & Thermal<br />

properties <strong>of</strong> petroleum, ASTM, TBP, EFV distillation curves.<br />

Unit III: Distillation: Pretreatment, Electric desalting, atmospheric and vacuum distillation, petroleum<br />

products and their quality control tests.<br />

Unit IV: Value addition <strong>of</strong> petrochemicals from feedstock to consumer end products, chemical reactions<br />

<strong>of</strong> hydrocarbons like Decomposition (Thermal & Catalytic), Halogenations, Isomerization, Hydrogenation,<br />

Alkylation, Nitration, Sulfonation, etc. with chemistry and reaction mechanism.<br />

BOOKS:<br />

1. Speight, J.C.; “The Chemistry and <strong>Technology</strong> <strong>of</strong> Petroleum”, Marcel Dekkar, New York, 3/e1999.<br />

2. Lucas, A.G. (ed.), “Modern Petroleum <strong>Technology</strong>”, Vol. 2, Downstream, John Wiley & Sons<br />

Limited, New York, 6/e, 2000.<br />

3. Simanzhenkov, V. and Idem, R., “Crude oil Chemistry”, Marcel Dekker Inc., New York, 2003.<br />

4. Hobson, G.D., “Modern Petroleum <strong>Technology</strong>” Vol I & II, John Wiley & Sons, New York, 5/e,<br />

1984<br />

5. Rao, B.K.B., “Modern Petroleum Refining Processes”, Oxford & IBH Co. Pvt. Ltd., New Delhi, 4/e,<br />

2002,<br />

6. Prasad, R., “Petroleum Refining <strong>Technology</strong>”, Khanna Publishers, New Delhi, 2000<br />

ME – 290: MACHINE DRAWING AND COMPUTER<br />

GRAPHICS<br />

Drawing <strong>of</strong> following machine parts: threaded fasteners, screw jack, flexible coupling, stuffing box, swivel<br />

bearing, stop valve and some introduction <strong>of</strong> Auto CAD.<br />

FOURTH SEMESTER<br />

AM-: NUMERICAL METHODS AND OPTIMISATION<br />

UNIT I: General iteration method, Newton Raphson method, application <strong>of</strong> Newton Raphson<br />

method, Solution <strong>of</strong> system <strong>of</strong> linear equation by Gauss elimination method and Gauss Siedel<br />

method, Convergence <strong>of</strong> iteration.<br />

UNIT II: Interpolation-Finite difference operator, Central difference operator, backward<br />

difference operator, relation between operators, Newton’s forward Interpolation formula,<br />

Newton’s backward Interpolation formula, Newton’s Interpolation formula for unequal interval,<br />

Lagrange’s Interpolation formula for unequal interval.<br />

UNIT III: Numerical Differentiation- Newton’s divided difference formula; Numerical integration-<br />

Trapezoidal rule, Simpson’s rule, Weedle’s rule; Numerical Solution <strong>of</strong> differential equation-<br />

Solution with Taylor’s series, Euler’s method, modified Euler method, Runge-Kutta method,<br />

Boundary value problems.<br />

26

UNIT IV: Graphical and analytical methods <strong>of</strong> optimization, Numerical search methods, search <strong>of</strong><br />

optimum over single and several design variables, Optimum <strong>of</strong> process systems, linear<br />

programming.<br />

BOOKS :<br />

1. Sastry, S.S., “Introductory Methods <strong>of</strong> Numerical Analysis”, Prentice Hall <strong>of</strong> India Pvt. Ltd.,<br />

2004.<br />

PK – 221: CHEMICAL ENGINEERING THERMODYNAMICS<br />

UNIT I: The scope <strong>of</strong> thermodynamics, dimensions and units, measures <strong>of</strong> amount or size, force,<br />

temperature, pressure, work, energy and heat. The first law <strong>of</strong> thermodynamics and other basic<br />

concepts, Joules’ experiment, internal energy, the first law <strong>of</strong> thermodynamics, energy balance<br />

for closed systems, thermodynamic state and state functions, equilibrium, the phase rule, the<br />

reversible process, constant volume and constant pressure process, enthalpy, heat capacity. The<br />

second law <strong>of</strong> thermodynamics, statements <strong>of</strong> the second law, heat engines, thermodynamic<br />

temperature scales, entropy, entropy changes <strong>of</strong> an ideal gas, mathematical statement <strong>of</strong> the<br />

second law, entropy balance for open systems, calculation <strong>of</strong> ideal work, the <strong>third</strong> law <strong>of</strong><br />

thermodynamics.<br />

UNIT II: Refrigeration and Liquefaction: the Carnot refrigerator, the vapour – compression cycle,<br />

the choice <strong>of</strong> refrigerant, absorption refrigeration, the heat pump, liquefaction process. Vapour-<br />

Liquid Equilibrium: The nature <strong>of</strong> equilibrium, the phase rule-Duchem’s theorem, VLE –<br />

Quantitative behaviour, VLE by modified Raoult’s Law, VLE from k-value correlations.<br />

UNIT III: Solution thermodynamics: theory, fundamental property relation, the chemical<br />

potential and phase equilibria, partial properties, ideal-gas mixtures, fugacity and fugacity<br />

coefficients, pure species, species in solution, generalized correlations for the fugacity<br />

coefficient, the ideal solution, excess properties. Application ; liquid phase properties from VLE<br />

data, models for the excess Gibb’s energy, property changes <strong>of</strong> mixing, heat effects <strong>of</strong> mixing<br />

processes.<br />

UNIT IV: Chemical Reaction Equilibria: The reaction coordinate, application <strong>of</strong> equilibrium<br />

criteria to chemical reactions, the standard Gibbs. Energy change and the equilibrium constant,<br />

effect <strong>of</strong> temperature on the equilibrium constants, relation <strong>of</strong> equilibrium constants to<br />

composition, equilibrium conversions for single reactions, phase rule and Duhem’s theorem for<br />

reacting systems.<br />

BOOKS:<br />

1. Rao, Y.V.C. , “Chemical <strong>Engineering</strong> Thermodynamics”, Universities Press, India 2/e, 2001.<br />

2. Rao, Y.V.C., “Theory and Problems <strong>of</strong> Thermodynamics”, New Age International (P) Ltd, New<br />

Delhi, 2000<br />

3. Smith, J.M., Van Ness, H.C. and Abbott, M.M., “Chemical <strong>Engineering</strong> Thermodynamics”,<br />

Tata McGraw-Hill Publishing, New Delhi, 6/e, 2003.<br />

4. Kyle; B.G., “Chemical and Process Thermodynamics"; Prentice Hall, New York, 3/e, 1999<br />

PK 223 PROCESS DEVELOPMENT AND EQUIPMENT DESIGN<br />

UNIT I: Principles <strong>of</strong> process synthesis: reaction path synthesis, species allocation, separation task<br />

selection, task integration.<br />

27

Unit II: Diagrams for understanding chemical processes: Block Flow Diagram, Process Flow<br />

Diagram, Piping & Instrumentation Diagram. Structure and synthesis <strong>of</strong> process flow diagrams.<br />

Unit III: Chemical product design, tracing chemicals through the process flow diagram,<br />

understanding process conditions.<br />

UnitIV: Introduction to design codes, design <strong>of</strong> cylindrical and spherical shells, design <strong>of</strong> storage<br />

tanks, designs <strong>of</strong> tall vertical vessels, selection and design <strong>of</strong> flanges and supports for<br />

equipment.<br />

BOOKS:<br />

1. Turton, Richard, Bailie, Richard C., Wallace B. Whiting, Shaeiwitz, Joseph A.; “Analysis,<br />

Synthesis and Design <strong>of</strong> Chemical Processes”, Prentice Hall, USA 3/e, 2009.<br />

2. Douglas, J.M., “Conceptual Design <strong>of</strong> Chemical Processes”, McGraw-Hill, 1988<br />

3. Joshi, M.V. and Mahajani, V.V.; Process Equipment Design, 3/e, 1996, MacMillan India<br />

Ltd, New Delhi<br />

4. Bhattacharya, B.C. Introduction to Chemical Equipment Design –Mechanical Aspect,<br />

Chemical <strong>Engineering</strong> Education Development Centre I.I.T Madras.<br />

PK-223: SEPARATION PROCESSES<br />

UNIT-I: Introduction to separation processes, Phase equilibrium thermodynamics, Flash<br />

calculation, Distillation: Flash distillation, Differential distillation & Steam distillation; Binary<br />

distillation, Multi stage tray towers; McCabe & Thiele method, Ponchon & Savarit method,<br />

Continuous contact system (packed towers).<br />

UNIT-II: Multi-component distillation, Adsorption: Adsorption Equilibrium, Fixed bed adsorption<br />

column, Ion exchange method<br />

UNIT-III: Liquid-Liquid Extraction: Extraction Equilibrium, Extractive solvent, Extraction<br />

equipment, Multistage cross current and counter current operations, Liquid-solid leaching<br />

operation.<br />

UNIT-IV: Membrane Separation Processes: Types <strong>of</strong> membrane process, liquid and gas<br />

permeation membrane process, types <strong>of</strong> membrane, Applications<br />

BOOKS:<br />

1. Treybal, Robert E., “Mass Transfer Operations”, McGraw Hill Publications, 3/e, 2003.<br />

2. Geankoplis, Christie J., “Transport Processes and Unit Operations”, Prentice Hall <strong>of</strong> India,<br />

New Delhi, 3/e, 1997.<br />

3. Seader, J.D., Henley, Ernest J., “Separation Process Principles”, John Wiley & Sons, Inc,<br />

1998.<br />

PK-224 A HETEROGENEOUS REACTION ENGINEERING (DE-I)<br />

Unit 1: Catalysts, selecting catalytic agents, properties and characteristics <strong>of</strong> industrial catalysts,<br />

preparation <strong>of</strong> catalysts, catalyst testing, Classification and Kinetics <strong>of</strong> Catalysis.<br />

Unit II: Steps in catalytic reactions, synthesizing a rate law, mechanism and rate limiting steps<br />

design <strong>of</strong> reactors for non catalytic and catalytic reactions, gas-solid reactions. Heterogeneous<br />

Data Analysis for reactor design, catalyst deactivation.<br />

28

Unit III: External Diffusion effects on Heterogeneous Reactions, Diffusion and Reaction in Porous<br />

Catalysts, Effectiveness factors<br />

Unit IV: Reactor modeling with the RTD, zero parameter models, analysis <strong>of</strong> nonideal reactors,<br />

one parameter and two parameter models, testing a model and determining its parameters.<br />

BOOKS:<br />

1. Denbigh, K.G. and Turner, J.C.R., “Chemical Reactor Theory- An Introduction”, ELBS<br />

Publishing House, Cambridge, 2/e, 1981.<br />

2. Fogler, H. S., “Elements <strong>of</strong> Chemical Reaction <strong>Engineering</strong>”, Prentice Hall <strong>of</strong> India Private<br />

Limited, New Delhi, 3/e, 2005.<br />

3. Smith, J.M., “Chemical <strong>Engineering</strong> Kinetics”, McGraw Hill , New York, 3/e, 1981.<br />

4. Holland, C.D., and Anthony, R.G., “Fundamentals <strong>of</strong> Chemical Reaction <strong>Engineering</strong>”,<br />

Prentice Hall, New Jersey, 3/e, 1989.<br />

5. LE Page, J.F., “Applied Heterogeneous Catalysis-Design. Manufacture and Use <strong>of</strong> solid<br />

Catalysts”, Editions Technip..<br />

PK-224B: CATALYSIS (DE I)<br />

Unit I: Introduction <strong>of</strong> catalysis, Properties & chrematistics <strong>of</strong> catalysis<br />

Unit II: Preparation, testing and classification <strong>of</strong> catalysis.<br />

Unit III: Heterogeneous catalysis: Active centers, adsorption phenomena, active, encumbers &<br />

electron notions.<br />

Unit IV: Poisoning & Deactivation <strong>of</strong> Catalysis.<br />

BOOKS:<br />

1. Panchenkou, G.M. and Lebedev, V.P., “Chemical Kinetics & Calalysis, Mir Publishers,<br />

Moscov, 1976.<br />

2. Viswananthan. B., Sivasankar and Ramaswamy, A.V. (ed.), “Catalysis – Principles and<br />

Applications”, Narose Publishing House, New Delhi, 2002.<br />

3. Thomas, J.W. and Thomas, W.U., “Introduction to the Principle <strong>of</strong> Heterogeneous Catalysis,<br />

Academic Press, 1967.<br />

PK-224C CHEMICAL REACTOR DESIGN (DE-I)<br />

UNIT I: Behavior <strong>of</strong> Chemical Reactors: Ideal & Non-Ideal Flow; Classification <strong>of</strong> Reactors:<br />

Isothermal, Ideal batch, CSTR, PFR, Multiple Reactors, Non-isothermal Reactors,<br />

Multiplicity, Non-ideal reactors, Fluid Solid Non-Catalytic reactions, Fluidized Beds.<br />

UNIT II: Introduction to Reactor Design; Detailed Design <strong>of</strong> Batch Reactors.<br />

UNIT III: Flow Reactors; Detailed Design for CSTR; CSTR Design; Single CSTR Battery; CSTR at<br />

Differential Temperature etc.<br />

UNIT IV: Detailed Design for Plug Flow Reactor: Single; Series And Parallel; Mixed Reactor<br />

(Combination); Reactor stability, Design aspects for Non-ideal Reactors.<br />

BOOKS:<br />

1. Octave Levenspiel, “Chemical Reaction <strong>Engineering</strong>”, 3rd Edition, John Wiley &Sons (Asia)Pte Ltd.<br />

29

(1998), ISBN: 978-0-471-25424-9.<br />

2. H. Scott Fogler, “Elements <strong>of</strong> Chemical Reaction <strong>Engineering</strong>” 3rd Edition November,<br />

Prentice Hall <strong>of</strong> India Pvt Ltd (1998).<br />

3. L. D. Schmidt, “The <strong>Engineering</strong> <strong>of</strong> Chemical Reactions”, Oxford Press (1998).<br />

4.J.M. Smith, “Chemical <strong>Engineering</strong> Kinetics”, 2nd, McGraw-Hill (1981).<br />

CH – 292: UNIT OPERATION LAB-I<br />

EXPERIMENTS:<br />

1. To investigate validity <strong>of</strong> Bernoulli’s theorem as applied to flow <strong>of</strong> water in tube <strong>of</strong> varying<br />

cross section<br />

2. To find the efflux time <strong>of</strong> the tank<br />

3. Flow through straight circular tube<br />

4. Capillary flow viscometer<br />

5. Flow through helical tube coils<br />

6. Flow through spiral tubes<br />

7. Pipe flow <strong>of</strong> compressible fluids<br />

8. Flow through annulus<br />

PK-391: PETROLEUM TESTING LABORATORY<br />

Various Experiments related Analysis & Testing <strong>of</strong> Petroleum and Petroleum Products.<br />

FIFTH SEMESTER<br />

PK-311: PETROLEUM REFINING PROCESSES<br />

Unit I: Thermal conversion processes like Visbreaking, Delayed Coking, Fluid coking, Flexicoking,<br />

etc.<br />

Unit II: Catalytic conversion processes - fluid catalytic cracking, RFCC, DCC, Hydrocracking,<br />

Hydrotreating processes, etc.<br />

Unit III: Reforming, hydrogen production, Alkylation, Polymerization, Isomerisation etc.<br />

Unit IV: Evaluation <strong>of</strong> crude for LOBS, Production <strong>of</strong> lubes and waxes.<br />

BOOKS:<br />

1. Speight, J.G. and Ozum, B. “Petroleum Refining Processes”, Marcel Dekker Inc, New York,<br />

2002.<br />

2. Gary, J.H. and Handiwerk, G.E., “Petroleum Refining <strong>Technology</strong> and Economics”, Marcel<br />

Dekker, Inc., New York, 2001.<br />

3. Hobson, G.D., “Modern Petroleum <strong>Technology</strong>” Vol I & II, John Wiley & Sons, New York,<br />

5/e, 1984<br />

30

4. Rao, B.K.B., “Modern Petroleum Refining Processes”, Oxford & IBH Co. Pvt. Ltd., New Delhi,<br />

4/e, 2002,<br />

5. Prasad, R., “Petroleum Refining <strong>Technology</strong>”, Khanna Publishers, New Delhi, 2000<br />

PK-315: NATURAL GAS PROCESSING<br />

Unit I: Natural Gas-origin and occurrence, properties <strong>of</strong> natural gases, phase behavior <strong>of</strong> Natural<br />

Gas systems, vapor liquid equilibrium calculations.<br />

Unit II: Natural gas- liquid separation, separation principles, separation equipment, low<br />

temperature separation.<br />

Unit III: Water-hydrocarbon phase behaviour, measurement <strong>of</strong> water content in Natural gases,<br />

Hydrate formation and prevention <strong>of</strong> hydrates, Gas dehydration- types <strong>of</strong> processes.<br />

Unit IV: Acid gases in natural gas, acid gas treatment, types <strong>of</strong> processes. Natural gas<br />

storage, Natural gas liquids removal, Transportation <strong>of</strong> Natural Gas, LNG chain.<br />

BOOKS:<br />

1. Kumar, S., “Gas Production <strong>Engineering</strong>”, Gulf Publishing Company Book Division, London,<br />

1960.<br />

2. Mokhatab, S., William, A.P. and Speight, J.G., “Handbook <strong>of</strong> Natural Gas Transmission and<br />

Processing”, Gulf Pr<strong>of</strong>essional Publishing, Oxford, 2006.<br />

3. Francis, S.M. and Thompson, R.E., “Oil Field Processing <strong>of</strong> Petroleum, Volume one: Natural<br />

Gas”, Penn Well Books, Penn Well Publishing Company, Oklahoma, 1995.<br />

PK-313: MASS TRANSFER OPERATIONS<br />

UNIT I: General Introduction: Mass transfer operations and its classifications, Diffusion mass<br />

transfer, Mass transfer coefficient, Mass transfer models, Mass transfer with chemical reactions<br />

UNIT II: Gas Absorption Operations: Equilibrium, Choice <strong>of</strong> solvents, co-solvents, co-current and<br />

counter current operations, packed bed and staged columns.<br />

UNIT III: Humidification Operations: Psychrometry, Adiabatic humidification and<br />

dehumidification operations, Packed bed columns, Humidification equipments.<br />

Drying: Fundamentals, drying curves, equipment for drying<br />

UNIT IV: Equipment for Gas-Liquid Operations: Sparged vessels, mechanically agitated vessels.<br />

BOOKS:<br />

1. Treybal, R.E., “Mass Transfer Operations, Mc. Graw Hills, New York, 3/e, 1983<br />

2. Geankoplis, C.J., “Transport Processes and Unit Operations”, Prentice Hall <strong>of</strong> India, New<br />

Delhi, 4/e, 2003.<br />

3. Mc. Cabe, W.L., Smith, J.C., and Harriot, P., “Unit Operations <strong>of</strong> Chemical <strong>Engineering</strong>”, Mc.<br />

Graw Hills, New York, 6/e, 2001<br />

4. Skelland, A.H.P., “Diffusional Mass Transfer”, John Wiley and Sons, New York, 1974<br />

31

PK- 312: HEAT TRANSFER OPERATIONS<br />

UNIT I: Steady State heat conduction in one dimension: heat conduction through plane wall,<br />

composite wall, single layer cylinder, multi layer cylinder, sphere, Fourier’s Law <strong>of</strong> conduction<br />

and thermal conductivity, critical thickness <strong>of</strong> insulation, overall heat transfer coefficients.<br />

Forced Convection: forced convection past planar surface, inside cylindrical pipes and tubes and<br />

in non-circular sections, forced convection for external flow normal to tubes, tube banks.<br />

UNIT II: Heat Transfer by Free Convection: Governing equation for free convection, working<br />

correlations for free convection, analytical solution <strong>of</strong> free convection past vertical plane<br />

surfaces. Heat Transfer in Boiling and Condensing: working correlations <strong>of</strong> film condensation,<br />

dropwise condensation, heat transfer for boiling <strong>of</strong> a liquid, working correlations for pool<br />

boiling, forced convection boiling.<br />

UNIT III: Heat transfer by radiation: basic definition, laws <strong>of</strong> radiation, black body, gray body,<br />

shape factors. Heat Exchangers: Various types, general characteristics, overall heat transfer<br />

coefficient <strong>of</strong> heat exchanger, heat exchanger mean temperature difference, heat exchanger<br />

effectiveness and number <strong>of</strong> transfer units, performance <strong>of</strong> heat exchanger and design <strong>of</strong> heat<br />

exchanger.<br />

UNIT IV: Evaporation and Evaporators: types <strong>of</strong> evaporators, their construction and operation,<br />

evaporator auxiliaries, principles <strong>of</strong> evaporation, single effect evaporator, multiple effect<br />

evaporator, modes <strong>of</strong> feed supply to the evaporator, evaporator selection, effect <strong>of</strong> boiling point<br />

on multiple effect evaporator.<br />

BOOKS<br />

1. Chapman, A.J.,“Heat Transfer”, Mc Millan Publishing Company, New York, 4/e, 1984.<br />

2. Holman, J.P., “Heat Transfer”, Tata McGraw Hill Publishing Company, New Delhi, 9/e, 2009.<br />

AC-: ENGINEERING MATERIALS<br />

UNIT I Introduction to materials – basis <strong>of</strong> materials properties , atomic structure, bonding aggregates <strong>of</strong><br />

atom Iron & Steel : Crystals Structure – brief outlines <strong>of</strong> atomic bonding crystal structure , periodicity in<br />

crystal, different types <strong>of</strong> structures – SC, BCC, FCC and HCP crystals system, crystal lattice unit cell crystal<br />

direction, crystal planes, Miller indices, inter planar spacing , X-ray analysis, Crystals defects –<br />

classifications and impact on the properties <strong>of</strong> engineering materials<br />

UNIT II Phase equilibria – phase rule phase changes in pure Iron, binary systems, solid solution , Eutectic ,<br />

Eutectoid , Peritectic and Peritectoid reactions, General principles <strong>of</strong> heat treatment: Annealing,<br />

normalizing, Hardening, tempering and age hardening.<br />

UNIT III Properties and applications <strong>of</strong> materials <strong>of</strong> construction, factors affecting selection <strong>of</strong> materials,<br />

corrosion <strong>of</strong> materials <strong>of</strong> construction and its control.<br />

UNIT IV.Characterization <strong>of</strong> microstructure using Scanning Electron Microscopy (SEM), Transmission<br />

Electron Microscopy (TEM) and its sample preparation techniques, EDS, Atomic force microscopy (AFM),<br />

Dielectric spectroscopy, Fluorescence spectroscopy.<br />

BOOKS<br />

1. Van Vlack L.H. “Elements <strong>of</strong> Materials Science and <strong>Engineering</strong>” ed 6 th Addison Wesley Inc New York<br />

2. E.d. Dyson R.W “<strong>Engineering</strong> Polymers”, Blackie, New York.<br />

32

3. Smith C.O “The Science <strong>of</strong> <strong>Engineering</strong> Materials <strong>third</strong> edition, Prentice Hall Inc New Jersey.<br />

PK-314: REFINERY ENGINEERING CALCULATIONS<br />

Unit I: Overview <strong>of</strong> Global and Indian Refining Industry, Refinery configurations, ASTM, TBP, EFV<br />

distillation curves, computation <strong>of</strong> the curves Average boiling points. Separation criteria in crude oil<br />

fractionation<br />

Unit II: Atmospheric distillation tower, types <strong>of</strong> refluxes, Watkins method <strong>of</strong> converting crude TBP to<br />

product TBP curves, concept <strong>of</strong> overflash. Energy balance in a topping tower, and calculations involve<br />

estimation <strong>of</strong> top , side, bottom draw tray temperatures. Calculation <strong>of</strong> side steam strippers<br />

Unit III: Vacuum distilation tower, type <strong>of</strong> operations, economic consideration, flash zone & tower base<br />

calculations, flash zone pressure, steam requirements, heat & material balance calculation<br />

Unit IV: Types <strong>of</strong> pipe still heaters, calculations <strong>of</strong> radiant absorption rates, Wilson lobo Hotel equations,<br />

lobo Evans method pipe still design. Heat exchanger in refinery design and operational problems fluid<br />

mechanics and refinery applications use <strong>of</strong> combustion Charts.<br />

BOOKS<br />